If you’re wondering about the right drill bit size for a 1/8 NPT tap, you’ve come to the right place! Figuring out the correct size for your drilling needs can be a bit tricky, but don’t worry, I’m here to help you out.

Choosing the right drill bit size is essential for tapping threads accurately and securely. So, let’s dive right in and explore the best drill bit size for a 1/8 NPT tap.

By the end of this article, you’ll have all the information you need to confidently tackle your drilling project. So, let’s get started on finding the perfect drill bit size!

Now that you know what we’ll be discussing, let’s jump into the details and find the perfect drill bit size for your 1/8 NPT tap. Exciting, isn’t it? Let’s get drilling!

What Size Drill Bit for 1/8 NPT Tap: A Comprehensive Guide

When it comes to tapping holes for pipe threads, using the right drill bit size is crucial. In the case of a 1/8 NPT (National Pipe Taper) tap, selecting the correct drill bit ensures proper thread engagement and a secure connection. In this article, we will delve into the world of NPT taps and guide you on choosing the suitable drill bit size for a 1/8 NPT tap. Whether you’re a DIY enthusiast or a professional, this comprehensive guide will provide you with the knowledge you need to make accurate and efficient connections.

Understanding NPT Taps: The Basics

Before we dive into the specifics of drill bit sizes, let’s first understand the basics of NPT taps. The National Pipe Taper thread is a widely used standard for pipe connections, especially in plumbing and fuel systems. NPT taps create tapered threads that form a tight seal when joined with a corresponding NPT fitting. The taper ensures a secure connection by gradually increasing the thread diameter as it goes deeper into the hole. It’s essential to choose the right drill bit size to achieve an accurate thread depth for optimal engagement and sealing.

When using a 1/8 NPT tap, the key measurements to consider are the thread diameter and the pitch. The thread diameter for a 1/8 NPT tap is approximately 0.405 inches, while the pitch is 27 threads per inch. To accurately tap a hole for a 1/8 NPT thread, you’ll need a drill bit that allows for proper thread engagement while leaving enough material for the threads to bite into. Let’s explore the recommended drill bit size for 1/8 NPT taps.

Recommended Drill Bit Size for 1/8 NPT Tap

The recommended drill bit size for tapping a hole with a 1/8 NPT tap is a #21 drill bit. A #21 drill bit has a diameter of 0.1590 inches or 4.04mm. This drill bit size provides the ideal balance between creating an accurate thread depth and leaving enough material for the threads to grip securely. Using a drill bit that is too large may result in insufficient thread engagement, leading to leaks and a weak connection. Conversely, using a smaller drill bit may cause the tap to bind and make it challenging to create the threads properly.

When using a #21 drill bit, it’s important to remember to use cutting oil or a suitable lubricant to facilitate the drilling process and prolong the life of both the drill bit and the tap. Apply steady pressure and use a slow and controlled drilling motion to prevent overheating or breaking the drill bit. Furthermore, always ensure that you have a securely held workpiece and a stable drilling surface for safety and precision.

Benefits of Using the Correct Drill Bit Size

Using the appropriate drill bit size for a 1/8 NPT tap offers several benefits. Firstly, it ensures that the threads have enough material to bite into, creating a strong and secure connection. Insufficient thread engagement can result in leaks and an unreliable joint. Secondly, using the correct drill bit size prevents the tap from binding and damaging the workpiece. By using a drill bit that matches the tap size, you can smoothly create the necessary threads without any complications. Lastly, using the proper drill bit size helps maintain the integrity and accuracy of the NPT threads, ensuring a tight seal and optimal performance.

Overall, choosing the right drill bit size for a 1/8 NPT tap is crucial for achieving accurate and reliable pipe connections. By understanding the basics of NPT taps, using a #21 drill bit, and following proper drilling techniques, you can create quality threads that provide a secure and leak-free joint. Remember to always exercise caution and use appropriate safety measures when working with power tools. Now that you have the knowledge, go forth and confidently tackle your next NPT tapping project!

Common Mistakes When Using a 1/8 NPT Tap

While using a 1/8 NPT tap may seem straightforward, there are several common mistakes that can compromise the quality of the threads and the overall connection. Understanding these mistakes can help you avoid them and ensure successful tapping. Let’s explore some of the most common errors made when using a 1/8 NPT tap and how to prevent them:

Mistake 1: Using the Wrong Drill Bit Size

One of the most prevalent mistakes when tapping for a 1/8 NPT thread is using the incorrect drill bit size. Using a drill bit that is too large will result in insufficient thread engagement and a weak connection, while using a drill bit that is too small can cause the tap to bind and make it difficult to create the threads properly. Always refer to the recommended drill bit size for a 1/8 NPT tap, which is a #21 drill bit, to achieve optimal results.

Mistake 2: Failing to Use Proper Lubrication

Lubrication is essential when tapping with a 1/8 NPT tap as it helps facilitate the drilling process and prolong the life of both the drill bit and the tap. Failing to use a suitable cutting oil or lubricant can result in excessive heat, premature wear of the cutting edges, and reduced thread quality. Apply ample lubrication before and during the tapping process to ensure smooth and accurate thread creation.

Mistake 3: Applying Too Much Force

Exerting excessive force while using a 1/8 NPT tap can lead to broken taps, damaged workpieces, and compromised threads. Tapping requires a steady and controlled drilling motion with moderate pressure. Avoid using excessive force, as it can cause the tap to bind and break. Use a tap handle or a tapping wrench to provide leverage and control during the drilling process.

…

…

Wrap-Up: Conclude with a paragraph summarizing key points or offering advice without a specific heading.

In conclusion, choosing the correct drill bit size for a 1/8 NPT tap is crucial for achieving accurate, secure, and leak-free pipe connections. Using a #21 drill bit provides the optimal balance between thread engagement and material for the threads to grip. Remember to always use proper lubrication, avoid applying excessive force, and follow best drilling practices for successful tapping. With the knowledge gained from this comprehensive guide, you can confidently tackle your next NPT tapping project and achieve professional results. Happy tapping!

What Size Drill Bit for 1/8 NPT Tap?

- When tapping threads with a 1/8 NPT tap, it is recommended to use a 11/32 drill bit.

- This drill bit size provides the proper hole diameter for the tap to create compatible threads.

- Using the correct drill bit size ensures a tight and secure fit for your 1/8 NPT connections.

- Always double-check the specific recommendations provided by the manufacturer of your tap for the appropriate drill bit size.

- Taking the time to find the right drill bit size will result in successful and efficient threading with your 1/8 NPT tap.

Frequently Asked Questions

Welcome to our FAQ section about drill bits for 1/8 NPT taps. Below, you’ll find answers to common questions regarding the size and selection of drill bits for this specific application. Read on to learn more!

1. What size drill bit should I use for a 1/8 NPT tap?

When tapping a hole for a 1/8 NPT (National Pipe Thread) tap, it is recommended to use a drill bit that is slightly smaller than the size of the tap. In this case, a #21 drill bit (0.159 inches or 4.04mm) is commonly used. This bit size allows for the tap to create threads that fit properly without being too loose or too tight.

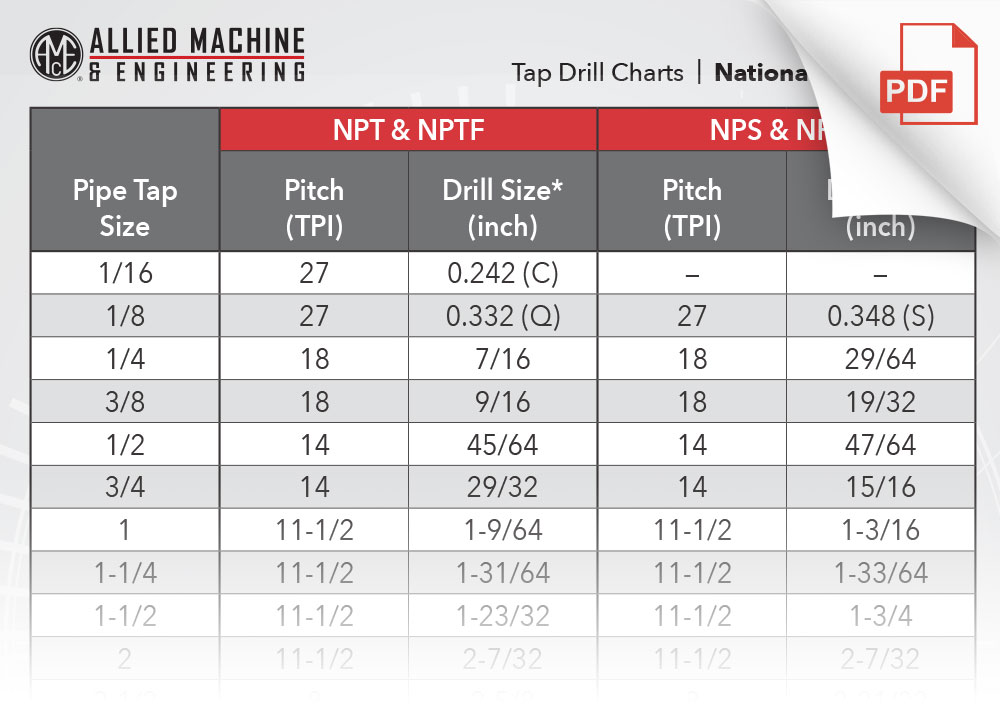

Using the right size drill bit is crucial for the success of your threading operation. A drill bit that is too small may result in weak threads that can easily strip or break, while a drill bit that is too large may not allow the tap to properly create the desired threads. It’s always a good idea to refer to a tap and drill chart for the specific drill bit sizes recommended for NPT taps.

2. Can I use a different size drill bit for a 1/8 NPT tap?

While it is generally recommended to use a #21 drill bit for a 1/8 NPT tap, there may be instances where you can use a slightly different size. Drill bit sizes such as #20 (0.161 inches or 4.09mm) or #19 (0.166 inches or 4.22mm) can also work, depending on the material and the specific requirements of your project.

However, it’s important to note that using a significantly larger or smaller drill bit size may affect the quality and integrity of the threads. It’s always best to consult a tap and drill chart or seek expert advice to ensure you select the most appropriate drill bit size for your 1/8 NPT tap.

3. What happens if I use a drill bit that is too large for a 1/8 NPT tap?

If you use a drill bit that is too large for a 1/8 NPT tap, the threads you create may be loose and weak. This can result in leakages or parts that are not securely fastened together. Additionally, using a larger drill bit can compromise the structural integrity of the material you’re working with.

In some cases, using a significantly larger drill bit may even make it impossible to create proper NPT threads. The tap won’t be able to grip the material properly, and the threads may not form correctly. To ensure the best results, it’s always recommended to use the appropriate drill bit size for your 1/8 NPT tap.

4. What should I do if I don’t have the recommended drill bit size for a 1/8 NPT tap?

If you don’t have the recommended drill bit size for a 1/8 NPT tap, it’s best to purchase the correct drill bit before proceeding with the tapping operation. Using an incorrect drill bit size can lead to unsatisfactory results and potentially damage your workpiece or the tap itself. Investing in the right tool for the job will save you time, effort, and material costs in the long run.

If purchasing a drill bit is not an option, it may be possible to adjust the tapping process by using a different tap size or modifying the application requirements. However, this is not recommended unless you have expertise in tapping operations and understand the potential risks involved. It’s always best to use the appropriate tools and sizes for your specific project to ensure the best possible outcome.

5. Can I use a drill press for tapping with a 1/8 NPT tap?

Yes, a drill press can be used for tapping with a 1/8 NPT tap. However, it is important to consider the specific requirements of your project and the capabilities of your drill press. Some key factors to consider include the speed and torque settings of your drill press, as well as the stability and alignment of your workpiece.

It’s recommended to use a tapping attachment or a tapping head designed specifically for drill presses to ensure proper alignment and control during the tapping process. These attachments help maintain perpendicularity between the tap and the workpiece, resulting in accurate and well-formed threads. Always refer to your drill press manufacturer’s guidelines and follow proper safety measures when tapping with a 1/8 NPT tap.

Summary

So, to sum it up, when using a 1/8 NPT tap, you’ll need to use a drill bit that is slightly smaller in size, usually around 7/32 or 11/32. This will allow the tap to create threads in the material without any issues. Remember to go slow and use lubrication for better results. Happy tapping!

In conclusion, choosing the right drill bit size for a 1/8 NPT tap is crucial for successful threading. By using a slightly smaller drill bit and following the proper techniques, you can achieve clean and precise threads in your material. Just remember to be patient and take your time. Good luck with your projects!