Are you wondering what size inverter you need for your power tools? Look no further! Whether you’re a DIY enthusiast or a professional, choosing the right inverter is essential for powering your tools efficiently. In this guide, we’ll walk you through everything you need to know about selecting the perfect size inverter to keep your power tools running smoothly. So, let’s dive in and find the best fit for your electrical needs!

When it comes to using power tools on the go, having a reliable inverter is crucial. An inverter is a device that converts DC power from a battery into AC power, allowing you to use your power tools wherever you are. But how do you determine the right size for your tools? Don’t worry, we’ve got you covered! In the next few paragraphs, we’ll break it down for you, making sure you have all the information to make an informed decision.

Before we delve into the technical aspects, let’s make sure we have our basics covered. You may be wondering, “Why do I need an inverter for my power tools in the first place?” Well, power tools typically run on AC electricity, which is what you get from an outlet in your home. However, when you’re working in a remote location or have limited access to electrical outlets, an inverter becomes your best friend. It allows you to connect your power tools to a DC power source like a battery or a generator. Cool, right? Now let’s move on and find the perfect inverter size for your power tools!

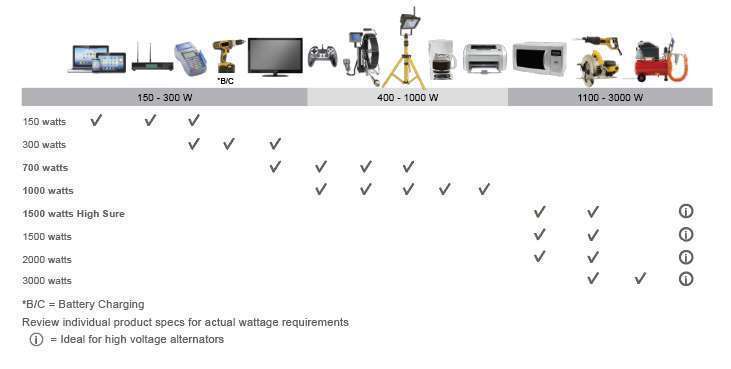

When determining the size of the inverter needed for power tools, there are a few factors to consider. First, calculate the power requirements of your tools by checking their wattage ratings. Add up the wattage of all the tools you intend to use simultaneously. Next, consider the inrush current or surge power required when the tools start up. Finally, choose an inverter that can handle both the total power and surge power requirements of your tools. This will ensure smooth operation and prevent damage to your equipment.

What Size Inverter Do I Need for Power Tools?

When it comes to powering your tools on the go, a reliable inverter is essential. However, choosing the right size inverter for your power tools can be a bit confusing. You don’t want to end up with an inverter that is too small and unable to handle the load, or one that is unnecessarily large and costly. In this article, we will walk you through the process of determining the size inverter you need for your power tools, ensuring that you have the right equipment to get the job done efficiently.

The Basics: Understanding Inverter Power Ratings

Before we dive into the specifics of selecting the right size inverter for your power tools, let’s first understand the basics of inverter power ratings. Inverters are rated based on their maximum power output, usually expressed in watts. This rating determines the capacity of the inverter to handle the power demand from your tools.

1. Identify the Power Requirements of Your Tools

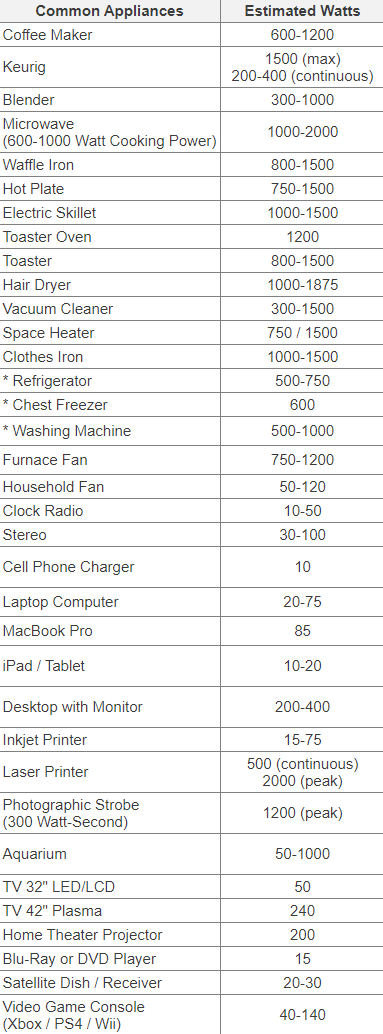

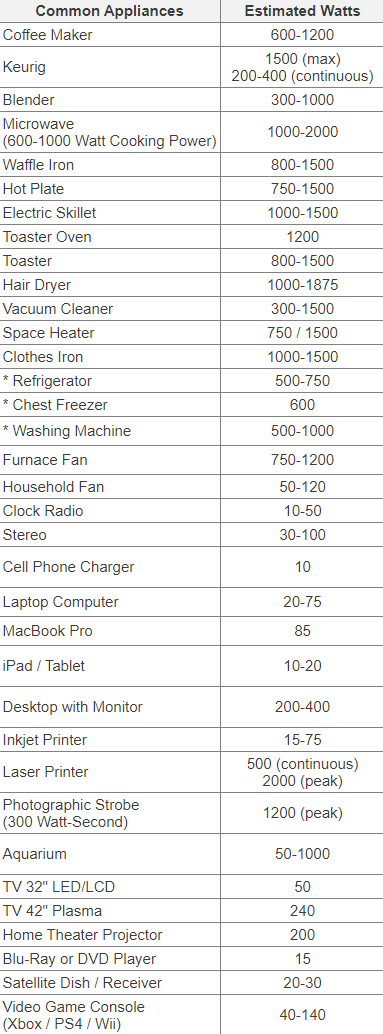

The first step in determining the size inverter you need is to identify the power requirements of your power tools. Every tool comes with a label that indicates its power consumption, typically in watts. Make a list of all the tools you intend to power with the inverter, noting down their individual power ratings.

Once you have the power ratings of all your tools, it is important to consider whether you will be using them simultaneously or one at a time. If you plan to use multiple tools simultaneously, add up the power ratings of all the tools to get the total power requirement.

It is crucial to remember that some power tools, such as drills and saws, have a surge current when they start up. Inverter manufacturers usually provide a surge power specification, which indicates the maximum power the inverter can handle for a short duration without tripping. Take note of this surge power rating as it may affect the size of the inverter you need.

2. Calculate the Continuous Power Requirement

Once you have the total power requirement for your tools, the next step is to calculate the continuous power requirement. This is the power that your inverter will need to supply consistently to ensure smooth operation of your tools.

It is important to choose an inverter with a continuous power rating that is equal to or higher than the continuous power requirement of your tools. Failure to do so can result in the inverter overheating, tripping, or not being able to handle the load effectively.

Take into account any future tool additions or upgrades you may make to ensure that the inverter you select can accommodate your growing power needs. It’s always better to have a little extra capacity than to find yourself with an inadequate inverter.

3. Consider Efficiency and Safety Factors

While the continuous power requirements of your tools are the primary consideration when selecting an inverter, it’s important to account for efficiency and safety factors as well. Inverters have different efficiency levels, with some models being more efficient than others. Higher efficiency means less power loss and better performance.

Additionally, check for safety features such as over-temperature and over-voltage protection. These safeguards can prevent damage to your inverter and protect your tools from potential power surges or fluctuations.

By considering both the power requirements of your tools and these efficiency and safety factors, you can ensure that you select the right size inverter that meets all your needs.

Choosing the Best Inverter for Your Power Tools: Key Considerations

When it comes to choosing the best inverter for your power tools, there are a few key considerations that can help you make an informed decision. Let’s explore these considerations in detail.

1. Pure Sine Wave vs. Modified Sine Wave Inverters

One important factor to consider is the type of inverter you need: pure sine wave or modified sine wave. Pure sine wave inverters produce a clean and stable power output, similar to what you get from a standard household wall outlet. They are best suited for sensitive electronics and high-end power tools that may not operate optimally or may even get damaged with a modified sine wave.

Modified sine wave inverters, on the other hand, produce a power output that is a modified version of a sine wave. While they are more affordable, they may not be suitable for certain types of power tools, especially those with complex electronics or motors.

If you primarily have basic power tools and don’t require a high level of precision or performance, a modified sine wave inverter may suffice. However, if you have more advanced tools or electronics that require a consistent and smooth power supply, investing in a pure sine wave inverter is highly recommended.

2. Inverter Size and Portability

Another important consideration is the size and portability of the inverter. If you primarily use your power tools in a fixed location, such as a workshop or construction site with a stable power supply, you may opt for a larger, more powerful inverter. These inverters generally have a higher power output and can handle larger tool loads.

However, if you often find yourself working in different locations or need to power your tools on the go, a smaller, more portable inverter would be a better choice. Portable inverters are typically lighter, compact, and easier to transport. They may have a lower power output compared to their larger counterparts, but they are designed for convenience and versatility.

Consider your specific needs and usage scenarios to determine whether portability or power is of greater importance to you when selecting an inverter.

3. Additional Features and Safety Considerations

When selecting an inverter for your power tools, it’s worth exploring additional features and safety considerations that can enhance your overall experience and protect your equipment.

Some inverters come with built-in USB ports or AC outlets, allowing you to charge small devices or power other equipment simultaneously. This can be a useful feature, especially if you rely on other electronics or gadgets during your work.

Look for inverters with advanced safety features such as overload protection, short circuit protection, and low voltage shutdown. These features not only protect your inverter from damage but also safeguard your power tools from potential electrical hazards.

Additionally, consider the noise level of the inverter, especially if you work in environments where noise is a concern. Quieter inverters can provide a more comfortable working environment.

Conclusion

Choosing the right size inverter for your power tools is crucial to ensure smooth operation and avoid any power-related issues. By understanding the power requirements of your tools, calculating the continuous power requirement, and considering efficiency and safety factors, you can select an inverter that meets your needs.

When making a decision, also take into account factors such as the type of inverter (pure sine wave or modified sine wave), size and portability, and additional features and safety considerations. By considering all these factors, you can make an informed choice and enjoy the convenience of powering your tools wherever you go.

Key Takeaways: What Size Inverter Do I Need for Power Tools?

- Consider the power requirements of your power tools.

- Calculate the wattage of your power tools.

- Choose an inverter with a continuous power rating higher than the total wattage of your power tools.

- Consider starting and surge power requirements for power tools with motors.

- Ensure the inverter has enough outlets and the right type of outlets for your power tools.

Frequently Asked Questions

When it comes to using power tools with an inverter, there are a few important things to consider, including the size of the inverter you’ll need. Here are some common questions and answers to help you determine the right size inverter for your power tools.

1. Can I use any size inverter for power tools?

While it might be tempting to use any size inverter you have on hand, it’s important to choose the right size for your power tools. Power tools typically have varying power requirements, so using an inverter that doesn’t meet those requirements can result in inefficient or insufficient power. It’s best to check the power requirements of your specific power tools and choose an inverter that can handle their needs.

Additionally, pay attention to the surge power capabilities of the inverter. Some power tools may require a higher surge power when starting, so make sure your chosen inverter can handle these brief power spikes to prevent any electrical issues.

2. How do I determine the size of inverter needed for my power tools?

To determine the size of inverter you need for your power tools, you’ll need to determine the power requirements of each tool. Check the labels or manuals of your power tools for information on their wattage or amperage ratings. Once you have that information, add up the power requirements of all the tools you plan to use simultaneously. This total power requirement will give you an idea of the minimum size of inverter you’ll need.

It’s important to choose an inverter with a higher capacity than the total power requirement, to account for any power surges or fluctuations that may occur. This ensures that your inverter can handle the power demand of your power tools without any issues.

3. Can I use a smaller inverter for occasional use of power tools?

If you only plan on using your power tools occasionally or for short periods of time, you may be able to get away with using a smaller inverter. However, it’s still important to check the power requirements of your specific power tools and make sure the inverter can handle them.

Keep in mind that using a smaller inverter may result in reduced or inconsistent power output, which can affect the performance of your power tools. It’s always better to choose an inverter that matches or exceeds the power requirements of your tools for optimal results.

4. What other factors should I consider when choosing an inverter for power tools?

In addition to the size of the inverter, there are a few other factors to consider when choosing one for your power tools. The quality and reliability of the inverter are important, as well as its surge power capabilities. Look for inverters that are specifically designed for powering tools and have features like overload protection and built-in cooling fans.

Portability is also a consideration if you plan on using your power tools in different locations. Choose an inverter that is compact and lightweight for ease of transport. Finally, make sure the inverter has the necessary output ports to connect your power tools, whether it’s standard outlets or specific connectors.

5. Can I use an inverter with other electronic devices as well?

Absolutely! Inverters can be used to power a wide range of electronic devices, not just power tools. They are commonly used for charging laptops, powering small appliances, and even running electronics in RVs or boats. Just make sure to choose an inverter with sufficient capacity to handle the power requirements of all the devices you plan to use simultaneously.

Keep in mind that different devices may have different power requirements, so it’s important to check their specifications before connecting them to the inverter. Some devices may also be sensitive to power fluctuations, so choosing an inverter with stable and reliable power output is crucial for their optimal performance.

What Size Inverter Do I Need? – How to Choose the Right Size Inverter | Accelerate Auto Electrics

Summary

So, to recap, when choosing an inverter for power tools, it’s important to consider the wattage and startup surge.

Make sure to add up the wattage of all the tools you plan to use simultaneously, and choose an inverter that can handle that total. Don’t forget to factor in any additional appliances or devices you want to run. Remember, it’s better to oversize the inverter to ensure it can handle your needs. Happy tooling!

In conclusion, the size of the inverter you need for power tools depends on the total wattage of the tools and any additional devices you want to power. It’s crucial to choose an inverter that can handle the combined wattage, including startup surge. Going for a slightly larger inverter is always a good idea to guarantee it can meet your requirements. Happy tooling and stay powered up!