Are you wondering what size inverter you need in order to power your favorite tools? Well, look no further! In this article, we’ll delve into the world of power tools and help you determine the perfect inverter size for your needs. Whether you’re a seasoned DIY enthusiast or just starting out, understanding the right inverter size is crucial for a smooth and efficient power tool experience.

You might be thinking, “Why do I even need an inverter?” The answer is simple: power tools require electricity to operate, and an inverter is what converts the direct current (DC) from your battery into the alternating current (AC) that your tools need. But finding the right size inverter can be a bit tricky if you’re not familiar with the technicalities.

Not to worry! We’ve got you covered. In this guide, we’ll walk you through the factors to consider when choosing an inverter size, explain the importance of wattage, and provide some practical tips to ensure that your power tools run smoothly and efficiently. So let’s dive right in and unlock the secrets of finding the perfect inverter size for your power tools!

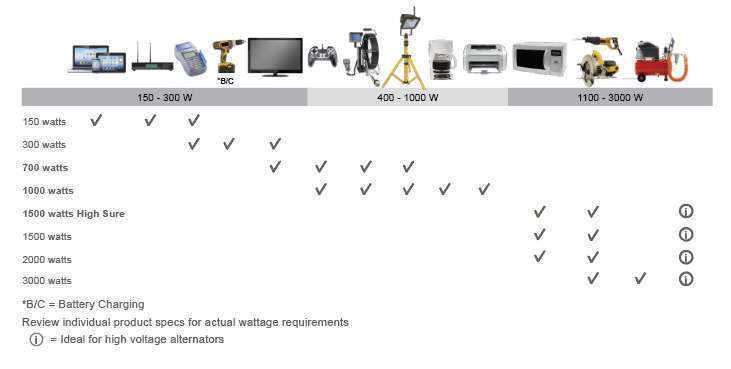

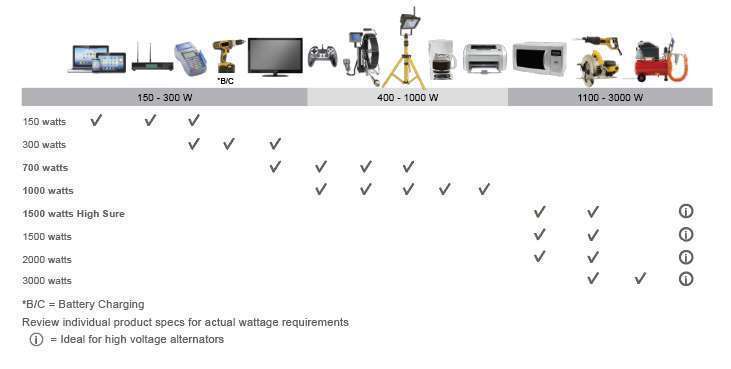

When running power tools, determining the right size inverter is crucial. Calculate the total wattage of all the tools you plan to use simultaneously and choose an inverter with a capacity slightly higher than that. Consider factors like starting power requirements and the efficiency of your tools. A 2000-watt inverter is often sufficient for most power tools. However, it’s best to consult the user manuals or contact the manufacturers for specific power requirements.

What Size Inverter Do I Need to Run Power Tools?

Power tools are an essential part of many DIY projects and professional work. However, when working in remote locations or during power outages, it can be challenging to find a reliable source of electricity to power these tools. This is where inverters come in. Inverters convert DC power such as that from a battery into AC power, allowing you to use your power tools even without access to a traditional power outlet. But what size inverter do you need to run power tools? In this article, we will explore the factors to consider when determining the appropriate inverter size for running power tools and provide you with a comprehensive guide to help you make the right choice.

Factors to Consider When Choosing an Inverter for Power Tools

Before we dive into the specifics of inverter sizes, it’s important to understand the factors that determine the appropriate size for running power tools. Here are three key considerations:

1. Power Consumption

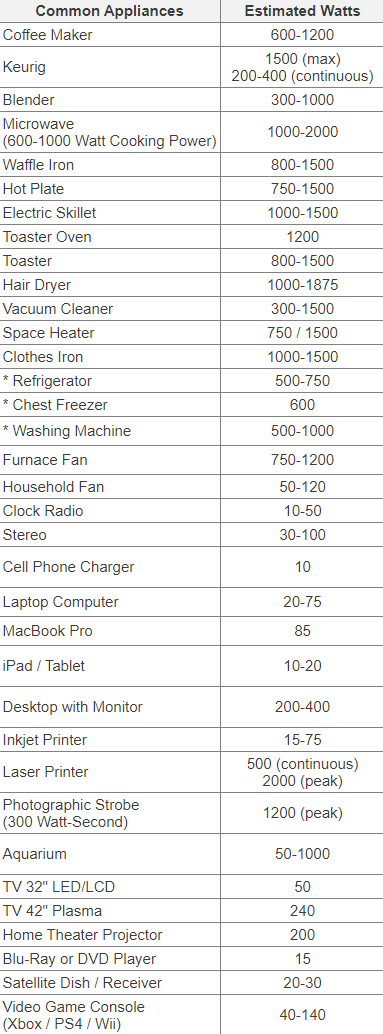

The first factor to consider is the power requirement of your power tools. Different tools have different power ratings, which are usually indicated in watts or amps. Within a workshop or job site, you may have various power tools with different power ratings. It’s essential to calculate the total power consumption to determine the minimum size of the inverter required. To do this, add up the wattage or amperage ratings of all the tools you plan to power simultaneously. Make sure to take into account any power surges or spikes that may occur during tool usage.

For example, if you have a circular saw rated at 1200 watts, a drill rated at 600 watts, and a sander rated at 800 watts, the total power consumption would be 1200 + 600 + 800 = 2600 watts. In this case, you would need an inverter with a continuous power rating of at least 2600 watts to run these tools simultaneously.

2. Surge Capacity

In addition to the continuous power rating, you also need to consider the surge capacity of the inverter. Power tools often have a higher power draw when they are first started or when there is a sudden increase in demand. This surge capacity helps the inverter handle these spikes in power without shutting down or causing any damage. Most power tools have a surge or peak power rating specified by the manufacturer. It’s crucial to choose an inverter with a surge capacity that can accommodate the power tool with the highest surge rating.

Using the previous example, if the circular saw has a surge power rating of 2000 watts, you would need an inverter with a surge capacity of at least 2000 watts to handle the initial power draw of the saw.

3. Inverter Type

The type of inverter you choose also plays a role in determining the appropriate size. There are two main types of inverters: modified sine wave inverters and pure sine wave inverters. Modified sine wave inverters are more affordable but may not be suitable for certain power tools, particularly those with sensitive electronics. Pure sine wave inverters, on the other hand, provide a clean and stable power output similar to what you would get from a traditional power outlet. If you have power tools with sensitive electronics, it’s recommended to choose a pure sine wave inverter to avoid any potential damage or performance issues.

Determining the Right Inverter Size for Your Power Tools

Now that we’ve covered the key factors to consider, let’s explore how to determine the right inverter size for your power tools. To simplify the process, follow these steps:

Key Takeaways: What Size Inverter Do I Need to Run Power Tools?

- An inverter is a device that converts DC power from a battery to AC power for running household appliances and tools.

- The size of the inverter you need to run power tools depends on the power requirements of the tools you want to use.

- Check the power rating (wattage) of each power tool you plan to use and add them up to get the total power requirement.

- Choose an inverter with a continuous power rating that matches or exceeds the total power requirement of your power tools.

- Consider getting an inverter with a higher power rating to accommodate power surges and ensure smooth tool operation.

Frequently Asked Questions

Interested in running power tools using an inverter? We have compiled some commonly asked questions and their answers below to help guide you in determining the right size inverter for your needs.

1. Can I use any size inverter to run power tools?

While you may be tempted to use any inverter you have on hand, it is important to choose the right size to ensure efficient and safe power supply for your tools. Different power tools have varying power requirements, so it is essential to match the inverter’s capacity with the total power needed.

Check the power consumption of each tool, typically provided in watts, and add them up to determine the total wattage. From there, choose an inverter that can handle at least the total wattage and has a peak power rating that can accommodate any initial surge or startup requirements of the tools.

2. How do I calculate the power requirements of my power tools?

To calculate the power requirements of your power tools, refer to the label or manual of each tool. Look for the power consumption rating, usually expressed in watts or amps.

If the label only provides the amperage rating, multiply it by the voltage of your power supply (typically 120 volts in the US) to convert it to watts. Sum up the wattage of all the tools you wish to run simultaneously to determine the total power requirement.

3. What are the common power tools and their power requirements?

Power tools have varying power requirements based on their motor sizes and the tasks they are designed to perform. Here are some common power tools and their average power consumption:

– Circular Saw: 1,200 to 1,800 watts

– Drill: 500 to 1,000 watts

– Angle Grinder: 1,000 to 2,000 watts

– Jigsaw: 300 to 800 watts

– Air Compressor: 1,200 to 1,600 watts

Remember to add up the power requirements of all the tools you intend to use simultaneously to determine the overall power needed from the inverter.

4. What size inverter do I need for intermittent use of power tools?

If you only need to use your power tools intermittently or for short durations, you can opt for a smaller inverter with a lower continuous power rating. Determine the power requirements of your most power-hungry tool and select an inverter that can handle that wattage.

For occasional use, you can also consider inverters with a higher peak power rating, as long as the continuous rating meets the requirements of your tools. This way, the inverter can handle the initial surge of power required for startups, even if the continuous power draw is lower than the tool’s rating.

5. Can I run power tools from a car battery and inverter?

Yes, it is possible to run power tools from a car battery and an inverter. However, it is crucial to check the power rating of your car battery and choose an inverter that matches or is lower than that rating. Exceeding the battery’s capacity can lead to draining it quickly, potentially causing damage.

Additionally, it’s important to consider the runtime of the battery when using power tools. Higher wattage tools can drain a car battery significantly faster. It is recommended to use the tools sparingly or have a backup power source available to ensure you don’t run out of power in the middle of a task.

What Size Inverter Do I Need? – How to Choose the Right Size Inverter | Accelerate Auto Electrics

Summary

So, to wrap it up, when choosing an inverter for power tools, there are a few key things to consider. First, look at the wattage rating of your tools and add them up to find the total power required. Next, choose an inverter that can handle that power load, making sure it has a higher continuous wattage rating than your tools. Finally, consider any additional features you may need, like USB ports or a built-in cooling fan. Remember to always consult the tool’s manual and follow safety guidelines when using power tools with an inverter.

In conclusion, finding the right size inverter for power tools is all about understanding your tools’ power needs, choosing an inverter with a higher continuous wattage rating, and considering any additional features you might require. With these considerations in mind, you’ll be able to safely and efficiently power your tools wherever you go.