Looking to power your tools on the go? Wondering what size inverter is best for the job? Well, you’ve come to the right place! In this guide, we’ll explore the world of power tools and help you determine the ideal inverter size to keep your tools running smoothly, no matter where you are. So let’s dive in and get you equipped with the knowledge you need!

Picture this: you’re out on a construction site or camping in the wilderness, and you need to use your power tools. But there’s no electrical outlet in sight. That’s where an inverter comes in handy. It’s a device that converts DC power from your car or battery into AC power, allowing you to plug in your power tools and use them on the go!

But here’s the million-dollar question: what size inverter do you need to power your tools effectively? Don’t worry, we’ve got you covered. In this guide, we’ll walk you through the factors to consider, such as the wattage requirements of your tools and the peak power they may need. By the end, you’ll be well equipped to make an informed decision and power your tools wherever your projects take you. Let’s get started!

Choosing the right inverter size for power tools is crucial for efficient and safe operation. To determine the appropriate size, follow these steps:

- Identify the power requirements of your tools.

- Add up the wattage of the tools you plan to use simultaneously.

- Consider the surge power required during startup.

- Choose an inverter that can handle the total wattage and surge power.

- Ensure the inverter’s voltage matches your power tools.

Following these steps will help you select the correct size inverter and prevent any issues when using power tools.

What Size Inverter Do You Need for Power Tools?

When it comes to powering your tools on the go or in remote locations, having the right size inverter is crucial. An inverter converts DC power from a battery into AC power, allowing you to use standard household appliances and power tools. But how do you determine what size inverter you need for your power tools? In this article, we will dive into the factors you should consider, the different power ratings, and provide practical tips to help you choose the right size inverter for your power tools.

Factors to Consider When Choosing an Inverter

Before diving into the technical details of power ratings, it’s important to understand the key factors that influence the size of the inverter you need:

Battery Voltage

The first factor to consider is the voltage of your battery. Inverters are available in different voltage ratings, such as 12V, 24V, or 48V. You need to ensure that the voltage of your inverter matches the voltage of your battery to ensure compatibility and efficient operation. Check the specifications of your battery or consult a professional to determine the voltage.

Power Output

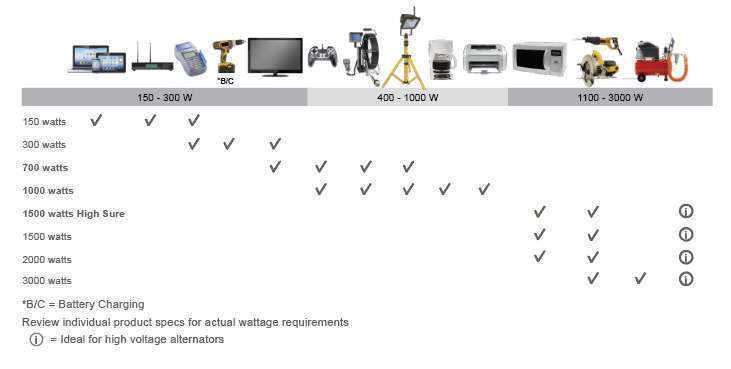

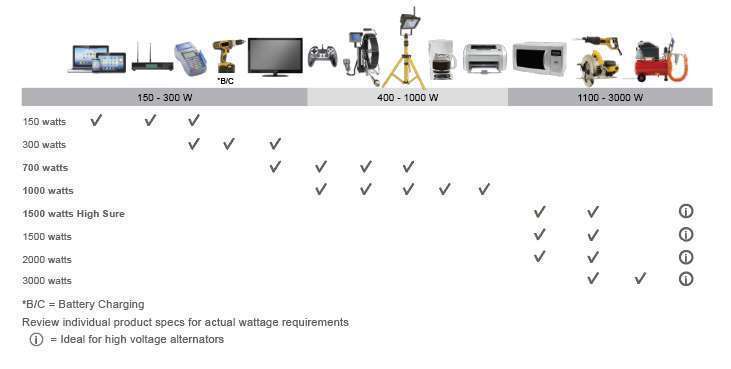

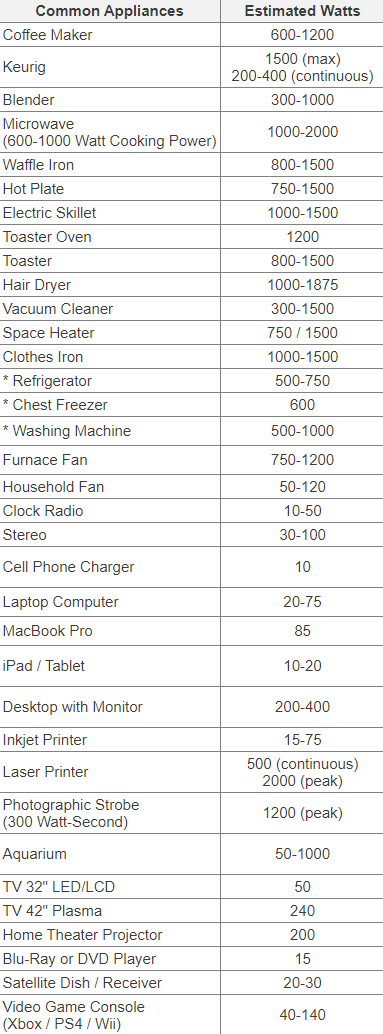

The power output of your power tools is another crucial factor. Different tools have different power requirements, typically measured in watts. You need to determine the total power output of all the tools you intend to run simultaneously. Summing up the power requirements will help you choose an inverter with sufficient capacity to handle the load without overloading or damaging the inverter.

Surge Power Capability

Power tools often have a surge power requirement, which is the initial burst of power required to start the tool. This surge power requirement can be significantly higher than the rated power of the tool. It’s essential to choose an inverter with a surge power capability that matches or exceeds the peak surge power of your tools to prevent tripping or damaging the inverter.

Inverter Efficiency

Inverter efficiency is another factor to consider. The efficiency of an inverter determines how much power is lost during the conversion process. Higher efficiency inverters will waste less power and provide more usable AC power to your tools. Look for inverters with higher efficiency ratings to ensure optimum utilization of your battery power.

Additional Features

Lastly, consider any additional features you may require in an inverter. Some inverters come with built-in safety features like overload protection, short circuit protection, or low voltage shutdown to ensure the longevity of your tools and battery. These features can provide peace of mind and protect your investment.

Sizing Your Inverter: Understanding Power Ratings

Now that we have discussed the key factors, let’s dive into understanding power ratings and how they relate to choosing the right size inverter for your power tools.

Continuous Power Rating

The continuous power rating of an inverter refers to the maximum power it can output continuously without overheating or tripping the system. It is usually expressed in watts. To determine the size of the inverter you need, add up the power requirements of all the tools you plan to use simultaneously. Make sure the continuous power rating of the inverter is equal to or greater than the total power requirement to ensure smooth and uninterrupted operation.

Surge Power Rating

The surge power rating of an inverter is the maximum power it can output for a short period to handle the initial surge or starting power required by some power tools. Surge power is often higher than the continuous power rating. When choosing an inverter, make sure the surge power rating is sufficient to handle the starting power requirements of your tools. It’s always better to have a higher surge power rating to accommodate unexpected spikes in power demand.

Choosing the Right Size Inverter

To choose the right size inverter for your power tools, consider the total power requirement and surge power requirements of your tools. Look for an inverter with a continuous power rating equal to or greater than the total power requirement of your tools. Additionally, ensure that the surge power rating can handle the starting power requirements of your tools. It’s better to choose an inverter with a slightly higher power rating to allow for future tool additions or increased power demands.

Key Takeaways: What Size Inverter for Power Tools?

- An inverter is an important device that can convert DC power from a battery into AC power, allowing you to use power tools even when you’re away from an electrical outlet.

- When determining the size of the inverter you need for your power tools, consider the wattage of the tools as well as any potential surge requirements.

- It’s essential to choose an inverter with a continuous power rating that matches or exceeds the total power consumption of your power tools.

- Additionally, you should take into account any high-current tools that require a surge of power when starting up, such as air compressors or table saws.

- Remember to also factor in the length of time you will be using the power tools, as this will affect the overall power consumption and battery life.

Frequently Asked Questions

In this section, we will answer some commonly asked questions about determining the right size inverter for power tools.

Can I use any size inverter for power tools?

While it may be tempting to use any inverter for your power tools, it is crucial to choose the right size. The size of the inverter depends on the power requirements of your tools. Each tool has a wattage rating, which indicates how much power it consumes. To determine the right size inverter, add up the wattage ratings of all the tools you plan to use simultaneously and choose an inverter with a capacity higher than that total. This will ensure your inverter can handle the power load without any issues.

Using an undersized inverter can lead to overheating and system failure, while an oversized inverter may not be cost-effective and could be unnecessarily bulky. By appropriately sizing your inverter for your power tools, you can ensure optimal performance and avoid any potential damage.

How do I calculate the power consumption of my power tools?

To calculate the power consumption of your power tools, first, check the rating label on each tool. The label typically provides information about the wattage or amperage rating. If it specifies amperage, multiply the amperage by the voltage to get the wattage. If the tool only provides the wattage, you can use that directly.

Add up the wattage ratings of all the power tools you plan to use simultaneously. This will give you the total power consumption in watts. Remember to factor in any additional devices or accessories that will be connected to the inverter.

What happens if I choose an inverter with a lower capacity than required?

If you choose an inverter with a lower capacity than required, it may not be able to meet the power demands of your tools. This can result in the inverter overheating, tripping circuit breakers, or shutting down. In some cases, it could even cause damage to your power tools. Therefore, it is essential to choose an inverter with a capacity that exceeds the total power consumption of your tools.

Additionally, an undersized inverter may not provide stable power output, which can lead to reduced tool performance and potentially affect the lifespan of the tools. It’s always better to err on the side of caution and choose an inverter with a higher capacity if you are unsure about the power requirements of your tools.

What are the benefits of using the right size inverter for power tools?

Using the right size inverter for your power tools offers several benefits. Firstly, it ensures that your tools receive a stable and consistent power supply, which is crucial for their performance and longevity. An appropriately sized inverter prevents potential damage to the tools and minimizes the risk of overheating or system failure.

Moreover, choosing the right size inverter ensures efficient energy consumption. An oversized inverter may consume more power than necessary, leading to higher energy costs. On the other hand, an undersized inverter might struggle to meet the power demands, resulting in inefficient operation. By selecting the correct size inverter, you can optimize energy usage and save on electricity expenses.

Are there any other factors to consider when choosing an inverter for power tools?

Yes, apart from the size and power requirements, there are a few other factors to consider when choosing an inverter for power tools. One important factor is the type of inverter. There are modified sine wave and pure sine wave inverters. While modified sine wave inverters are more affordable, pure sine wave inverters provide a cleaner and more stable power output, making them ideal for sensitive electronic devices.

Additionally, consider the availability of outlets and the number of tools you plan to connect simultaneously. Make sure the inverter has enough outlets and the necessary voltage compatibility for your specific power tools. Finally, take into account the physical size and weight of the inverter, especially if you need a portable solution. These factors will help you make an informed decision when selecting an inverter for your power tools.

Summary

When choosing an inverter for power tools, it’s important to consider the wattage and surge capacity. The inverter’s wattage rating should exceed the total power consumption of your tools. The surge capacity should be enough to handle any initial power spikes. It’s also important to choose an inverter with the right type of outlets for your tools.

Additionally, it’s crucial to ensure that the inverter is compatible with your power source, whether it’s a car battery or a portable generator. Lastly, it’s wise to consider the inverter’s size and weight, especially if you plan to use it in different locations frequently. By considering all these factors, you can select the right inverter to power your tools safely and efficiently.