Wondering what size inverter you need to charge your power tools? Look no further! We’ve got all the answers you need. Whether you’re a seasoned DIY enthusiast or just starting out, finding the right inverter is crucial for powering your tools on the go. Don’t worry, we’ll break it down for you in simple terms. Let’s dive in and get to the bottom of this!

So, you’ve got your power tools but need a reliable way to keep them charged when you’re away from an electrical outlet. That’s where inverters come in. An inverter is a device that converts DC power from a battery into AC power, which is what most power tools require. But how do you know what size inverter you need? Well, it depends on a few key factors.

First, consider the power requirements of your power tools. Each tool has a wattage rating, which indicates how much power it needs to operate. You’ll need an inverter that can handle the combined wattage of all the tools you plan to use simultaneously. And don’t forget to account for power surges that may occur when starting certain tools.

Choosing the right size inverter is essential for keeping your power tools charged and ready to go. By considering the power requirements of your tools and factoring in any potential surges, you can ensure that your inverter can handle the load. So, let’s get started and find the perfect inverter to power your tools on your next adventure!

Wondering what size inverter you need to charge power tools? Choosing the right size is crucial to ensure efficient operation. To determine the size, follow these steps:

- Identify the power tool’s wattage requirement.

- Calculate the total wattage of all the power tools you want to charge simultaneously.

- Consider the inverter’s efficiency rating.

- Add a safety margin to account for power surges.

- Select an inverter size that can handle the calculated total wattage.

By following these steps, you’ll be able to choose the appropriate inverter size for charging your power tools.

What Size Inverter Do You Need to Charge Power Tools?

Understanding Power Tool Energy Consumption

When it comes to using power tools off the grid or in remote locations where traditional power sources are not available, an inverter is a crucial tool. Power tools have varying energy consumption, and it is essential to choose the right size inverter to ensure efficient and effective operation. To determine the size of the inverter needed to charge power tools, it is crucial to understand power tool energy consumption.

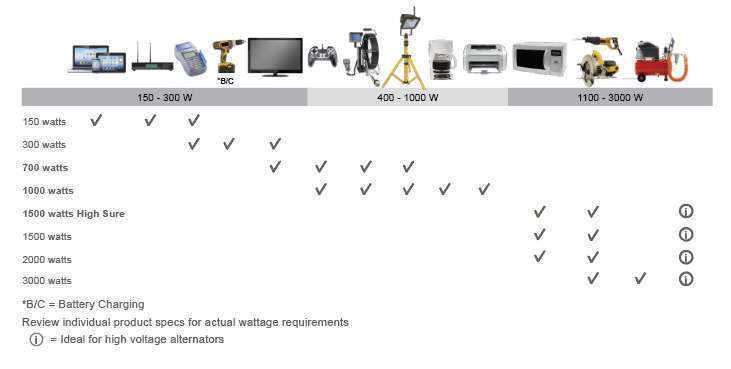

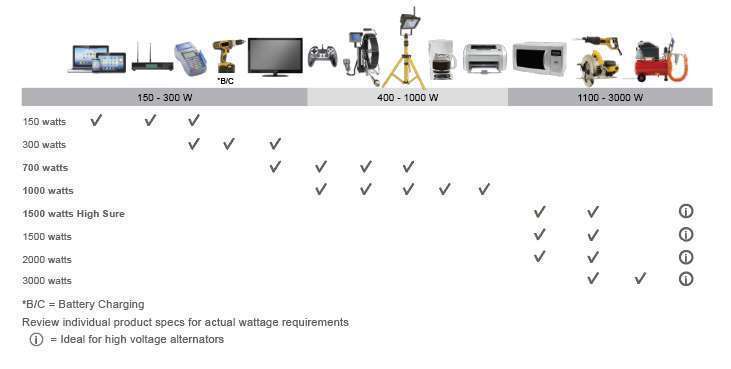

Power tools come in various types and sizes, and their energy consumption can vary significantly. Smaller power tools like drills and sanders typically require around 500 to 1500 watts to operate efficiently. Larger power tools like miter saws, table saws, and air compressors can require anywhere from 1500 to 5000 watts or more. Before choosing an inverter, it is essential to check the power requirements of your specific power tools or consult the user manual for accurate information.

Calculating Power Tool Energy Consumption

To determine the right size inverter for your power tools, you need to calculate their energy consumption. The formula for calculating energy consumption is simple:

Energy Consumption = Power (in watts) x Time (in hours)

For example, if you are using a drill that requires 1000 watts of power and you plan to use it continuously for 2 hours, the energy consumption would be:

Energy Consumption = 1000 watts x 2 hours = 2000 watt-hours

By calculating the energy consumption for each power tool you plan to use, you can get an idea of the total power requirements and choose an inverter that can handle that load.

Selecting the Right Size Inverter

Once you have calculated the total power requirements of your power tools, it’s time to select the right size inverter. Inverters come in various sizes, typically measured in watts. To ensure reliable and efficient operation, it is recommended to choose an inverter that can handle a slightly higher load than the total power requirements of your power tools.

For example, if the total power requirements of your power tools amount to 3500 watts, it would be wise to choose an inverter with a capacity of at least 4000 watts. This allows some headroom for power surges and ensures that the inverter can handle the load without overheating or tripping.

The Benefits of Choosing the Right Size Inverter

Choosing the right size inverter for your power tools offers several benefits. Firstly, it ensures that your power tools receive a steady and uninterrupted power supply, preventing any issues with performance or damage to the tools. Secondly, it maximizes the efficiency of the inverter, as it operates within its optimal load range. This can lead to longer inverter lifespan and reduced energy consumption.

Additionally, selecting the correct inverter size allows for future expansion. If you plan to add more power tools to your toolkit in the future, having an inverter with a higher capacity gives you room to grow without the need for frequent upgrades.

In conclusion, determining the right size inverter to charge power tools involves calculating the total power requirements of your tools and selecting an inverter that can handle that load. By doing so, you ensure efficient operation, prevent performance issues, and maximize the lifespan of your power tools and inverter.

Key Takeaways: What Size Inverter to Charge Power Tools?

- 1. To determine the right size inverter for power tools, consider their wattage requirements.

- 2. Add up the wattage of all the power tools you plan to use simultaneously.

- 3. Choose an inverter with a continuous power rating greater than the total wattage calculated.

- 4. It’s safer to choose an inverter with a 20% higher continuous power rating than the calculated wattage.

- 5. Keep in mind the surge power required by power tools when they start up.

Frequently Asked Questions

Welcome to our FAQ section where we provide answers to common questions about choosing the right size inverter for charging power tools. Read on to find out more!

1. Can I use any size inverter to charge power tools?

No, you cannot use any size inverter to charge power tools. The size of the inverter you need depends on the power requirements of your power tools. Different power tools have different power ratings, which indicate the amount of power they consume. To determine the right size inverter, you need to add up the power ratings of all the tools you plan to use simultaneously. Make sure the inverter’s continuous power rating is equal to or greater than this total. It’s also a good idea to leave some room for future tool additions or upgrades.

2. What happens if I use an inverter that is too small?

If you use an inverter that is too small to power your tools, you may run into a few issues. First, the inverter may overheat or shut down due to the excessive load. Second, the voltage output of the inverter may drop below the recommended level, affecting the performance of your power tools. This can lead to reduced power output, slower tool operation, or even damage to the tools themselves. It’s important to choose an inverter that can handle the power requirements of your tools to ensure safe and efficient operation.

3. How can I determine the power rating of my power tools?

To determine the power rating of your power tools, you can usually find this information on the tool itself or in the tool’s user manual. Look for the specifications or technical details section, where you will find the power rating expressed in watts, amps, or volts. If you are unable to find this information, you can contact the manufacturer or search for the tool’s model number online to find the necessary specifications. It’s important to have accurate power ratings to ensure you choose the right size inverter for charging your power tools.

4. Can I use a generator instead of an inverter to charge power tools?

Yes, you can use a generator instead of an inverter to charge power tools. Like inverters, generators provide alternating current (AC) power. However, there are a few differences to consider. Generators are generally larger and heavier than inverters, making them less portable. They also require fuel, such as gasoline or propane, to operate, while inverters can be powered by batteries or connected to a power source. Additionally, generators may produce more noise and emissions compared to inverters. The choice between a generator and an inverter depends on your specific needs, preferences, and the availability of power sources in your location.

5. Are there any additional considerations when using an inverter to charge power tools?

Yes, there are a few additional considerations when using an inverter to charge power tools. First, make sure you have the appropriate cables and connectors to connect your inverter to the power tools. Secondly, consider the run time of your inverter. If you plan to use your power tools for an extended period, you’ll need to ensure your inverter has enough battery capacity to support this. Finally, it’s important to use proper safety precautions and follow the manufacturer’s instructions when operating your inverter and charging your power tools. This includes avoiding overloading the inverter, keeping it in a well-ventilated area, and using it in accordance with any safety guidelines provided.

Summary

If you want to charge power tools using an inverter, there are a few things to consider. First, check the wattage ratings of your tools, and make sure the inverter can handle the total power needed. Second, pay attention to the peak power rating of the inverter, as some power tools require a higher power surge when starting up. Lastly, consider the battery capacity and the charging time required for your tools. With these factors in mind, you can select the right size inverter to charge your power tools effectively.

Remember, it’s essential to choose a suitable inverter to avoid damage to your power tools and ensure a safe and efficient charging process. So, take the time to assess your tools’ power requirements and find an inverter that meets those needs. Happy tool charging!