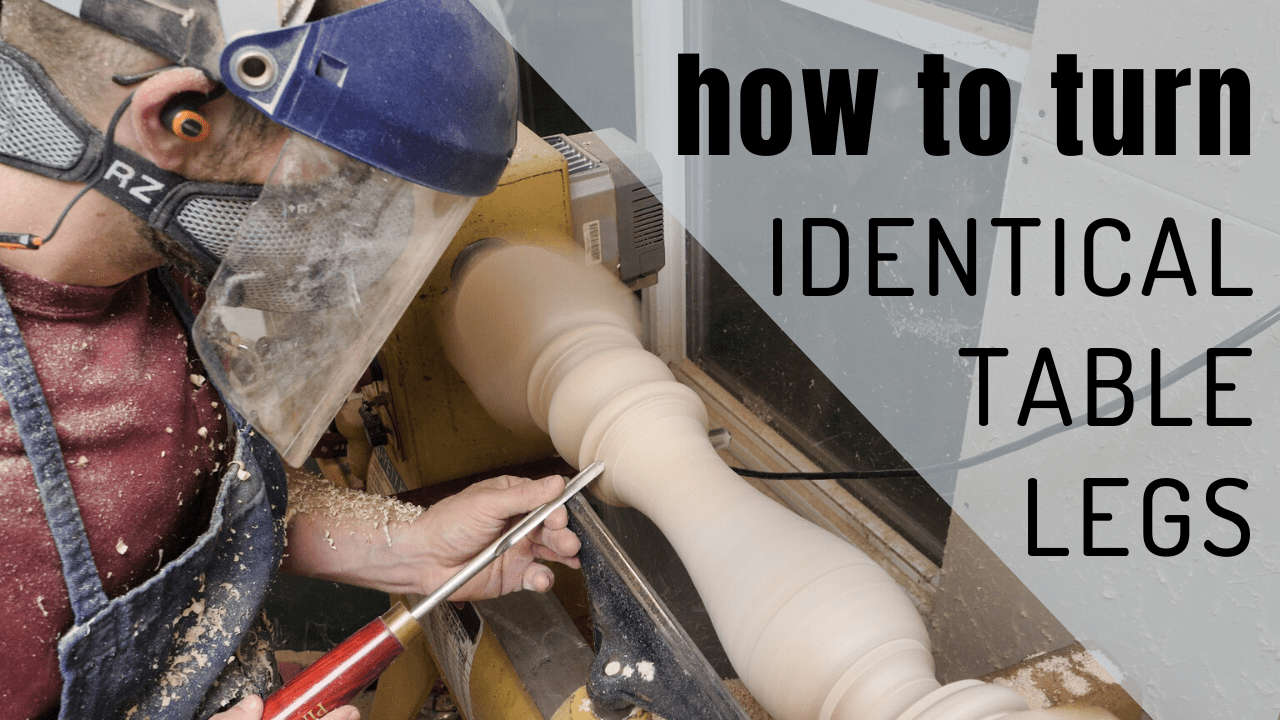

If you’ve ever wondered, “What size lathe do I need for table legs?” then you’ve come to the right place! Whether you’re a beginner or a seasoned woodworker, choosing the right lathe size is essential for creating beautiful and sturdy table legs. In this guide, we’ll walk you through everything you need to know to make an informed decision. So let’s dive in and explore the fascinating world of lathes and table leg turning!

When it comes to selecting the right lathe size for your table legs, there are a few key factors to consider. First up is the length of the table legs you want to make. Longer legs will require a lathe with a larger swing capacity, allowing you to turn the entire length without any restrictions. Next, think about the diameter or thickness of the legs you’re aiming for. Thicker legs may require a more powerful motor and a sturdier lathe bed to handle the increased workload. Lastly, consider the type of wood you’ll be using, as harder woods may require more power and stability.

Now that we’ve covered the basics, let’s dig a little deeper into the different lathe sizes available. From mini lathes for small projects to full-size lathes for professional woodworkers, there’s a wide range of options to choose from. The size you ultimately select will depend on your specific needs, budget, and available space. By understanding the dimensions of your table legs and considering your woodworking goals, you’ll be able to find the perfect lathe size to bring your vision to life.

So, whether you’re dreaming of turning elegant Queen Anne-style legs or rustic farmhouse-inspired table supports, understanding what size lathe you need is crucial. By taking into account factors like the length, diameter, and wood type of your table legs, you’ll be able to make an informed decision and choose a lathe that meets your requirements. In the following sections, we’ll explore different lathe sizes in more detail, so stay tuned for all the valuable information coming your way!

If you’re wondering what size lathe to use for table legs, here’s a guide to help you. First, consider the size of the table legs you plan on turning. A mini lathe is suitable for small to medium-sized legs, while a midi lathe is better for larger legs. Next, think about the length and weight of the legs. Ensure that the lathe you choose can handle the dimensions and weight capacity. Finally, consider your budget and choose a lathe that fits your needs and preferences.

The Right Size Lathe for Table Legs: Everything You Need to Know

When it comes to crafting table legs, choosing the right size lathe is crucial. Whether you’re a seasoned woodworker or just starting out, having the appropriate lathe size can significantly impact your project’s success. In this article, we’ll explore the factors to consider when determining the size of the lathe you need for table legs and provide helpful insights to guide you through your decision-making process.

Factors to Consider

Before diving into the different sizes of lathes suitable for table legs, let’s first understand the key factors that will influence your decision.

Budget and Workspace

When choosing a lathe, it’s important to consider your budget and workspace limitations. Lathes can vary significantly in price, and while larger models offer greater versatility, they may also come with a higher price tag. Additionally, you’ll need to evaluate your available workspace to ensure that the lathe size you choose can comfortably fit in your workshop.

If you’re just starting out or have space constraints, a smaller benchtop lathe might be the right choice. These lathes are compact, portable, and more affordable. However, if you have a dedicated workshop with ample space and a larger budget, a floor-standing lathe with a greater capability might be a better fit.

Project Requirements

The size of the table legs you plan to turn is another crucial factor in determining the ideal lathe size. Consider the length, diameter, and shape of the table legs you typically work on. If you primarily create smaller, delicate table legs, a mini-lathe with a smaller swing capacity would be adequate. On the other hand, if you frequently work on larger, more substantial table legs, a lathe with a larger swing and bed length would be necessary to accommodate those dimensions.

It’s important to think about your future goals as well. If you anticipate working on a variety of different-sized table legs, investing in a larger lathe with adjustable features will give you the flexibility to tackle any project that comes your way.

Experience Level

Your experience level as a woodworker should also influence your choice of lathe size. If you’re a beginner, a smaller lathe with user-friendly features can be a great starting point. These lathes often have slower speed ranges and simpler controls, allowing you to learn and practice without feeling overwhelmed.

However, if you have more experience and are comfortable with larger, more complex machines, a mid-sized or full-sized lathe may be a worthwhile investment. These lathes offer more power, speed options, and advanced features, giving you greater control and versatility in your projects.

Now that we’ve covered the key factors to consider, let’s delve into the different lathe sizes suitable for table leg turning.

Mini-Lathes for Small Table Legs

If you predominantly work with small table legs, a mini-lathe might be the perfect choice for you. These lathes typically have a swing range of around 10-12 inches and a bed length of 15-20 inches. They are compact, lightweight, and often more affordable.

Mini-lathes are ideal for turning delicate, intricate designs and are well-suited for beginners or those with limited workshop space. They offer a great starting platform to hone your skills and experiment with different techniques.

Benefits of Mini-Lathes for Small Table Legs

- Compact and portable

- More affordable compared to larger lathes

- Perfect for beginners and small-scale projects

- Great for turning delicate designs and intricate details

While mini-lathes are excellent for smaller table legs, they may not provide the necessary swing capacity and bed length for larger projects. So, if you plan to work on bigger table legs, you’ll need to consider larger lathe options.

Mid-Sized Lathes for Medium-Sized Table Legs

If you frequently work with medium-sized table legs, a mid-sized lathe could be the ideal choice. These lathes typically have a swing range of around 12-16 inches and a bed length of 30-36 inches. They strike a balance between size and versatility, offering a wider range of turning options compared to mini-lathes.

Mid-sized lathes provide ample swing capacity and bed length to accommodate medium-sized table legs. They offer more power, stability, and advanced features, making them suitable for intermediate to advanced woodworkers.

Benefits of Mid-Sized Lathes for Medium-Sized Table Legs

- Increased swing capacity and bed length compared to mini-lathes

- More power and stability

- Advanced features for greater control and precision

- Can accommodate a wide range of projects

Mid-sized lathes provide the versatility needed to work on various table leg sizes, making them an excellent choice for woodworkers who require that flexibility.

Full-Sized Lathes for Large Table Legs

If you often tackle large table leg projects or want the freedom to work on different-sized legs, a full-sized lathe is your best option. These lathes typically have a swing range of 16 inches or larger and a bed length of 36 inches or more. They offer maximum power, stability, and control for handling larger and more substantial table legs.

Full-sized lathes are heavy-duty machines designed for experienced woodworkers and professionals. They can handle demanding projects with ease and precision. These lathes often come equipped with variable speed controls, adjustable rest positions, and other advanced features to tackle any table leg turning challenge.

Benefits of Full-Sized Lathes for Large Table Legs

- Maximum swing capacity and bed length for larger projects

- Robust power and stability

- Advanced features for precise control

- Can handle a wide range of table leg sizes and shapes

While full-sized lathes offer enhanced capabilities, it’s important to note that they can be more expensive and require a dedicated workshop space due to their size and weight.

Choosing the Right Lathe for Your Needs

When determining the right size lathe for table legs, consider your budget, workspace, project requirements, and experience level. Each lathe size has its own advantages and is tailored to different woodworking needs. Whether you opt for a mini-lathe, mid-sized lathe, or full-sized lathe, ensure that it aligns with your current and future woodworking goals.

Keep in mind that the versatility of a lathe is not solely determined by its size, but also by additional features such as adjustable speed controls and tool-rest positions. Prioritize your specific requirements, and carefully evaluate the different options available within your chosen lathe size category.

By selecting the right size lathe, you’ll have the tools necessary to create beautiful table legs that perfectly complement your furniture projects. Happy turning!

Key Takeaways: What Size Lathe Do I Need for Table Legs?

- A lathe with a swing capacity of at least 12 inches is recommended for turning table legs.

- The distance between centers should be equal to or greater than the length of your table legs for stability.

- A variable speed lathe allows you to control the rotation speed for different wood types and turning techniques.

- Consider the motor power of the lathe to ensure it can handle the size and hardness of the wood you’ll be working with.

- Accessories like a steady rest and a live center can assist in turning longer and narrower table legs.

Frequently Asked Questions

Here, we’ve compiled the answers to some common questions you may have about selecting the right size lathe for table legs.

1. What factors should I consider when choosing a lathe size for table legs?

When selecting a lathe size for table legs, there are a few important factors to consider. First, think about the diameter of the legs you plan to turn. Larger diameters will require a lathe with a greater swing capacity. Additionally, consider the length of the table legs. Longer legs will require a lathe with a sufficient distance between centers to accommodate them. Finally, think about the type of wood you plan to use. If you plan to turn hard or dense woods, a larger lathe with more power may be necessary.

By carefully considering the diameter, length, and wood type, you can choose a lathe size that will allow you to comfortably and safely turn the table legs you desire.

2. What swing capacity should I look for in a lathe for table legs?

The swing capacity of a lathe refers to the maximum diameter of the workpiece that can be turned without obstruction. For table legs, it’s important to choose a lathe with a swing capacity that is greater than the desired diameter of your legs. This ensures that you have enough space to work with and prevents the workpiece from hitting the lathe bed or tool rest during turning. A general rule of thumb is to choose a lathe with a swing capacity at least 2 inches larger than the diameter of your legs.

By selecting a lathe with an appropriate swing capacity, you can confidently turn table legs of various diameters without any limitations or difficulties.

3. What distance between centers should I consider for turning table legs?

The distance between centers on a lathe refers to the maximum length of the workpiece that can be supported between the headstock and tailstock. For table legs, you’ll want to choose a lathe with a distance between centers that is greater than the desired length of your legs. This allows you to comfortably turn long legs without any overhang or instability. It’s generally recommended to select a lathe with a distance between centers at least 25% longer than the length of your legs to ensure sufficient support.

By considering the length of your table legs and choosing a lathe with an appropriate distance between centers, you can ensure stability and accuracy when turning your legs.

4. Is horsepower important when selecting a lathe size for table legs?

Horsepower is an important consideration when selecting a lathe size for table legs, especially if you plan to work with harder or denser woods. Higher horsepower provides more torque and allows the lathe to handle larger and more demanding turning projects. While lower horsepower lathes can still turn table legs, a more powerful lathe will provide smoother and more efficient turning, particularly when working with tough materials. Consider the types of wood you plan to work with and choose a lathe with enough horsepower to handle your projects.

By opting for a lathe with sufficient horsepower, you’ll have the necessary strength and control to turn your table legs with ease, regardless of the wood species or complexity of the design.

5. Can I use a mini lathe for turning table legs?

While mini lathes can be great for smaller projects, they may not be ideal for turning table legs. Mini lathes typically have limited swing capacities and shorter distances between centers, making them less suitable for larger and longer workpieces like table legs. Additionally, mini lathes often have lower horsepower, which may make it more challenging to turn table legs from harder or denser woods.

It’s recommended to opt for a full-sized lathe with a larger swing capacity, greater distance between centers, and higher horsepower when planning to turn table legs. This will ensure you have the necessary space, support, and power to successfully create your desired table leg designs.

What Size Lathe Should You Buy?

Summary

So, to recap, when it comes to choosing the right lathe size for table legs, there are a few things to consider. First, think about the size and thickness of the legs you plan to turn. A mini or midi lathe should work well for smaller projects, while a full-sized lathe is better for larger and thicker legs. Additionally, the length of the lathe bed is important. Make sure it is long enough to accommodate the length of your legs. Finally, don’t forget to factor in your budget and personal preferences. Happy turning!