If you’re stepping into the world of metalworking and you’re wondering, “What size metal lathe do I need?” – you’ve come to the right place! Choosing the right size of a metal lathe can make all the difference in your projects. So, let’s dive in and explore the factors to consider when selecting the perfect size for your lathe.

First things first, let’s talk about why size matters when it comes to metal lathes. The size of a lathe determines the maximum diameter and length of the workpiece it can handle. So, depending on the types of projects you have in mind, you’ll want to ensure that your lathe can accommodate the size of your workpieces comfortably.

When determining the size of the metal lathe you need, there are a few key factors to consider. These include the size of the projects you’ll be working on, the available space in your workshop, and your budget. By keeping these factors in mind, you’ll be well on your way to finding the perfect size metal lathe to suit your needs. So, let’s get started!

What Size Metal Lathe Do I Need? A Comprehensive Guide

Metal lathes are essential tools for machining metal parts, but choosing the right size can be overwhelming for beginners. The size of a metal lathe refers to its capacity to handle different dimensions and weights of workpieces. Selecting the appropriate size is crucial to ensure efficient and accurate machining. In this article, we will provide a comprehensive guide to help you determine the ideal size of a metal lathe for your specific needs. Whether you are a hobbyist or a professional machinist, this guide will equip you with the knowledge to make an informed decision.

The Importance of Choosing the Right Size Metal Lathe

Before diving into the details of selecting the right size metal lathe, it is essential to understand why this decision carries such significance. The size of a metal lathe directly impacts its versatility, precision, and overall performance. A lathe that is too small may limit the size of the workpieces you can machine, while a lathe that is too large may waste space and increase costs. By choosing the right size, you can optimize your machining capabilities, enhance productivity, and achieve the best possible results. Now, let’s explore the factors to consider when determining the ideal size for your metal lathe.

1. Workpiece Dimensions and Weight

The first and most crucial factor to consider is the size and weight of the workpieces you will be machining. Measure the largest dimensions of your typical workpiece, such as the diameter and length, and ensure that the lathe’s specifications can accommodate those dimensions. Additionally, consider the weight of your workpieces. A lathe must be capable of supporting the weight without straining the machine’s components or compromising stability. It is generally recommended to choose a lathe with a higher weight capacity than your heaviest workpiece for safety and efficient operation.

Workpiece dimensions are not the only consideration; you should also evaluate the potential for future projects. If you anticipate working on larger or heavier parts in the future, it is wise to invest in a lathe that can handle those future projects. This way, you won’t need to upgrade or replace your lathe as your skills and needs evolve.

It is important to note that larger lathes can often handle smaller workpieces, but smaller lathes may not be suitable for larger workpieces. Therefore, it is generally safer to err on the side of a slightly larger lathe than to risk limitations in your machining capabilities.

2. Workspace and Accessibility

Another critical factor to consider when determining the size of your metal lathe is the available workspace in your workshop or garage. Measure the dimensions of the area where the lathe will be placed, taking into account additional space required for movement and access. Ensure that there is enough room for the lathe, including sufficient clearance for the tailstock, tool rest, and any accessories or attachments.

Additionally, consider the accessibility of the work area. Will you be able to maneuver around the lathe comfortably? Can you easily access the controls and tooling? These aspects are essential for ensuring your safety, convenience, and overall enjoyment while working with the lathe. A cramped or awkwardly positioned lathe can negatively impact your efficiency and restrict your ability to perform certain operations.

While it is essential to maximize the use of your available space, avoid choosing a lathe that is too large for your workshop. Oversized machines can lead to a crowded and cluttered workspace, hindering your ability to move around and work efficiently. Strike a balance between the dimensions of the lathe and the available workspace to create a comfortable and functional setup.

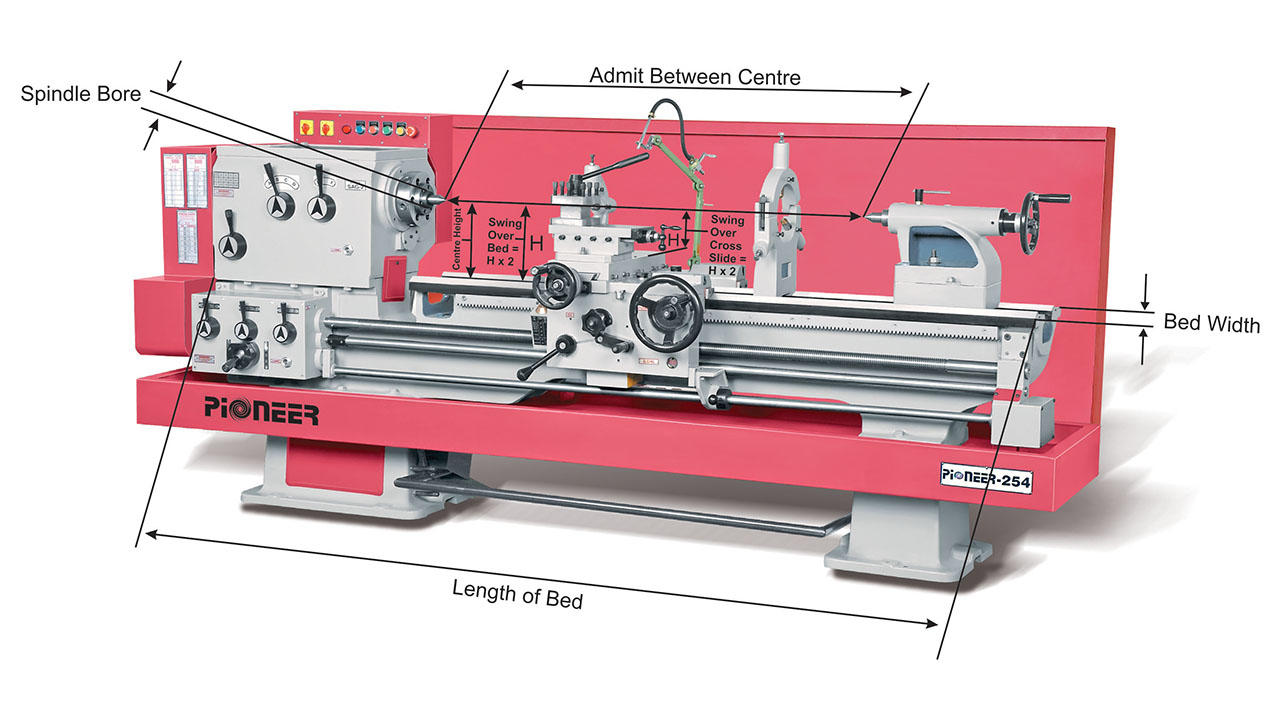

3. Bed Length and Swing Capacity

The bed length and swing capacity of a metal lathe are crucial specifications that determine the size of workpieces the machine can accommodate. The bed length refers to the distance between the lathe’s headstock and tailstock, horizontally along the lathe’s bed. It is a vital consideration for machining long workpieces. If you primarily work on short or small parts, a shorter bed length may be sufficient. However, if you frequently machine longer parts, choosing a lathe with a longer bed length will prevent you from facing limitations.

The swing capacity of a lathe refers to the maximum diameter of a workpiece it can accommodate. This measurement is determined by the distance from the center of the spindle to the bed. Consider the largest diameter of workpieces you anticipate machining and ensure that the swing capacity of the lathe allows for comfortable and unrestricted operations.

Both the bed length and swing capacity should be chosen based on your current and future workpiece requirements. It is advisable to choose a lathe with slightly larger specifications than your immediate needs to allow for growth and versatility in your machining projects.

4. Speed Range and Power

The speed range and power of a metal lathe are essential factors to consider when determining the appropriate size for your needs. The speed range refers to the number of rotational speeds that a lathe can offer, usually measured in revolutions per minute (RPM). Different workpiece materials and machining operations require specific speed settings for optimal results. Ensure that the lathe you choose offers a broad speed range that can accommodate your intended applications.

The power of a lathe is typically measured in horsepower (HP) and determines its ability to handle various cutting operations. Higher horsepower translates to more cutting force and the ability to work on tougher materials. Consider the type of materials you will be machining and the complexity of your projects to determine the minimum power requirement for your lathe. Choosing a lathe with sufficient power will ensure smooth and efficient machining, preventing strain on the machine and enabling high-quality results.

5. Budget and Cost Considerations

Budget is an important factor that influences the size of the metal lathe you can afford. As with any machinery, larger and more advanced lathes generally come with a higher price tag. Before making a purchase, determine your budget and weigh it against your machining requirements. While it is tempting to opt for the largest and most feature-rich lathe available, it may not be financially feasible or necessary for your specific needs.

Research and compare prices, taking into account the additional costs of accessories, tooling, and maintenance. It may be beneficial to consult with experienced machinists or join online communities to gather opinions and recommendations. Ultimately, aim for the best balance between your budget and the capabilities offered by the lathe.

Remember, investing in a high-quality lathe that meets your specific requirements will save you money in the long run by minimizing the need for upgrades or replacements. Consider your present and future machining projects, as well as your budget, to make an informed decision.

6. Accessories and Attachments

When choosing the size of your metal lathe, consider the availability and compatibility of accessories and attachments. These additional tools can enhance the functionality and versatility of your lathe. Examples of common accessories include different types of chucks, tool rests, steady rests, and indexing attachments. Determine which accessories are essential for your intended projects and ensure that they are compatible with the lathe you choose.

Availability of accessories can vary depending on the size and brand of the lathe. It is advisable to do thorough research to confirm the amount and variety of accessories available for the lathe you are considering. Additionally, take into account the cost of these accessories when evaluating the overall investment required.

7. Reviews and Recommendations

Finally, before making a final decision on your metal lathe size, consider reading reviews and seeking recommendations from experts and experienced users. Online forums, machining communities, and professional organizations can provide valuable insights and firsthand experiences that can help you make an informed choice. Consider factors such as durability, reliability, customer support, and overall user satisfaction.

While reviews and recommendations should not be the sole basis for your decision, they can provide valuable perspective and shed light on potential issues or advantages specific to a particular lathe model or brand. Leverage the collective knowledge and experience of others in the machining community to make a well-informed decision.

By considering these seven factors – workpiece dimensions and weight, workspace and accessibility, bed length and swing capacity, speed range and power, budget and cost considerations, accessories and attachments, and reviews and recommendations – you can determine the ideal size of a metal lathe for your specific needs. Remember that selecting the right size is essential for optimizing your machining capabilities, achieving accurate results, and ensuring a satisfying and productive machining experience. Happy machining!

Key Takeaways: What Size Metal Lathe Do I Need?

- Consider the size of the projects you plan to work on with the lathe.

- Take into account the available space in your workshop or garage.

- Think about the type of materials you will be working with.

- Consider your skill level and experience with operating lathes.

- Consult with experts or experienced hobbyists for advice on suitable lathe sizes.

Frequently Asked Questions

Welcome to our FAQ section on finding the right size metal lathe for your needs. Below, we answer five common questions to help guide you in your decision-making. Whether you’re a beginner or an experienced user, we’ve got you covered!

1. What factors should I consider when determining the size of a metal lathe?

When selecting the size of a metal lathe, several factors come into play. Firstly, you’ll want to consider the size and weight of the projects you plan to tackle. It’s important to choose a metal lathe that can handle the dimensions and weight of your workpieces. Additionally, think about the available space in your workshop. If you have limited space, a compact or benchtop lathe may be more suitable. Finally, consider your budget and the features you require. It’s essential to strike a balance between your needs and what you can afford.

Ultimately, by considering the size and weight of your projects, the available space in your workshop, and your budget, you can determine the right size metal lathe for your needs.

2. What are the advantages of a larger metal lathe compared to a smaller one?

Opting for a larger metal lathe has its advantages. The increased size allows you to work on larger projects, accommodating larger workpieces and handling heavier loads. With a larger lathe, you have greater stability, reducing the likelihood of vibration and ensuring more precise results. Additionally, larger lathes often come with more powerful motors, enabling you to work on tougher materials with ease.

On the other hand, smaller metal lathes offer their own benefits. If you have limited space or frequently work on smaller projects, a compact or benchtop lathe may be a better fit. Smaller lathes are often lighter and more portable, making them easier to move around. They are also typically more affordable, making them a practical choice for hobbyists or those on a budget.

3. Can I use a small metal lathe for larger projects?

While a small metal lathe may have limitations with larger projects, it is possible to work on them with some adjustments. One option is to divide the project into smaller sections that can be machined individually on the lathe. Another approach is to utilize “outboard turning.” This involves extending the turning capability of the lathe by attaching the workpiece to the outboard side of the headstock. Keep in mind that these methods may have limitations in terms of size and precision compared to using a lathe specifically designed for larger projects.

It’s worth noting that while it is technically possible to use a small metal lathe for larger projects, it may not provide the same level of stability and precision as a lathe designed for larger workpieces. If you frequently work on larger projects, it is advisable to invest in a lathe that can handle the size and weight requirements.

4. Are there any safety considerations when using a metal lathe?

Yes, safety is paramount when using a metal lathe. Always wear appropriate personal protective equipment (PPE) such as safety glasses, gloves, and ear protection. Ensure that long hair, loose clothing, and jewelry are secured or tucked away. Familiarize yourself with the specific safety features of your lathe and follow the manufacturer’s instructions for proper usage. It’s crucial to keep the lathe area clear of any debris or obstructions and have a well-ventilated workspace, especially when machining metals.

Additionally, take the time to learn and implement safe operating procedures for your lathe. This includes properly securing workpieces, using the correct cutting tools and techniques, and maintaining a steady and controlled operation. Regularly inspect and maintain your lathe to ensure it is in good working condition and make any necessary repairs or adjustments promptly.

5. Can I upgrade my metal lathe to a larger size later?

In some cases, it is possible to upgrade your metal lathe to a larger size. However, it depends on the specific lathe model and manufacturer. Some lathes may have compatible accessories or extension options that allow you to increase the working area or capacity. Before purchasing a lathe, it’s worth researching if there are expansion options available for that particular model.

Keep in mind that while upgrading may be an option, it can be a complex and costly process. It is often more cost-effective to purchase a lathe that meets your desired size requirements from the start. If you anticipate working on larger projects in the future, it is advisable to invest in a lathe that can accommodate your needs rather than relying on the possibility of upgrades.

Summary

Deciding what size metal lathe you need can be a bit confusing. The first thing to consider is the size of the projects you’ll be working on. If you’re planning to work on small items like jewelry or watch parts, a mini lathe would be a good choice. However, if you want to work on larger projects like engine parts or furniture legs, a larger lathe would be better. Another factor to consider is your workspace. Make sure you have enough room for the lathe and can comfortably operate it. And finally, don’t forget your budget. Choose a lathe that fits your needs and also your wallet.

Remember, the right size metal lathe for you depends on the size of your projects, your workspace, and your budget. Consider these factors and make an informed decision. Happy lathing!