So you’re thinking about getting a metal lathe, huh? Well, you’ve come to the right place! Choosing the right size for your metal lathe can be a bit tricky, but don’t worry, I’m here to help you out. In this guide, we’ll walk through everything you need to know about finding the perfect size for your needs. Let’s dive in!

When it comes to selecting a metal lathe, size really does matter. But how do you determine what size metal lathe you should buy? Well, it depends on a few factors. First off, what kind of projects do you plan on tackling? Are you looking to work on small hobbyist projects or larger industrial-grade pieces? Understanding the scope of your projects will help you determine the right size for your lathe.

Another factor to consider is the size of the materials you’ll be working with. If you plan on turning larger pieces of metal, you’ll need a lathe with a bigger swing over bed and a longer distance between centers. On the other hand, if you primarily work with smaller materials, a smaller lathe might be more suitable.

Now that we’ve covered the basics, let’s dive deeper into the different sizes of metal lathes available and the advantages they offer. Understanding the various options will empower you to make an informed decision and find the perfect size metal lathe for your needs. So, let’s get started!

Choosing the right size for a metal lathe depends on your specific needs and projects. Consider factors such as the size of the materials you’ll be working with and the types of projects you’ll be undertaking. It’s also important to think about the available workspace and your budget. Research different sizes and models, read customer reviews, and consult with experts to make an informed decision. Remember, the best size metal lathe for you is the one that meets your unique requirements.

What Size Metal Lathe Should I Buy?: A Comprehensive Guide

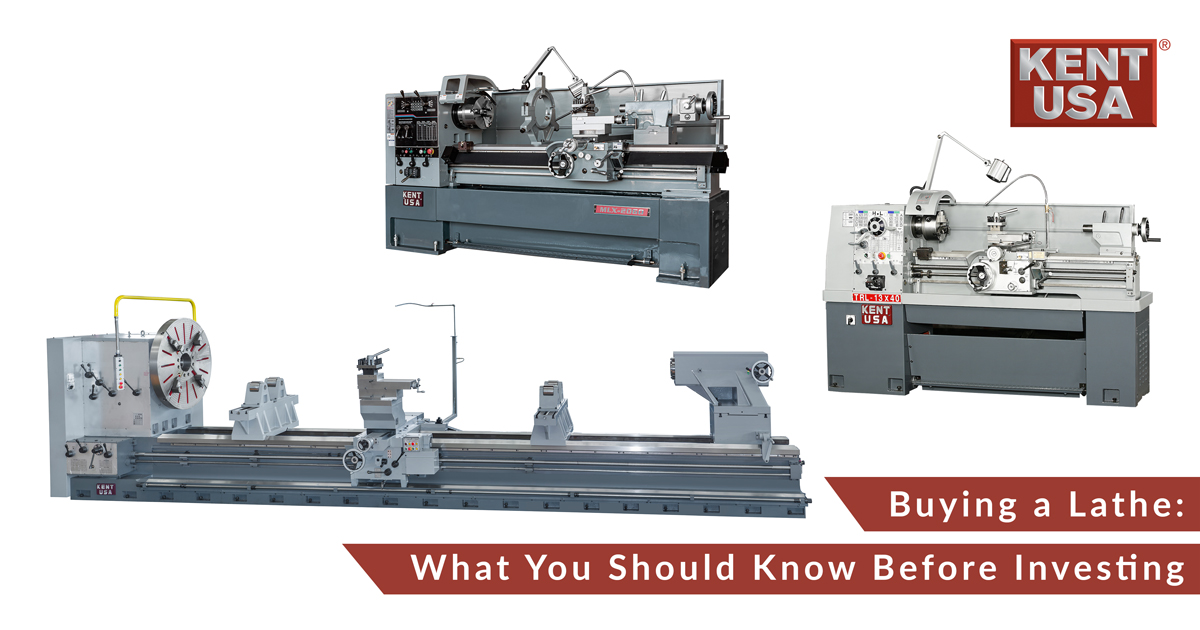

Metal lathes are essential tools for machining and shaping various metal materials. However, choosing the right size metal lathe can be a daunting task, especially for beginners. With a wide range of options available on the market, it’s important to consider several factors before making a purchase. In this comprehensive guide, we will explore the different sizes of metal lathes, their features, and how to determine the right size for your needs.

Sizes of Metal Lathes: Explained

When it comes to metal lathes, size refers to the swing capacity or the maximum diameter of workpiece that can be turned over the bed. The swing capacity is typically measured in inches or millimeters and is an essential consideration when determining the right size lathe for your projects.

Small Size Lathes (9-12 inch swing capacity)

Small size lathes, with a swing capacity ranging from 9 to 12 inches, are ideal for hobbyists, beginners, and those working on small-scale projects. These lathes are compact, lightweight, and easy to operate. They are suitable for turning small workpieces such as pens, jewelry, and model making. Additionally, small size lathes are generally more affordable, making them a great starting point for beginners.

Small size lathes often come with variable speed controls, allowing users to adjust the speed based on the materials being machined. Despite their limitations in terms of swing capacity, they can still handle a wide variety of materials, including brass, aluminum, and steel. However, it’s important to note that larger and heavier workpieces may not fit or be adequately supported on these lathes.

Medium Size Lathes (12-16 inch swing capacity)

Medium size lathes, with a swing capacity ranging from 12 to 16 inches, offer a balance between size and versatility. These lathes are suitable for both hobbyists and professionals involved in larger-scale projects. With a larger swing capacity, they can accommodate larger workpieces and allow for more complex machining operations.

Medium size lathes often come equipped with additional features such as variable speed controls, digital readouts, and power feeds. These features provide greater precision and control, allowing users to achieve more intricate designs. Additionally, medium size lathes are more durable and stable, making them suitable for working with heavier materials such as cast iron and stainless steel.

Large Size Lathes (16 inch and above swing capacity)

Large size lathes, with a swing capacity of 16 inches and above, are designed for heavy-duty industrial applications. These lathes are typically found in professional workshops and manufacturing facilities where large-scale projects are common. They are capable of handling oversized workpieces and can accommodate the machining needs of industries such as aerospace and automotive.

Large size lathes often come equipped with advanced features like digital controls, multiple cutting tool holders, and automatic threading mechanisms. These features enhance productivity, efficiency, and precision. However, it’s important to note that large size lathes require a significant amount of space and are considerably more expensive compared to smaller options.

Considering the size of the workpieces you intend to machine, your budget, and the available space in your workshop are all essential factors to consider when deciding on the size of metal lathe that is right for you.

Key Factors to Consider When Choosing a Metal Lathe Size

When determining the right size metal lathe for your needs, it’s important to consider the following factors:

1. Project Size and Scope

Consider the typical size and complexity of the projects you will be working on. If you mainly work on small-scale projects, a small to medium size lathe may be sufficient. However, if you anticipate working on larger and more intricate projects, investing in a larger lathe with a higher swing capacity would be more appropriate.

2. Available Workspace

The size of your workshop or workspace will dictate the maximum size of the lathe you can accommodate. Ensure that you have sufficient space for the lathe, leaving enough room for proper maneuverability and safe operation.

3. Budget

Set a budget for your lathe purchase and consider the price range associated with the different sizes of lathes. Smaller lathes are generally more affordable, while larger lathes can be significantly more expensive. Strike a balance between your budget and the features you require for your projects.

4. Skill Level

Consider your level of experience and skill in metalworking. If you are a beginner, starting with a smaller lathe may be more appropriate as they are easier to learn and operate. More advanced users may benefit from the additional features and capabilities of larger lathes.

5. Future Growth

Anticipate your future needs and growth in your metalworking pursuits. If you foresee an expansion in the scale and complexity of your projects, investing in a slightly larger lathe that can accommodate future requirements may be a wise decision.

In conclusion, choosing the right size metal lathe is crucial in ensuring that you can effectively and efficiently work on your metal machining projects. Consider the size and scope of your projects, available workspace, budget, skill level, and future growth when making your decision. By carefully assessing your needs and considering these factors, you can find the perfect size lathe that will meet your requirements and allow you to achieve exceptional results.

Key Takeaways: What Size Metal Lathe Should I Buy?

- Consider the size of the projects you’ll be working on.

- Choose a lathe with a swing over bed that accommodates your largest workpiece.

- Factor in the distance between centers to determine the maximum length of workpiece you can turn.

- Determine the horsepower and torque required for your desired applications.

- Consider the space available in your workshop for the lathe.

Frequently Asked Questions

Shopping for the right metal lathe can be overwhelming, especially if you’re unsure about the size you need. To help you make an informed decision, we’ve answered some common questions related to choosing the right size metal lathe.

1. What factors should I consider when deciding on the size of a metal lathe?

When determining the size of a metal lathe, consider the maximum swing over the bed and the distance between centers. The swing over the bed determines the maximum diameter of the workpiece the lathe can handle. The distance between centers determines the length of the workpiece the lathe can accommodate. Additionally, consider the weight of the lathe, as larger machines are often heavier and require more space.

It’s also important to consider the types of projects you’ll be working on. If you primarily work on small or medium-sized projects, a smaller lathe may suffice. However, if you plan to work on large or heavy-duty projects, a larger lathe with a higher power capacity would be more suitable.

2. How does the size of a metal lathe affect its performance?

The size of a metal lathe directly affects its performance and capabilities. A larger lathe typically has a higher horsepower motor, allowing it to handle larger and tougher materials. It also provides a greater swing over the bed and longer distance between centers, enabling you to work on larger workpieces with ease. The extra power and capacity of a larger lathe make it ideal for heavy-duty machining tasks.

However, it’s essential to note that larger lathes may require more space, consume more power, and come with a higher price tag. So, if you primarily work on smaller projects and have limited space or budget, a smaller lathe may still be a suitable choice. Consider your specific needs and limitations to make the best decision.

3. Can I use a small metal lathe for larger projects if I work in sections?

While it is possible to work on larger projects using a small metal lathe by working in sections, it may not always be the most efficient or practical solution. Working in sections means you would need to turn and align the workpiece multiple times, increasing the chances of inaccuracies and inconsistencies in the final result.

If you frequently work on larger projects, it’s generally advisable to invest in a lathe that can accommodate the size of the workpiece without the need for sectioning. This ensures better precision and efficiency in your machining processes. However, if you occasionally work on larger projects and do not have the budget or space for a larger lathe, working in sections can be a viable option, albeit with some limitations.

4. Should I prioritize swing over bed or distance between centers when choosing a metal lathe?

The importance of swing over bed and distance between centers depends on the types of projects you’ll be working on. If you primarily work on projects with larger diameters, swing over bed becomes crucial as it determines the maximum diameter the lathe can handle. On the other hand, if you often work on longer workpieces, such as shafts or bars, you should prioritize distance between centers to ensure the lathe can accommodate the length of your workpieces.

In many cases, striking a balance between swing over bed and distance between centers is essential. Consider the average size of your projects and choose a lathe that can meet those requirements. It’s also worth noting that some lathes offer extension options or bed extensions that can increase the distance between centers, providing more flexibility for longer workpieces.

5. Are there any advantages to choosing a smaller metal lathe?

Choosing a smaller metal lathe has its advantages, especially if you primarily work on smaller projects or have limited space. Smaller lathes typically cost less, consume less power, and require less floor space. They are also easier to move and transport if needed. Moreover, smaller lathes can still handle a wide range of machining tasks with precision and efficiency.

Additionally, smaller lathes are often more beginner-friendly, making them a suitable choice for those new to metalworking. They offer a manageable learning curve and are less overwhelming to operate. If you’re a hobbyist or need a lathe for occasional use, a smaller size might be a practical option. However, if you work on heavier or larger projects more frequently, a larger lathe may offer better performance and versatility.

Summary

So, when it comes to choosing the right size metal lathe, there are a few things to consider. First, think about the types of projects you will be working on. If you’re planning on working with small or medium-sized pieces, a benchtop lathe would be sufficient. However, if you have larger projects in mind, you might want to consider a larger floor-standing lathe. Remember to also think about the space you have available in your workshop. And finally, don’t forget about your budget. It’s important to find a lathe that fits within your price range.

When it comes down to it, the size of the metal lathe you should buy depends on your specific needs and circumstances. Whether you choose a benchtop or a floor-standing lathe, just make sure it’s the right size for the projects you have in mind. So, take some time to think about what you’ll be working on, how much space you have, and what you can afford. With these factors in mind, you’ll be able to make the best decision for yourself and your workshop.