Looking to delve into metalworking and wondering, “What size metal lathe should I get?” Well, you’ve come to the right place! Choosing the right size for your metal lathe is crucial for a successful and enjoyable experience.

But don’t worry, I’m here to help break it down for you in a simple and easy-to-understand way. Whether you’re a beginner or an experienced hobbyist, finding the right size lathe will ensure you can tackle a wide range of projects without limitations.

So, let’s dive right in and explore the factors you should consider when determining the perfect size for your metal lathe. Get ready to embark on your metalworking journey and unleash your creativity!

Choosing the Right Size Metal Lathe

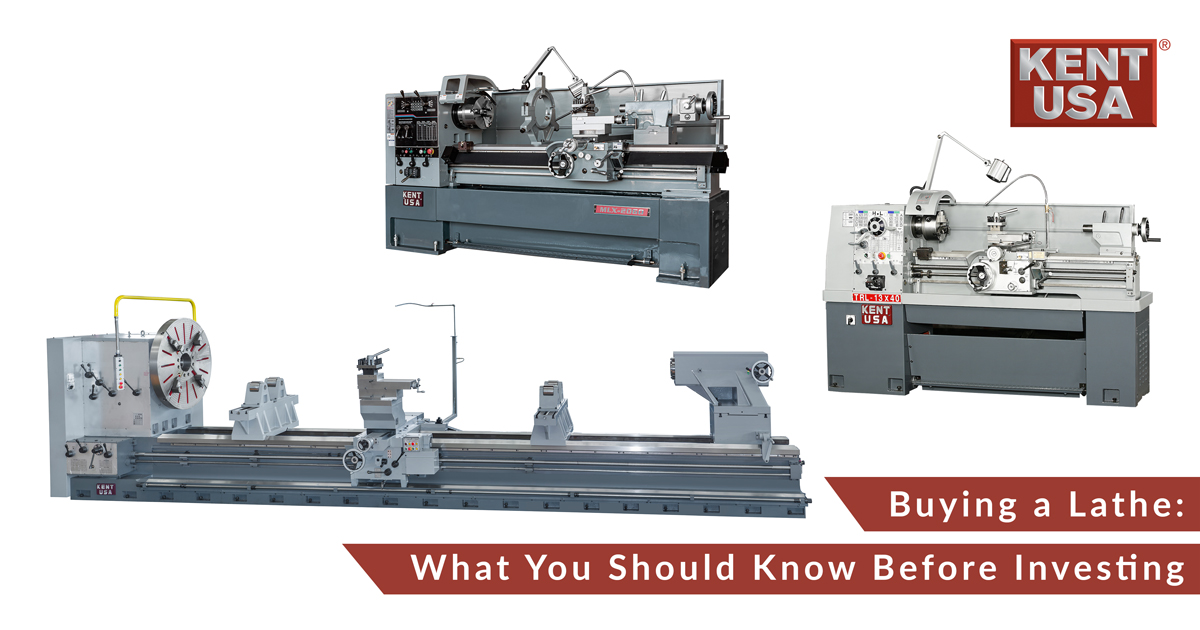

When it comes to purchasing a metal lathe, one important consideration is the size. The size of a lathe refers to its maximum swing, which is the diameter of the largest workpiece that can be accommodated. It is crucial to choose the right size lathe for your needs to ensure optimal performance and efficiency. In this article, we will explore different factors to consider when determining what size metal lathe to get.

1. Understanding Swing and Bed Length

The swing is one of the fundamental specifications to look at when choosing a metal lathe. It determines the maximum diameter of the workpiece that can be turned. The swing is measured by doubling the distance from the center of the lathe spindle to the bed. For example, a lathe with a 10-inch swing can handle workpieces with a diameter of up to 20 inches. However, it is essential to leave some room for tool clearance and other factors.

Another crucial factor is the bed length, which determines the maximum length of the workpiece that can be turned. Longer bed lengths allow for greater flexibility and the ability to work on larger projects. However, it is important to consider the space available in your workshop and the types of projects you will be working on before deciding on a specific bed length.

In general, it is recommended to choose a lathe with a swing that comfortably accommodates the largest workpiece you anticipate working on and a bed length that suits your project requirements and workshop space.

2. Determining Power and Speed Requirements

Another important consideration when choosing the size of a metal lathe is the power and speed requirements. Larger lathes generally have more powerful motors and can handle heavier workpieces with ease. They also tend to offer a wider range of speed options to suit different materials and cutting requirements.

However, it is crucial to assess your specific needs and budget before opting for a larger lathe. Consider the materials you will be working with and the type of machining operations you will be performing. If you mainly work with smaller workpieces or have limited power supply, a smaller lathe may be more appropriate and cost-effective.

It is also worth noting that some larger lathes can be equipped with features like variable speed control, which provides greater control and precision. These features can enhance your overall lathe experience but may come at a higher cost.

3. Evaluating Cost and Budget

Cost is another crucial factor to consider when determining the size of a metal lathe to purchase. Generally, larger lathes with higher swing capacity and bed lengths tend to be more expensive. It is important to set a budget and prioritize your requirements and preferences.

Consider the types of projects you will be working on and the level of precision and performance you require. If you are a hobbyist or occasional user, a smaller lathe may be more suitable and cost-friendly. However, if you are a professional machinist or have frequent high-demand projects, investing in a larger and more powerful lathe may be a wise long-term decision.

Be sure to research different brands and models, compare prices, and read reviews to gain insight into the quality and value offered by different lathe options. Additionally, consider the availability of accessories, replacement parts, and customer support when evaluating the cost and overall value of a metal lathe.

Additional Considerations for Choosing a Metal Lathe

4. Available Accessories and Attachments

When choosing the size of a metal lathe, it is important to consider the availability of accessories and attachments that can expand the capabilities of the machine. Different lathe sizes may have varying options and compatibility with accessories such as chucks, steady rests, taper attachments, and tooling options. Assess your project requirements and ensure that the chosen lathe can accommodate the necessary accessories to suit your needs.

5. Workspace and Shop Constraints

Before finalizing your decision on the size of a metal lathe, evaluate the available workspace and any constraints in your shop. Measure the area where you intend to place the lathe and consider factors like maneuverability, safety clearance, and ventilation requirements. Lack of space may limit your options, so it is important to choose a lathe size that fits comfortably within your workspace without compromising on functionality.

6. Future Growth and Versatility

It is also wise to consider your future growth and the versatility of the lathe. While you may be working on smaller projects currently, there may come a time when you need to tackle larger workpieces. Choosing a lathe with some growth potential can save you from having to upgrade in the future. Additionally, a versatile lathe that can handle different materials and machining operations will provide more flexibility and potential for expanding your skills and capabilities.

Conclusion

Choosing the right size metal lathe is a crucial decision that can impact the efficiency and success of your machining projects. Consider the maximum swing, bed length, power and speed requirements, cost and budget, available accessories, shop constraints, and future growth potential when making your decision. It is essential to strike a balance between your current needs and future aspirations to ensure the chosen lathe meets your requirements and allows for growth. Remember to research, compare, and seek expert advice if needed to make an informed decision and invest in a quality metal lathe that will serve you well.

Key Takeaways: What Size Metal Lathe Should I Get?

- Consider the types of projects you’ll be working on to determine the right size of metal lathe.

- Smaller lathes are suitable for hobbyists and simple projects, while larger lathes are better for professional use and complex parts.

- Take into account the maximum swing and distance between centers to ensure the lathe can accommodate your desired workpiece size.

- Think about the available space in your workshop or garage, as larger lathes require more room.

- Consider your budget and try to find a balance between the size and quality of the metal lathe.

Frequently Asked Questions

When it comes to choosing the right size metal lathe, there are a few factors to consider. Here are some common questions and answers to help you decide which size is right for you.

1. How do I determine the right size metal lathe for my needs?

When determining the right size metal lathe, consider the size of the projects you plan to work on. If you primarily work on smaller projects, a benchtop lathe may be sufficient. However, if you anticipate working on larger projects, a floor-standing lathe with a larger swing and bed length would be more suitable. Additionally, consider the space you have available in your workshop, as larger lathes require more room.

Ultimately, it’s important to assess your specific needs and match them to the capabilities of the lathe. Taking into account the project sizes and your available space will help guide you in choosing the right size lathe.

2. What is the swing capacity of a metal lathe and how does it affect my choice?

The swing capacity of a metal lathe refers to the maximum diameter of material that can be turned on the lathe. It is measured as the distance from the center of the spindle to the bed of the lathe. The swing capacity is an important consideration when choosing a lathe because it determines the size of the projects you can work on.

If you primarily work on smaller projects with smaller diameters, a lathe with a smaller swing capacity will be sufficient. However, if you plan on working on larger projects, you will need a lathe with a larger swing capacity to accommodate the larger workpieces. It’s essential to choose a lathe with a swing capacity that aligns with the sizes of the projects you plan to undertake.

3. What is bed length and why is it important in selecting a metal lathe size?

The bed length of a metal lathe refers to the distance between the headstock and the tailstock. It determines the maximum length of material that can be turned on the lathe. When selecting a lathe, consider the length of projects you typically work on.

If you often work on shorter projects, a lathe with a shorter bed length may be suitable. However, if you plan on working on longer pieces, such as table legs or tool handles, a longer bed length is necessary. It’s crucial to choose a lathe with a bed length that allows you to comfortably work on your desired project lengths.

4. Should I choose a benchtop or floor-standing metal lathe?

The decision between a benchtop or floor-standing metal lathe depends on your specific needs and available space. A benchtop lathe is typically smaller and more compact, making it ideal for those with limited workshop space or who primarily work on smaller projects. These lathes can be placed on a sturdy workbench or stand.

On the other hand, a floor-standing lathe is larger and offers more power and capabilities. If you have sufficient workshop space and plan to work on larger projects, a floor-standing lathe would be a better choice. They often have a larger swing capacity, bed length, and more power, allowing for more versatile turning options.

5. Can I upgrade to a larger metal lathe in the future if my needs change?

Yes, it is possible to upgrade to a larger metal lathe in the future if your needs change. It’s important to consider the compatibility of the accessories and tooling you already have with the new lathe. If the lathe you currently have is from the same manufacturer as the larger lathe you intend to upgrade to, it is more likely that your existing accessories and tooling will be compatible.

However, if you switch to a different brand or significantly larger lathe, you may need to invest in new accessories and tooling. It’s always recommended to do proper research and consult with experts before making a decision to upgrade your lathe.

Summary

Choosing the right size metal lathe depends on what you want to make. A smaller lathe is good for small projects and hobbyists. If you plan to work on bigger pieces or have a professional workshop, a larger lathe is better. Consider your space, budget, and future goals when deciding on the size.

Remember, safety is important when using a metal lathe. Always wear protective gear and follow the instructions. Start with smaller projects to practice and gain experience. With the right size lathe and some patience, you can create amazing things. So go ahead and choose the size that suits you best, and have fun with your metal lathe adventures!