If you’re wondering what size power inverter you need for your power tools, you’ve come to the right place! Power inverters are incredibly useful when you’re working on the go or in areas without access to electricity. But finding the right size can be a bit confusing. Don’t worry, though, because I’m here to break it down for you in a language that even a 13-year-old can understand!

Now, you might be wondering, “What exactly is a power inverter?” Well, think of it as a magical device that turns your vehicle’s battery power into the electricity you need to run your power tools. It’s like having a portable power outlet on-the-go! But choosing the right size for your power inverter is crucial for it to work efficiently and power your tools effectively.

So, how do you determine the size of power inverter you need? We’ll cover all the important factors, like the wattage of your power tools, the duration of use, and even some handy tips to help you make the right decision. By the end of this article, you’ll have all the knowledge you need to choose the perfect power inverter for your power tools. Let’s dive in!

1. Identify the power requirements of your tools by checking their labels or manuals.

2. Add up the wattage of all the tools you plan to run simultaneously.

3. Choose an inverter with a continuous wattage rating higher than the total wattage calculated.

4. Consider getting an inverter with some extra capacity to accommodate power surges.

Remember, it’s always better to have a slightly higher wattage inverter to ensure smooth and uninterrupted power supply to your tools.

What Size Power Inverter Do I Need for Power Tools?

Power tools are a crucial part of many projects, whether you’re a professional contractor or a DIY enthusiast. However, using these tools on the go can be a challenge if you don’t have access to a power source. This is where power inverters come in handy. These devices convert DC power from a battery into AC power that can be used to operate power tools. But with so many options available, how do you know what size power inverter you need for your specific tools? In this article, we will explore the factors to consider and provide you with a comprehensive guide to choosing the right size power inverter for your power tools.

The Importance of Power Inverters for Power Tools

Before delving into the specifics, let’s first understand why power inverters are crucial for powering your tools. Power tools typically run on AC power sourced from a wall outlet. However, when working on remote job sites or in areas without electrical infrastructure, accessing a wall outlet may not be feasible. This is where a power inverter comes into play. It allows you to tap into a DC power source, like a car battery or a portable generator, and convert it into the AC power your tools require. This eliminates the need for a traditional power source, giving you the flexibility to work anywhere.

Factors to Consider When Choosing a Power Inverter

When selecting a power inverter for your power tools, several factors come into play. It’s essential to understand these factors to ensure you choose the right size inverter that meets your specific needs. Here are the key considerations:

1. Power Rating of Your Tools

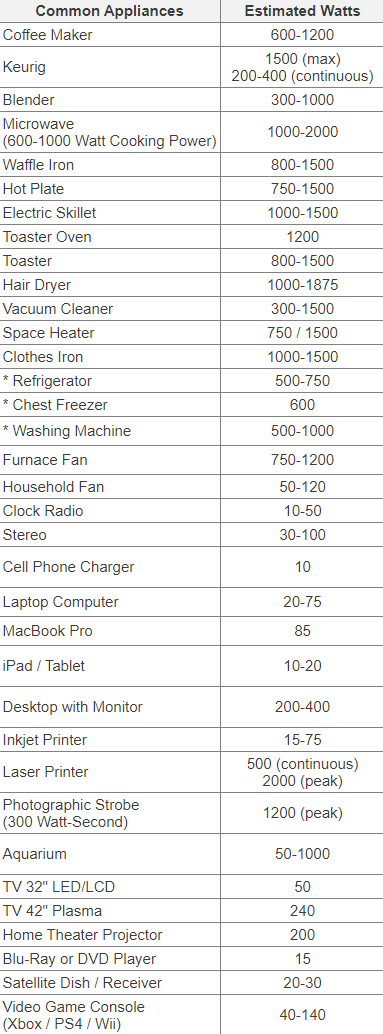

The power rating of your tools is perhaps the most crucial factor to consider. Power tools have a wattage or amperage rating that indicates the amount of power they consume. To determine the power inverter size you need, add up the wattage or amperage rating of all the tools you plan to use simultaneously. This will give you an idea of the minimum power output required for your inverter.

2. Surge or Starting Power

Some power tools require an extra surge of power when starting up. This surge is typically higher than the tool’s continuous power requirement. Make sure to account for the surge power when choosing an inverter. Look for inverters that offer a higher surge power capacity to handle these initial power demands without overloading the system.

Inverter Sizes and Their Capacities

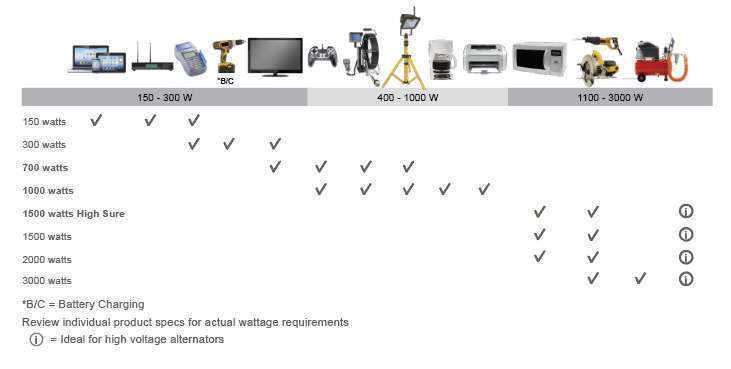

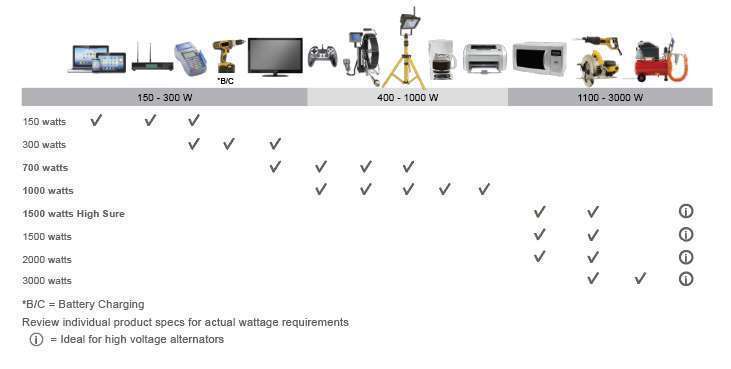

Power inverters are available in various sizes and capacities to accommodate different power needs. The most common inverter sizes you’ll come across are 300 watts, 600 watts, 1000 watts, and 2000 watts. Let’s examine the capacity and typical applications of each:

1. 300-Watt Inverter

This is the smallest and most portable type of power inverter. It is suitable for low-power tools and appliances like laptops, mobile phones, and small power tools with low wattage requirements. It is not intended for heavy-duty applications and won’t be able to power larger tools effectively.

2. 600-Watt Inverter

The 600-watt inverter offers more power and can handle a wider range of tools and appliances. It is suitable for medium-sized power tools like drills, saws, and small air compressors. However, it may struggle with high-power tools or multiple tools running simultaneously.

3. 1000-Watt Inverter

The 1000-watt inverter is a popular choice for contractors and professionals. It has the ability to power a wide range of tools, including circular saws, angle grinders, and medium-sized air compressors. It provides enough power for most job site requirements and can handle moderate simultaneous tool use.

4. 2000-Watt Inverter

If you work with high-power tools or need to run multiple tools simultaneously, a 2000-watt inverter is the way to go. It can handle heavy-duty tools like table saws, miter saws, and large air compressors. It provides a substantial power output and is ideal for demanding applications.

Determining the Right Size Inverter for Your Tools

Now that you have a clear understanding of the factors to consider and the available inverter sizes, it’s time to determine the right size inverter for your specific power tool needs. Follow these steps:

1. Assess Your Power Requirements

Start by assessing your power requirements. Make a list of all the power tools you plan to use and note down their wattage or amperage rating. Add up the total power requirement by either summing up the wattages or calculating the total amperage.

2. Account for Surge Power

Check if any of your tools have a significantly higher surge power requirement. Add the surge power to your total power requirement. This will give you a more accurate representation of the inverter size you need.

3. Choose the Right Size Inverter

Based on your power requirements, select the appropriate size inverter. If the total power requirement falls within the capacity of a specific inverter size, you can opt for that. However, it’s always recommended to choose an inverter with a slightly higher capacity to allow for future tool additions or potential power fluctuations.

By following these steps and considering the power needs of your tools, you’ll be able to choose the right size power inverter to ensure optimal performance and reliable power supply for your power tools. Remember, it’s better to have a slightly larger capacity than to risk overloading the inverter and potentially damaging your tools.

Tips for Using Power Inverters with Power Tools

Here are some helpful tips to ensure a smooth and efficient experience when using power inverters with your power tools:

1. Select a High-Quality Inverter

Invest in a high-quality power inverter from a reputable brand. Cheap or low-quality inverters may not provide a stable power supply, leading to performance issues or potential damage to your tools.

2. Properly Size the Inverter

Ensure the inverter you choose is appropriately sized for your power tool requirements. Oversized or undersized inverters may not deliver the optimal power output, affecting tool performance and potentially causing damage.

3. Use the Correct Cables and Connectors

Use high-quality cables and connectors that are compatible with the power output of your inverter. This will help minimize power loss and ensure safe and reliable connections.

4. Monitor Battery Levels

When using a power inverter with a battery as the power source, monitor the battery levels regularly. If the battery starts to run low, recharge it promptly to avoid any interruptions in power supply.

5. Take Safety Precautions

Follow all safety guidelines provided by the manufacturer of both the power inverter and your power tools. This includes proper grounding, avoiding overloading the inverter, and using appropriate safety gear.

6. Test the Inverter before Use

Before relying on the power inverter for your work, test it in a controlled environment to ensure it can handle the power requirements of your tools without any issues.

By following these tips, you’ll be able to maximize the efficiency and longevity of your power tools while using a power inverter.

Key Takeaways: What Size Power Inverter Do I Need for Power Tools?

- When choosing a power inverter for power tools, consider the wattage and surge rating of your tools.

- Calculate the total wattage of the tools you plan to use simultaneously to determine the minimum power rating you need.

- It’s recommended to choose an inverter with a power rating at least 1.5 times higher than the total wattage of your tools.

- Consider the type of tools you’ll be using, as some power tools may require a higher power rating.

- Remember to account for any future power tool purchases and choose an inverter with enough capacity for future needs.

Frequently Asked Questions

Welcome to our frequently asked questions section regarding power inverters for power tools!

1. Can I use any size power inverter for my power tools?

It is crucial to use the correct size power inverter for your power tools to ensure their functionality and safety. Power inverters come in various sizes, and selecting the right size depends on the power consumption of your tools. To determine the appropriate size, you need to calculate the power requirement of your tools.

Start by checking the power rating on each power tool and adding up the wattage. Make sure to include the starting wattage if it is specified. Once you have the total wattage, add an additional 20% to accommodate any power spikes or fluctuations. This sum will give you the minimum wattage capacity required for your power inverter.

2. What happens if I use an undersized power inverter for my power tools?

If you use an undersized power inverter for your power tools, it can lead to various issues. Firstly, your power tools may not receive enough power to operate at their full capacity since the inverter won’t provide sufficient wattage. This can result in reduced performance and potentially damage your tools in the long run.

In addition, using an undersized power inverter can cause the inverter to overheat and fail, posing a safety risk. The inverter may also trip the circuit breaker or blow a fuse, disrupting your work and potentially damaging other electrical equipment. To avoid these problems, it is essential to use a power inverter that meets or exceeds the power demands of your tools.

3. How do I know the power rating of my power tools?

The power rating of your power tools is typically indicated on a label or plate attached to the tool. Look for a label that provides information such as “Wattage” or “Power Consumption.” This label will display the maximum power requirement in watts, allowing you to determine the size of power inverter you need.

If you cannot find a label on your power tool, consult the user manual or contact the manufacturer for specifications. It is crucial to have accurate information about the power rating of your tools to choose the appropriate power inverter and ensure optimal performance.

4. Can I run multiple power tools simultaneously with a single power inverter?

Yes, you can run multiple power tools simultaneously with a single power inverter, provided that the inverter has enough wattage to support the combined power requirements of the tools. To determine the required wattage, add up the wattage of each tool and account for any power spikes or fluctuations.

It is important to note that running multiple power tools simultaneously will increase the load on the power inverter. Therefore, it is advisable to choose an inverter with a higher wattage capacity to ensure uninterrupted power supply and prevent any potential overloads or strain on the equipment.

5. Are there any safety precautions I should take when using a power inverter for power tools?

When using a power inverter for power tools, there are several safety precautions to keep in mind. First, ensure that the inverter is suitable for the type of power tools you will be using and that it meets quality and safety standards. Read the manufacturer’s instructions and guidelines before installation and use.

Additionally, make sure to connect the power inverter directly to a stable and adequately grounded power source. Avoid using extension cords or power strips that are not rated for the inverter’s power requirements. Regularly inspect the inverter for any signs of damage or wear, and discontinue use if any issues are identified.

Summary

Power tools can drain a lot of power, so it’s important to use the right size power inverter.

To figure out what size you need, determine the peak power and continuous power of your tools, and choose an inverter that can handle that load. Remember to factor in any additional devices you might want to power at the same time. It’s better to choose an inverter with a higher wattage rating to ensure it can handle your tools and other devices. Lastly, make sure to check the inverter’s voltage and current ratings to match your power tools.

By following these steps and considering your power needs, you can select the right size power inverter and ensure that your power tools operate efficiently and safely.