What size wire should you use for woodworking? It’s a common question that aspiring woodworkers often come across. Whether you’re building furniture or crafting intricate designs, having the right wire gauge is essential. Lucky for you, I’m here to shed some light on the matter and help you navigate through the world of wires in woodworking.

So why does the size of the wire matter? Well, different woodworking tasks require different wire gauges to ensure optimum performance and safety. Using the wrong size wire can result in insufficient power supply, electrical hazards, or even damage to your tools. But fear not, because I’m going to guide you through the wire gauge choices for woodworking.

In this article, we’ll explore how to choose the appropriate wire gauge for specific woodworking tasks, the key factors to consider, and some practical tips to make your woodworking projects a breeze. So, grab your tools, fasten your seatbelt, and let’s embark on this electrifying journey into the world of wire gauges for woodworking!

1. Identify the type of woodworking project you’re working on.

2. Determine the electrical load requirements of the tools or equipment you’ll be using.

3. Consult the National Electric Code (NEC) or a wire sizing chart for guidance.

4. Select a wire size based on the ampacity requirements.

5. Consider factors such as voltage drop and insulation type.

Remember, always prioritize safety and consult a professional if you’re unsure.

What Size Wire for Woodworking? A Guide to Choosing the Right Wire

Woodworking is a versatile and rewarding hobby that requires various tools and materials. One essential component in woodworking projects is wire. Whether you need to secure pieces of wood together, create structural support, or add decorative elements, choosing the right wire size is crucial for achieving the desired results. In this guide, we will explore the factors to consider when selecting the appropriate wire size for woodworking projects, providing you with the information you need to tackle your next woodworking endeavor with confidence.

Understanding Wire Gauge for Woodworking

Wire gauge refers to the thickness of the wire and is denoted by numerical values. The higher the number, the thinner the wire. When it comes to woodworking, it’s essential to choose a wire gauge that can withstand the intended purpose. Thicker wire provides greater strength and stability, while thinner wire allows for more delicate and intricate designs. Understanding the wire gauge system is crucial before diving into any woodworking project.

When selecting wire gauge for woodworking, consider the size of the holes or gaps you need to fill, the weight-bearing capacity required, and the overall aesthetic you want to achieve. For lightweight decorative elements, such as scrollwork or inlay designs, a thinner wire, typically ranging from 20 to 24 gauge, is suitable. If you need to secure two pieces of wood together, choose a slightly thicker wire, such as 18 or 16 gauge, depending on the weight and size of the pieces.

Benefits of Choosing the Right Wire Size

Choosing the appropriate wire size for woodworking projects offers several benefits. First and foremost, the right wire ensures structural integrity. Using a wire that is too thin for the intended purpose can lead to weak joints, compromising the overall stability of the project. On the other hand, using a wire that is too thick can be challenging to manipulate and may not provide the desired flexibility for certain woodworking techniques.

Another benefit of selecting the right wire size is achieving the desired aesthetic. Thicker wire can create bolder and more pronounced lines, while thinner wire allows for intricate and delicate designs. By carefully considering the wire gauge, you can enhance the visual impact of your woodworking projects, adding a touch of elegance or a bold statement.

Tips for Choosing Wire Gauge for Woodworking

To ensure you choose the right wire gauge for your woodworking projects, consider the following tips:

1. Understand the purpose: Determine the specific tasks the wire will fulfill in your project, such as structural support or decorative accents.

2. Know the weight requirements: Consider the weight-bearing capacity required to support the intended load and select a wire gauge accordingly.

3. Consider the size of holes or gaps: If you need to fill small gaps or weave the wire through tight spaces, opt for a thinner wire gauge.

4. Experiment with different gauges: Familiarize yourself with various wire gauges by experimenting with different sizes and applications to understand their capabilities and limitations.

5. Seek professional advice: If you’re unsure about the appropriate wire gauge, consult with experienced woodworkers or visit a specialized woodworking store for guidance.

By following these tips, you can confidently choose the right wire gauge for your woodworking projects, ensuring a successful outcome.

Comparison of Wire Gauges for Woodworking

For a quick reference, here’s a table comparing common wire gauges used in woodworking:

| Wire Gauge | Wire Thickness (in inches) | Recommended Use |

|---|---|---|

| 16 | 0.051 | Securing thicker pieces of wood together |

| 18 | 0.040 | Securing medium-sized pieces of wood together |

| 20 | 0.032 | Decorative scrollwork and fine inlays |

| 22 | 0.025 | Delicate decorative accents and fine detail work |

| 24 | 0.020 | Extremely delicate and intricate designs |

Remember, these are general guidelines, and the specific requirements of your woodworking project may vary. It’s always a good idea to test different wire gauges on scrap pieces of wood to determine the best fit for your needs.

Tips for Working with Wire in Woodworking

Now that you have a better understanding of choosing the right wire gauge for woodworking projects, here are a few additional tips to help you work with wire more effectively:

Avoid Over-tightening:

When securing pieces of wood with wire, be mindful not to over-tighten the wire. Over-tightening can lead to dents, warping, or even splitting the wood. Use just enough tension to hold the pieces together securely.

Use Appropriate Tools:

Invest in quality wire cutters and pliers designed specifically for working with wire. These tools will make it easier to manipulate the wire and achieve clean and precise cuts.

Experiment with Wire Types:

In addition to choosing the right wire gauge, consider experimenting with different wire types, such as steel, brass, or copper, to achieve unique looks and textures in your woodworking projects. Each type of wire can add its own distinct charm and character to your designs.

Remember, practice makes perfect when working with wire for woodworking. Take the time to familiarize yourself with different techniques, gauges, and wire types to unleash your creativity and achieve stunning results in your woodworking endeavors.

Common Wire Sizes for Woodworking Projects

16 Gauge Wire

16 gauge wire, with a thickness of approximately 0.051 inches, is commonly used for securing thicker pieces of wood together in woodworking projects. It provides excellent stability and support, making it suitable for heavy-duty applications. Whether you’re constructing furniture or building large wooden structures, 16 gauge wire offers the strength and durability required to ensure strong and secure joints.

When working with 16 gauge wire, it’s important to consider the size of the wood pieces being connected. It’s generally recommended for connecting medium to large-sized wooden components. However, for smaller pieces or more delicate projects, a thinner gauge may be more appropriate to maintain a balanced aesthetic.

18 Gauge Wire

18 gauge wire is slightly thinner than 16 gauge wire, with a thickness of approximately 0.040 inches. This wire size is commonly used for securing medium-sized pieces of wood together. It strikes a balance between strength and flexibility, offering stability while still allowing some maneuverability during assembly.

When using 18 gauge wire, ensure that the thickness is appropriate for the weight-bearing capacity required for your project. It is ideal for joining pieces of wood in cabinets, smaller furniture items, or woodworking projects where a medium level of support is needed.

20 Gauge Wire

When it comes to decorative scrollwork, inlays, or intricate designs in woodworking, 20 gauge wire is often the go-to choice. With a thickness of approximately 0.032 inches, this wire gauge is perfect for adding delicate accents and fine details to your projects. It allows for excellent control and precision, making it suitable for intricate designs that require careful weaving and bending.

Although 20 gauge wire is not intended for heavy-duty applications, it can still provide a level of stability when used in conjunction with other fasteners or joinery techniques. It’s important to remember that the primary purpose of this gauge is to enhance the visual appeal of your woodworking projects.

Wire Size Considerations for Specific Woodworking Techniques

Wire for Joinery and Assembly

When joining wood pieces together, whether through mortise and tenon joinery, dovetailing, or other methods, wire can provide additional support and reinforcement. In such cases, it’s important to select a wire size that complements the joinery technique and enhances the overall strength of the connection.

For example, if you’re using a dovetail joint, where the interlocking parts create a strong bond, selecting a thinner wire (20 or 22 gauge) may be sufficient since the primary load-bearing force is concentrated on the joint itself. However, if you’re using wire as the primary means of securing the pieces, a thicker gauge (16 or 18) might be more appropriate to ensure structural integrity.

Wire for Hanging or Suspension

In woodworking projects that involve hanging or suspending objects, such as shelves or decorative accents, wire plays a critical role in providing the necessary support. The size and weight of the objects being hung will dictate the wire gauge needed for optimal suspension.

For lightweight items, such as small shelves or decorative signs, a thinner wire gauge (22 or 24) can adequately hold the weight. However, for heavier items like large shelves or cabinets, a thicker wire gauge (16 or 18) is recommended to ensure the stability and longevity of the suspension.

Wire for Sculptural or Artistic Elements

When creating sculptural or artistic elements in woodworking, wire can be used to add unique shapes, curves, and visual interest. In such cases, the wire gauge selection depends on the specific design intent and the level of structural support required.

For intricate and delicate designs, a finer wire gauge (24) allows for more flexibility and detail, enabling precise shaping and positioning. On the other hand, if you’re aiming for bolder, more pronounced lines or structural support in your sculptural work, a thicker wire gauge (16 or 18) would be more suitable.

In summary, the choice of wire size in woodworking is crucial for achieving both structural stability and aesthetic appeal. By considering the project’s requirements, experimenting with different wire gauges, and practicing various techniques, you’ll be able to select the most appropriate wire size to enhance your woodworking projects. So, next time you embark on a woodworking adventure, remember to choose the right wire gauge and let your creativity flow.

What Size Wire for Woodworking?

When it comes to woodworking, choosing the right size wire is essential for a safe and efficient operation. Here are five key takeaways:

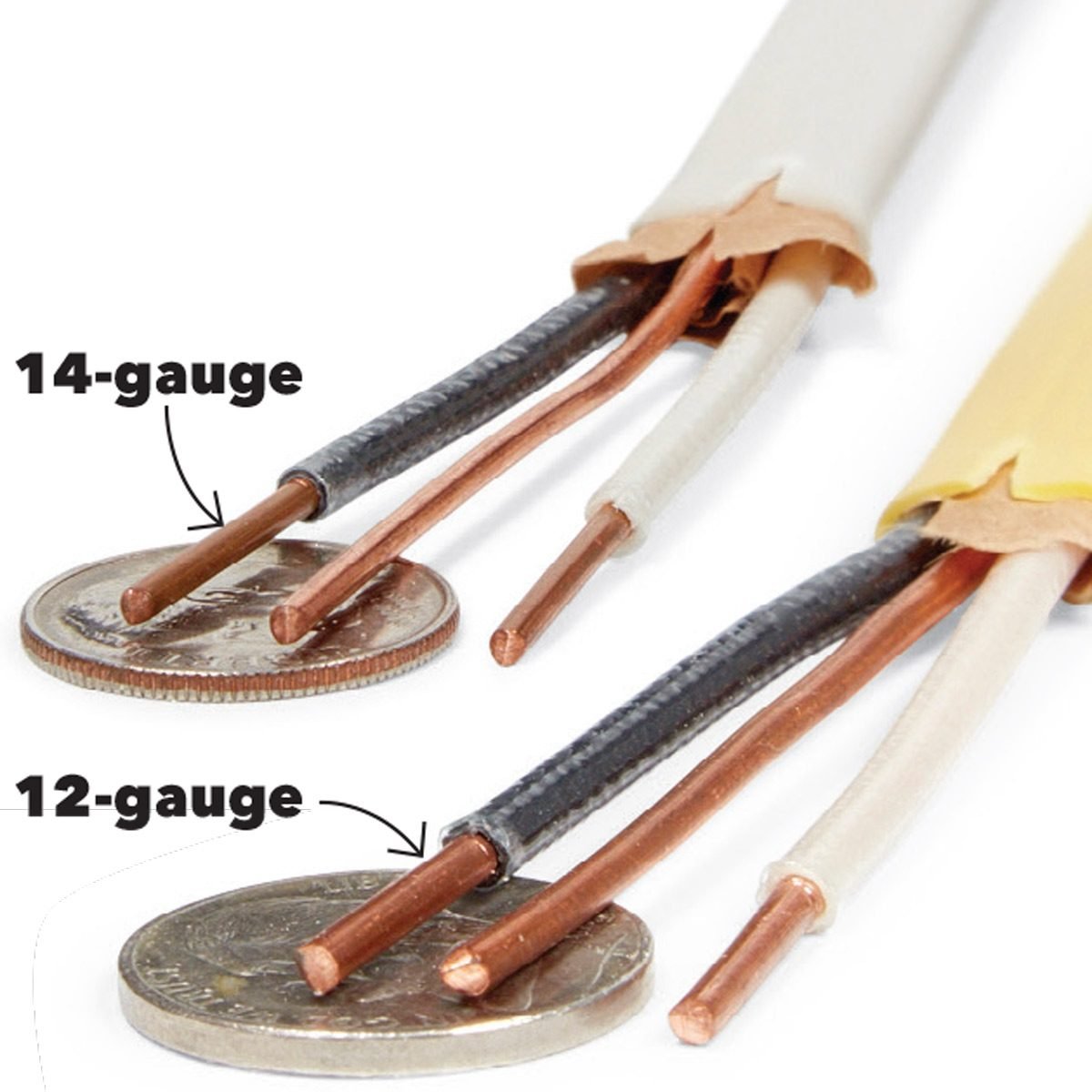

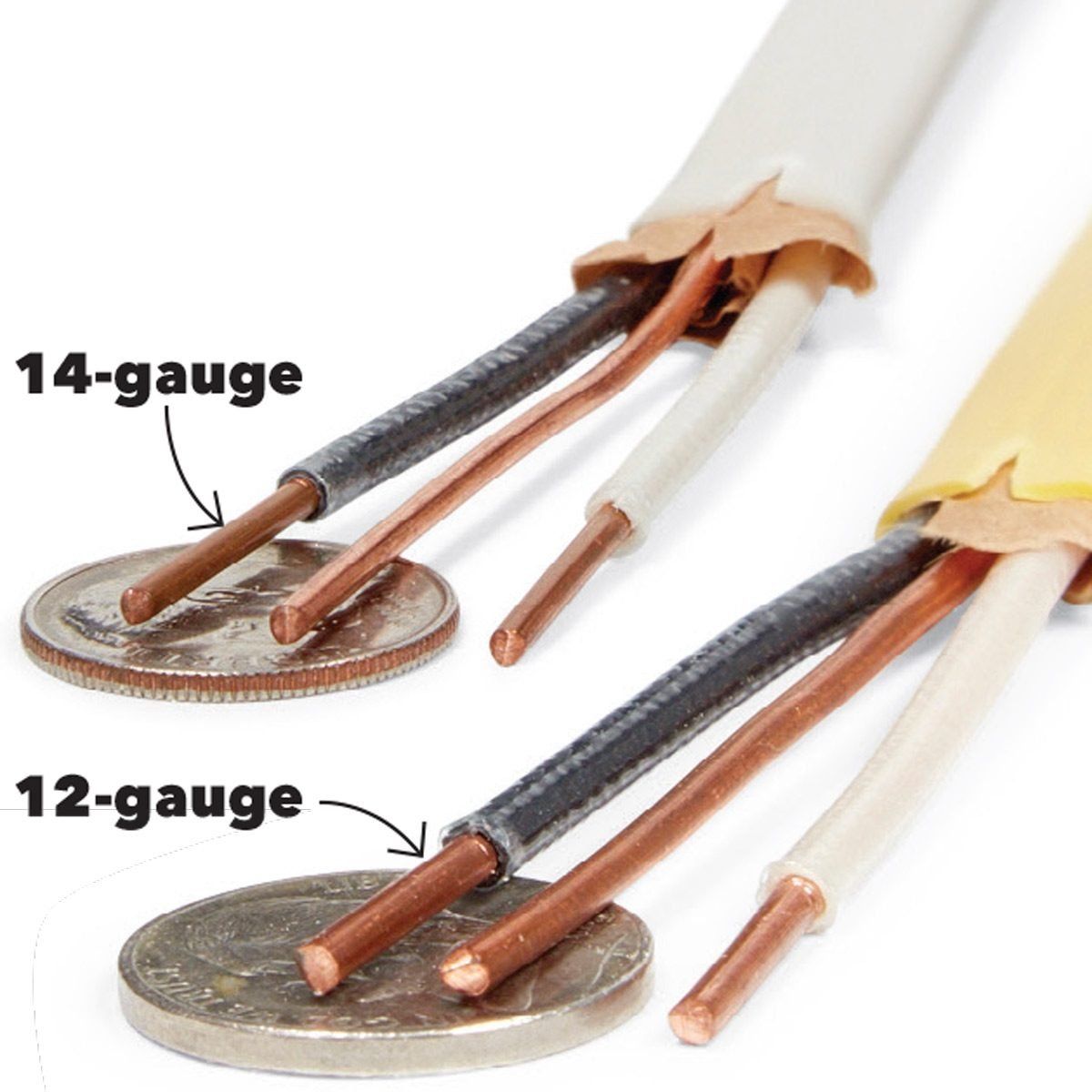

- Use 16-gauge wire for light-duty woodworking tasks like attaching trim or making small furniture pieces.

- For medium-duty projects such as building cabinets or larger furniture, opt for 14-gauge wire.

- Heavy-duty woodworking tasks, like constructing structures or installing machinery, require 12-gauge wire.

- Always consult local electrical codes to ensure compliance and safety.

- If in doubt, it’s best to consult with a professional electrician for guidance on wire sizing for your specific woodworking needs.

Frequently Asked Questions

Welcome to our Frequently Asked Questions section about choosing the right wire size for woodworking projects. If you’re unsure about which wire size to use, you’ve come to the right place. We’ve got answers to your burning questions below.

Q: Why is choosing the right wire size important in woodworking?

A: Choosing the right wire size is crucial for woodworking projects because it directly affects the safety and efficiency of your electrical connections. The wire size determines the amount of current that can safely flow through it, preventing overheating and potential fire hazards. Using the correct wire size ensures that your tools and machinery receive the appropriate amount of power, avoiding voltage drops and performance issues.

Additionally, the wire size affects the flexibility and durability of the wire. In woodworking, where cables may need to be routed through tight spaces or endure constant movement, using the right wire size helps prevent wire damage and ensures longevity in your electrical setups.

Q: How do I determine the right wire size for my woodworking project?

A: To determine the right wire size, you need to consider two main factors: the current requirements of your woodworking tools or machinery and the distance the wire needs to travel. The National Electrical Code (NEC) provides guidelines and tables based on the required current capacity and the wire’s length, considering both voltage drop and safety standards.

Start by determining the maximum amperage of your tools or machinery. Then, measure the distance between the power source and the equipment. Using an ampacity chart or consulting a qualified electrician can help you match the appropriate wire size for your project. Remember to err on the side of caution and choose a wire size with a higher capacity to allow for future upgrades or potential changes in your woodworking setup.

Q: What wire gauge should I consider for typical woodworking tools?

A: For typical woodworking tools, such as table saws, band saws, and jointers, a wire gauge of 12 or 14 is commonly used. These wire sizes can handle the amperage requirements of most woodworking tools and provide a good balance between safety and flexibility.

Remember to always check the specific power requirements of your tools and consult the manufacturer’s recommendations. If your woodworking tools have higher power demands or require longer wire runs, you may need to consider a larger wire gauge, such as 10 or 8, to avoid voltage drops and overheating issues.

Q: Can I use extension cords for woodworking projects?

A: Yes, you can use extension cords for woodworking projects, but it’s important to choose the right extension cord and wire gauge. When using an extension cord, make sure it is rated for the amperage of your tools and has a suitable gauge for the length of cord you need.

Using a lower gauge wire in your extension cord helps minimize voltage drops and ensures sufficient power delivery. It’s also essential to avoid using long extension cords, as longer cords can lead to more significant voltage drops. If possible, try to position your woodworking tools closer to the power source to minimize the need for extension cords.

Q: Are there any safety precautions I should keep in mind when working with wires in woodworking?

A: Absolutely! Safety should always be a priority when working with wires in woodworking projects. Here are a few key safety precautions to keep in mind:

1. Ensure all electrical connections are properly insulated and protected from any potential hazards, such as sawdust or moisture.

2. Use approved electrical connectors and follow manufacturer instructions for proper installation.

3. Turn off the power before making or modifying any electrical connections.

4. Regularly inspect your wiring setup for any signs of damage or wear, and replace any faulty wires or connectors immediately.

5. Wear appropriate personal protective equipment (PPE), like insulated gloves, when handling live wires.

By taking these safety measures, you can enjoy woodworking projects with peace of mind, knowing that your electrical connections are secure and reliable.

Summary

Choosing the right wire size for woodworking is important to ensure safety and efficiency.

Remember, smaller gauge numbers mean thicker wires, and thicker wires can handle more electricity.

If you’re unsure, it’s best to consult an electrician or use a wire size calculator to determine the appropriate size for your woodworking projects.

Using the correct wire size will help prevent overheating, electrical hazards, and potential problems in your workshop.

So, always prioritize safety and use the right wire size for your woodworking needs.