Are you wondering what speed you should use for your drill press? Well, you’ve come to the right place! Knowing the correct speed is crucial for achieving optimal drilling results and preventing damage to your workpiece or drill bit. In this article, we’ll break down the factors that determine the ideal speed for your drill press, so you can drill with confidence and precision. Let’s dive in!

When it comes to drill presses, one size does not fit all. The speed you should use depends on various factors, such as the material you’re drilling and the size of the drill bit. Different materials require different speeds to ensure efficient drilling and avoid overheating or dulling of the bit. Plus, larger drill bits require slower speeds, while smaller bits work better at higher speeds. It’s like choosing the right gear on a bike for the terrain you’re riding on!

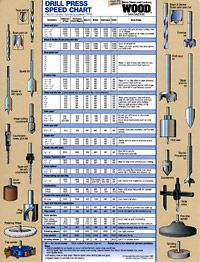

So how do you determine the perfect speed for your drill press? Don’t worry, it’s not as complicated as it sounds. Many drill presses come with a handy speed chart that provides guidelines based on the material and drill bit size. Additionally, you can refer to the drill bit manufacturer’s recommendations for specific speeds. Consider these recommendations as your trusty drill press GPS, guiding you towards smooth and successful drilling adventures!

Now that you have a general idea of what factors to consider when setting the speed for your drill press, let’s explore them in more detail. Understanding the impact of material type, drill bit size, and the proper RPM (revolutions per minute) range for each combination will ensure that you achieve excellent results every time. Get ready to unlock the power of your drill press and take your drilling skills to the next level! Let’s get drilling!

What Speed for Drill Press? A Comprehensive Guide

When it comes to using a drill press, one of the most critical factors to consider is the speed at which the drill bit rotates. The speed at which the drill press operates can greatly impact the efficiency, effectiveness, and safety of your drilling tasks. With different materials and drill bit sizes requiring varying speeds, understanding what speed to use for a drill press is crucial. In this comprehensive guide, we will explore the factors that influence speed selection, the recommended speeds for different materials, and tips for achieving the best results with your drill press.

Factors Influencing Speed Selection for a Drill Press

The Material Being Drilled

The type of material being drilled is a critical factor in determining the appropriate speed for your drill press. Different materials have varying densities, hardness, and thermal characteristics, all of which affect the speed at which the drill bit should rotate. For example, drilling through metal requires slower speeds to prevent overheating and excessive wear, while wood drilling can be done at higher speeds.

In general, softer materials like wood and plastic can be drilled at higher speeds, while harder materials like metal require slower speeds. A good rule of thumb is to start at a lower speed and gradually increase until you find the optimum balance between efficiency and precision.

Drill Bit Size

The size of the drill bit also impacts the ideal speed for drilling. Larger drill bits require slower speeds to ensure efficient drilling and reduced risk of damage. Smaller drill bits, on the other hand, can be operated at higher speeds without compromising accuracy.

Using the correct drill bit size and corresponding speed setting for your drill press will help prevent overheating, reduce the risk of the bit becoming dull, and ensure clean and precise holes.

Type of Drilling Operation

The type of drilling operation being performed is another factor to consider when determining the speed for a drill press. Different drilling techniques, such as drilling pilot holes, counterboring, or countersinking, may require different speed settings.

For example, when drilling pilot holes, it is generally recommended to use a higher drill speed to quickly create a guide hole. Counterboring and countersinking, which involve enlarging existing holes, may require slower speeds to achieve precision and prevent damage to the workpiece.

Recommended Speeds for Different Materials

Wood

For drilling wood using a drill press, the recommended speed ranges from 1000 to 3000 RPM (rotations per minute) depending on the density and hardness of the wood. Softer woods like pine or cedar can be drilled at higher speeds, while harder woods like oak or maple require slower speeds.

When drilling through hardwoods, it is advisable to start at a lower speed and gradually increase until the desired hole is achieved. This approach helps prevent splintering and ensures a cleaner finish.

Metal

When drilling through metal using a drill press, the recommended speed range is typically lower compared to drilling wood. For most metals, a speed range of 500 to 2000 RPM is suitable.

It is important to note that drilling through harder metals like stainless steel or cast iron may require slower speeds, while softer metals like aluminum or brass can be drilled at higher speeds. Using cutting lubricants when drilling through metal can help reduce heat buildup and extend the life of your drill bits.

Plastic

Drilling through plastic can be done at higher speeds compared to wood or metal. The recommended speed range for drilling plastic using a drill press is usually between 2000 and 4000 RPM.

However, it is essential to exercise caution when drilling plastic, as it has a lower thermal resistance than wood or metal. High speeds may cause the plastic to melt or warp. Always start at a lower speed and adjust as needed to prevent damage to the plastic material.

Choosing the Right Speed: Tips for Optimal Performance

Refer to the Drill Press Manual

Every drill press model comes with a user manual that provides specific guidance on speed settings for different materials and drill bit sizes. It is crucial to familiarize yourself with the manufacturer’s recommendations and follow them for optimal performance and safety.

Consider the Drill Bit Coating

Some drill bits come with specialized coatings like titanium or cobalt, which increase their cutting efficiency and durability. These coatings can handle higher speeds without compromising performance. If you’re using coated drill bits, check the manufacturer’s recommendations for the appropriate drill press speed.

Experiment and Adjust

It’s always a good idea to experiment with different speed settings on scrap material before starting your actual drilling project. This allows you to assess the effect of different speeds on the material and make adjustments accordingly.

Remember, finding the ideal drill press speed may require some trial and error, especially when working with materials you’re unfamiliar with. Take your time, be patient, and make adjustments until you achieve the desired results.

Conclusion

Choosing the right speed for a drill press is fundamental to achieving efficient drilling, preventing overheating, and ensuring the longevity of your drill bits. Factors such as the material being drilled, the size of the drill bit, and the type of drilling operation all influence the appropriate speed to use.

By following the recommended speed ranges for different materials, consulting your drill press manual, and considering factors like drill bit coatings, you can optimize your drill press performance and achieve accurate and clean results. Remember to experiment and make adjustments as necessary to find the optimum speed for your specific drilling needs.

Key Takeaways: What Speed Should I Use for a Drill Press?

- Choose a slower speed when drilling metals or large holes to prevent overheating and ensure accuracy.

- Higher speeds are suitable for drilling through wood or soft materials.

- Consider the type of drill bit you are using and refer to the manufacturer’s guidelines for recommended speeds.

- Adjust the speed based on the size of the hole and the material being drilled.

- Experiment with different speeds to find the optimal balance of speed, precision, and efficiency for your specific project.

Frequently Asked Questions

When operating a drill press, understanding the appropriate speed settings is important for achieving optimal results. Below, we have addressed some common questions related to determining the right speed for a drill press.

How do I determine the right speed for my drill press?

The speed for a drill press depends on several factors, including the material being drilled and the size of the drill bit. As a general rule of thumb, larger drill bits require slower speeds, while smaller bits are best used at higher speeds. It is also essential to consider the hardness of the material being drilled, as harder materials typically require slower speeds.

Consult the drill press manual or refer to speed charts available online to find recommended speed settings for various materials and drill bit sizes. It’s a good practice to start at a lower speed and gradually increase if needed, while monitoring the drilling process for any signs of overheating or excessive vibration.

Why is it important to use the correct speed for a drill press?

Using the correct speed for your drill press is crucial for a few reasons. Firstly, it ensures that you achieve clean and precise holes without damaging the workpiece or the drill bit. Secondly, using the appropriate speed helps prevent overheating of the drill bit, which can lead to dulling or even breakage. Lastly, it improves the overall efficiency and effectiveness of the drilling process, saving you time and effort.

By using the right speed, you can optimize the cutting action and reduce the likelihood of accidents or errors. Remember to always consult the drill press manual or speed charts for specific recommendations based on the material and drill bit size you are working with.

Can I use the same speed for all materials when using a drill press?

No, the speed for a drill press should vary depending on the material being drilled. Different materials have different hardness levels, and using the wrong speed can result in damage to both the material and the drill bit. Softer materials like wood or plastic can typically be drilled at higher speeds, while harder materials like metal or stone require slower speeds.

Refer to the drill press manual or consult speed charts available online for recommended speed ranges for different materials. It is always better to start at a slower speed and gradually increase if necessary, while monitoring the drilling process for any signs of overheating or difficulty in cutting through the material.

What are the consequences of using the wrong speed on a drill press?

Using the wrong speed on a drill press can have several negative consequences. Firstly, if the speed is too high for the material, it can cause the drill bit to overheat and become dull or even break. This can result in poor-quality holes and may require you to replace the drill bit.

Conversely, if the speed is too slow for the material, it can cause excessive friction, leading to a slower drilling process and potential damage to both the workpiece and the drill bit. Using the wrong speed can also result in rough cuts, chipping, and vibrations, which can compromise the precision and quality of the work being done.

Are there any general guidelines for determining the correct speed for a drill press?

While there are general guidelines for determining the correct speed for a drill press, it is important to note that these guidelines may vary depending on the specific drill press model, the drill bit size, and the material being drilled. As a starting point, consult the drill press manual or look for speed charts available online that provide recommended speed ranges for different materials and drill bit sizes.

Additionally, consider factors such as the hardness of the material, the desired hole size, and the cutting efficiency you want to achieve. Through trial and error, you can find the speed that works best for your specific drilling requirements, making adjustments as necessary based on the results you obtain.

Summary:

When using a drill press, it’s important to know the right speed for different materials. For metal, use slower speeds to prevent overheating and ensure accuracy. Higher speeds are better for wood, plastics, and softer materials. Don’t forget to adjust the speed using the pulley system and consider the size and type of drill you’re using.

Remember, safety first! Always wear protective gear like safety goggles and secure your workpiece properly. Consult the drill press manual for specific instructions and experiment with different speeds to find the best one for your project. Happy drilling!