Are you wondering what speed you should run your drill press at? Well, you’ve come to the right place! Figuring out the right speed for your drill press is crucial for ensuring the best results and avoiding any mishaps. So, let’s dive in and discover the answer to this burning question!

When it comes to operating a drill press, knowing the ideal speed is like having a secret superpower. It can make all the difference in achieving clean and precise holes in your workpiece. But hey, don’t worry, I’m here to demystify this process for you!

Now, finding the optimal speed for your drill press depends on various factors such as the material you’re working with and the size of the drill bit. So, let’s buckle up and explore the world of drill press speeds together!

What Speed Should I Run My Drill Press?

When it comes to using a drill press, one of the commonly asked questions is, “What speed should I run my drill press?”. The speed at which you operate your drill press can significantly impact the quality and efficiency of your work. This article will provide you with detailed information on determining the right speed for different types of drill bits and materials. Whether you are a hobbyist or a professional, understanding drill press speeds is crucial for achieving optimal results.

Factors to Consider When Determining Drill Press Speed

Before we delve into the specifics of drill press speeds, let’s explore the factors that influence the speed selection. When choosing the appropriate speed for your drill press, keep the following factors in mind:

1. Hardness of Material

The hardness of the material you are drilling through plays a significant role in determining the drill press speed. Softer materials, such as wood or plastic, require higher speeds, while harder materials like metal necessitate slower speeds to prevent overheating and premature wear on the drill bit.

When drilling into metal, it is essential to use lubrication to reduce friction and maintain the integrity of the material. The right speed combined with appropriate lubrication will help you achieve clean and precise holes without damaging the drill bit.

2. Drill Bit Type and Size

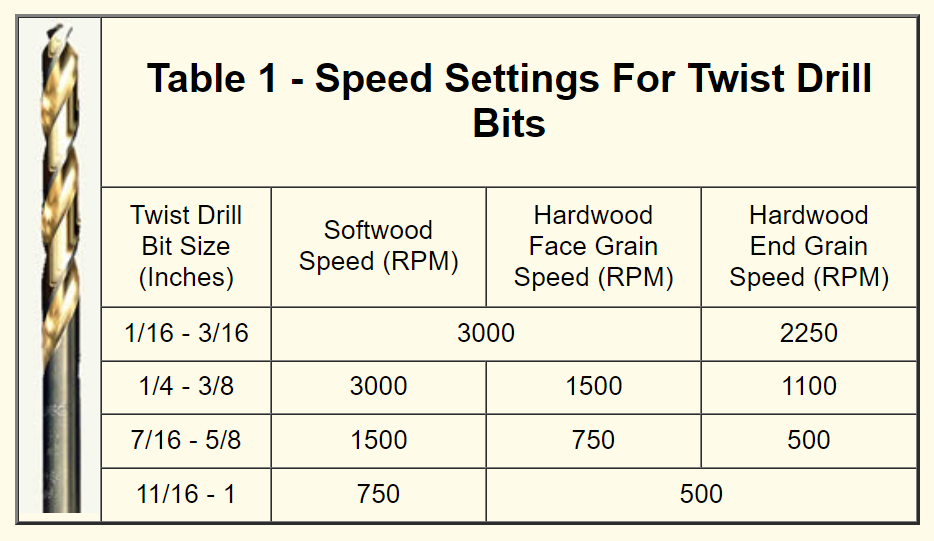

The type and size of the drill bit you are using also impact the recommended speed for your drill press. Different materials and drill bits require varying speeds to ensure efficient cutting and prevent breakage.

Generally, larger drill bits with wider diameters require slower speeds to prevent overheating. Smaller drill bits, on the other hand, can be operated at higher speeds for quicker and smoother drilling. Always refer to the manufacturer’s recommendations for the maximum operating speed of your drill bits to avoid damaging them.

3. Desired Hole Quality

The quality of the hole you want to achieve also influences the drill press speed. If you require a clean and precise hole, it is advisable to use lower speeds to have better control over the drilling process. Higher speeds, on the other hand, are suitable for rough drilling or when speed is more important than precision.

Keep in mind that slower speeds may result in cleaner holes but may also take longer to complete the job. Finding the right balance between speed and hole quality is crucial for efficient and satisfactory outcomes.

4. Feed Rate

The feed rate refers to how quickly the drill bit advances into the material being drilled. It is essential to match the feed rate with the drill press speed to ensure optimal performance.

As a general rule, slower speeds require slower feed rates, while higher speeds can handle faster feed rates. Consistency between the speed and feed rate will help prevent excessive heat buildup and ensure accurate drilling.

5. Drill Press Power and Stability

Your drill press’s power and stability also play a role in determining the appropriate speed. More powerful drill presses can handle higher speeds and heavier loads without straining the motor and compromising the precision of the drilling. Stability is essential to maintain control and accuracy during high-speed operations.

Ensure that your drill press is securely mounted or placed on a stable workbench to eliminate vibrations and achieve smoother drilling. If your drill press is not equipped with variable speed settings, you may need to use different pulley arrangements to adjust the speed.

6. Safety Considerations

While speed is crucial for effective drilling, ensuring safety should always be the primary concern. Always wear appropriate safety gear, such as goggles and gloves, when operating a drill press. Understand the limitations of your drill press and stay within its recommended speed range to prevent accidents and damage to the equipment.

Now that you are familiar with the factors influencing drill press speeds, let’s explore recommended speeds for various materials and drill bits:

Recommended Drill Press Speeds for Different Materials and Drill Bits

1. Wood

Wood is a common material used in various woodworking projects, and the appropriate drill press speed depends on the type of wood and the task at hand. Here are some general guidelines:

Standard Drill Bits:

- Softwood: 1500-2000 RPM

- Hardwood: 1000-1500 RPM

Forstner Bits:

- Softwood: 500-1000 RPM

- Hardwood: 250-500 RPM

Hole Saws:

- Softwood: 150-300 RPM

- Hardwood: 100-200 RPM

These speeds are general recommendations and may vary depending on the specific wood type and density. Always perform test holes on scrap wood to determine the optimal speed before proceeding with your workpiece.

2. Metal

When drilling through metals, it is essential to use slower speeds to prevent overheating and premature wear on the drill bit. The appropriate speed for drilling metal may vary depending on the type and thickness of the metal, as well as the drill bit being used.

Standard Drill Bits:

- Mild Steel: 500-1000 RPM

- Stainless Steel: 250-500 RPM

- Aluminum: 1500-2000 RPM

Sheet Metal Step Bits:

- Mild Steel: 250-500 RPM

- Stainless Steel: 100-250 RPM

- Aluminum: 1500-2000 RPM

3. Plastic

Plastic materials are relatively soft and can be drilled at higher speeds compared to metal or wood. However, excessive speed can cause melting or the formation of rough holes. Here are some recommended speeds for drilling different types of plastic:

Standard Drill Bits:

- Acrylic: 1500-2000 RPM

- PVC: 1000-1500 RPM

- HDPE: 1500-2000 RPM

Straight Flute Bits:

- Acrylic: 1000-1500 RPM

- PVC: 500-1000 RPM

- HDPE: 1000-1500 RPM

4. Glass and Ceramic

Drilling through glass and ceramic requires special care and specific drill bits designed for these materials. The speed should be kept low to prevent cracking or shattering. It is crucial to use water or a lubricant to keep the drill bit cool and minimize the risk of damage.

Diamond Core Bits:

- Glass: 500-1000 RPM

- Ceramic: 250-500 RPM

Tips for Optimal Drill Press Speed Performance

Here are some additional tips to ensure optimal drill press speed performance:

1. Always refer to the manufacturer’s recommendations for recommended drill press speeds for specific drill bits and materials.

These recommendations are often provided on the packaging of drill bits or in product manuals. Following the manufacturer’s guidelines will help you achieve the best possible results and prevent damage to the drill bits and materials.

2. Start with a slower speed and increase gradually if necessary.

If you are unsure of the appropriate drill press speed, it is better to start with a slower speed and gradually increase it as needed. This allows you to gauge the performance and adjust accordingly, ensuring cleaner holes and avoiding potential damage.

3. Monitor the drill bit during operation.

Keep a close eye on the drill bit as you drill to ensure it remains sharp and does not overheat. If you notice any signs of dullness or excessive heat, stop drilling and allow the drill bit to cool down or replace it if necessary.

4. Lubricate when necessary.

When drilling through materials like metal or glass, lubrication is essential to reduce friction and heat buildup. Apply appropriate lubricants such as cutting oil, wax, or water to ensure smoother and safer drilling.

5. Secure your workpiece properly.

Ensure that your workpiece is securely clamped or held in place to prevent movement or potential accidents. A stable workpiece allows for more precise drilling and reduces the risk of injury.

6. Regularly clean and maintain your drill press.

Keeping your drill press clean and well-maintained ensures optimal performance and longevity. Regularly remove any debris or dust that accumulates on the drill press and lubricate moving parts as recommended by the manufacturer.

In conclusion, determining the right speed for your drill press is essential for achieving efficient and precise drilling results. Consider the hardness of the material, drill bit type and size, desired hole quality, feed rate, drill press power and stability, and safety considerations when selecting the appropriate speed. Refer to recommended speeds for different materials and drill bits as a starting point, but always test on scrap pieces or consult the manufacturer’s recommendations to ensure optimal performance. By following these guidelines and incorporating proper maintenance, you can maximize the capabilities of your drill press and achieve exceptional results in your projects.

Key Takeaways – What Speed Should I Run My Drill Press?

- Choose the appropriate speed based on the material you are drilling into.

- Refer to the manufacturer’s recommendations for optimal speed settings.

- Start with a slower speed and gradually increase if needed.

- Using high speeds on larger drill bits may cause overheating or breakage.

- Always wear safety goggles and follow proper drilling techniques.

Frequently Asked Questions

Welcome to our frequently asked questions section regarding the speed at which to run your drill press. We understand that it can be confusing to determine the right speed for different materials and drill bits. This guide aims to answer your queries and help you use your drill press effectively and safely.

1. How do I determine the ideal speed for my drill press?

When determining the speed for your drill press, you should consider two factors: the type of material you’re drilling into and the size of the drill bit. Smaller drill bits require higher speeds, while larger bits need slower speeds. Additionally, harder materials, like metal, require slower speeds compared to softer materials like wood or plastic.

Keep in mind that most drill presses have a speed chart. Refer to it to find the recommended speeds for specific materials and drill bit sizes. By matching the material and bit size, you can easily find the ideal speed for your drill press.

2. Can I use the highest speed setting on my drill press for all materials?

Using the highest speed setting on your drill press for all materials is not recommended. It can cause the drill bit to overheat, resulting in dulling or even breaking. It’s important to match the speed to the material and bit size to ensure optimal performance and longevity of your drill press.

Running at lower speeds for harder materials will prevent excessive heat generation and ensure clean, precise holes. By adjusting the speed according to the material, you’ll achieve better results and prolong the life of your drill press.

3. What should I do if I don’t have a speed chart for my drill press?

If you don’t have a speed chart for your drill press, you can refer to general guidelines. For wood, a range of 500-3,000 RPM (revolutions per minute) is usually safe. For metal, a range of 500-1,500 RPM is commonly recommended. Always start with the lowest speed and gradually increase it until you find the right balance of speed and effectiveness.

Remember, if you encounter excessive heat, burning, or smoking, it’s a sign that your speed is too high. Stop immediately, reduce the speed, and reassess the material and bit size to ensure the proper setting.

4. Should I always use the lowest speed when drilling into hard materials?

While it’s generally recommended to use slower speeds when drilling into hard materials, always consider the thickness and hardness of the material. If you’re drilling into a thin sheet of metal, you may need to increase the speed slightly to prevent the bit from grabbing or tearing the material. Pay attention to how the material reacts and adjust the speed accordingly.

However, if you’re drilling into a thick block of metal or other hard materials, it’s best to start at a slower speed and gradually increase as needed. This approach ensures better control and reduces the risk of overheating or damaging the drill bit.

5. Can I rely on the speed recommendations provided by the drill bit manufacturer?

While the speed recommendations provided by the drill bit manufacturer can serve as a starting point, it’s important to remember that they may vary depending on the specific drill press you’re using. Factors like the power of your drill press and the condition of the bit can influence the ideal speed for your specific setup.

It’s always a good idea to refer to the manufacturer’s recommendations as a guideline but also to experiment and adjust the speed settings as needed to find the optimal performance for your drill press and the materials you’re working with.

Summary

Hey there! So, when it comes to using a drill press, here’s what you need to keep in mind. First, start with the right speed based on the material you’re drilling. For softer materials like wood, go for slower speeds. But for metal or harder materials, faster speeds work best.

Next, remember to adjust the speed using the pulleys on your drill press. The smaller pulleys increase speed, while the larger ones slow it down. Then, match the speed to the size of the drill bit you’re using. Bigger bits need slower speeds, while smaller ones can handle faster speeds.

Lastly, always listen to your drill press. If it starts to sound strained or make weird noises, it’s a sign that the speed is too high. So, make sure to adjust it accordingly. And there you have it! Just remember these tips, and you’ll be running your drill press like a pro in no time.