Do you love working with your hands and creating cool projects? If so, you’ve probably come across plexiglass—a versatile material that’s perfect for all sorts of DIY projects. But when it comes to cutting plexiglass with a table saw, choosing the right blade is essential. You want to make sure you get clean, crisp cuts without any cracking or chipping. So, what table saw blade should you use to cut plexiglass? Let’s dive in and find out!

Plexiglass, also known as acrylic, is a durable and transparent plastic that’s commonly used in everything from windows to signage. It’s a fantastic material for DIY enthusiasts because it’s easy to work with and comes in various colors and thicknesses. However, cutting plexiglass requires some special considerations, especially when using a table saw. The type of blade you use can make a world of difference in your results.

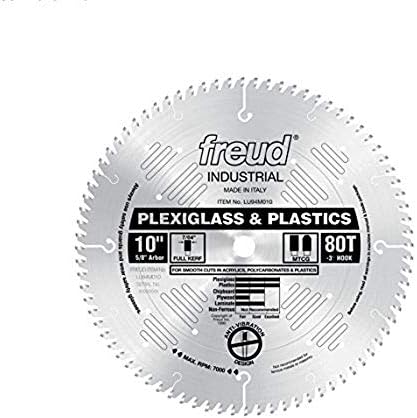

To ensure a successful cut, you’ll want to use a blade specifically designed for cutting plastics like plexiglass. A blade with a high tooth count, around 80 to 100 teeth, is ideal for achieving clean and chip-free cuts. These blades have finely spaced teeth that minimize the chances of the plexiglass cracking or shattering during the cutting process. Safety is crucial, so make sure to wear protective goggles and take your time when cutting to avoid accidents.

So, to recap, when it comes to cutting plexiglass with a table saw, you’ll want to use a blade with a high tooth count to achieve clean and chip-free cuts. Keep in mind the importance of safety and take your time to ensure the best results. Now that you know what blade to use, you’re ready to tackle all sorts of fantastic projects with plexiglass! Let your creativity soar and have fun with your DIY endeavors!

When cutting plexiglass with a table saw, you’ll want to use a specialized blade to ensure clean and smooth cuts. Look for a carbide-tipped blade with a high tooth count, ideally around 80-100 teeth. This will help prevent chipping or melting of the plexiglass. Additionally, consider using a blade with a negative hook angle, as it reduces the likelihood of grabbing and splintering the material. By using the right blade, you can achieve precise and professional-looking cuts on plexiglass.

What Table Saw Blade to Cut Plexiglass?

Plexiglass is a popular material used in various applications, from home renovations to DIY projects. When it comes to cutting Plexiglass with a table saw, choosing the right blade is crucial. A proper blade will ensure clean and precise cuts without causing any damage to the material. In this article, we will discuss the different types of table saw blades suitable for cutting Plexiglass and provide you with valuable tips to achieve the best results.

1. Standard Blade with a High Tooth Count

A standard table saw blade with a high tooth count is one of the most common choices for cutting Plexiglass. These blades typically have fine teeth, usually around 80 to 100 teeth or more. The high tooth count helps to minimize chipping and splintering of the Plexiglass, resulting in clean and smooth cuts. It is crucial to ensure that the blade is sharp to prevent any melting or melting of the material. A dull blade can cause the Plexiglass to heat up quickly, leading to undesired results.

Another essential factor to consider when using a standard blade is the feed rate. It is recommended to feed the Plexiglass slowly and steadily to prevent any snagging or binding of the blade. Additionally, using a zero-clearance insert on your table saw can further minimize chipping and splintering.

2. Specialty Plexiglass Cutting Blade

For more precise and delicate cuts on Plexiglass, you may opt for a specialty Plexiglass cutting blade. These blades are specifically designed to reduce chipping and provide clean edges. They have an extended cutting edge and higher tooth count compared to standard blades. Most specialty Plexiglass cutting blades also have carbide tips, which increase their durability and longevity.

When using a specialty blade, it is essential to adjust the cutting speed of your table saw. Slower cutting speeds help prevent the Plexiglass from overheating and melting. It is recommended to experiment with different cutting speeds and feed rates to find the optimal settings for your specific project.

3. Triple-Chip Grind Blade

A triple-chip grind blade is another suitable option for cutting Plexiglass. These blades have a unique tooth design that combines flat-top teeth with alternating chamfered teeth. The flat-top teeth chip away the material, while the chamfered teeth create a smooth finish. This tooth configuration helps to reduce chipping and minimize heat buildup during cutting.

When using a triple-chip grind blade, it is crucial to adjust the cutting height correctly. The blade should only extend slightly above the thickness of the Plexiglass to prevent excessive heat buildup. Moreover, using a lubricant such as cutting wax or soap can further improve the cutting experience and reduce the risk of melting.

4. Diamond-Coated Blade

If you frequently work with Plexiglass or other hard plastics, investing in a diamond-coated blade can be a wise choice. Diamond-coated blades are incredibly durable and can withstand the abrasiveness of Plexiglass for an extended period. The diamond coating provides excellent heat dissipation and helps prevent melting or chipping of the material during cutting.

When using a diamond-coated blade, it is crucial to follow the manufacturer’s instructions regarding cutting speed and feed rate. These blades may require slower cutting speeds and more significant downward pressure to achieve optimal results. Additionally, it is recommended to wear appropriate safety gear, such as safety glasses and a dust mask, when cutting Plexiglass with a diamond-coated blade.

5. Benefits of Using the Right Blade

Using the right table saw blade for cutting Plexiglass offers several benefits. Firstly, it ensures clean and precise cuts, minimizing the need for additional finishing work. Secondly, a suitable blade helps prevent chipping and splintering, resulting in a smooth edge finish. Lastly, using the correct blade reduces the risk of the Plexiglass melting or warping due to excessive heat buildup.

6. Tips for Cutting Plexiglass

To achieve the best results when cutting Plexiglass with a table saw, consider the following tips:

1. Always wear appropriate safety gear, including safety glasses and a dust mask, to protect yourself from flying debris and harmful fumes.

2. Make sure the Plexiglass is properly secured before starting the cutting process to prevent any movement or vibration.

3. Use masking tape or painter’s tape along the cutting line to reduce chipping and splintering.

4. Feed the Plexiglass slowly and steadily, allowing the blade to do the work without excessive force.

5. Maintain a constant cutting speed and avoid sudden changes in direction to prevent the blade from binding or snagging.

6. If you encounter any resistance while cutting, stop and assess the situation. Never force the blade through the material, as it can lead to undesirable results.

Remember to always read and follow the manufacturer’s instructions for both the blade and the Plexiglass material you are working with to ensure the best results.

7. Conclusion

Choosing the right table saw blade for cutting Plexiglass is essential to achieve accurate and clean cuts. Consider the type of blade, tooth count, and tooth design to determine the most suitable option for your specific project. Additionally, make sure to follow proper safety precautions and use the appropriate cutting techniques to avoid accidents and achieve the desired results. With the right blade and technique, you can effortlessly cut Plexiglass with precision and confidence.

Key Takeaways: What Table Saw Blade to Cut Plexiglass?

- Choose a fine-toothed blade specifically designed for cutting plastic materials.

- Look for blades with a high tooth count for smoother cuts and less chipping.

- Consider using a blade with carbide-tipped teeth for increased durability.

- Make sure the blade is properly aligned and securely attached to the table saw.

- Take proper safety precautions, such as wearing protective eyewear and using a slow cutting speed.

Frequently Asked Questions

Below are some common questions related to cutting plexiglass with a table saw blade.

1. Can I use any type of table saw blade to cut plexiglass?

While it’s technically possible to use any type of table saw blade to cut plexiglass, it’s highly recommended to use a specific blade designed for this purpose. A blade with a higher tooth count and a triple-chip grind is ideal for cutting plexiglass. This type of blade minimizes heat buildup, reduces chipping, and provides smoother and cleaner cuts. Using a blade designed for plexiglass will help avoid damage to the material and ensure a better overall result.

When selecting a table saw blade for cutting plexiglass, look for a blade that has a high tooth count (80 to 100 teeth) and is made from carbide or polycrystalline diamond (PCD). These blades are specifically designed to handle the unique characteristics of plexiglass and will deliver the best cutting performance and results.

2. Can I use a regular woodworking blade to cut plexiglass?

While it’s possible to use a regular woodworking blade to cut plexiglass, it’s not recommended. Regular woodworking blades typically have a lower tooth count and a flat or alternate top bevel (ATB) grind, which can cause excessive heat buildup and lead to chipping or melting of the plexiglass. Additionally, the larger gullets in a woodworking blade may cause the material to catch, resulting in a less precise cut or even damage to the plexiglass.

If you must use a woodworking blade, select one with a higher tooth count (at least 80 teeth) and a triple-chip grind to minimize heat buildup and reduce the risk of chipping. However, it’s still best to use a blade specifically designed for plexiglass to ensure clean, precise cuts without any potential damage to the material.

3. What type of blade should I use for thin plexiglass?

If you’re working with thin plexiglass sheets (up to 1/8 inch thick), it’s recommended to use a crosscutting blade with a high tooth count. A crosscutting blade, also known as a plywood or finish blade, has more teeth and a higher tooth angle which helps prevent chipping and provides a smooth, clean cut on thin materials. Look for a blade with at least 80 teeth and a triple-chip grind designed for crosscutting tasks.

It’s important to note that regardless of the blade you choose, always take extra precautions when cutting thin plexiglass. Support the material properly to prevent it from vibrating or flexing during the cut, which can lead to chipping or cracking. Additionally, using a zero-clearance insert on your table saw can help minimize tear-out and further improve the quality of the cut.

4. Do I need a special blade for thick plexiglass?

When it comes to cutting thick plexiglass, it’s recommended to use a ripping blade specifically designed for thick materials. Ripping blades have fewer teeth and a flat-top or alternate top bevel (ATB) grind, allowing them to bite into the material more aggressively and remove material more efficiently. A blade with around 24 to 40 teeth and a flat-top or ATB grind is suitable for cutting thick plexiglass.

However, keep in mind that even with a suitable blade, cutting thick plexiglass requires extra caution. Take your time, make multiple passes if necessary, and use proper support to ensure the material remains stable throughout the cut. Taking these precautions will help minimize the risk of chipping, melting, or cracking the thick plexiglass.

5. How should I prepare the table saw for cutting plexiglass?

Before cutting plexiglass on a table saw, there are a few steps you should take to ensure optimal results. First, ensure the table saw is clean and free from any dust or debris that can scratch or mar the surface of the plexiglass. You can use a damp cloth or a vacuum with a soft brush attachment to clean the table and the blade area.

Next, check the blade to ensure it’s clean and sharp. A dull or dirty blade can cause more friction and increase the chances of chipping or melting the plexiglass. If necessary, clean the blade or replace it with a new one specifically designed for cutting plexiglass. Finally, make sure all safety guards and accessories are properly installed and adjusted to prevent any accidents during the cutting process.

Summary

So, to sum it up, when cutting plexiglass with a table saw, there are a few things to keep in mind. First, choose the correct blade specifically designed for cutting acrylic materials. Look for a blade with a high tooth count and a low tooth angle to prevent chipping. Second, make sure to set the table saw speed to the lowest setting to avoid overheating the plexiglass. Finally, use a slow and smooth feeding motion to prevent the plexiglass from cracking or breaking.

In addition, remember to wear safety goggles and gloves for protection, and ensure that the plexiglass is properly supported and secured before cutting. By following these guidelines, you’ll be able to safely and effectively cut plexiglass with a table saw. So, go ahead, give it a try and enjoy your DIY projects with plexiglass!