You might be wondering, what should you put under plywood when cutting? Well, fret not, young DIY enthusiast! This introduction is here to shed some light on this handy question. So, let’s dive right in and discover the simple yet essential steps you need to follow for a successful plywood cutting experience.

When it comes to cutting plywood, having the right setup is crucial. But what should you put under plywood when cutting? Fear not, my friend, for I shall reveal the secret to achieving clean and precise cuts. Whether you’re tackling a small craft project or a larger home improvement task, this knowledge will come in handy, guaranteed.

Are you ready to unleash your inner carpenter? Then stay tuned as I unravel the mystery behind what to put under plywood when cutting. By the end of this article, you’ll be equipped with all the knowledge necessary to tackle your cutting projects like a pro. Let’s get started!

What to Put Under Plywood When Cutting?

1. Importance of Using a Support Surface

When cutting plywood, it is crucial to have a support surface underneath to ensure clean and accurate cuts. Without proper support, plywood can sag or splinter, resulting in uneven edges and potentially ruining your project. Additionally, a support surface provides stability and reduces vibrations, making the cutting process safer and more precise. There are several options for what to put under plywood when cutting, each with its own advantages and considerations.

One of the simplest and most accessible options is using sawhorses. Sawhorses are sturdy, portable stands designed to hold materials for cutting. They provide a stable base for plywood and can be easily adjusted to the desired height. If you don’t have sawhorses, you can use a workbench or a table with a smooth and flat surface. Just remember to secure the plywood to prevent movement during cutting.

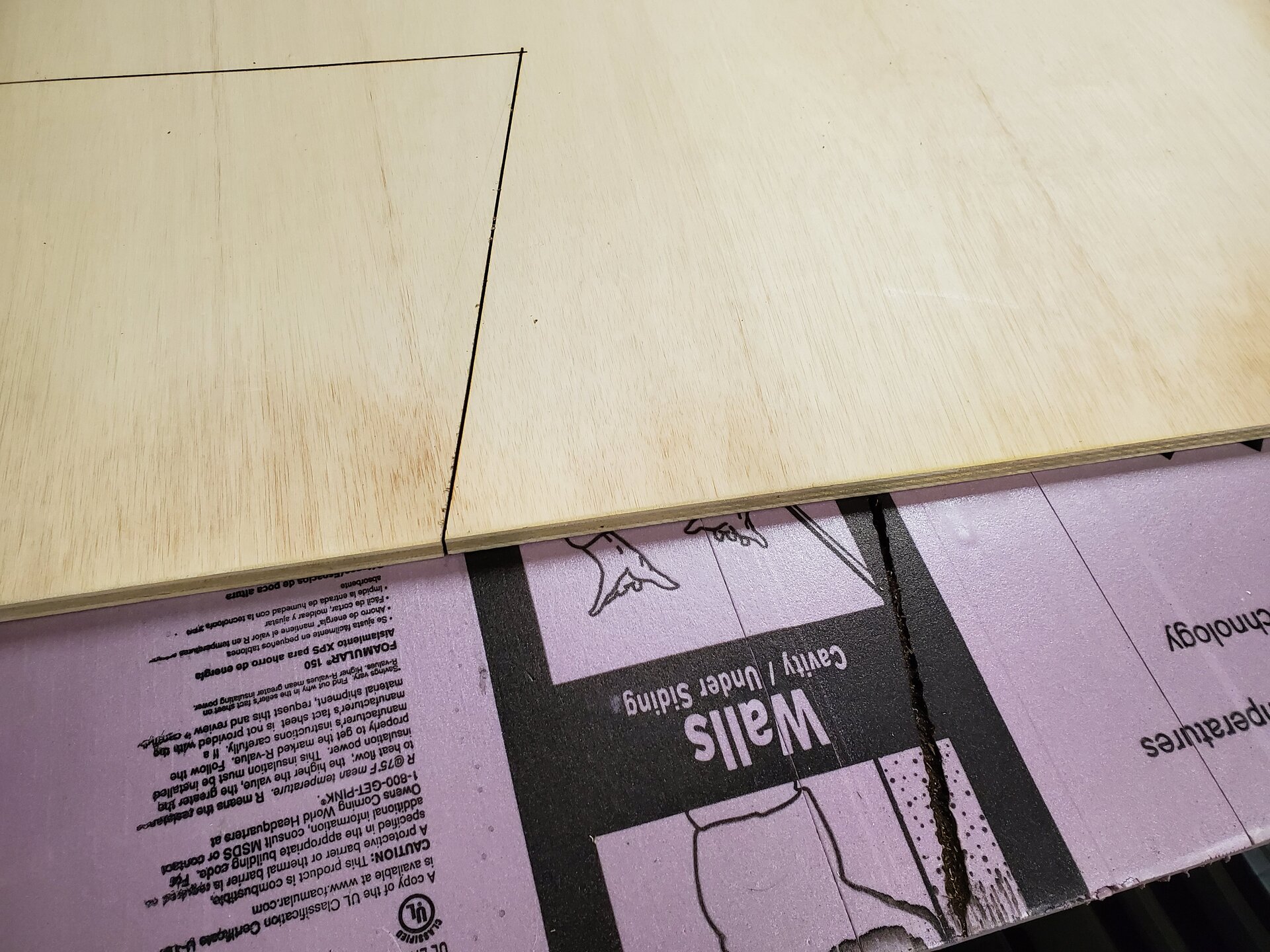

Another option is to use foam insulation boards. These lightweight and affordable boards provide excellent support while also reducing the risk of splintering. They can be easily cut to size, and their soft surface helps protect the bottom layer of the plywood from damage. However, it’s important to ensure the foam boards are smooth and level to avoid any inconsistencies in the cutting process.

2. Using Clamps and Plywood Sheathing Clips

Clamps are another useful tool when cutting plywood. They can be used to secure the plywood to a workbench or sawhorses, preventing any movement during the cutting process. When using clamps, ensure they are placed at equal intervals along the edges of the plywood to provide even support. This will help maintain the stability of the material and result in cleaner cuts.

Plywood sheathing clips are specifically designed for holding plywood in place during cutting. These metal clips are attached to the edges of the plywood and provide a secure grip, preventing any movement or sagging. They are easy to install and remove, making them a convenient option for DIY enthusiasts and professionals alike. However, it’s important to note that plywood sheathing clips are more commonly used for larger sheets of plywood and may not be necessary for smaller projects.

Regardless of the method you choose, always prioritize safety when cutting plywood. Wear protective gear such as safety glasses and gloves, and ensure your cutting tools are sharp and securely fastened. Taking these precautions will help you achieve accurate and professional-looking cuts while minimizing the risk of injuries.

3. Benefits of Using a Sacrificial Sheet

A sacrificial sheet is a thin piece of material placed between the plywood and the support surface to protect both the surface and the bottom layer of the plywood. It acts as a sacrificial layer, absorbing any damage that may occur during the cutting process. Using a sacrificial sheet is particularly useful when cutting materials that have a tendency to splinter, such as hardwood or melamine-coated plywood.

There are several materials that can be used as sacrificial sheets, including particle board, MDF (medium-density fiberboard), or plywood scraps. These materials are readily available and affordable, making them a practical choice for many DIYers. When using a sacrificial sheet, make sure it is larger than the piece of plywood being cut, providing ample protection for both the plywood and the support surface.

Using a sacrificial sheet not only protects your work area and tools but also extends the life of your cutting blade. By reducing the wear and tear on your blade, a sacrificial sheet can save you money in the long run. Additionally, it ensures cleaner cuts by preventing tear-out, resulting in a more professional finish to your project.

4. Choosing the Right Blade and Cutting Technique

Along with the support surface, the type of blade and cutting technique you use can significantly affect the quality of your cuts when working with plywood. When cutting plywood, it is recommended to use a blade specifically designed for crosscutting or fine woodworking. These blades typically have a high tooth count, which helps to minimize tear-out and produce smooth edges.

When it comes to the cutting technique, a slow and steady approach is key. Push the plywood through the blade at a consistent pace, allowing the blade to cleanly cut through the material without putting excessive strain on it. Additionally, consider making multiple passes for thicker plywood or when dealing with hardwood to avoid putting too much stress on the blade.

Furthermore, always double-check your measurements before cutting and mark the cutting line clearly on the plywood. This will help you achieve accurate cuts and minimize the risk of errors. If you are new to cutting plywood or working on a complex project, it may be beneficial to practice on scrap pieces first to refine your technique.

5. Other Considerations for Cutting Plywood

When cutting plywood, there are a few additional factors to consider to ensure optimal results. Firstly, keep the size and weight of the plywood in mind. Larger and heavier sheets might require additional support, such as extra sawhorses or clamps, to prevent sagging or movement.

Secondly, be mindful of the grain direction of the plywood. The direction of the grain can affect the cutting process and the overall strength and stability of the finished piece. It is generally recommended to cut with the grain to minimize tear-out, but depending on the project, cutting against the grain may be necessary.

Lastly, proper maintenance of your cutting tools is essential for achieving clean and accurate cuts. Regularly clean and sharpen your blades to ensure optimal performance. Dull or dirty blades can result in splintering, burning, and imprecise cuts.

#Additional H2 Topics

Different Tools for Cutting Plywood

– Hand saws

– Circular saws

– Jigsaws

Benefits of Using a Circular Saw

– Versatility and portability

– Precise and efficient cuts

– Requires less physical effort than other tools

Tips for Achieving Smooth Cuts

– Use masking tape on the cut line

– Cut with a slow, steady motion

– Support the off-cut to prevent splintering

Comparison: Sawhorses vs. Workbench

– Portability and convenience

– Stability and weight capacity

– Adjustability and versatility

Different Types of Sawhorses

– Traditional sawhorses

– Folding sawhorses

– Adjustable sawhorses

Choosing the Right Blade for Plywood Cutting

– Tooth count and configuration

– Blade material and durability

– Blade thickness and kerf size

How to Prevent Tear-Out When Cutting Plywood

– Cut with a sharp blade

– Use a backing board

– Score the cut line before sawing

Key Takeaways: What to Put Under Plywood When Cutting?

- Using a sacrificial piece of plywood underneath helps prevent the main plywood from splintering.

- A foam board or soft material like carpet can provide cushioning and prevent scratches on the work surface.

- Clamps or weights can be used to secure the plywood and keep it from moving while cutting.

- Applying painter’s tape along the cut line can help reduce splintering and provide a guide for precise cuts.

- Wearing protective goggles and using appropriate cutting tools is essential for safety while cutting plywood.

Frequently Asked Questions

When cutting plywood, it’s important to consider what you should put underneath it for support and protection. Here are some commonly asked questions about what to put under plywood when cutting:

1. Why do I need to put something under plywood when cutting?

Putting something underneath plywood when cutting serves a few purposes. First, it helps to protect your work surface from any damage caused by the saw blade. Additionally, it provides support to prevent the plywood from splintering or breaking during the cutting process. By using a proper support material, you can ensure cleaner and more accurate cuts.

Furthermore, placing something underneath the plywood can help prevent the wood from sagging or flexing under its own weight. This can result in more precise cuts and reduce the risk of accidents while cutting.

2. What are some common materials I can use under plywood when cutting?

There are a few options for materials that you can use as support when cutting plywood. One common choice is a sacrificial piece of plywood or MDF (medium-density fiberboard). This sacrificial piece can bear the weight of the main plywood sheet and provide a clean, stable surface for cutting.

Another option is to use foam insulation board or rigid foam as support. This lightweight material can be easily cut to the size needed and provides a soft surface that can help reduce splintering or chipping of the plywood. However, keep in mind that foam may compress under the weight of the plywood, so additional support may be necessary.

3. How do I secure the plywood to the support material when cutting?

Securing the plywood to the support material when cutting is crucial for safety and accuracy. One way to do this is by using clamps to hold the plywood securely in place on top of the support material. Make sure the clamps are tight and evenly distributed to prevent any movement during the cutting process.

Alternatively, you can use adhesive tape or double-sided tape to temporarily attach the plywood to the support material. This can be especially useful if you’re working with smaller pieces of plywood or when using foam insulation boards as support. Just make sure the tape is strong enough to hold the plywood firmly while cutting.

4. Is it necessary to use a specific thickness of support material when cutting plywood?

The thickness of the support material you use when cutting plywood can depend on a few factors. In general, it’s recommended to use a support material that is at least as thick as the plywood you’re cutting. This helps ensure stability and prevents the plywood from flexing or sagging during the cutting process.

However, if you’re using a sacrificial piece of plywood or MDF, a thickness of 1/2 inch (12mm) is often sufficient. For foam insulation boards, a thickness of at least 1 inch (25mm) is usually recommended to provide adequate support and prevent compression.

5. Can I use scrap wood as a support when cutting plywood?

Yes, using scrap wood as a support when cutting plywood can be a cost-effective option. However, it’s important to ensure that the scrap wood is flat, stable, and free from any defects. Any unevenness or defects in the support material can transfer to the plywood, affecting the quality of your cuts.

If using scrap wood, make sure it is securely clamped or attached to the work surface to prevent any movement while cutting. Also, be mindful of the thickness of the support material to provide adequate stability and prevent sagging or flexing of the plywood.

Cutting Large Sheets With A Circular Saw

Summary

When cutting plywood, it is important to have a solid surface underneath to support the wood. This can prevent splintering and ensure cleaner cuts. A workbench or sawhorses are good options for providing a sturdy base. Additionally, using a sacrificial piece of wood or foam insulation can help protect the cutting surface and prolong the life of your saw blade.

If the plywood is thin or prone to splintering, placing painter’s tape along the cutting line can help prevent tear-out. It’s also important to use the correct blade for your saw, such as a fine-toothed blade for clean cuts. Taking these steps will result in better, smoother cuts and make your woodworking projects more successful. So, get your tools ready and have fun cutting plywood with confidence!