Looking to dive into the fascinating world of lathes? Wondering what tools are used on a lathe? Well, you’re in the right place! In this article, we’ll explore the essential tools that craftsmen and machinists employ to shape and create amazing things using a lathe.

Now, you might be asking, what exactly is a lathe? Think of it as a powerful spinning machine that allows you to shape various materials like wood, metal, or plastic with precision. But here’s where things get exciting – to unlock its full potential, you’ll need the right set of tools.

Whether you’re a beginner or a seasoned pro, understanding the tools used on a lathe is crucial for achieving accurate and impressive results. So, let’s get ready to discover a world of cutting tools, chisels, and gauges that will take your lathe projects to new heights!

What Tools are Used on a Lathe? A Comprehensive Guide

When it comes to working with a lathe, having the right tools is essential. Whether you’re a seasoned professional or just starting out, understanding the various tools used on a lathe is crucial for achieving precision and producing high-quality work. In this article, we will dive into the world of lathe tools, exploring their types, functions, and how they contribute to the overall lathe operation.

1. Turning Tools

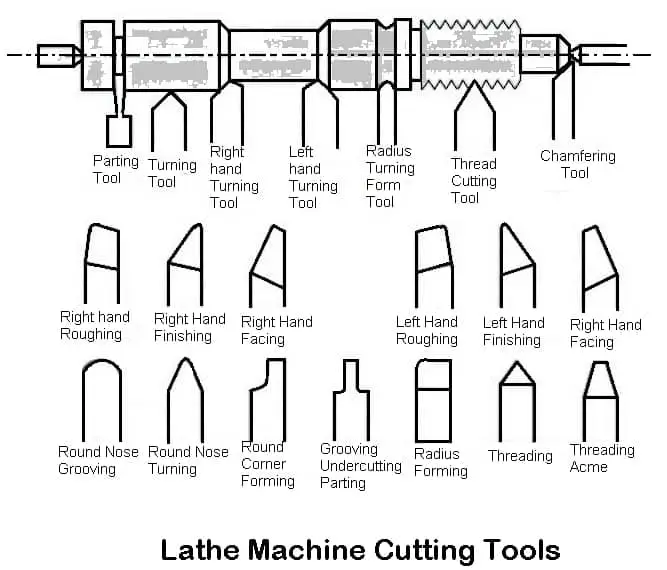

One of the most common types of tools used on a lathe is the turning tool. These tools are specifically designed for shaping and cutting material as it rotates on the lathe. Turning tools feature a cutting edge made of high-speed steel or carbide, which allows them to effectively remove material during the turning process. There are various types of turning tools, including roughing, finishing, and parting tools, each with its own unique purpose and design.

Additionally, turning tools often come with different types of angles, such as rake angle, clearance angle, and cutting angle. These angles play a critical role in determining how the tool interacts with the material being turned, affecting factors like surface finish, chip evacuation, and cutting forces. Understanding the different turning tool angles and their impact on the machining process is essential for achieving desired results.

Furthermore, turning tools can be used to work with a wide range of materials, including wood, metal, and plastic. However, it’s important to choose the appropriate cutting tips and tool geometry based on the material being worked on to achieve optimal results in terms of surface finish, accuracy, and tool life.

2. Boring Tools

Another essential set of tools used on a lathe is the boring tools. As the name suggests, these tools are specifically designed for enlarging and refining the diameter of existing holes. Boring tools are used to achieve precise dimensions, concentricity, and surface finish when working with cylindrical features on a lathe.

Boring tools typically consist of a cutting edge and a shank that fits into the lathe’s toolpost or a boring bar holder. They come in various shapes and sizes to accommodate different hole sizes and depths. These tools can be used to bore through-holes, blind holes, and even tapered holes, making them incredibly versatile for a wide range of applications.

It’s worth noting that boring tools can be used for internal threading as well. By utilizing specialized boring bars with threading inserts, it’s possible to create precise internal threads on a lathe. This highlights the versatility and importance of boring tools in the overall lathe tool arsenal.

3. Parting Tools

When it comes to separating a workpiece from the main stock, parting tools are indispensable. Parting tools, also known as cutoff tools, are specifically designed to create a clean and precise cut across the workpiece, separating it from the rest of the stock. These tools feature a thin, pointed blade that can be easily inserted into the material to make a clean cut.

Parting tools typically come in different widths, allowing you to choose the appropriate tool for the desired cut width. The cutting edge of a parting tool is usually perpendicular to the axis of rotation, ensuring a straight and accurate cut. However, parting off can be a challenging operation that requires careful attention and proper tool positioning to avoid tool breakage or causing damage to the workpiece or lathe.

Despite the challenges, parting tools are essential for creating separate parts or sections in a workpiece. Whether you’re creating multiple components from a single stock or dividing a workpiece to perform specific operations, parting tools are an invaluable tool in a lathe operator’s toolkit.

4. Thread Cutting Tools

Thread cutting is a common operation performed on a lathe, and having the right tools for this task is essential. Thread cutting tools are specifically designed to create internal or external threads on a workpiece, allowing for the assembly of threaded components or creating threaded features for improved functionality.

There are two main types of thread cutting tools: single-point and multiple-point tools. Single-point thread cutting tools consist of a single cutting edge that creates the threads by traversing the workpiece at a specified pitch. On the other hand, multiple-point thread cutting tools, also known as dies, have multiple cutting edges and are used to cut threads on external surfaces or to chase existing threads.

Thread cutting tools come in different sizes and shapes to accommodate various thread sizes and depths. They are commonly used in industries such as automotive, engineering, and manufacturing, where threaded connections play a critical role in the overall functionality and performance of the products.

5. Knurling Tools

Knurling is a process used to create a textured pattern on a workpiece, improving grip and aesthetic appeal. Knurling tools are specifically designed to perform this task on a lathe. These tools consist of a pair of wheels or discs with a pattern of hardened teeth that press into the workpiece as it rotates. The pressure created by the knurling tool forms the desired pattern on the material’s surface.

Knurling tools come in various patterns and sizes, allowing for different types of knurling patterns to be created. The choice of knurling tool depends on factors such as the desired pattern, material hardness, and the end application of the workpiece. Knurling is commonly seen on components such as handles, knobs, and other parts where grip and texture are important.

It’s worth noting that knurling can be a delicate operation, as the pressure applied by the tool can affect the overall dimensions of the workpiece. Careful attention and proper setup are required to ensure the knurling process does not deform or damage the workpiece. However, with the right technique and tools, knurling can add a touch of elegance and functionality to your lathe projects.

6. Indexable Inserts

Indexable inserts are a type of cutting tool that offers versatility and cost-effectiveness. Unlike traditional tools with a single cutting edge, indexable inserts feature multiple cutting edges that can be rotated or replaced when worn out. These inserts are usually made of carbide or ceramic materials, offering excellent cutting performance and durability.

Indexable inserts are commonly used in turning, milling, and boring operations on a lathe. They have removable inserts that allow for quick and easy tool changes, reducing downtime and increasing productivity. These inserts come in various shapes and sizes, allowing for different machining operations and material types to be accommodated.

One of the key advantages of indexable inserts is their cost-effectiveness. Instead of replacing an entire tool when the cutting edge becomes dull or worn out, you can simply replace the insert, reducing tooling costs in the long run. This makes indexable inserts a popular choice among lathe operators looking for a balance between performance, convenience, and cost savings.

7. Lathe Chuck

The lathe chuck is not a tool in the traditional sense, but it plays a crucial role in holding and securing the workpiece during lathe operations. A lathe chuck is a specialized device mounted on the lathe’s spindle that allows for secure gripping and rotation of the workpiece.

Chucks come in various types, including three-jaw chucks, four-jaw chucks, and collet chucks. The choice of chuck depends on factors such as the type and size of the workpiece, the desired gripping force, and the nature of the machining operation to be performed. Three-jaw chucks are commonly used for holding cylindrical workpieces, while four-jaw chucks offer greater flexibility in clamping irregularly shaped or non-symmetrical workpieces.

The lathe chuck is an essential component of a lathe setup, providing stability and enabling precise machining operations. It’s important to choose the right chuck for the job and ensure proper setup and alignment to achieve accurate and high-quality results.

Additional Tools for Lathe Operations

Aside from the tools discussed above, there are several other tools that are commonly used in lathe operations. These tools include, but are not limited to:

1. Drill Bits

Drill bits are used for creating holes on a workpiece. While they are primarily used in drilling operations, drill bits can also be used in the lathe for creating holes with precision and accuracy.

2. Live Centers

Live centers are used to support long workpieces that extend beyond the chuck. They help reduce deflection and ensure stability during the machining process.

3. Steady Rests

Steady rests are used to support long and slender workpieces that may experience excessive vibration or deflection during lathe operations. They provide additional stability and prevent workpiece flexing.

4. Faceplate

A faceplate is a large, flat plate that is mounted on the lathe’s spindle and used for securely holding irregularly shaped workpieces that cannot be clamped in a chuck.

5. Tailstock

The tailstock is a movable component located on the opposite end of the lathe’s chuck. It is used for providing additional support to the workpiece during operations such as drilling, reaming, or turning long shafts.

6. Lathe Centering Tool

A lathe centering tool is used to accurately align the centerline of the workpiece with the centerline of the lathe’s spindle, ensuring proper alignment and minimizing errors during machining.

7. Countersink Tools

Countersink tools are used for creating chamfered holes or countersinks on a workpiece. They are commonly used in applications where fasteners need to sit flush with the surface.

8. Tool Holders

Tool holders are used to securely hold cutting tools, including turning tools and boring tools. They provide stability, rigidity, and accurate tool positioning during lathe operations.

9. Dial Indicators

Dial indicators are precision measuring instruments used to measure and check the accuracy of various parameters such as surface finish, concentricity, and tool alignment during lathe operations.

10. Thread Gauges

Thread gauges are used to measure the pitch, major diameter, and minor diameter of threaded features. They are essential for ensuring the dimensional accuracy and quality of threaded components.

11. Carbide Inserts

Carbide inserts are cutting inserts made of carbide material. They offer superior hardness and wear resistance, making them ideal for high-speed machining with enhanced tool life.

12. Grinding Wheels

Grinding wheels are used for sharpening and reshaping cutting tools. They come in various shapes and sizes and are essential for maintaining the cutting performance and longevity of lathe tools.

13. Knurling Wheels

Knurling wheels, similar to knurling tools, are used for creating textured patterns on a workpiece. These wheels are mounted on a lathe’s compound rest and pressed against the rotating workpiece to create the desired knurling pattern.

14. Parting Off Blades

Parting off blades, also known as parting blades, are similar to parting tools but are designed to be clamped onto a tool holder or cutting tool block. They offer more stability and rigidity during the parting process.

15. Chamfer Tools

Chamfer tools are used to create chamfered edges on a workpiece. These tools come in various shapes and sizes, allowing for the creation of different chamfer profiles.

16. Tool Bits

Tool bits are small cutting tools commonly used in manual lathe operations. They are made of high-speed steel and can be ground to specific shapes to match the desired machining operation.

17. Threading Inserts

Threading inserts are cutting inserts specifically designed for creating external or internal threads on a workpiece. They come in various sizes and designs to accommodate different thread profiles.

18. Abrasive Pads

Abrasive pads, such as sanding discs or abrasive sheets, are used for sanding and refining the surface finish of a workpiece on a lathe. They help achieve smooth and polished surfaces.

19. Lathe Dogs

Lathe dogs, also known as carriers, are used to drive and rotate the workpiece during lathe operations. They are commonly used for irregularly shaped workpieces or for machining operations that require precise indexing.

20. Calipers

Calipers are precision measuring tools used for measuring and checking dimensional tolerances during lathe operations. They come in various types, including outside calipers, inside calipers, and depth calipers.

Conclusion

Understanding the various tools used on a lathe is vital for anyone looking to achieve precision and quality in their machining projects. From turning tools and boring tools to parting tools and knurling tools, each plays a critical role in the overall lathe operation. Additionally, a variety of other tools, such as drill bits, live centers, and dial indicators, complement the lathe tool arsenal, further enhancing the operator’s ability to create complex and accurate components.

By familiarizing yourself with these tools and their functions, you can expand your capabilities as a lathe operator and unlock endless possibilities in the world of machining. With practice, experience, and the right tools at your disposal, you’ll be able to turn raw materials into exquisite and functional creations, showcasing your skills and craftsmanship.

Key Takeaways: What Tools are Used on a Lathe?

- A lathe uses various cutting tools to shape and create objects.

- The most common tools used on a lathe include gouges, parting tools, and skew chisels.

- Gouges are used for roughing and shaping, while parting tools are used for separating finished parts.

- Skew chisels are versatile tools used for smoothing and shaping cylindrical objects.

- Other tools used on a lathe may include scrapers, boring bars, and drill bits.

Frequently Asked Questions

Are you curious about the tools used on a lathe? Look no further – we have the answers to your questions!

1. What are some common tools used on a lathe?

The lathe is a versatile machine that uses various tools to shape and create different objects. Some common tools include the gouge, skew chisel, parting tool, and spindle roughing gouge. The gouge is used for shaping and removing excess material, while the skew chisel is great for creating smooth finishes. The parting tool is used to cut grooves and create precise separations, and the spindle roughing gouge is perfect for quickly removing large amounts of material.

Keep in mind that these are just a few examples of the tools used on a lathe. There are many other specialized tools available, each serving a unique purpose depending on the project at hand.

2. What safety precautions should I take when using lathe tools?

When working with lathe tools, safety should always be a top priority. Here are a few precautions to remember:

Firstly, always wear appropriate safety gear, including safety goggles, a dust mask, and ear protection. This will help protect your eyes, lungs, and ears from potential hazards. Secondly, make sure the lathe is securely anchored to avoid any movement or vibrations. Additionally, be mindful of your body position and avoid wearing loose clothing or jewelry that could get caught in the machine. Lastly, always read and follow the manufacturer’s instructions for operating the lathe and using the tools correctly. Safety should never be compromised!

3. How do I maintain the tools used on a lathe?

To ensure the longevity and effectiveness of your lathe tools, proper maintenance is crucial. Here are a few tips:

Start by cleaning the tools after each use. Use a cloth or brush to remove any dirt or debris. Next, inspect the tools for any signs of damage or wear. Dull or damaged tools should be sharpened or replaced to maintain optimal performance. Proper storage is also important – keep your tools in a dry and clean area to prevent rust or corrosion. Finally, remember to oil any movable parts or hinges regularly to keep them functioning smoothly.

4. Can I use different tools interchangeably on a lathe?

While some tools may appear similar, it is not advisable to use them interchangeably on a lathe. Each tool is designed with specific characteristics and purposes in mind. Using the wrong tool can not only affect the quality of your work but also pose safety risks. It’s best to familiarize yourself with the different tools and their functions to ensure you choose the right tool for each task.

If you’re unsure which tool to use, consult the manufacturer’s guidelines, instructional videos, or seek advice from experienced lathe users. Remember, using the correct tool for the job will help you achieve the best results and ensure a safe working environment.

5. What are the benefits of using specific tools on a lathe for different projects?

Using specific tools on a lathe for different projects offers several benefits. Firstly, it allows for greater precision and control. Each tool is designed to perform specific tasks, enabling you to shape and manipulate the material with accuracy. Secondly, specialized tools often lead to improved efficiency by enabling you to work faster and more effectively. Thirdly, using the right tools for the job can enhance the overall quality of your work. The appropriate tool will produce smoother finishes, cleaner cuts, and finer details. Lastly, using the correct tool ensures safety, minimizing the risk of accidents or damage to the workpiece.

Overall, using specific tools on a lathe allows you to unleash your creativity and achieve professional-looking results. So, don’t shy away from exploring different tools and techniques – they can elevate your woodworking or metalworking projects to new heights!

Summary

When using a lathe, there are some important tools that you should know about. One of these tools is the cutting tool, which is used to shape the material being turned. The lathe also requires a chuck to hold the material in place and a tailstock to support longer pieces. Another tool used on a lathe is the carriage, which moves the cutting tool along the material. Lastly, a lathe often has a variety of accessories, such as steady rests and faceplates, that can help with different projects.

It’s important to understand the purpose of these tools and how they work together to shape and create objects on a lathe. Whether you’re just starting out or have some experience, knowing these tools will help you make the most of your lathe and enjoy the process of turning materials into something unique and special. So go ahead, give it a try and see what you can create with your lathe!