Welcome to the world of woodturning! Have you ever wondered what tools you need to embark on this exciting craft? Well, you’ve come to the right place. In this article, we’ll explore the essential tools for woodturning in a fun and engaging way that’s perfect for beginners. So, let’s dive in and discover “what tools do you need for woodturning?”

Woodturning is a creative process that involves shaping a piece of wood while it spins on a lathe. To get started, you’ll need a few key tools. First up, we have the gouge, which is like the Swiss Army knife of woodturning. It’s a versatile tool that allows you to shape and hollow out your wooden creations with ease.

Next on our list is the skew chisel, a tool that requires a steady hand and a bit of practice to master. The skew chisel is excellent for refining details and creating smooth finishes on your turned projects. It’s a bit like a magician’s wand in the hands of a skilled woodturner.

Last but not least, we have the parting tool. This tool helps you separate your workpiece from the rest of the wood. It’s perfect for making precise cuts and creating depth and dimension in your finished pieces. With these three essential tools in your arsenal, you’ll be well-equipped to unleash your creativity and bring your woodturning projects to life.

So, whether you’re a budding woodturning enthusiast or simply curious about the craft, understanding what tools you need is a crucial first step. Now that you know the basics, let’s explore these tools further and delve into the fascinating world of woodturning together!

Essential Tools for Woodturning: A Guide for Beginners

Woodturning is a rewarding craft that allows you to transform raw pieces of wood into beautiful and functional objects. However, to embark on this journey, you need the right set of tools. In this article, we will explore the essential tools for woodturning, their functions, and tips on choosing the right ones for your needs. Whether you’re a beginner or expanding your collection, this guide will help you navigate the vast array of options and get started on your woodturning projects.

The Lathe: The Heart of Woodturning

The lathe is the centerpiece of any woodturner’s workshop. It is a machine that rotates the wood piece while you shape and carve it using various tools. When choosing a lathe, consider factors such as size, power, and speed control. Mini lathes are suitable for small projects and beginners, while larger lathes offer more versatility. Look for a lathe with a variable speed control to adjust the rotation speed according to the size and type of wood. Additionally, ensure that the lathe has sturdy construction and a reliable motor for smooth operation.

Key Features to Consider:

1. Size: Determine the maximum length and diameter of wood you plan to turn. Choose a lathe that accommodates your desired dimensions.

2. Power: Consider the motor’s horsepower to handle the size and hardness of the wood you’ll be working with.

3. Speed Control: Variable speed control allows you to adjust the rotation speed for different cuts and wood types.

4. Construction: Look for a lathe made from durable materials like cast iron for stability and vibration dampening.

Chisels and Gouges: Shaping Your Wood Creations

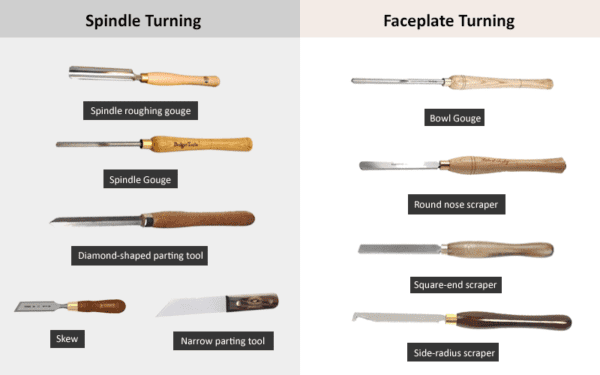

Chisels and gouges are essential tools for cutting and shaping the wood on a lathe. These tools come in various shapes and sizes, each designed for a specific purpose. Bowl gouges, spindle gouges, and parting tools are commonly used in woodturning. High-speed steel (HSS) tools are durable and hold their edge well, making them ideal for beginners. It’s recommended to start with a basic set of chisels and gradually expand your collection as you gain experience and work on different projects.

Tips for Choosing Chisels and Gouges:

1. Variety: Start with a basic set that includes spindle gouges, bowl gouges, and parting tools to cover a range of woodturning tasks.

2. Size and Shape: Consider the size and shape of the tools based on the projects you plan to undertake. Different profiles allow for different cuts and designs.

3. Handles: Look for chisels and gouges with comfortable and ergonomic handles for better control and reduced fatigue during long turning sessions.

4. Sharpening System: Invest in a sharpening system to maintain the sharpness of your tools. Sharp tools result in cleaner cuts and improved safety.

Sanding and Finishing: Achieving a Smooth and Stunning Surface

The Importance of Sanding:

Sanding is a crucial step in woodturning as it helps achieve a smooth surface and prepares the wood for finishing. Sanding can be done manually using sandpaper or with the help of sanding pads and discs attached to a drill or lathe. Start with coarse-grit sandpaper to remove any tool marks or rough spots, and gradually progress to finer grits for a polished finish. Proper sanding not only enhances the aesthetics of your work but also prevents the wood from splintering and ensures a long-lasting finish.

Finishing for Protection and Beauty:

To showcase the natural beauty of the wood and protect it from moisture and stains, applying a finish is essential. There are various finishes available in the market, such as lacquer, shellac, and oil-based finishes. Each type offers different levels of protection and aesthetics. Experiment with different finishes to find the one that suits your project and personal preferences. Apply finishes according to the manufacturer’s instructions and allow ample drying time between coats for a professional-looking result.

Optional Tools: Enhancing Your Woodturning Experience

While the lathe, chisels, and finishing tools are the core essentials, additional tools can enhance your woodturning experience and broaden your creative possibilities. Here are a few optional tools you might consider adding to your collection:

1. Hollowing Tools:

Hollowing tools are specialized tools used to create hollow forms such as vases and bowls. They allow you to remove wood from the interior of a turned piece with precision and control. Hollowing tools come in various designs, including scrapers, gouges, and captive ring tools.

2. Calipers and Measuring Tools:

Calipers and measuring tools are crucial for accurately measuring and sizing your woodturning projects. They help ensure consistency and precision in dimensions, which is especially important when replicating designs or creating matching sets of objects.

3. Faceplate and Chuck:

A faceplate and chuck system expands the versatility of your lathe by allowing you to securely hold irregularly shaped or unbalanced pieces of wood. Faceplates are attached directly to the lathe spindle, while chucks grip the wood using jaws or specialized hardware. These accessories provide stability and safety when working on challenging projects.

In conclusion, woodturning is an art that requires skill, creativity, and the right tools. The lathe, chisels, gouges, and sanding tools are the fundamental essentials for any woodturner. Adding finishing tools and optional accessories can enhance your woodworking experience and allow for more diverse projects. Remember to prioritize safety by wearing appropriate protective gear and always follow best practices when using woodworking tools. With practice and a passion for the craft, you’ll be creating stunning turned wood pieces in no time.

Key Takeaways:

- Woodturning requires specific tools such as a lathe, gouges, and chisels.

- A lathe is the central tool used in woodturning, allowing you to shape the wood with precision.

- Gouges and chisels are essential for cutting and shaping the wood on the lathe.

- Other necessary tools include a faceplate, live center, and sandpaper for finishing touches.

- When starting out, it’s best to invest in a basic set of tools and gradually add more specialized tools as needed.

Frequently Asked Questions

Welcome to our Frequently Asked Questions section, where we’ll address some common queries about woodturning tools. If you’re curious about the essential tools needed for woodturning, you’re in the right place. Read on to find the answers you’re looking for!

Q1: What are the basic tools needed for woodturning?

Woodturning requires a few essential tools to get started. The must-haves include a lathe, turning tools, a faceplate or chuck, a sharpening system, and safety equipment. The lathe is the centerpiece of any woodturning setup, while turning tools, such as gouges and chisels, allow you to shape and cut the wood. A faceplate or chuck securely holds the wood on the lathe, and a sharpening system ensures your tools stay razor-sharp. Lastly, don’t forget safety equipment like goggles and a face shield to protect yourself from flying wood chips.

To summarize, the basic tools for woodturning are a lathe, turning tools, a faceplate or chuck, a sharpening system, and safety equipment.

Q2: Should I invest in high-quality turning tools?

When it comes to turning tools, it’s a good idea to invest in higher quality ones. High-quality turning tools tend to have better craftsmanship, durability, and sharper cutting edges. They can provide a smoother cutting experience and produce cleaner, more precise cuts. Additionally, they often maintain their sharpness for longer, meaning you won’t have to sharpen them as frequently. While they may be more expensive upfront, the long-term benefits make them a worthwhile investment for serious woodturners.

However, if you’re just starting out and not ready to make a big financial commitment, there are affordable turning tools available that can still get the job done. As you gain more experience and decide to pursue woodturning further, you can gradually upgrade your tools to higher quality ones.

Q3: Is a mini lathe suitable for woodturning projects?

A mini lathe can be a great option for woodturners, especially beginners or those with limited workshop space. Mini lathes have a smaller footprint, making them easier to fit into smaller workshops or even personal studios. They are also more affordable compared to larger, professional-grade lathes.

While mini lathes have their advantages, they do have limitations. The smaller size means they have a lower maximum capacity, restricting the size of the projects you can undertake. Additionally, they may not have as powerful motors as larger lathes, which can affect their ability to handle certain types of wood. However, if you mainly plan to work on smaller projects like pens, bottle stoppers, or bowls, a mini lathe can be a suitable and cost-effective choice.

Q4: How often do I need to sharpen woodturning tools?

The frequency of sharpening your woodturning tools depends on various factors, such as the type of wood you’re working with and the amount of use your tools get. As a general guideline, you should sharpen your tools when you notice a decrease in cutting performance. Dull tools can result in tear-outs, rough surfaces, and an overall frustrating experience.

Some woodturners prefer to sharpen their tools after every few hours of use, while others may only sharpen them when necessary. It’s a good idea to regularly inspect your tools for any signs of dullness or damage. Investing in a reliable sharpening system will make the process easier and ensure your tools stay in optimal condition.

Q5: Are there any safety precautions I need to take when woodturning?

Absolutely! Woodturning can be a rewarding hobby, but it’s important to prioritize safety. Always wear eye protection, such as safety glasses or goggles, to shield your eyes from wood chips and debris. Additionally, a face shield is highly recommended to protect your face from any potential accidents while turning.

It’s also crucial to secure your workpiece properly using a faceplate or chuck, ensuring it is tightened securely before starting the lathe. Never wear loose clothing or jewelry that could get caught in the lathe. Always pay attention to your surroundings and maintain a clean and organized workspace to minimize trip hazards. Lastly, take your time and learn proper techniques to avoid accidents and injury. Woodturning can be safe and enjoyable as long as you follow these safety precautions.

Summary

So, to recap, when it comes to woodturning, there are a few tools you’ll need. First, you’ll need a lathe, which is the main machine used in woodturning. Next, you’ll need some turning tools, like gouges and chisels, to shape and cut the wood. Additionally, having a chuck and centers will help secure the wood on the lathe. Finally, don’t forget about safety gear like goggles and a face mask to protect yourself while woodturning.

In conclusion, woodturning requires a lathe, turning tools, a chuck, centers, and safety gear. With these tools, you’ll be ready to embark on your woodturning adventure. Have fun and be safe!