Are you wondering what type of bandsaw blade you should use for cutting metal? Well, you’ve come to the right place! Let’s dive into the world of bandsaw blades and discover which TPI (teeth per inch) is best suited for metal cutting.

When it comes to cutting metal, choosing the right bandsaw blade can make all the difference. The TPI refers to the number of teeth on the blade, and it plays a crucial role in determining the blade’s performance. So, it’s essential to understand which TPI is ideal for metal cutting tasks.

With a wide range of TPI options available, it’s easy to get overwhelmed. But fear not! In this guide, we’ll explore the different TPI options and help you find the perfect bandsaw blade for your metal cutting needs. So, let’s get started and find the TPI bandsaw blade that will make your metal cutting projects a breeze.

What TPI Bandsaw Blade is Best for Metal? A Comprehensive Guide

When it comes to cutting metal with a bandsaw, choosing the right TPI (teeth per inch) blade is crucial. The TPI determines the speed, quality, and efficiency of your cuts. With so many options available, it can be overwhelming to determine which TPI bandsaw blade is best for metal. In this comprehensive guide, we will delve into the factors to consider, the popular options, and expert tips to help you make an informed decision.

Factors to Consider When Choosing a TPI Bandsaw Blade for Metal

Before we dive into the specifics of TPI bandsaw blades for metal, it’s important to understand the factors that influence your choice. By considering these factors, you can ensure that you select the right blade for your cutting needs.

Material Being Cut

The type of metal you will be cutting plays a significant role in determining the ideal TPI for your bandsaw blade. Harder metals, such as stainless steel or tool steel, require a lower TPI to withstand the hardness of the material. Softer metals, like aluminum or copper, can be cut effectively with a higher TPI blade.

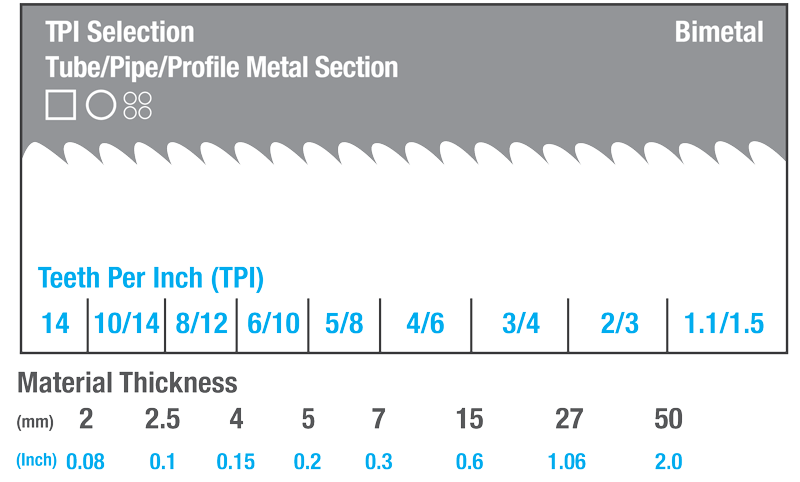

Additionally, consider the thickness of the material. Thicker metals require fewer teeth per inch to ensure proper cutting, while thinner metals benefit from a higher TPI blade for precision cuts.

Cutting Speed

The cutting speed refers to how fast the bandsaw blade moves through the metal. It is crucial to match the speed of the blade with the cutting speed of your bandsaw. Higher TPI blades tend to cut slower, making them ideal for intricate cuts that require precision. Lower TPI blades, on the other hand, are faster and suitable for rough cuts.

Desired Finish

The TPI bandsaw blade you choose also affects the finish of your cuts. A higher TPI blade produces a smoother finish, making it ideal for applications where aesthetics or minimal clean-up are important. Lower TPI blades yield rougher finishes, which may require additional grinding or sanding to achieve the desired smoothness.

Blade Durability

The durability of the blade is a crucial factor, especially if you will be making frequent cuts or cutting harder materials. Higher TPI blades tend to be more fragile and prone to damage, while lower TPI blades offer better durability and resistance to wear. Consider the longevity of the blade and factor in the cost of frequent replacements.

Budget

Lastly, your budget should also be considered when choosing a TPI bandsaw blade for metal. Higher TPI blades are often more expensive but offer enhanced precision and quality. Lower TPI blades are more cost-effective but may require additional finishing work.

Popular TPI Bandsaw Blades for Metal

Now that we have discussed the factors to consider, let’s explore some popular TPI bandsaw blades for metal cutting:

1. 14 TPI (Teeth Per Inch)

The 14 TPI bandsaw blade is a versatile option that strikes a balance between speed and precision. It is suitable for cutting various metals, including aluminum, brass, and mild steel. This blade is ideal for general metal fabrication and maintenance applications.

2. 24 TPI (Teeth Per Inch)

The 24 TPI bandsaw blade is perfect for fine cuts in thinner metals. It offers excellent precision and delivers a smooth finish. This blade is commonly used in jewelry making, model building, and other intricate metalwork.

3. 8 TPI (Teeth Per Inch)

The 8 TPI bandsaw blade is designed for cutting thicker metals and delivers fast cutting speed. It is commonly used in industrial settings for fabrication and heavy-duty metal cutting tasks.

Tips for Choosing the Right TPI Bandsaw Blade

Now that you are familiar with some popular TPI bandsaw blades for metal, here are a few expert tips to help you select the right blade:

1. Experiment and Test

Every cutting task is unique, and it may take some trial and error to find the perfect TPI bandsaw blade for your specific needs. Start with a blade that is commonly recommended for your intended application and make adjustments as required.

2. Consult the Manufacturer’s Guidelines

The bandsaw and blade manufacturers often provide guidelines on the recommended TPI for different materials and thicknesses. Consult these guidelines for a starting point and adjust based on your specific requirements.

3. Consider Multi-Tooth Blades

Multi-tooth blades, such as variable pitch blades, feature different TPI along the length of the blade. These blades offer versatility and adaptability for cutting different materials and thicknesses. Consider using them if you have a range of cutting tasks.

4. Maintain Proper Blade Tension and Speed

Ensure that your bandsaw blade is properly tensioned and that you are operating the bandsaw at the appropriate speed for the specific TPI blade you are using. Incorrect tension or speed can lead to poor cutting performance and premature blade wear.

Conclusion

Choosing the right TPI bandsaw blade for metal is essential for achieving clean, precise cuts. By considering factors like the material being cut, cutting speed, desired finish, blade durability, and budget, you can make an informed decision. Popular TPI options like 14 TPI, 24 TPI, and 8 TPI offer versatility for different cutting tasks. Remember to experiment, consult guidelines, and maintain proper tension and speed for optimal cutting results. With the right TPI bandsaw blade, you can tackle your metal cutting projects with confidence and precision.

Key Takeaways: What TPI Bandsaw Blade for Metal?

- A bandsaw blade with a lower TPI (teeth per inch) count is ideal for cutting thicker metal.

- For thinner metals, a bandsaw blade with a higher TPI count will provide smoother cuts.

- Consider the material you are cutting when choosing the TPI of your bandsaw blade.

- To cut aluminum and other soft metals, use a blade with a TPI count between 10 and 14.

- When cutting hard metals like steel, opt for a blade with a TPI count between 6 and 10 for better results.

Frequently Asked Questions

Looking for the right TPI bandsaw blade for metal cutting? We’ve got you covered with some commonly asked questions.

1. What is the ideal TPI (Teeth Per Inch) for cutting metal on a bandsaw?

When it comes to cutting metal on a bandsaw, a rule of thumb is to use a blade with a lower TPI. Blades with 8 to 14 TPI are ideal for cutting thicker metal, while 14 to 18 TPI blades work well for thinner materials. A lower TPI ensures that the blade can handle the higher resistance and hardness of metal, resulting in cleaner cuts.

It’s important to note that the optimal TPI can also depend on the type of metal being cut. For example, softer metals like aluminum may require a higher TPI blade for precision cuts.

2. Can I use a wood bandsaw blade for cutting metal?

While it may be tempting to use a wood bandsaw blade for cutting metal, it is not recommended. Wood bandsaw blades are designed with fewer teeth and a different tooth geometry, making them unsuitable for cutting metal. They are not built to withstand the hardness and resistance of metal, and using them could result in blade damage or accidents.

Investing in a dedicated metal-cutting bandsaw blade with the appropriate TPI will ensure efficient and safe cutting operations.

3. Are bi-metal bandsaw blades a good choice for cutting metal?

Yes, bi-metal bandsaw blades are an excellent choice for cutting metal. These blades are made from two different types of high-quality steel, combining the strength and flexibility of one steel with the hardened cutting edge of another. This construction allows the blade to handle the toughness of metal while providing long-lasting performance.

Bi-metal blades also have a higher heat resistance, making them suitable for cutting a variety of metal materials without compromising the blade’s durability.

4. How do I determine the blade width for cutting metal?

The blade width for cutting metal will depend on the size and thickness of the metal being cut. As a general guideline, select a blade width that is at least three times the thickness of the material. For example, if you’re cutting a 1/4-inch thick metal, choose a blade with a width of 3/4-inch or more.

Using a wider blade helps distribute the cutting force more evenly, resulting in better stability and reduced vibration during the cutting process.

5. What are some signs that indicate I need to replace my bandsaw blade for metal cutting?

Several signs indicate that it’s time to replace your bandsaw blade for metal cutting. These include: excessive vibration during cutting, poor cutting performance, visible wear or damage to the blade’s teeth, or difficulty in achieving straight and accurate cuts. If you notice any of these signs, it’s best to replace the blade to ensure optimal cutting results.

Regular inspection and maintenance of your bandsaw blade will help prolong its lifespan, but knowing when to replace it is crucial to maintain safe and efficient metal cutting operations.

Summary

When choosing a TPI bandsaw blade for metal, it’s important to select the right tooth pitch. A fine TPI blade is best for thin materials like sheet metal, while a coarse TPI blade is ideal for thicker metals. The blade’s tooth count determines the quality of the cut, so consider the material thickness and desired cut quality when making a decision. Remember to use lubrication and proper feed rates for better performance and blade longevity.

In addition to tooth pitch, blade material is crucial for cutting metal effectively. High-speed steel or bi-metal blades are recommended for cutting different types of metals. Make sure to choose a blade specifically designed for metal cutting to ensure safety and efficiency. Regular blade maintenance, such as cleaning and sharpening, is also essential for obtaining excellent results and prolonging the blade’s lifespan.