Hey there! Let’s dive into the fascinating world of lathe tailstocks. Have you ever wondered what functions a lathe tailstock can perform? Well, wonder no more! In this article, we’ll explore the two essential functions that a lathe tailstock can fulfill. So, hop on board and let’s get started!

Now, you might be thinking, “What exactly is a lathe tailstock?” Good question! The lathe tailstock is an important component found on a lathe machine. It is located at the opposite end of the lathe bed from the lathe headstock.

But what can this tailstock do? Well, it’s time to unveil its first function—providing support. The tailstock acts as a sturdy support for the workpiece that you’re turning on the lathe. It helps to stabilize and keep the workpiece securely in place during the machining process. No wobbling or wiggling here!

And guess what? The lathe tailstock isn’t just about support. It also has another handy function—drilling. Yes, you read that right! The tailstock can be used as a drilling tool. By attaching a drill chuck or a center drill to the tailstock, you can transform it into a drilling machine. This allows you to create precise and accurate holes in your workpiece.

So, there you have it! The lathe tailstock is a versatile tool that can perform two important functions—providing support and acting as a drilling machine. Pretty cool, right? Now that we’ve uncovered these functions, let’s explore them in more detail. I promise you’ll be amazed by what the lathe tailstock can do!

The Two Functions of a Lathe Tailstock: A Comprehensive Guide

Welcome to our comprehensive guide on the two essential functions of a lathe tailstock. Whether you’re a beginner or an experienced machinist, understanding the capabilities of the tailstock is crucial for maximizing the potential of your lathe. In this article, we will explore the primary functions of the tailstock, discuss its benefits, and provide expert tips to help you make the most of this important tool.

Function 1: Supporting Workpieces

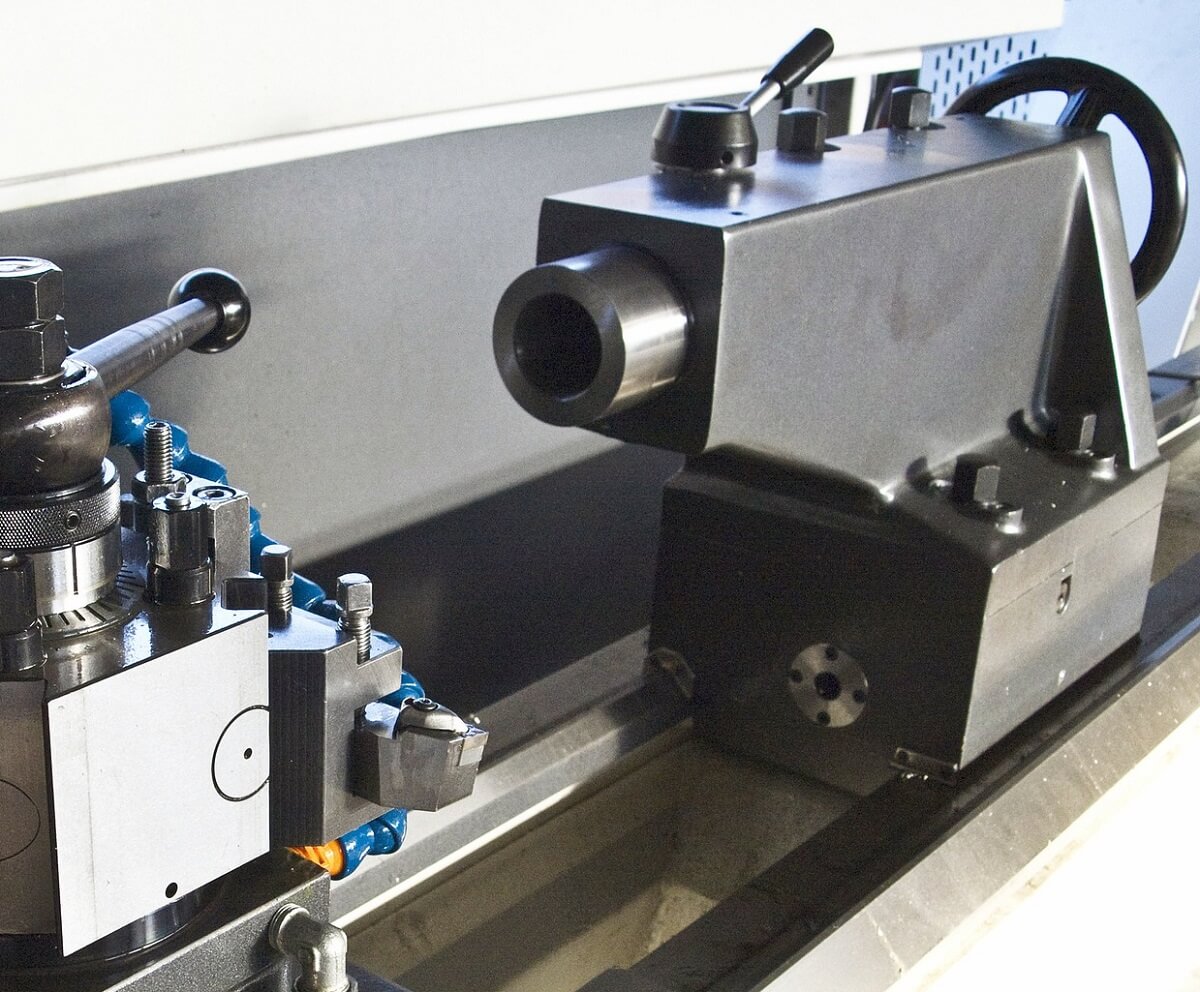

One of the primary functions of the lathe tailstock is to support workpieces during the machining process. The tailstock is located at the opposite end of the lathe bed from the headstock and consists of a quill, a housing, and various mechanisms for adjustment.

When machining long workpieces, it’s essential to have support at both ends to prevent deflection. The tailstock quill can be extended and locked into position, providing crucial support to the workpiece and minimizing deflection. This function is especially important when working with delicate or thin materials that are prone to bending or vibrating during machining.

The tailstock also allows for alignment and centering of the workpiece. By adjusting the position of the tailstock housing and quill, machinists can ensure that the workpiece is perfectly centered along the lathe’s axis. This is critical for achieving precise and accurate machining results.

Function 2: Drilling Operations

In addition to supporting workpieces, the lathe tailstock is equipped with a drill chuck or a live center, allowing for drilling operations. This function is particularly useful when you need to create holes in a workpiece with precision and accuracy.

By using a drill chuck in the tailstock, machinists can securely hold and rotate drill bits, enabling them to drill precise holes at various depths. This is especially handy when working on projects that require multiple holes at consistent intervals, such as in woodworking or metalworking.

If you’re working with cylindrical or tubular workpieces, a live center can be used in the tailstock. A live center is a rotary bearing that supports the end of the workpiece during drilling operations. This eliminates the need to use a drill chuck and allows for the drilling of deeper holes. Additionally, a live center can help maintain concentricity and reduce wobbling while drilling.

Benefits of Using the Lathe Tailstock

Using the lathe tailstock provides several benefits that contribute to the overall efficiency and accuracy of your machining projects:

- Improved stability and reduced deflection during machining

- Accurate centering of workpieces for precise machining

- Increased versatility for drilling operations

- Enhanced control and ease of use

- Saves time and effort by eliminating the need for additional support fixtures

Tips for Utilizing the Lathe Tailstock Effectively

To make the most of your lathe tailstock, consider the following tips:

- Always ensure that the tailstock is securely locked in place before starting any machining operations. This will prevent any movement or slipping during the process.

- Regularly clean and lubricate the tailstock mechanism to maintain smooth operation and prevent jamming.

- When using the tailstock for drilling operations, use the appropriate cutting tools and lubrication to enhance the accuracy and prolong the life of the tools.

- Take advantage of the tailstock’s adjustment mechanisms to fine-tune the alignment and centering of the workpiece.

- Experiment with different attachments and accessories for the tailstock, such as steady rests or collets, to expand its capabilities and accommodate a wider range of projects.

Additional Functions of the Lathe Tailstock

Aside from its primary functions, the lathe tailstock can also be utilized for various secondary purposes:

Function 3: Holding Mandrels or Arbors

The tailstock can hold mandrels or arbors for supporting and rotating cylindrical workpieces during machining. This is particularly useful when working with long and slender pieces that may flex or bend under their own weight.

Function 4: Taper Turning

By utilizing the taper attachment feature, the tailstock can assist in turning tapered workpieces. This is accomplished by adjusting the position or angle of the tailstock housing, allowing the machinist to achieve the desired taper.

Function 5: Using Tapping Attachments

Tapping attachments can be mounted on the tailstock for tapping operations, providing a convenient and efficient way to create threaded holes in workpieces.

Conclusion

The lathe tailstock is a versatile and essential tool that performs multiple functions, including supporting workpieces and enabling drilling operations. By understanding its capabilities and using it effectively, you can enhance the stability, accuracy, and versatility of your lathe projects. Remember to follow the tips provided and explore additional functions to make the most of your lathe tailstock. Happy machining!

Key Takeaways: What Two Functions Can the Lathe Tailstock Perform?

1. The lathe tailstock can provide support and stability for longer workpieces during machining.

2. It can also be used for drilling holes, as it often includes a drill chuck or a center for mounting the tool.

3. The tailstock can be adjusted for different workpiece lengths, allowing for flexibility in machining operations.

4. It helps in maintaining accuracy by ensuring proper alignment of the workpiece with the lathe’s spindle.

5. Additionally, the tailstock can be utilized for turning operations, such as taper turning or facing operations.

Frequently Asked Questions

Welcome to our Frequently Asked Questions section where we explore the various functions of a lathe tailstock. Read on to find answers to common queries about this essential tool in metalworking and woodworking.

Q1: What is the purpose of the tailstock on a lathe?

The tailstock on a lathe serves two main functions: providing support for long workpieces and facilitating drilling operations. It acts as a counterpoint to the headstock, which holds the rotating workpiece. By securing the opposite end of the workpiece, the tailstock ensures stability and reduces deflection during machining.

Additionally, the tailstock can be used to mount a drill chuck or live center, allowing precise positioning and drilling of holes. This enables the creation of accurate and evenly spaced holes along the length of the workpiece without the need for manual alignment.

Q2: How does the tailstock provide support for long workpieces?

When working with long workpieces, such as cylindrical rods or dowels, the tailstock can be extended to provide support. This is achieved using a quill, which is a retractable spindle within the tailstock. By aligning the quill with the center axis of the lathe, the tailstock provides additional support to prevent bending or sagging of the workpiece.

The quill can be locked into position, ensuring that the workpiece remains stable during machining. This support is crucial for accurate cutting, turning, or shaping of long workpieces, preventing unnecessary vibrations and ensuring consistent results.

Q3: Can the tailstock be used for taper turning?

Yes, the tailstock can be utilized for taper turning operations. By adjusting the angle of the tailstock using the handwheel or a taper attachment, the lathe can cut tapered surfaces on the workpiece. The tailstock, in conjunction with the cross-slide and compound rest, allows for precise control of the angle and depth of the taper cut.

This feature is particularly useful when creating tapered furniture legs, tool handles, or other components that require an angled shape. Taper turning on a lathe offers versatility in design, and the tailstock plays a crucial role in achieving accurate and symmetrical taper profiles.

Q4: Can the tailstock be used for threading operations?

While the primary function of the tailstock is not threading, it can contribute to thread cutting operations to a certain extent. By properly aligning and securing the workpiece between the headstock and tailstock, the lathe can accurately cut threads using a thread-cutting tool or a die. The tailstock provides necessary support and stability to ensure the workpiece remains in position during the threading process.

However, for more intricate threading operations, specialized attachments such as a thread dial indicator or a lead screw may be required. These attachments enhance the lathe’s capabilities and provide precise control over thread pitch, depth, and alignment.

Q5: What are some safety considerations when using the lathe tailstock?

When operating a lathe with a tailstock, it is essential to follow safety guidelines to prevent accidents and injuries. Always ensure that the workpiece is securely fastened and properly aligned before starting the lathe. This reduces the risk of the workpiece becoming dislodged or projectiles being launched during rotation.

Additionally, use appropriate personal protective equipment such as safety glasses and gloves to protect against flying debris and sharp tools. It is also crucial to familiarize yourself with the lathe’s functions and controls before use to avoid accidental misuse or damage.

How to Align the Tailstock On a Metal Lathe – Quick Machining Tip #18

Summary

The lathe tailstock has two important functions that help with different tasks. First, it provides support for long workpieces to prevent them from bending or wobbling. Second, it can be used to hold different tools, like drills, for making precise holes in the workpiece.

By using the lathe tailstock properly, we can make sure our workpieces are steady and secure, and we can easily create accurate holes. So, if you ever get a chance to use a lathe, don’t forget how handy the tailstock can be!