Hey there! Are you curious about what type of bandsaw can be used for friction cutting? Well, you’ve come to the right place. In this article, we’ll explore the world of bandsaws and discover which ones are perfect for friction cutting. So, let’s dive in and find out!

When it comes to bandsaws, there are various types available on the market. But not all of them are designed for friction cutting. Friction cutting requires a specific kind of bandsaw that can handle the heat and pressure generated during the process. So, which bandsaw should you look for?

The ideal bandsaw for friction cutting is one that features a high-powered motor, sturdy construction, and a sharp-toothed blade. These characteristics will ensure that the bandsaw can cut through tough materials with ease and precision. Now that you know what to look for, let’s explore some popular options that fit the bill.

Stay tuned as we reveal the best bandsaws for friction cutting and uncover the features that make them perfect for this task. Whether you’re a hobbyist or a professional, finding the right bandsaw can make a world of difference in your friction cutting projects. So, let’s get started and discover the perfect bandsaw for your needs!

What Type of Bandsaw Can Be Used for Friction Cutting?

Friction cutting is a unique method used in various industries that allows for efficient and precise cutting of materials. One of the key tools used in this process is a bandsaw. However, not all bandsaws are suitable for friction cutting. In this article, we will explore the different types of bandsaws that can be used for friction cutting, their features, benefits, and tips for choosing the right one. So, let’s dive in and explore the world of bandsaws for friction cutting.

The Horizontal Bandsaw: A Versatile Option for Friction Cutting

The horizontal bandsaw is a popular choice when it comes to friction cutting. It is a versatile machine that can handle a wide range of materials, including wood, metal, and plastics. The horizontal design allows for easy handling of larger workpieces and makes it suitable for industrial applications.

One of the key advantages of a horizontal bandsaw for friction cutting is its ability to make straight cuts with high precision. This is essential when working with materials that require accurate measurements and clean edges. Moreover, the horizontal bandsaw offers adjustable cutting speeds, allowing operators to tailor the cutting process to their specific needs. This versatility makes it suitable for a variety of friction cutting applications.

When choosing a horizontal bandsaw for friction cutting, it is important to consider the size and capacity of the machine. Different models are available with varying cutting capacities and throat depths, allowing you to choose the one that best suits your needs. Additionally, look for features such as hydraulic downfeed control, blade guides, and automatic shut-off mechanisms for enhanced safety and ease of use.

The Vertical Bandsaw: Perfect for Precision Friction Cutting

The vertical bandsaw is another type of bandsaw commonly used for friction cutting. As the name suggests, this machine features a vertical orientation, with the workpiece being fed into the blade from above. The vertical design makes it ideal for making intricate cuts and curves, making it a popular choice for woodworking and other fine-detail applications.

One of the key benefits of a vertical bandsaw for friction cutting is its ability to make accurate and intricate cuts due to the perpendicular orientation of the blade. This makes it a preferred choice for tasks such as contouring, shaping, and cutting irregular shapes. Additionally, vertical bandsaws often come equipped with a tilting table, allowing operators to make beveled cuts at various angles.

When selecting a vertical bandsaw for friction cutting, consider factors such as blade size and speed. The blade size determines the maximum width of the cut, while the speed affects the performance and efficiency of the cutting process. Additionally, look for features such as blade tension adjustment, blade guides, and a sturdy frame for stable and smooth operation.

The Importance of Blade Selection for Friction Cutting

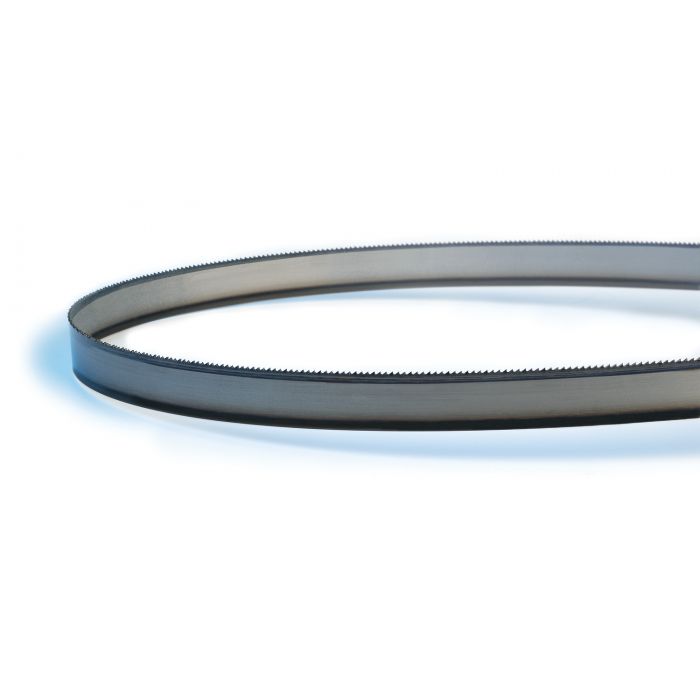

When it comes to friction cutting, the type of blade you use is crucial for achieving optimal results. The selection of the right blade depends on factors such as the material being cut, the desired finish, and the cutting speed required. Let’s explore a few popular blade options for friction cutting.

1. Bi-metal bandsaw blades: These blades are made from two different types of steel, combining the cutting performance of high-speed steel with the durability of carbon steel. They are ideal for cutting through various metals, including stainless steel and alloy steel.

2. Carbide-tipped bandsaw blades: These blades feature carbide teeth, which are incredibly hard and long-lasting. They are suitable for cutting abrasive materials such as composites, laminates, and hardwoods.

3. Diamond-tipped bandsaw blades: Designed for cutting extremely hard materials such as ceramics, glass, and stone, diamond-tipped blades offer exceptional cutting precision and durability.

Remember to choose a blade with the appropriate tooth pitch for your specific application. A finer tooth pitch provides a smoother finish, while a coarser pitch is suitable for faster cutting.

Tips for Choosing the Right Bandsaw for Friction Cutting

Selecting the right bandsaw for friction cutting can greatly impact the quality and efficiency of your cutting process. Here are a few tips to help you make the right choice:

1. Consider the materials you will be cutting: Different bandsaws are designed to handle specific materials. Determine the materials you will be cutting most frequently and choose a bandsaw that is suitable for those materials.

2. Evaluate the cutting capacity and throat depth: Consider the size of the workpieces you will be working with and ensure that the bandsaw has a cutting capacity and throat depth that can accommodate your needs.

3. Look for safety features: Bandsaws can be dangerous if not used properly, so prioritize safety features such as blade guards, emergency stop buttons, and automatic shut-off mechanisms.

4. Check for ease of use and maintenance: Choose a bandsaw that is easy to set up, operate, and maintain. Look for features such as quick-release blade tension mechanisms and easy access to blade guides for hassle-free adjustments.

5. Consider your budget: Bandsaws come in a wide range of prices, so determine your budget and find a model that offers the best combination of features and quality within your budget.

By considering these factors and understanding the different types of bandsaws available for friction cutting, you can make an informed decision and choose the right bandsaw that will meet your specific needs.

In conclusion, selecting the appropriate bandsaw for friction cutting is crucial for achieving precise and efficient cuts. The horizontal bandsaw offers versatility and straight cutting capabilities, while the vertical bandsaw is ideal for intricate and curved cuts. Remember to choose the right blade for your application and consider factors such as materials, cutting capacity, safety features, ease of use, and budget when choosing a bandsaw for friction cutting. With the right bandsaw in hand, you can enhance the quality and productivity of your friction cutting processes.

Key Takeaways: What Type of Bandsaw Can Be Used for Friction Cutting?

– A horizontal bandsaw is commonly used for friction cutting.

– The bandsaw blade should have a smooth and continuous edge.

– The bandsaw should have variable speed control for optimal cutting.

– It is important to choose a bandsaw with a sturdy frame for stability.

– Look for a bandsaw with a reliable tensioning system to ensure proper blade tension.

Frequently Asked Questions

Welcome to our FAQ section on the different types of bandsaws used for friction cutting. Below, you will find answers to commonly asked questions that will help you understand the various options available and make an informed decision for your cutting needs.

What are the different types of bandsaws used for friction cutting?

There are several types of bandsaws that can be used for friction cutting, including horizontal bandsaws, vertical bandsaws, and dual column bandsaws. Each type has its own set of advantages and is suitable for specific applications.

Horizontal bandsaws are ideal for cutting larger workpieces in a straight line. They provide excellent stability and precision, making them perfect for heavy-duty cutting tasks. Vertical bandsaws, on the other hand, are designed for cutting curves, irregular shapes, and intricate patterns. They allow for greater flexibility and are commonly used in woodworking and metalworking shops. Dual column bandsaws combine the benefits of both horizontal and vertical bandsaws, providing the versatility to cut both straight lines and curves with ease.

What factors should I consider when choosing a bandsaw for friction cutting?

When selecting a bandsaw for friction cutting, there are a few key factors to consider. The first is the size and capacity of the bandsaw. Make sure it can accommodate your workpiece size and cutting requirements.

The second factor is the power and speed of the bandsaw. Ensure that the bandsaw has enough power to cut through your materials effectively, and that it offers adjustable speed settings to handle different types of cuts.

Additionally, consider the durability and quality of the bandsaw. Look for a well-built machine that is made from sturdy materials and has a reliable reputation. Finally, take into account your budget and choose a bandsaw that offers the best value for your investment.

Can a portable bandsaw be used for friction cutting?

Yes, a portable bandsaw can be used for friction cutting, but there are some limitations to consider. Portable bandsaws are designed for on-the-go cutting tasks, and they offer the advantage of being lightweight and easy to transport. However, they may not have the same cutting capacity and power as larger stationary bandsaws.

If you are working with smaller workpieces and require mobility, a portable bandsaw can be a suitable choice for friction cutting. However, for heavy-duty cutting tasks or larger workpieces, it is recommended to use a stationary bandsaw with greater power and capacity.

What are the benefits of using a bandsaw for friction cutting?

Using a bandsaw for friction cutting offers several benefits. First and foremost, bandsaws provide precise and accurate cuts, allowing you to achieve clean and smooth edges. They are also versatile and can be used to cut a wide range of materials such as wood, metal, plastic, and more.

Bandsaws are known for their efficiency and speed, making them a time-saving tool for various cutting projects. They also offer the advantage of being relatively safe to use, as most modern bandsaws are equipped with safety features to prevent accidents.

Do I need any special training to use a bandsaw for friction cutting?

While using a bandsaw for friction cutting does require some skill and knowledge, it is not overly complicated. It is recommended to familiarize yourself with the operating manual provided by the manufacturer, which will outline important safety instructions and guide you through the setup and operation process.

Additionally, it is advisable to practice on scrap materials before working on your actual project. This will help you get comfortable with the machine and improve your cutting technique. If you have any specific concerns or questions, it is always a good idea to consult with an experienced professional or attend a training course to gain further expertise.

Summary

Cutting things with a bandsaw can be tricky. There are different types of bandsaws for different materials. Friction cutting needs a metal-cutting bandsaw because it’s fast and can handle the heat. Wood-cutting bandsaws won’t work because they are not strong enough. Make sure to choose the right bandsaw for the type of cutting you want to do. Safety first!