What was the boring machine? If you’ve ever wondered about the gigantic machines used in construction projects, you’ve come to the right place! In this article, we’ll delve into the fascinating world of boring machines and their role in shaping the world we live in. So buckle up and get ready for an exciting journey underground!

Picture this: you’re standing at the entrance of a tunnel, and as you step inside, you notice the dimly lit surroundings. The sound of drilling fills the air as the massive boring machine, also known as a tunnel boring machine (TBM), begins its mission. Its purpose? To dig tunnels with exceptional precision and efficiency, like a mole burrowing through the ground!

So, why are these machines called “boring” machines? It’s not because they’re dull or uninteresting – quite the opposite! The term “boring” refers to the process of creating tunnels or holes by drilling through various materials, such as soil, rocks, and even mountains. These incredible machines make the seemingly impossible possible, allowing us to construct underground transportation systems, mines, and even underground water pipes.

Join us as we unearth the inner workings and incredible feats of the boring machine. From their history, engineering marvels, to the impact they have on our modern infrastructure, we’ll explore it all. So, let’s dig deep and discover the fascinating world of boring machines together!

Exploring the Boring Machine: Unraveling Its Marvels Underground

Welcome to the world of the boring machine, a fascinating invention that has revolutionized underground construction. In this article, we will delve into the depths of what a boring machine is, how it works, its various types, applications, and the benefits it offers. Join us as we uncover the mysteries of these incredible machines that have reshaped the way we build underground structures.

How Does a Boring Machine Work?

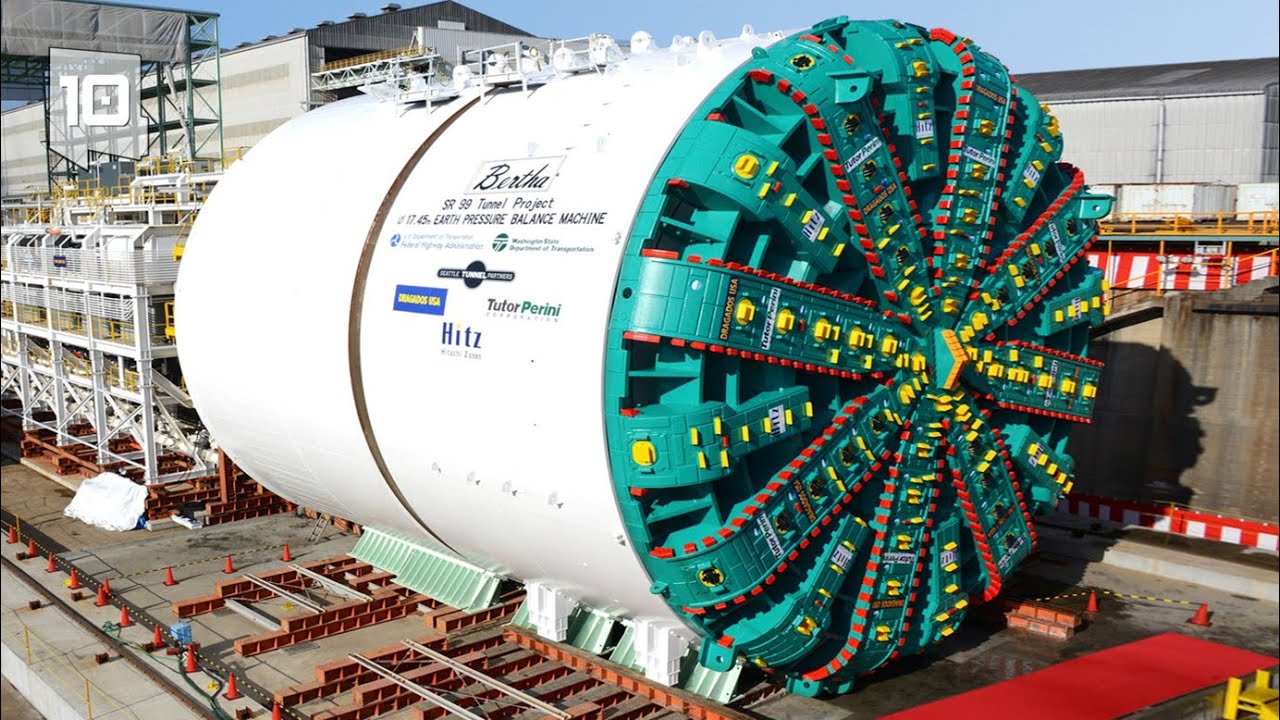

When it comes to excavating tunnels or creating underground passages, the boring machine takes center stage. Also known as a tunnel boring machine (TBM), it is a massive piece of equipment designed to excavate rock and soil with precision and efficiency. The boring machine consists of several crucial components, including a rotating cutting head, conveyor system, and shield that provides stability during the tunneling process.

As the boring machine advances, the cutting head grinds away the rock or soil, creating small fragments that are transported through the conveyor system to the surface. This continuous process eliminates the need for manual excavation and significantly speeds up construction timelines. Additionally, the shield surrounding the cutting head protects workers and stabilizes the tunnel face, ensuring safety and structural integrity.

The Three Main Types of Boring Machines

There are three major types of boring machines: the slurry shield or earth pressure balance machine, the rock tunneling machine, and the microtunneling machine. Each type is designed for specific geological conditions and project requirements.

1. Slurry Shield or Earth Pressure Balance Machine

The slurry shield or earth pressure balance machine is commonly used in soft ground conditions with high water content. This type of boring machine applies counter pressure to the excavation face, preventing cave-ins. It also utilizes a slurry system that supports the tunnel walls and transports excavated material to the surface.

2. Rock Tunneling Machine

As the name suggests, the rock tunneling machine is specifically designed for hard rock formations. Equipped with robust cutting tools and advanced drilling mechanisms, this type of machine can bore through solid rock with ease. It is ideal for tunnels and underground spaces that demand exceptional strength and stability.

3. Microtunneling Machine

The microtunneling machine is a smaller version of the traditional boring machine, used for constructing smaller tunnels or pipelines. It is commonly employed in urban areas where space is limited and precision is crucial. This compact machine is capable of navigating obstacles and creating tunnels with accurate dimensions.

Applications of Boring Machines

Boring machines have diverse applications in numerous industries, ranging from transportation and infrastructure development to mining and environmental engineering. Let’s explore some of the key areas where these machines excel:

Underground Transportation:

Boring machines play a vital role in the construction of tunnels for metro systems, railways, and roadways, enabling efficient and safe transport infrastructure. They ensure smooth excavation processes and minimize disruptions to existing transport networks.

Utility Installations:

Boring machines are used to create tunnels for installing utility pipelines, such as water, sewer, and communication lines. These machines offer precise control and accuracy, minimizing the impact on surrounding infrastructure and reducing the time required for construction.

Mining and Resource Extraction:

In the mining industry, boring machines are employed for tunneling and shaft excavation, allowing for the extraction of valuable resources from deep within the earth. These machines improve mining efficiency and safety by providing a controlled and predictable excavation method.

Environmental Engineering:

Environmental engineering projects often require the construction of underground storage facilities, reservoirs, or waste management systems. Boring machines enable the excavation of these structures with minimal disturbance to the surrounding environment.

Benefits of Boring Machines

Now that we have explored the workings and applications of boring machines, it’s essential to understand the benefits they offer. Here are some key advantages of using boring machines in construction:

- Increased Efficiency: Boring machines significantly expedite the excavation process, allowing for faster project completion compared to traditional digging methods.

- Enhanced Safety: With the shielded cutting head and automated processes, the risk of accidents and injuries is reduced, ensuring the safety of workers.

- Precision and Accuracy: Boring machines offer precise control over the excavation, resulting in tunnels with accurate dimensions and minimal deviations.

- Reduced Surface Disruption: By operating underground, boring machines minimize the disruption to the surface environment, mitigating disturbances to urban areas.

- Cost Savings: Although the initial investment for a boring machine may be high, the overall cost savings can be significant, considering the shortened construction time and increased efficiency.

The Future of Boring Machines

The advancements in technology and engineering continue to propel the development of boring machines. Future innovations aim to improve efficiency, environmental sustainability, and flexibility in tunneling operations. Some areas of focus include:

1. Automation and Artificial Intelligence:

Integrating automation and artificial intelligence will enhance the capabilities of boring machines, allowing for more precise and efficient excavation.

2. Green and Sustainable Solutions:

Efforts are being made to reduce the environmental impact of boring machines by utilizing renewable energy sources and implementing sustainable construction practices.

3. Versatility and Adaptability:

Future boring machines may be designed to adapt to a wide range of geological conditions, enabling their usage in various types of projects.

In conclusion, the boring machine has revolutionized underground construction, providing a safe, efficient, and precise method for excavating tunnels and creating underground passages. With their remarkable capabilities and countless applications, these machines continue to shape the way we build the infrastructure of the future.

Key Takeaways: What Was the Boring Machine?

- A boring machine is a powerful tool used for drilling holes in the ground or through solid materials like rock or concrete.

- It is often used in construction projects, such as building tunnels or underground pipelines, as it can dig through tough surfaces.

- The boring machine works by rotating a cutting head with sharp blades that chip away the material, while the machine moves forward.

- These machines can be massive in size and require skilled operators to control them safely and efficiently.

- Advancements in boring machine technology have made tunneling and excavation faster, more precise, and less disruptive to the surrounding environment.

Frequently Asked Questions

Welcome to our frequently asked questions section on the topic of the boring machine. Here, we’ll address common queries to help you understand what a boring machine is and what it is used for.

Q1: How does a boring machine work?

A: A boring machine is a powerful tool used in construction and mining projects to excavate and create tunnels and holes in the ground. It works by rotating a cutting head fitted with various tools, such as drill bits or augers, that break apart the soil or rock. As the cutting head rotates, the machine applies force to remove the excavated material and create the desired hole or tunnel. Some models also have advanced features like a conveyor belt to remove the debris.

The process begins by positioning the boring machine at the desired starting point of the excavation. The cutting head is then lowered into the ground, and the machine is operated to rotate the cutting tools while pushing forward. This action allows the boring machine to steadily progress and create tunnels or holes of various sizes and shapes.

Q2: What are the key applications of a boring machine?

A: Boring machines have a wide range of applications across different industries. In construction, they are used to create tunnels for underground utilities like water and sewage pipelines. Boring machines are also essential in mining operations for excavation work. They can be used to dig shafts for mining or to create tunnels for accessing underground mineral deposits.

In addition to construction and mining, boring machines also play a vital role in the field of geotechnical engineering. They are used to take soil samples or install foundation piles for buildings and infrastructure projects. Boring machines are versatile and can be adapted to perform various tasks depending on the specific requirements of the project.

Q3: What are the advantages of using a boring machine?

A: Using a boring machine offers several advantages over traditional excavation methods. One of the main benefits is the ability to create tunnels or holes without disturbing the surrounding area significantly. This is especially useful in urban areas where minimizing disruption to buildings and infrastructure is crucial. Boring machines can operate underground without causing vibrations or noise pollution, making them ideal for sensitive environments.

Another advantage is the precision and control provided by boring machines. They can accurately dig tunnels or bore holes with specific dimensions and alignments, ensuring the desired outcome of the project. Boring machines also reduce the need for manual labor, as they can operate autonomously or with minimal human intervention, enhancing productivity and efficiency.

Q4: Are there different types of boring machines?

A: Yes, there are various types of boring machines available, each designed for specific purposes. One common type is the tunnel boring machine (TBM), which is used for large-scale tunneling projects. These machines are capable of excavating tunnels of considerable length with diameters ranging from a few feet to several feet. Another type is the directional boring machine, which is used to create holes or tunnels that have a specific direction or angle, such as for installing utility lines underground.

There are also portable or handheld boring machines that are smaller and more maneuverable. These machines are often used for smaller scale projects or in locations where larger machines may not be feasible. The type of boring machine chosen for a particular project depends on factors such as the scale of the excavation, the type of material being excavated, and the specific requirements of the project.

Q5: What are the safety considerations when using a boring machine?

A: Safety is paramount when operating a boring machine. It is crucial to ensure that operators are properly trained and follow all safety protocols. Protective gear, such as helmets, safety glasses, and ear protection, should be worn at all times. Adequate ventilation and proper lighting are important to maintain a safe working environment, especially in confined spaces.

Regular maintenance and inspection of the machine are essential to identify any potential issues or hazards. Boring machines should be operated within their specified load capacities and in accordance with manufacturer guidelines. It is also important to be aware of potential underground obstacles or hazards, such as utilities or unstable ground, to minimize the risk of accidents.

Tunnel Boring Machine for Children | Truck Tunes for Kids | Twenty Trucks Channel | Big Bertha

Summary

A boring machine is a big tool that helps dig tunnels and holes underground. It can go through different kinds of materials like rocks and soil. The machine has a rotating head with sharp cutting tools that break up the ground as it moves forward. The pieces of broken ground are then transported out of the tunnel by the machine’s conveyor belts. Boring machines are used for many important projects, like building subway tunnels and mining for resources deep within the Earth. They are efficient and save time compared to traditional methods of digging, making them an essential tool in construction and exploration.