Are you stepping into the fascinating world of woodworking and wondering what woodworking clamps you need? Look no further! In this guide, we’ll explore the essential clamps that every woodworker should have in their toolbox.

Woodworking clamps are like the unsung heroes of the workshop. They may not get all the glory, but they play a vital role in ensuring the success of your projects. Whether you’re joining pieces of wood together, securing them for sanding or gluing, or holding them in place while waiting for the glue to dry, clamps are your trusty companions.

But with so many types and sizes available, it can be overwhelming to figure out which ones you really need. That’s where we come in! In this article, we’ll break it down for you, providing clear explanations and examples along the way. So let’s dive in and discover the clamps that will take your woodworking skills to the next level!

1. F-clamps: Ideal for holding large pieces together.

2. Bar clamps: Perfect for applying pressure across a wide surface area.

3. C-clamps: Great for securing materials to your workbench.

4. Spring clamps: Convenient for light-duty tasks and holding small pieces.

5. Pipe clamps: Excellent for gluing up long, narrow pieces.

These clamps cover a wide range of woodworking needs and will ensure you have the right tools for any project.

Everything You Need to Know About Woodworking Clamps

Woodworking clamps are essential tools for any woodworker. They play a crucial role in holding pieces of wood together securely during various woodworking projects. But with the wide array of clamps available in the market, it can be overwhelming to determine which ones are necessary for your specific needs. In this comprehensive guide, we will walk you through the different types of woodworking clamps, their uses, and factors to consider when choosing the right clamps for your projects.

The Basics: Understanding Different Types of Woodworking Clamps

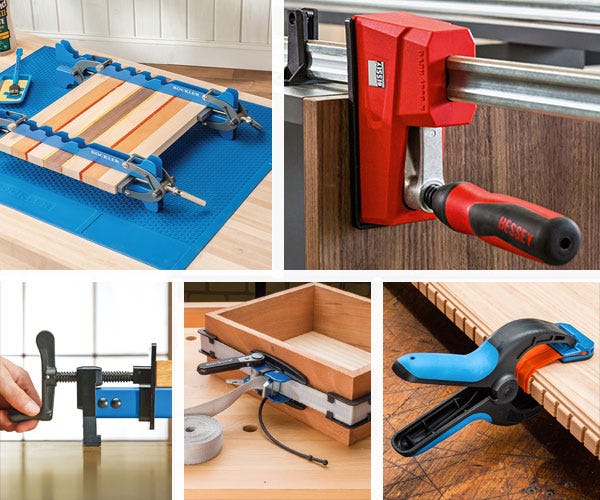

There are various types of clamps available in the market, each with its own unique features and purposes. Here are some of the most common types of woodworking clamps:

1. C-Clamps: C-shaped clamps that are versatile and can be used for a wide range of woodworking projects. They are often used for securing wood to a workbench or holding pieces of wood together.

2. Bar Clamps: These clamps consist of a long metal bar and a sliding jaw that can be adjusted to accommodate different widths. They are ideal for gluing large pieces of wood or assembling larger projects.

3. Pipe Clamps: As the name suggests, pipe clamps use a pipe as the main clamp mechanism. They are great for high-pressure clamping and can be used for larger projects.

4. F-Clamps: F-clamps are similar to C-clamps but have a wider opening capacity and a bar that can slide up and down for easy adjustments. They are often used for holding pieces of wood together during glue-ups.

5. Parallel Clamps: These clamps have jaws that remain parallel throughout their range, providing even pressure distribution. They are ideal for gluing large panels or tabletops.

6. Spring Clamps: Spring clamps are small, lightweight clamps that are quick and easy to use. They are often used for smaller projects or for temporarily holding pieces of wood in place.

7. Quick-Release Clamps: These clamps have a quick-release mechanism that allows for fast and easy setup and adjustments. They are convenient for repetitive tasks or when time is of the essence.

Each type of clamp has its own strengths and limitations. Understanding these differences will help you choose the right clamps for your woodworking projects.

Choosing the Right Clamps for Your Projects

When selecting woodworking clamps, there are several factors to consider:

1. Project Size: The size of your project will determine the length and capacity of the clamps you need. For larger projects, longer bar clamps or pipe clamps may be required. Smaller projects may only need smaller clamps or even spring clamps.

2. Clamp Strength: Consider the amount of force you will need to apply. Some projects require strong clamping pressure, while others may only need light pressure. Choose clamps with the appropriate strength for your specific needs.

3. Jaw Size and Shape: The shape and size of the clamp jaws should match the contour of the workpiece. For irregularly shaped objects, consider clamps with adjustable jaws or specialty clamps designed for specific shapes.

4. Durability: Look for clamps made from high-quality materials that can withstand the rigors of woodworking. Stainless steel or heavy-duty aluminum clamps are commonly preferred due to their durability.

5. Ease of Use: Consider the ease of setup, adjustments, and release when choosing clamps. Quick-release clamps or clamps with ergonomic handles can make your woodworking experience more efficient and enjoyable.

6. Budget: Woodworking clamps come in a wide range of prices. Consider your budget and select clamps that offer good value for money. Remember that investing in high-quality clamps will save you money in the long run.

By carefully considering these factors, you can pick the right clamps for your woodworking projects and achieve the best results.

Benefits of Using Woodworking Clamps

Using the right woodworking clamps can offer numerous benefits, such as:

1. Ensuring Precision: Clamps help hold pieces of wood securely in place, allowing for more accurate cuts and joinery. This precision is crucial, especially when it comes to creating intricate details or fitting joints seamlessly.

2. Increasing Safety: Woodworking can involve working with heavy and sharp tools. Clamps help stabilize workpieces, reducing the risk of accidents caused by slipping or movement while cutting or shaping wood.

3. Enhancing Glue Bonding: Proper clamping during glue-ups ensures strong and durable bonds between wood pieces. The even pressure provided by clamps helps eliminate gaps and air bubbles, resulting in better adhesion.

4. Streamlining Workflow: Using clamps frees up your hands, making it easier to focus on other tasks such as measuring, marking, or using power tools. This improved workflow can save valuable time and increase productivity.

5. Versatility: With different types of clamps available, you can adapt to various woodworking situations and materials. Whether you’re working with solid wood, plywood, or other materials, there is a clamp suitable for the job.

Choosing the right woodworking clamps and utilizing them properly can greatly enhance your woodworking experience and lead to better outcomes in your projects. So, take the time to explore the options and invest in quality clamps that will serve you well for years to come.

Tips for Proper Use and Maintenance of Woodworking Clamps

To ensure the longevity and optimal performance of your woodworking clamps, consider the following tips:

1. Keep your clamps clean: Regularly remove any debris or sawdust that may accumulate on your clamps. This will prevent any build-up that could affect their functionality.

2. Store them properly: Make sure to store your clamps in a dry area, away from moisture and extreme temperatures. This will prevent any rust or damage that could occur.

3. Avoid over-tightening: While it may be tempting to crank the clamp handle as tight as possible, over-tightening can cause damage to the clamp or the workpiece. Apply enough pressure to secure the pieces without straining the clamp.

4. Use protective pads: Placing protective pads or scraps of wood between the clamp jaws and the workpiece can prevent damage or marring of the wood surface when clamping.

5. Inspect for damage: Regularly inspect your clamps for any signs of wear or damage. Replace or repair any broken or faulty clamps to maintain their effectiveness and safety.

6. Lubricate moving parts: Apply a light coat of lubricant, such as silicone spray or machine oil, to the moving parts of your clamps. This will ensure smooth operation and prevent rust.

7. Avoid excessive force: While clamps are designed to exert pressure, avoid applying excessive force that could cause damage. Familiarize yourself with the clamps’ maximum recommended pressure and use accordingly.

By following these tips, you can prolong the lifespan of your woodworking clamps and ensure their optimal performance throughout your woodworking journey.

Conclusion:

Woodworking clamps are indispensable tools for any woodworker. They provide stability, precision, and versatility in various woodworking projects. By understanding the different types of clamps available, choosing the right ones for your needs, and using them properly, you can elevate your woodworking skills and achieve exceptional results. Remember to prioritize quality, durability, and safety when selecting clamps, and don’t forget to maintain them to ensure their longevity. So, make sure to equip yourself with the necessary clamps and embark on your woodworking journey with confidence. Happy woodworking!

Key Takeaways: What Woodworking Clamps Do I Need?

- Bar clamps are versatile and great for larger projects.

- Spring clamps are handy for quick and easy clamping.

- C-clamps are sturdy and useful for heavy-duty applications.

- Pipe clamps provide long lengths for larger workpieces.

- Bench vises are essential for securing workpieces on a workbench.

Frequently Asked Questions

Woodworking clamps are essential tools that help secure and stabilize wood pieces during various woodworking projects. Whether you’re a beginner or an experienced woodworker, choosing the right type of clamp is crucial for achieving accurate and precise results. Here are some common questions about woodworking clamps and the answers to help you determine which ones you need for your projects.

1. How do woodworking clamps work?

Woodworking clamps work by applying pressure to hold wood pieces together firmly during the gluing, clamping, or assembly process. They help ensure the pieces stay in place while the adhesive dries or the wood components are properly aligned and attached.

Typically, clamps have adjustable jaws or faces that can be tightened or loosened using screws or handles. This allows you to control the amount of pressure exerted on the wood. By securing the wood snugly, clamps prevent movement, maintain alignment, and create strong bonds or joints.

2. What are the different types of woodworking clamps?

There are various types of woodworking clamps available, each designed for specific purposes. Some common types include:

– Bar Clamps: These clamps consist of a long metal or wooden bar with adjustable jaw components on each end. They are versatile and great for general woodworking projects.

– C-Clamps: These clamps are shaped like the letter “C” and are commonly used for smaller woodworking tasks. They are easy to adjust and provide a secure grip on the workpiece.

– Pipe Clamps: Pipe clamps utilize a length of pipe fitted with a sliding jaw mechanism. They are particularly useful for larger glue-ups or when longer clamps are needed.

– Parallel Clamps: These clamps have jaws that remain parallel to each other while exerting pressure, ensuring even distribution and preventing misalignment.

– Quick-Release Clamps: As the name suggests, these clamps allow for quick and easy release of the grip, making them ideal for repetitive tasks or when time is a concern.

3. How many woodworking clamps do I need?

The number of clamps you need largely depends on the types of woodworking projects you undertake. It’s recommended to have a variety of clamps in different sizes and types to cater to different situations.

As a general rule of thumb, start with at least four to six clamps of varying lengths to cover most basic woodworking tasks. This allows you to clamp multiple pieces simultaneously, secure larger projects, or apply pressure evenly across different joints.

4. What factors should I consider when choosing woodworking clamps?

When choosing woodworking clamps, consider the following factors:

– Project Type: Different projects may require specific types of clamps, such as edge clamps for panel glue-ups or pipe clamps for tabletops.

– Size and Length: Select clamps that can accommodate the size and width of your workpieces. Ensure the clamp’s length is sufficient to cover the area you want to secure.

– Pressure Capacity: Consider the maximum pressure the clamp can exert. Higher pressure capacity allows for stronger bonds and secure clamping.

– Durability: Choose clamps made from sturdy materials that can withstand frequent use without losing their grip or functionality. Look for clamps with sturdy handles and mechanisms.

– Budget: Set a budget for your clamps and balance quality and affordability. It’s often better to invest in a few high-quality clamps than to buy numerous low-quality ones.

5. Can I mix different types of clamps in my woodworking projects?

Absolutely! Mixing different types of clamps in your woodworking projects can provide versatility and better results. By using the right clamps for specific tasks, you can achieve more precise alignment, evenly distributed pressure, and secure joints.

For instance, you can combine bar clamps and pipe clamps to secure large glued-up panels, or use parallel clamps alongside C-clamps for securing box joints. The key is to select clamps that complement each other and fulfill the specific needs of your project. Experimentation and finding the right combination for your woodworking needs will help you achieve professional-looking results.

How many clamps do you REALLY need? Woodworking basics.

Summary

Woodworking clamps are essential tools that help hold pieces of wood together securely. When choosing the right clamps for your projects, consider the type of woodworking you plan to do and the size of your workpieces. For general woodworking, having a few different types of clamps, such as bar clamps, pipe clamps, and spring clamps, can cover a wide range of needs. If you’ll be working with small pieces or need precision, consider getting some smaller clamps like C-clamps or hand screw clamps. Remember to choose clamps that are sturdy, easy to adjust, and suitable for the thickness of your material. As your skills and projects progress, you can add more clamps to your collection.

In addition, it’s important to use clamps correctly by applying even pressure and avoiding over-tightening. This will prevent damage to your workpieces and ensure a strong bond. By investing in the right clamps and using them properly, you’ll have the necessary tools to tackle various woodworking projects and achieve professional-looking results. Happy woodworking!