When is a lathe dog used? Well, let me tell you, my budding engineer! A lathe dog is a handy tool that plays a crucial role in turning operations on a lathe machine. You might be wondering, what on earth is a lathe machine? Don’t worry, I’ve got you covered.

Imagine a lathe machine as a magical tool that can shape and cut metal, wood, or other materials into different shapes with precision. A lathe dog, on the other hand, is like the trusty sidekick that holds the workpiece securely in place as it rotates on the lathe.

So, why is this important? Well, using a lathe dog ensures that the workpiece remains fixed, allowing the cutting tool to perform its magic without any wobbles or slips. This gives you super-smooth and accurate cuts, resulting in beautifully crafted objects. Fascinating, isn’t it?

Now that you know a bit about lathe dogs and how they contribute to the mesmerizing world of lathes, let’s take a deeper dive into when and why these helpful tools are used in various projects. Get ready to embark on a thrilling journey of turning operations and the wonders of the lathe dog!

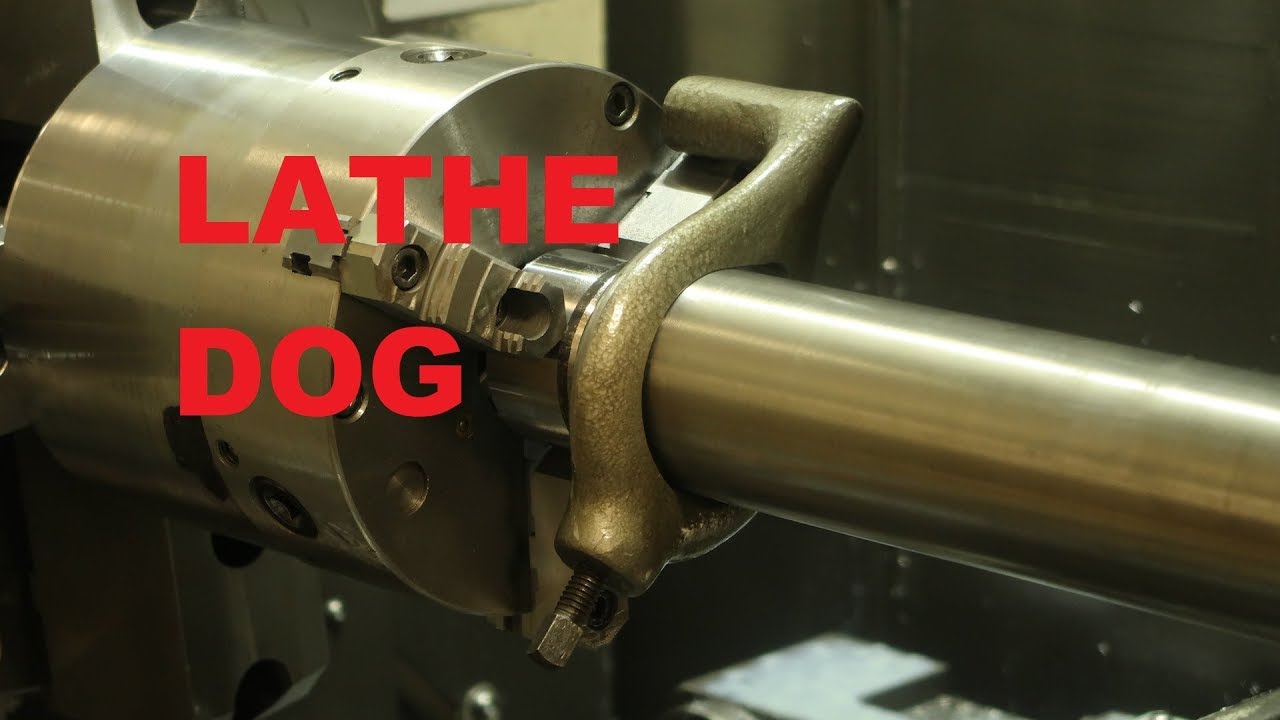

A lathe dog is a device used in metalworking to hold and rotate a workpiece on a lathe. It is commonly used when turning long, thin workpieces such as bars or shafts. The lathe dog ensures stability and prevents vibration during the machining process. By securely clamping onto the workpiece, it allows for precise cutting and shaping. Whether you’re a professional machinist or an avid hobbyist, knowing when to use a lathe dog can greatly improve your turning operations.

When Lathe Dog is Used: A Comprehensive Guide

In the world of machining and metalworking, the lathe dog is an essential tool that enables precise and efficient turning operations on a lathe machine. Whether you’re a professional machinist or a passionate DIY enthusiast, understanding when and how to use a lathe dog can greatly enhance your ability to create accurate and high-quality workpieces. In this article, we will delve into the details of when a lathe dog is used, its various applications, and the benefits it offers. So, let’s dive in and explore the fascinating world of lathe dogs!

Applications of Lathe Dog

When it comes to turning operations on a lathe machine, the lathe dog is a versatile tool that finds its applications in a wide range of scenarios. Here are three key applications where the use of a lathe dog is crucial:

1. Securing the Workpiece

One of the primary functions of a lathe dog is to secure the workpiece firmly to the lathe spindle or faceplate. By attaching the lathe dog to the workpiece, machinists can ensure that it rotates synchronously with the spindle, allowing for precise turning operations. The dog’s teeth grip into the workpiece, preventing any slippage or movement during the machining process. This enables the machinist to work confidently, knowing that the workpiece is securely held in place.

In addition to stability, using a lathe dog for workpiece securing also offers the advantage of flexibility. Unlike alternative methods such as collets or chucks, a lathe dog enables the machinist to work with irregularly shaped or non-cylindrical workpieces. This makes it a versatile solution for a wide variety of turning projects.

2. Achieving Balanced Rotation

Another crucial application of a lathe dog is to ensure balanced rotation of the workpiece. When working with long or unevenly distributed workpieces, such as shafts or bars, it’s essential to maintain symmetrical rotation to achieve accurate and smooth results. The lathe dog plays a vital role in achieving this balance.

By attaching the lathe dog to the workpiece at a strategic location, the machinist can counteract any irregular weight distribution and minimize vibrations. This promotes a more stable turning operation, preventing chatter marks or other surface defects from appearing on the workpiece. Through the use of a lathe dog, machinists can achieve high precision and surface finish quality, even with challenging workpieces.

3. Facilitating Threading Operations

Threading is a critical operation in metalworking, and the lathe dog proves invaluable when it comes to creating threaded components. When cutting threads on a lathe, the workpiece needs to rotate at a precise speed while interacting with the threading tool. The lathe dog ensures that the workpiece rotates synchronously and assists in maintaining the required thread pitch or lead.

To facilitate threading operations, machinists often use a combination of a lathe dog and a carriage stop. The lathe dog secures the workpiece, while the carriage stop limits the axial movement and helps maintain precise thread depth. This combination of tools allows for efficient and accurate threading, whether you’re creating external or internal threads.

Additional Uses and Tips for Lathe Dog

The applications mentioned above are just the tip of the iceberg when it comes to the versatility of a lathe dog. Here are a few more ways in which machinists utilize this handy tool:

1. Turning Tapers

When working on tapers, the lathe dog can be strategically positioned to ensure consistent angular movement of the workpiece. This allows for precise taper turning, where the machinist achieves a gradual increase or decrease in diameter along the length of the workpiece.

2. Cutting Keyways

Keyways are grooves or slots that accommodate keys in rotating components, such as gears or pulleys. Using a lathe dog in combination with a specialized milling attachment, machinists can create precise keyways by coordinating the movement of the lathe dog and the cutting tool.

3. External Turning on Faceplate

While lathe chucks are commonly used for external turning operations, a lathe dog can also be employed when working with large or irregularly shaped workpieces. By attaching the dog to the workpiece, machinists can securely rotate it on the faceplate, providing more flexibility and stability compared to other methods.

When working with a lathe dog, it’s essential to keep a few tips in mind to ensure optimal results:

- Always use a properly fitted lathe dog that matches the size and shape of the workpiece.

- Ensure that the jaws of the lathe dog are clean and free from any debris that could affect the grip.

- Choose the appropriate attachment method (such as a set screw or clamp) depending on the design of the lathe dog and the workpiece.

- Regularly inspect the lathe dog for any signs of wear or damage, as a malfunctioning dog can compromise the safety and quality of your work.

- Practice proper safety precautions when using a lathe dog, such as wearing protective gloves and eyewear.

In Summary

The lathe dog is an indispensable tool in the world of machining, offering a myriad of applications and benefits. From securing workpieces to achieving balanced rotation and facilitating threading operations, the lathe dog provides machinists with the tools they need to create accurate and high-quality work. By understanding when and how to use a lathe dog, you can take your turning projects to new heights and unleash your creativity in the workshop.

Key Takeaways: When Lathe Dog is Used?

- A lathe dog is a device used in metalworking to hold and rotate a workpiece on a lathe.

- It grips the workpiece securely, allowing it to be machined with precision.

- Lathe dogs are commonly used when turning long, slender workpieces that would otherwise flex or vibrate excessively.

- They help to ensure accurate cutting and prevent damage to the workpiece.

- Lathe dogs come in various shapes and sizes to accommodate different types of workpieces.

Frequently Asked Questions

Below are answers to some common questions about when a lathe dog is used.

What is a lathe dog and what is its purpose?

A lathe dog, also known as a lathe carrier or lathe driver, is a tool used in metalworking and woodworking. Its purpose is to securely hold a workpiece, such as a round or cylindrical object, in place while it is being turned on a lathe. The lathe dog consists of two parts: a body that clamps onto the workpiece and a curved arm that extends from the body.

When attached to the workpiece, the lathe dog prevents it from rotating freely, allowing the lathe’s drive mechanism to rotate the workpiece. This allows for precise shaping, cutting, and finishing operations to be performed on the workpiece using various lathe tools. The lathe dog plays a crucial role in ensuring stability and control during the turning process.

When should I use a lathe dog?

A lathe dog is typically used when working with long, slender workpieces that cannot be effectively held in a chuck or a faceplate alone. Examples of such workpieces include long rods, shafts, pipes, or any cylindrical objects with a significant length-to-diameter ratio.

When using a lathe dog, the workpiece is inserted into the lathe’s chuck or mounted on a faceplate, and then the lathe dog is attached to the workpiece. The lathe dog provides additional support, stability, and rotational control, preventing the workpiece from vibrating or slipping during the turning process. This ensures precise and accurate machining operations.

Are there different types of lathe dogs?

Yes, there are different types of lathe dogs available to suit various workpiece shapes, sizes, and materials. The most common types include the straight lathe dog, bent tail lathe dog, and spring lathe dog.

The straight lathe dog is the simplest type, with a straight body and arm. It is ideal for round workpieces with a consistent diameter. The bent tail lathe dog has a curved arm that offers more flexibility for accommodating workpieces with irregular shapes, varying diameters, or projections. The spring lathe dog features a compressible spring in its body, providing a self-adjusting grip on the workpiece.

What are the advantages of using a lathe dog?

Using a lathe dog provides several advantages in the turning process. Firstly, it allows the operator to work with long and slender workpieces that cannot be securely held in a chuck or faceplate alone. The lathe dog ensures stability and control, minimizing vibration and producing more precise results.

Secondly, a lathe dog allows for the efficient turning of long workpieces. By gripping the workpiece closer to the cutting tool, it reduces the risk of flexing or bending, resulting in better accuracy during the machining process. Additionally, the lathe dog enables the turning of stepped or irregularly shaped workpieces that may not fit properly in other holding devices.

Are there any precautions to take when using a lathe dog?

When using a lathe dog, it is important to ensure that it is securely attached to the workpiece. Proper clamping is essential to prevent the lathe dog from slipping or disengaging during the machining process, which can lead to damage to the workpiece or potential injury to the operator.

It is also recommended to select the correct type of lathe dog based on the workpiece’s shape, size, and material, as this will result in a more reliable grip and better overall performance. Regular inspection and maintenance of the lathe dog are important to identify any signs of wear or damage, ensuring safe and efficient operation.

How to machine between center’s using lathe dog

Summary

When using a lathe dog, it helps to secure the workpiece firmly and rotate it smoothly. This device is especially useful when turning irregularly shaped pieces or when the workpiece needs to be held securely in place. By attaching the lathe dog to the workpiece and engaging it with the lathe’s driving mechanism, you can ensure a more controlled and precise turning process.

Using a lathe dog requires proper positioning and alignment with the workpiece to prevent any unwanted movement or accidents. It is important to adjust the lathe dog’s position based on the size and shape of the workpiece, ensuring it is securely clamped without causing any damage. By understanding how and when to use a lathe dog, you can enhance your turning capabilities and achieve better results in your woodworking projects.