When operating a lathe, have you ever wondered what you can use when working with oversized stock? Well, fear not! In this article, we’ll explore some handy tools and techniques that can help you tackle this challenge with ease.

Working with oversized stock on a lathe can be tricky, but with the right tools, you’ll be able to turn those large pieces into magnificent creations. So, whether you’re a seasoned lathe operator or just starting out, read on to discover some practical solutions for handling oversized stock.

From steady rests to custom-made tool holders, we’ll discuss a range of options that can provide stability and precision when working with larger pieces. So, let’s dive in and explore the exciting world of operating a lathe with oversized stock!

When Operating a Lathe: What Can You Use When Working with Oversized Stock?

Operating a lathe can be a rewarding experience, allowing you to shape and create various pieces from metal, wood, or other materials. However, when working with oversized stock, you may face some challenges. In this article, we will explore the different tools and techniques that you can use to handle oversized stock effectively on a lathe. Whether you are a beginner or an experienced lathe operator, these tips will help you achieve precise and successful results.

Using Steady Rests for Stability

When working with oversized stock on a lathe, one of the primary concerns is maintaining stability and preventing vibration. This is where steady rests come in. Steady rests are accessories specifically designed to support long and heavy stock, keeping it steady during the turning process. They consist of three adjustable jaws that can be positioned around the stock, providing additional support and reducing any movement or chatter.

To use a steady rest, start by adjusting the jaws to fit snugly around the stock without applying excessive pressure. Position the steady rest along the length of the stock, making sure it is aligned correctly with the cutting tool. By using steady rests, you can ensure that the oversized stock remains stable and secure, allowing you to achieve precise and smooth cuts.

Additionally, using a steady rest can prevent any deflection or bending of the stock due to its weight or length, resulting in a more accurate and symmetrical finished piece.

Chucking Oversized Stock Using a Faceplate

Another method for working with oversized stock on a lathe is by chucking it using a faceplate. A faceplate is a circular metal plate with multiple mounting holes that attach to the lathe’s spindle. It provides a solid and secure connection between the lathe and the stock, allowing you to turn the oversized piece with confidence.

When using a faceplate, start by selecting the appropriate size that matches the dimensions of your stock. Attach the faceplate to the spindle, ensuring it is firmly in place. Next, mark the center point on both ends of the oversized stock and drill a hole at each marked point. Then, insert screws through the faceplate mounting holes into the holes on the stock, securing it tightly to the faceplate.

By chucking the oversized stock using a faceplate, you can work on larger pieces that may not fit within the limits of a regular chuck. This method provides a reliable and stable connection, allowing you to safely turn the stock and unleash your creativity.

The Importance of Tool Rests

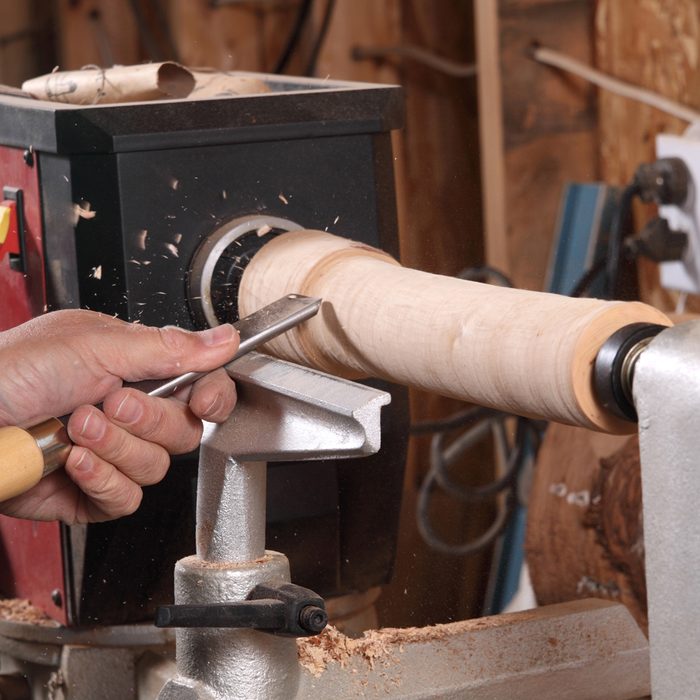

Tool rests are essential components when operating a lathe, and they play a crucial role when working with oversized stock. A tool rest is a support mechanism that holds the cutting tool in a fixed position relative to the rotating stock, allowing precise cuts and shaping. When working with oversized stock, the tool rest becomes even more critical in maintaining control and stability.

When setting up the tool rest for oversized stock, position it as close as possible to the stock without interfering with the cutting action. This close proximity provides additional support, reducing any potential vibration or movement. Ensure that the tool rest is securely tightened and adjusted to the desired height and angle, allowing for smooth and controlled movements of the cutting tool.

By utilizing the correct tool rest and proper positioning, you can effectively control the cutting process, resulting in clean and precise cuts on your oversized stock.

Overcoming Limitations with a Faceplate

Working with oversized stock on a lathe can sometimes present limitations due to the size and weight of the piece. However, utilizing a faceplate can help overcome these limitations and allow you to work on larger and heavier projects.

One of the advantages of using a faceplate is its ability to handle a wide range of stock sizes and shapes. Whether you are turning a large wooden bowl or a metal spindle, the faceplate provides a secure and reliable connection that withstands the forces involved in the turning process. This versatility allows you to explore creative possibilities and push the boundaries of your lathe’s capabilities.

Additionally, a faceplate can be useful when working with irregularly-shaped oversized stock. The mounting holes on the faceplate can be strategically placed to accommodate unique shapes, ensuring a secure attachment and minimizing the risk of accidents or mishaps during the turning process.

Enhancing Safety with Tailstock Support

When working with oversized stock, safety should always be a top priority. One way to enhance safety during the turning process is by utilizing tailstock support. The tailstock is a movable component of a lathe that provides additional support and stability to the stock. While it is commonly used for smaller projects, it can also be beneficial when working with oversized stock.

To utilize tailstock support, position the tailstock along the length of the stock, aligning it with the center point. Tighten the tailstock securely, ensuring that it provides enough pressure to support the weight of the oversized stock without deforming it. This additional support helps prevent any bending or deflection, resulting in a safer and more controlled turning experience.

By incorporating tailstock support into your lathe operations, you can minimize the risk of accidents or mishaps while working with oversized stock. Remember to always follow safety guidelines and use appropriate protective gear to ensure a safe and enjoyable turning experience.

Mastering Oversized Stock Turning Techniques

Working with oversized stock on a lathe requires skill, technique, and attention to detail. As you gain experience, you will develop a deeper understanding of how to handle large and heavy pieces effectively. Here are some additional tips to help you master the art of turning oversized stock:

1. Take your time:

Rushing through the turning process can lead to mistakes and compromise the quality of your work. Take your time and proceed at a steady pace, ensuring each cut and shaping action is accurate and controlled.

2. Use sharp cutting tools:

Working with oversized stock can put more strain on your cutting tools. Ensure that your tools are sharp and in good condition to achieve clean and precise cuts.

3. Minimize vibrations:

Large and heavy stock can cause increased vibrations during the turning process. Use techniques such as reducing the overhang, balancing the stock, and adjusting the lathe speed to minimize vibrations and achieve smoother results.

4. Measure and mark:

Accurate measurements and markings are essential when working with oversized stock. Take the time to measure and mark the dimensions, centers, and reference points to ensure precise shaping and alignment.

5. Consider multi-axis turning:

Multi-axis turning techniques allow you to create unique and intricate shapes on oversized stock. Explore the possibilities of off-center turning and techniques such as duplicating, spiraling, or textured surfaces to add depth and visual interest to your projects.

6. Embrace experimentation:

Working with oversized stock opens up a world of possibilities for creativity and experimentation. Don’t be afraid to try new techniques, explore different materials, and push the boundaries of traditional turning. Embrace the joy of discovery and let your artistic vision guide your projects.

Final Thoughts

When operating a lathe, working with oversized stock requires careful planning, the right tools, and proper technique. By utilizing tools such as steady rests, faceplates, and tailstock support, you can ensure stability and control while turning oversized pieces. Remember to prioritize safety, take your time, and practice regularly to master the art of working with oversized stock. With dedication and skill, you can create stunning and unique pieces that showcase your craftsmanship and passion.

Key Takeaways: What to Use When Working with Oversized Stock on a Lathe

- 1. Steady Rest: A device that supports the workpiece and prevents vibrations when working with oversized stock.

- 2. Faceplate: Attaching oversized stock directly to the faceplate for stability.

- 3. Tailstock Center: Using a tailstock center to secure the end of the workpiece and maintain balance.

- 4. Chuck Jaws: Using larger chuck jaws to accommodate the size of the oversized stock.

- 5. Tool Rest Extension: Adding a tool rest extension to reach and work with the entire length of the oversized stock.

Frequently Asked Questions

In the world of lathe operation, working with oversized stock presents certain challenges. To address these challenges, here are some commonly asked questions:

Q: How can I securely hold oversized stock on a lathe?

A: When working with oversized stock on a lathe, it is crucial to have a secure grip. One option is to use a four-jaw chuck. With adjustable jaws, a four-jaw chuck provides better flexibility to hold irregular or larger pieces of stock. Another option is to use a faceplate. A faceplate can be attached directly to the stock, offering stability and preventing any movement while turning.

Q: What cutting tools are recommended for working with oversized stock on a lathe?

A: When dealing with oversized stock on a lathe, it is advisable to use larger-sized cutting tools. These tools allow for more material to be removed in each pass, reducing the overall time needed to complete the turning process. Additionally, using tools with sturdy and sharp inserts will ensure clean and smooth cuts. Carbide inserts, for example, are known for their durability and longevity, making them an excellent choice for turning larger pieces of stock.

Q: Is it necessary to adjust the lathe speed when working with oversized stock?

A: Yes, it is necessary to adjust the lathe speed when working with oversized stock. The speed at which the lathe rotates determines the quality of the turning process. When working with larger stock, a lower lathe speed is recommended. This slower speed allows for more control, reduces the risk of accidents, and minimizes vibrations that could potentially damage the workpiece. Always refer to the manufacturer’s guidelines to determine the appropriate speed settings for your specific lathe model.

Q: How can I avoid chatter when turning oversized stock on a lathe?

A: Chatter, which refers to the vibration or bouncing of the workpiece, can be a significant challenge when working with oversized stock on a lathe. To avoid chatter, there are a few key practices to follow. First, ensure that the lathe is firmly secured and level. Any instability in the lathe can increase the likelihood of chatter. Secondly, make sure the cutting tools are sharp and properly aligned. Dull or misaligned tools can cause excessive vibration. Lastly, take lighter cuts and reduce the lathe speed if needed. Smaller cuts and slower speeds allow for better control and reduce the chances of chatter occurring during the turning process.

Q: Are there any safety precautions to consider when working with oversized stock on a lathe?

A: Safety should always be a top priority when operating a lathe, especially when working with oversized stock. Ensure that you are wearing appropriate personal protective equipment (PPE), including safety glasses and gloves. It is also vital to remove any loose clothing or jewelry that could get caught in the lathe. Regularly inspect the lathe for any damaged or worn-out parts that may pose a safety risk. Additionally, be mindful of the lathe’s weight capacity and never exceed its limits, as this could lead to accidents. Lastly, always follow proper lathe operating procedures and consult the lathe’s user manual for specific safety guidelines.

Summary

If you’re using a lathe and your stock is too big, don’t worry! You have a few options. One option is to use a steady rest, which supports the stock and reduces vibration. Another option is to use a faceplate, which allows you to mount the stock securely. Lastly, you can use a chuck, which gives you even more control and stability.

Remember, it’s important to choose the method that works best for your specific project and follow all safety precautions. By doing so, you’ll be able to work with oversized stock on a lathe like a pro!