When to use a drill press vise? Let’s find out! You may be wondering why you would need this handy tool in your workshop. Well, get ready to explore its benefits and understand when it’s the perfect time to put it to use. So, keep on reading, my curious friend, and discover the world of drill press vises!

Picture this: you’re working on a woodworking project and need to make precise, accurate holes. That’s where a drill press vise comes in. This beast of a tool securely holds your workpiece in place, providing stability and allowing you to drill with confidence. No more wobbly materials or misaligned holes!

But wait, there’s more! A drill press vise isn’t limited to just woodworking. It’s a versatile companion for any project that involves drilling, such as metalworking, jewelry making, or even small DIY repairs. With its strong grip and adjustable jaws, you can tackle various materials and ensure consistent results every time.

So, whether you’re a seasoned craftsman or a novice DIY enthusiast, the drill press vise is a game-changer. From woodworking wonders to metalworking masterpieces, this tool will elevate your drilling game. Get ready to unleash your creativity and say goodbye to frustrating mistakes. It’s time to embrace the drill press vise!

When to Use a Drill Press Vise: A Comprehensive Guide

Welcome to our comprehensive guide on when to use a drill press vise. In this article, we will explore the various applications and benefits of using a drill press vise, as well as provide practical tips for maximizing its efficiency and safety. Whether you are a DIY enthusiast or a professional woodworker, understanding when and how to use a drill press vise can greatly enhance the precision and ease of your drilling tasks. Let’s dive in and discover the wonders of this indispensable tool!

The Benefits of Using a Drill Press Vise

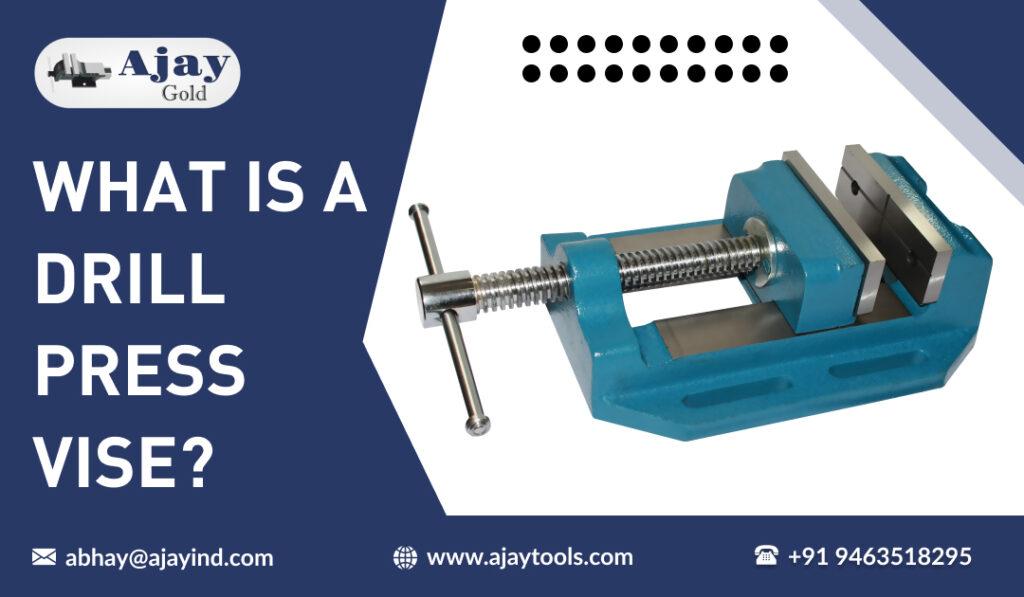

A drill press vise is a specialized tool designed to securely hold workpieces in place during drilling operations. Unlike handheld clamps or vises, a drill press vise is specifically engineered to provide stability and accuracy, ensuring precise drill holes. Here are some key benefits of using a drill press vise:

- Precision: One of the primary advantages of using a drill press vise is the ability to achieve consistent and accurate drill holes. The vise’s solid grip minimizes movement and eliminates the risk of slippage, resulting in precise and clean drill holes every time.

- Efficiency: With a drill press vise, you can streamline your workflow by securely holding your workpiece in place, allowing you to focus on drilling without the need for constant readjustment or repositioning. This efficiency translates into time saved and increased productivity.

- Safety: Using a drill press vise provides a secure and stable platform for drilling operations, reducing the risk of accidents or injuries that may occur when attempting to hold a workpiece by hand. The vise’s firm grip ensures that the workpiece remains in place, preventing dangerous movement during drilling.

Tips for Using a Drill Press Vise Effectively

Now that we understand the benefits of using a drill press vise, let’s explore some practical tips for using this tool effectively:

1. Choose the Right Vise for the Job

When selecting a drill press vise, consider the size and weight of the workpieces you typically handle. Opt for a vise that can securely hold your materials without straining the tool or compromising stability. Additionally, ensure that the vise is compatible with your drill press, both in terms of size and design.

Types of Drill Press Vises:

– Standard Drill Press Vises: These versatile vises are suitable for a wide range of drilling tasks and offer various clamping capacities.

– Cross Slide Vises: These vises provide greater versatility and precision as they allow for movement in multiple directions, enabling you to position your workpiece accurately.

– Tilting Vises: If you often drill at angles or require more flexibility in positioning, a tilting vise is an excellent choice. It allows you to tilt the workpiece in different directions, accommodating diverse drilling needs.

2. Securely Mount the Vise to the Drill Press

The stability of your drill press vise relies on proper installation and mounting. Follow the manufacturer’s instructions to securely attach the vise to your drill press. Ensure that the mounting bolts are tightened properly, eliminating any wobbling or movement during operation.

3. Position the Workpiece Correctly

Before securing your workpiece in the vise, ensure that it is properly positioned. Measure and mark the desired drilling locations, taking into account the depth and angle if necessary. Align the marked spots with the drill bit’s center point to achieve accurate and precise drilling.

4. Gradually Increase Pressure

When tightening the drill press vise, apply pressure gradually to avoid damaging the workpiece or the vise itself. Start with a moderate grip and adjust as needed. Remember that excessive force can lead to material deformation or even breakage.

5. Utilize Auxiliary Support

If you are working with particularly long or heavy workpieces, consider using additional support mechanisms, such as support blocks or adjustable stands. These aids can provide extra stability, especially when drilling near the edges or ends of the workpiece.

6. Maintain a Clean Workspace

Regularly clean your drill press vise and its components to ensure smooth operation and prevent the buildup of debris or contaminants. A clean vise not only enhances performance but also prolongs its lifespan.

Applications of a Drill Press Vise

A drill press vise has a wide range of applications that go beyond basic drilling tasks. Here are some common uses:

1. Woodworking

Woodworkers often rely on drill press vises to secure their workpieces when drilling holes for joinery, dowels, or hardware installation. The vise’s stability ensures precise and consistent holes, enabling seamless assembly and construction.

2. Metalworking

In metalworking, a drill press vise provides the necessary stability for drilling holes in various metals, including steel, aluminum, and brass. The vise’s solid grip minimizes vibrations and movement, resulting in accurate holes and smooth cutting.

3. Jewelry Making

Jewelers utilize drill press vises when working with precious metals or delicate materials. The vise’s firm grip allows for intricate hole drilling, making it ideal for creating precise settings or intricate designs.

4. Electronics

When drilling holes in circuit boards or electronic enclosures, a drill press vise holds the workpiece securely, ensuring accurate alignment and preventing damage to delicate components or circuits.

Final Thoughts

In conclusion, a drill press vise is an invaluable tool for those seeking precise and accurate drilling results. Whether you are a woodworker, metalworker, jeweler, or electronics enthusiast, understanding when and how to use a drill press vise can greatly enhance your workmanship. By following the tips provided in this guide and exploring the various applications of a drill press vise, you can take your drilling tasks to the next level. Enjoy the precision, efficiency, and safety that a drill press vise brings to your projects!

Key Takeaways: When to Use a Drill Press Vise

- A drill press vise is best used when you need to securely hold a workpiece in place while drilling.

- It is important to use a drill press vise when working with small or delicate materials to ensure accuracy and safety.

- When drilling at an angle or on uneven surfaces, a drill press vise can provide stability and prevent slippage.

- For repetitive drilling tasks, a drill press vise allows for consistent positioning and precise hole placement.

- Using a drill press vise can help minimize the risk of injuries and increase efficiency in your woodworking or metalworking projects.

Frequently Asked Questions

Welcome to our guide on using a drill press vise! Here, we’ve answered some common questions to help you understand when and how to use a drill press vise effectively. Read on to learn more.

1. Why should I use a drill press vise instead of holding the material by hand?

Using a drill press vise offers several advantages over holding the material by hand. Firstly, it provides stability, ensuring that the material remains secure and steady during drilling. This reduces the chances of accidents or errors. Additionally, a vise allows you to align the material precisely, ensuring accurate and consistent drill hole placements. When drilling through harder materials, such as metal or hardwood, a vise is especially useful as it provides the necessary grip and pressure to prevent the material from slipping.

In summary, using a drill press vise improves safety, accuracy, and stability, making it the preferred option for many drilling tasks.

2. When should I use a drill press vise?

A drill press vise is recommended whenever you are working with small or delicate materials that could be difficult to hold by hand safely. It is also ideal when you need to make precise or repeated drilling operations. Additionally, if you are drilling into a harder material, a vise becomes essential to prevent the material from moving or shifting during the drilling process.

Whether you are working on woodworking projects, metalworking applications, or any other drilling tasks that require accuracy and stability, using a drill press vise is a wise choice.

3. What types of materials can I use with a drill press vise?

A drill press vise can be used with a variety of materials, including wood, metal, plastic, and more. It is particularly useful when drilling through hardwoods, metals, or any materials that require a secure grip and precision. Size-wise, a drill press vise can accommodate both small and larger materials, depending on the size of the vise itself.

However, it’s important to note that the suitability of a drill press vise also depends on the type and power of the drill press you are using. Some drill presses may not be suitable for heavy-duty work or certain materials, so it’s always important to consult the manual or manufacturer’s guidelines before use.

4. How do I properly secure the material in a drill press vise?

To secure the material in a drill press vise, start by ensuring that the jaws of the vise are clean and clear of any debris. Place the material between the jaws, aligning it to the desired position for drilling. Next, tighten the vise by rotating the handle or turning the screw. Apply enough pressure to firmly hold the material in place, but be cautious not to overtighten, as excessive force can damage the material or vise.

Once the material is securely in place, double-check its alignment, making any necessary adjustments before proceeding with drilling. Always follow the recommended safety precautions when operating the drill press and vise to prevent accidents or injuries.

5. Can I use a drill press vise for other purposes besides drilling?

Although a drill press vise is primarily designed for use with a drill press, it can also be useful for other tasks. For example, you can use it as a clamp to hold materials together while gluing, sanding, or sawing. It can also act as a stabilizing tool, keeping materials in position during various woodworking or metalworking processes.

While a drill press vise may not be ideal for every application or task, its versatility makes it a valuable tool to have in your workshop.

Summary

A drill press vise is a handy tool that can help you work more safely and efficiently with your drill press. It is especially useful when you need to hold materials securely in place, preventing them from moving while you drill. The vise can be adjusted to hold objects of different sizes and shapes, making it versatile for various projects. However, it’s important to remember that not all situations require the use of a drill press vise. If you are working with smaller or lighter materials that can be easily held by hand or clamped down, you may not need to use the vise. Ultimately, the decision to use the vise depends on the specific requirements of your project and the level of stability and precision you need.