When to use a lathe dog? Well, if you’re curious about this handy tool, you’ve come to the right place! Using a lathe dog might sound strange, but it’s actually quite useful in the world of machining.

Picture this: you’re working with a lathe, shaping and smoothing a piece of material. Suddenly, you realize the piece needs additional support and stability. That’s where a lathe dog comes into play!

So, let’s dive deeper into the world of lathe dogs and understand when and how to use them. Ready to learn? Let’s get started!

When to Use a Lathe Dog: A Comprehensive Guide

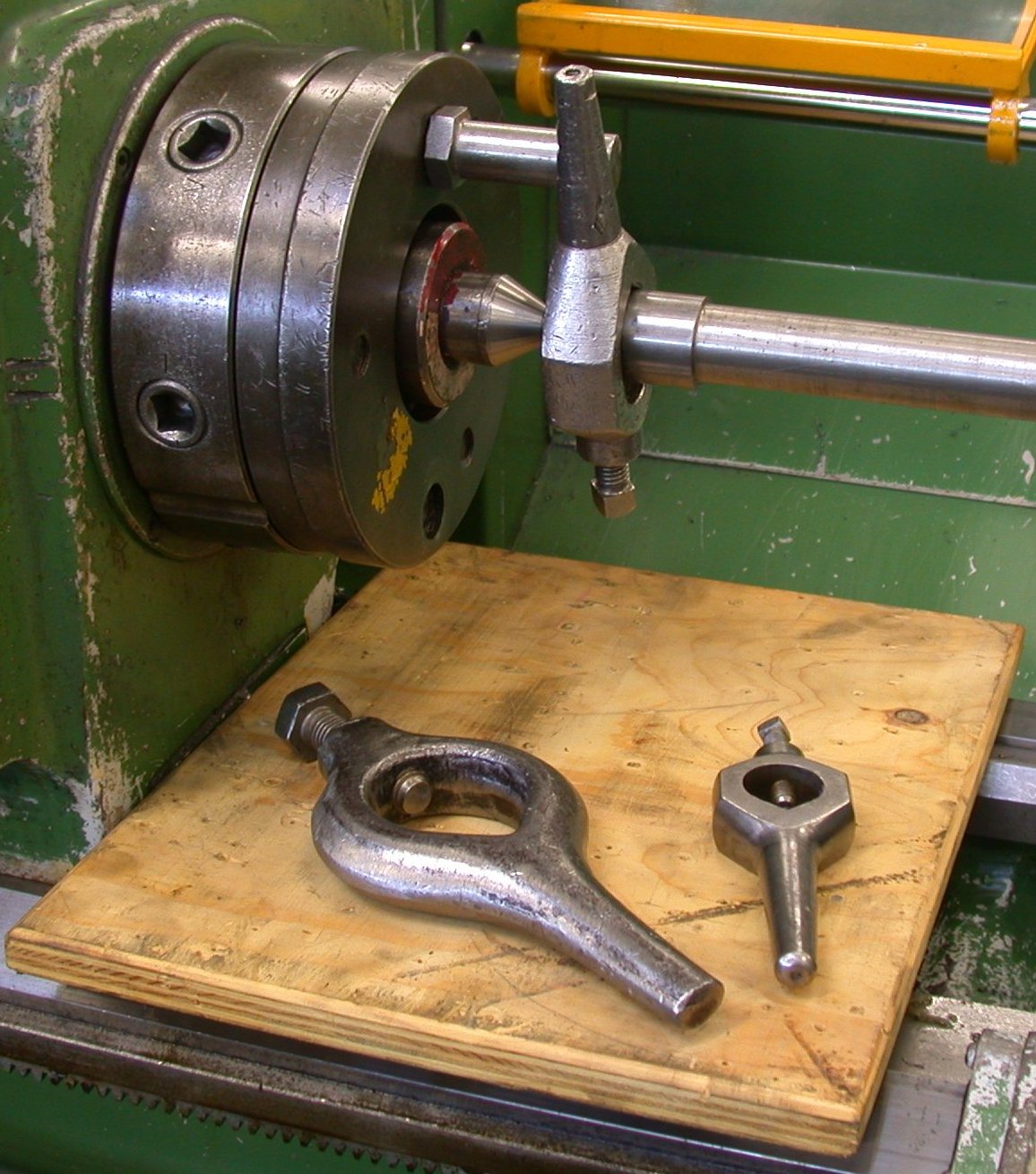

Lathe dogs are an essential tool in the world of machining, specifically in metalworking. They are commonly used in conjunction with a lathe machine to hold and rotate a workpiece securely. By engaging with the lathe’s driver plate or faceplate, a lathe dog provides the necessary grip and stability needed for various turning operations. In this article, we will explore the different scenarios and applications that call for the use of a lathe dog. From heavy-duty projects to intricate designs, understanding when to utilize this tool can greatly enhance your machining capabilities.

1. Heavy and Irregularly Shaped Workpieces

When working with large or irregularly shaped workpieces that cannot be easily held in a chuck, a lathe dog becomes indispensable. These workpieces often require the additional grip and stability that a lathe dog can provide. By attaching the lathe dog to the workpiece and engaging it with the lathe’s driver plate, you can turn and shape the workpiece without worrying about it slipping or moving during the process. This is especially useful when turning heavy-duty items such as engine crankshafts or large wooden logs for furniture.

Additionally, lathe dogs are particularly effective when working with tapered or uneven surfaces. The adjustable jaws of the lathe dog can accommodate various diameters, allowing you to securely hold asymmetrical workpieces while maintaining control and precision during the turning process. This versatility makes the lathe dog a valuable tool for shaping complex workpieces.

2. Turning Between Centers

One of the primary applications of a lathe dog is when turning between centers. This technique involves securing the workpiece between the headstock and tailstock of the lathe, with the lathe dog gripping one end of the workpiece. The lathe dog transfers the rotational force from the lathe’s spindle to the workpiece, allowing for precision turning and shaping.

Turning between centers is commonly used for tasks such as spindle turning, where long cylindrical workpieces such as table legs or stair balusters are created. The lathe dog ensures that the workpiece remains securely in place while spinning on its axis, enabling the machinist to achieve accurate and symmetrical results. It is crucial to choose the appropriate size and type of lathe dog for the job to ensure a secure hold and minimize the risk of accidents.

3. Cutting Keyways and Splines

When it comes to cutting keyways or splines on shafts and gears, a lathe dog offers excellent support and control. Keyways and splines are essential for creating connections that transmit torque between shafts and gears, ensuring proper alignment and power transmission. To achieve precise and accurate keyways and splines, the workpiece must be held securely in place during the cutting process.

A lathe dog is ideal for this purpose, as it allows you to firmly grip the workpiece while rotating it at a controlled speed. The lathe dog’s adjustable jaws ensure a secure hold on the workpiece, reducing the risk of slippage or movement that could compromise the accuracy of the cuts. Whether you are creating keyways for automotive components or splines for industrial machinery, employing a lathe dog will enhance both the safety and precision of the operation.

4. Cutting Threads

When it comes to cutting threads on cylindrical workpieces, a lathe dog proves invaluable. Threads are commonly employed in various industries, including automotive, aerospace, and plumbing, as they provide a secure means of joining components together. To create accurate and well-aligned threads, the workpiece must be held securely and rotated precisely.

Using a lathe dog in conjunction with a threading tool allows for the controlled rotation of the workpiece during the threading process. The lathe dog’s grip ensures that the workpiece remains firmly in place, preventing any unwanted movement that could result in misaligned or inconsistent threads. Whether you are threading pipes, bolts, or screws, a lathe dog is an essential tool to ensure the success and quality of the threaded connections.

5. Benefits of Using a Lathe Dog

The benefits of utilizing a lathe dog extend beyond its specific applications. Here are some advantages of incorporating a lathe dog into your machining practices:

– Improved Stability: A lathe dog provides a secure grip on the workpiece, minimizing the risk of slippage or movement during turning operations. This stability enhances safety and ensures greater accuracy in machining tasks.

– Versatility: Lathe dogs come in various sizes and types, allowing for the accommodation of different workpiece diameters and shapes. This versatility makes them suitable for a wide range of projects and applications.

– Increased Efficiency: By securely holding the workpiece, a lathe dog allows for better control and manipulation during turning operations. This results in more efficient and precise machining, minimizing the need for rework or adjustments.

– Cost-Effective Solution: Lathe dogs offer a cost-effective alternative to specialized holding fixtures or chucks for specific workpiece requirements. They are a versatile tool that can be adapted to various projects without the need for additional equipment investments.

– Enhanced Machining Capabilities: Incorporating a lathe dog into your machining practices expands your capabilities and allows you to tackle a wider range of projects. Whether you are working on large or irregularly shaped workpieces or engaging in precise turning operations, a lathe dog can significantly improve your results.

When to Use a Lathe Dog: Tips for Optimal Utilization

Now that we have explored the different scenarios and applications of a lathe dog, let’s delve into some tips for optimal utilization. Understanding how and when to use a lathe dog can help you achieve the best possible results in your machining endeavors.

1. Choose the Right Size and Type of Lathe Dog

When selecting a lathe dog, it is crucial to choose the appropriate size and type for the workpiece and operation at hand. Consider the diameter and shape of the workpiece, as well as the specific requirements of the turning or machining task. Ensure that the lathe dog’s adjustable jaws can securely grip the workpiece, providing the necessary stability and control.

2. Proper Positioning and Alignment

To achieve accurate results, it is essential to properly position and align the workpiece before engaging the lathe dog. Ensure that the workpiece is centered and aligned with the lathe’s spindle, minimizing any eccentricity or wobbling. This will help maintain balance and prevent vibrations during the turning process.

3. Regular Maintenance and Lubrication

To ensure the longevity and optimal performance of your lathe dog, it is important to perform regular maintenance and lubrication. Clean the mechanism and inspect for any signs of wear or damage. Apply lubrication to the adjustable jaws and other moving parts to minimize friction and promote smooth operation.

4. Exercise Caution with Heavy Workpieces

When working with heavy or unbalanced workpieces, exercise caution to avoid accidents or injuries. Ensure that the lathe dog is securely attached and that the workpiece is aligned and balanced. Use appropriate safety measures, such as wearing protective gear and employing supplemental supports if necessary.

5. Practice and Patience

Using a lathe dog effectively requires practice and patience. Familiarize yourself with the tool and its operation before attempting intricate or complex turning tasks. Start with simpler projects to build your confidence and gradually progress to more challenging workpieces. Remember to always prioritize safety and precision in your machining practices.

Common Mistakes to Avoid When Using a Lathe Dog

While a lathe dog can greatly enhance your machining capabilities, there are some common mistakes that should be avoided to ensure optimal results. By being aware of these pitfalls, you can avoid unnecessary setbacks and produce high-quality work.

1. Insufficient Grip

One of the most common mistakes when using a lathe dog is not achieving a sufficient grip on the workpiece. If the lathe dog is not properly tightened or adjusted, it may result in slippage or movement during turning operations. This can lead to inaccurate cuts or damage to the workpiece. Take the time to ensure a secure and tight grip before beginning any machining tasks.

2. Improper Centering and Alignment

Another mistake to avoid is improper centering and alignment of the workpiece. If the workpiece is not correctly aligned with the lathe’s spindle, it may wobble or vibrate during rotation, compromising the accuracy and quality of the turning. Carefully position and align the workpiece before engaging the lathe dog to prevent any eccentricity or misalignment.

3. Neglecting Regular Maintenance

Many machinists overlook the importance of regular maintenance and lubrication for their lathe dogs. Failing to clean and lubricate the adjustable jaws and mechanism can result in decreased performance and premature wear. Make it a habit to clean and inspect your lathe dog regularly, and apply lubrication to ensure smooth and efficient operation.

4. Overlooking Safety Measures

Safety should always be a priority when using any machining tool, and a lathe dog is no exception. Neglecting proper safety measures, such as wearing protective gear or using supplemental supports for heavy or unbalanced workpieces, can lead to accidents or injuries. Always adhere to safety guidelines and take the necessary precautions to safeguard yourself and those around you.

By being mindful of these common mistakes and diligently following best practices, you can fully harness the capabilities of a lathe dog. Whether you are tackling heavy-duty projects or working with intricate designs, the proper utilization of a lathe dog will undoubtedly elevate your machining skills and deliver exceptional results.

The Versatility of the Lathe Dog

The versatility of the lathe dog stems from its ability to securely grip and rotate workpieces in a wide range of scenarios. Here are a few additional applications where a lathe dog proves especially useful:

1. Removing Stubborn Screws or Bolts

When faced with a stubborn or stripped screw or bolt, a lathe dog can come to the rescue. By attaching the lathe dog to the workpiece and engaging it with the lathe’s driver plate, you can effectively apply torque to the stuck fastener, aiding in its removal.

2. Turning Ellipses or Ovals

While a lathe is typically designed for turning cylindrical workpieces, the use of a lathe dog can extend its capabilities to creating elliptical or oval shapes. By attaching the lathe dog at the desired pivot point on the workpiece, you can achieve controlled rotation, resulting in precisely shaped ellipses or ovals.

3. Maximizing Spindle Capacity

In situations where the spindle capacity of a lathe is limited, a lathe dog can be employed to extend the range of workpiece diameters that the machine can handle. By securely attaching the lathe dog to the workpiece, even larger or irregularly shaped items can be effectively turned using a lathe with a smaller spindle capacity.

In conclusion, the lathe dog is a versatile and essential tool in the world of machining. Whether you are working on heavy-duty projects, turning between centers, cutting keyways and splines, or creating threads, the lathe dog provides the necessary grip, stability, and control. By understanding when and how to use a lathe dog effectively, you can enhance your machining capabilities, expand your project options, and achieve remarkable results. Remember to follow best practices, exercise caution, and prioritize safety whenever utilizing a lathe dog in your machining endeavors.

Key Takeaways: When to Use Lathe Dog

– Use a lathe dog when working with long and slender workpieces that may vibrate or bend during turning.

– Lathe dogs provide support and prevent workpieces from slipping or moving while being turned.

– When using a lathe dog, ensure it is properly clamped onto the workpiece to avoid accidents or damage.

– Lathe dogs are commonly used in woodworking, metalworking, and other machining applications.

Frequently Asked Questions

Welcome to our Frequently Asked Questions section, where we have compiled answers to common queries about using a lathe dog. Below, you’ll find five engaging Q&A pairs that will help you understand when and how to use this indispensable tool.

Q1: How does a lathe dog work?

A1: A lathe dog is a clamping device used in metalworking to rotate a workpiece on a lathe. It consists of two parts: a body and a pointed, toothed arm. The body attaches to the lathe, while the arm engages with the workpiece. As the lathe rotates, the arm holds the workpiece firmly and prevents it from slipping or vibrating, allowing precision machining.

The arm of the lathe dog is inserted into a hole or groove on the workpiece, and the pointed teeth bite into the material, creating a secure grip. This ensures that the workpiece rotates smoothly, enabling the lathe’s cutting tools to shape it precisely according to the desired specifications.

Q2: When should I use a lathe dog?

A2: You should use a lathe dog whenever you need to machine a long workpiece that cannot be conveniently held in the lathe chuck or between centers. Lathe dogs are particularly useful for turning workpieces such as shafts, rods, or pipes that have a consistent diameter along their length.

If you were to solely rely on the lathe chuck or centers, these long workpieces may flex or vibrate, resulting in inaccurate cuts. By using a lathe dog, you can securely fasten the workpiece and eliminate any unwanted movement, ensuring precise machining. The lathe dog also allows you to work on one end of the workpiece while the other end extends out of the lathe, providing greater flexibility.

Q3: What are the benefits of using a lathe dog?

A3: Using a lathe dog offers several benefits. Firstly, it provides a secure grip on long workpieces, preventing slippage and ensuring accurate machining. This is crucial when you need to create consistent diameters, smooth tapers, or threads on the workpiece.

Secondly, a lathe dog allows you to work on one end of the workpiece while the other end extends beyond the lathe, enabling you to machine longer parts. This versatility is especially valuable when dealing with lengthy shafts or rods. Lastly, using a lathe dog reduces the stress on the lathe chuck and spindle, as it distributes the applied forces over a larger area, prolonging the lifespan of your lathe.

Q4: Can I use a lathe dog on any type of workpiece?

A4: While lathe dogs are versatile tools, they are most effective on workpieces with a consistent diameter along their length. This is because lathe dogs rely on a firm grip of the workpiece to prevent slippage. If your workpiece is tapered or irregularly shaped, it may not be suitable for using a lathe dog.

It’s important to ensure that the lathe dog’s arm engages firmly with the workpiece, biting into the material to create a secure hold. If the arm slips or cannot grip the workpiece properly, it may be necessary to explore alternative methods of securing the workpiece, such as using a steady rest or a different type of clamping device.

Q5: Are there different types of lathe dogs available?

A5: Yes, there are different types of lathe dogs available to suit various workpiece sizes and shapes. The most common types include the bent-tail dog, the plate dog, and the carrier dog. Each type is designed to provide a secure grip on different workpiece configurations.

The bent-tail dog is suitable for holding workpieces with a hole or groove, as it can be easily inserted and secured. The plate dog, on the other hand, is ideal for workpieces that have a flat surface for attachment. Lastly, the carrier dog is specifically designed for thin, cylindrical workpieces and features an adjustable arm to accommodate different diameters.

How to machine between center’s using lathe dog

Summary

When using a lathe, a lathe dog is a handy tool to secure and rotate workpieces. A lathe dog is made up of a body, jaws, and a connector. It’s important to choose the right lathe dog size to fit your workpiece properly. Lathe dogs are commonly used when working with long, slender workpieces that need extra support to prevent vibration or bending. They are also useful in situations where you need to rotate the workpiece at high speeds. By understanding when and how to use a lathe dog, you can ensure safer and more accurate turning operations on your lathe.