Are you curious about when to use a lathe faceplate? Well, you’ve come to the right place! In this article, we’ll explore the purpose and benefits of using a lathe faceplate, so you can better understand how and when to utilize this handy tool.

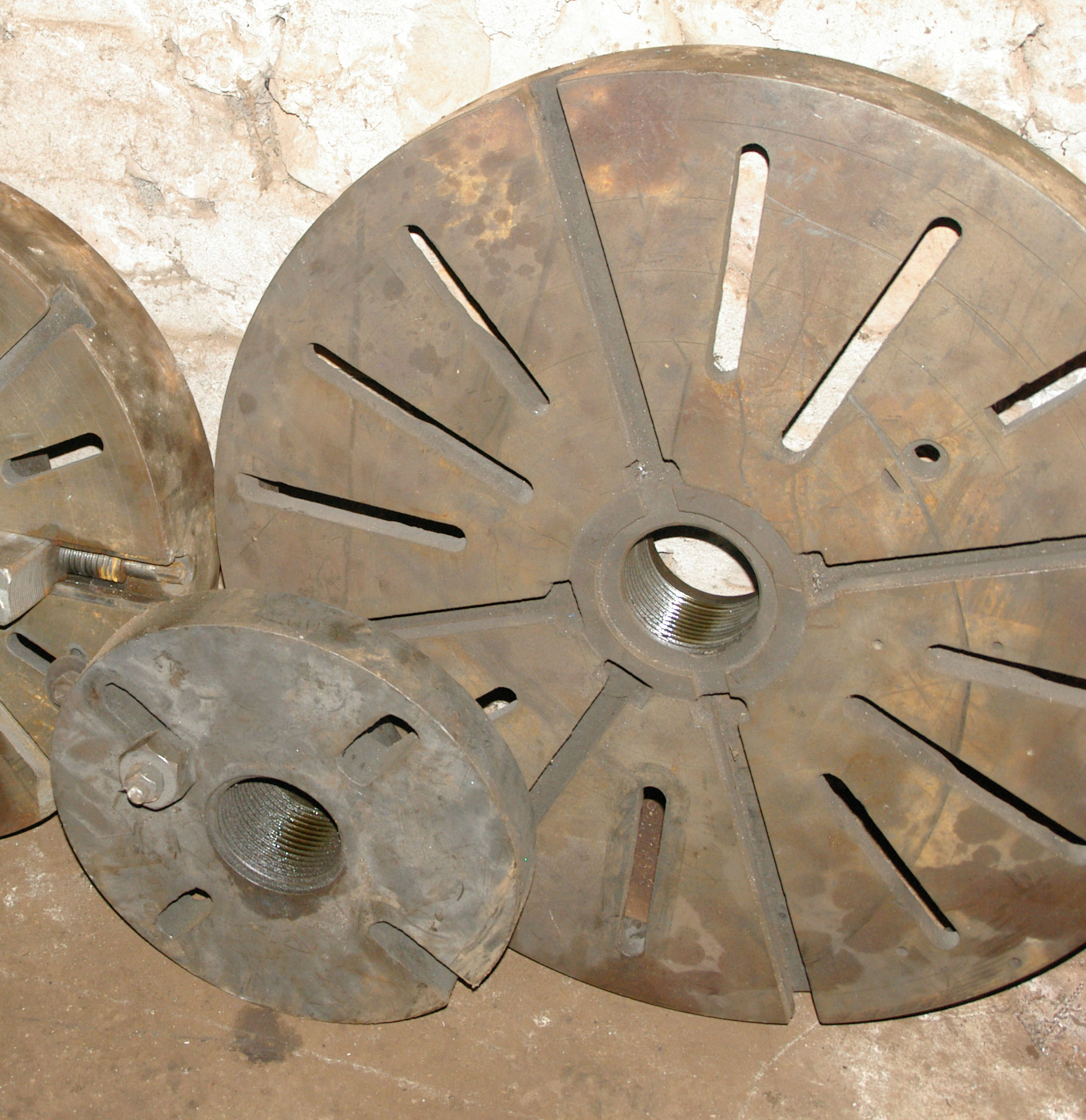

Picture this: you’re working on a woodworking or metalworking project and need to securely hold a large, uneven, or irregularly shaped workpiece on your lathe. That’s where the lathe faceplate comes in! This versatile accessory attaches to the spindle of your lathe and provides a flat, sturdy surface for mounting and turning various types of workpieces.

So, when should you reach for the lathe faceplate? Whenever you have a workpiece that you can’t easily grip with other lathe holding methods, such as a chuck or a collet. The faceplate allows you to securely hold and balance larger, heavier, or oddly shaped objects, giving you better control and accuracy during the turning process.

Whether you’re shaping a bowl, creating a custom baluster, or turning a wooden lamp base, knowing when to use a lathe faceplate can make all the difference in achieving a professional and precise result. So, let’s dive deeper into the specifics of when and how to effectively use this indispensable tool.

When to Use a Lathe Faceplate: A Comprehensive Guide

Welcome to our comprehensive guide on when to use a lathe faceplate. In this article, we will explore the various scenarios and applications where a lathe faceplate is an essential tool for woodturners, metalworkers, and enthusiasts alike. Whether you are a professional or a hobbyist, understanding when and how to use a lathe faceplate can significantly enhance your machining capabilities and improve the quality of your projects. Join us as we delve into the world of lathe faceplates and discover their versatility.

1. Bowl Turning

One of the primary uses of a lathe faceplate is for bowl turning. When it comes to creating bowls, a faceplate is crucial for securing the workpiece securely and providing stability during the turning process. The faceplate, typically attached to the headstock, allows for better control and precision while shaping the bowl. It helps eliminate vibrations, ensures the workpiece remains centered, and reduces the risk of accidents.

When using a lathe faceplate for bowl turning, it is essential to mount the workpiece securely using screws or a glue block. The faceplate provides a solid foundation for the bowl blank, allowing you to turn the outer shape, carve the interior, and add decorative details. Always follow proper safety procedures and ensure the faceplate is well-balanced and properly aligned for optimal results.

In conclusion, a lathe faceplate is an indispensable tool for bowl turning, offering stability, control, and enhanced safety. It allows the turner to create beautiful bowls with precision and finesse.

2. Large or Unbalanced Workpieces

When working with large or unbalanced workpieces on the lathe, using a faceplate is often the best option. The faceplate provides increased stability, especially when dealing with irregularly shaped or off-center materials. It ensures that the workpiece is securely fastened, minimizing the risk of movement or accidents during the turning process.

By properly mounting the workpiece on a faceplate, you can rotate it steadily, even if it has an unbalanced weight distribution. This capability allows for safer and more controlled turning operations on the lathe. Whether you are working on furniture legs, balusters, or other intricate pieces, a lathe faceplate provides the necessary support and stability.

In summary, a lathe faceplate is an invaluable tool for handling large and unbalanced workpieces, providing stability and control during the turning process.

3. Eccentric Turning

Eccentric turning refers to the process of creating off-center or asymmetrical designs on a lathe. This technique is commonly used in the creation of decorative wooden bowls, vases, and other artistic pieces. When engaging in eccentric turning, a lathe faceplate is essential for securely holding the workpiece at varying distances from the lathe’s center.

By attaching the workpiece to a lathe faceplate, the turner can create unique and intricate designs, resulting in visually stunning pieces. The faceplate allows for precise control over the off-center positioning, enabling the turner to achieve the desired shape and pattern. This technique adds a dynamic and artistic element to the turning process, turning an ordinary piece into a striking work of art.

In conclusion, a lathe faceplate is indispensable for eccentric turning, allowing the turner to create mesmerizing off-center designs and unleash their creativity.

4. Faceplate vs. Chuck: Pros and Cons

When considering whether to use a lathe faceplate or a chuck for a particular project, it is essential to understand the advantages and disadvantages of each option. While a faceplate and chuck serve similar purposes, they have distinct characteristics that make them suitable for specific scenarios.

Faceplate

Pros:

- Provides better stability for large or unbalanced workpieces

- Allows for eccentric turning

- Offers secure mounting for bowl turning

- Enables customization and creativity

Cons:

- Requires extra steps for attaching and removing the workpiece

- May leave marks on the workpiece

- Limited in terms of size and weight capacity

Chuck

Pros:

- Provides quick and easy workpiece changes

- Offers a wide range of gripping options

- Allows for more complex turning operations

- Provides better accessibility to the workpiece

Cons:

- May have limitations in terms of workpiece size and weight

- Less stable for large or unbalanced workpieces

- Not suitable for eccentric turning

In summary, choosing between a lathe faceplate and a chuck depends on the specific requirements of your project. Evaluate the pros and cons of each option and consider the nature of your workpiece to make an informed decision.

5. Tips for Using a Lathe Faceplate

Here are some valuable tips for using a lathe faceplate effectively:

- Ensure the faceplate is clean and free from debris to maintain a secure grip on the workpiece.

- Choose the appropriate size and weight capacity of the faceplate for your project.

- Inspect the faceplate for any defects or damage before use.

- Always use the appropriate screws or fasteners to secure the workpiece onto the faceplate.

- Ensure the workpiece is centered and balanced on the faceplate for optimal results.

- Regularly check the tightness of the screws during the turning process to prevent any movement or accidents.

- Follow proper safety procedures and use appropriate personal protective equipment when using a lathe faceplate.

By following these tips, you can maximize the effectiveness and safety of using a lathe faceplate in your projects.

6. Other Applications for a Lathe Faceplate

While bowl turning, handling large workpieces, and eccentric turning are the primary applications for a lathe faceplate, there are other scenarios where it can come in handy:

- Creating platters and trays

- Turning handles and knobs

- Making spindles and dowels

- Carving small sculptures

- Turning candlesticks

Each of these applications requires the stability and control provided by a lathe faceplate to achieve precise and high-quality results.

7. Explore the Possibilities of a Lathe Faceplate

In conclusion, a lathe faceplate is a versatile tool with numerous applications in woodworking and metalworking. From bowl turning to eccentric designs, it offers stability, control, and enhanced creativity. Use it to tackle your next project and unlock the endless possibilities that a lathe faceplate can provide. Remember to prioritize safety and follow proper techniques for optimal results. Happy turning!

Key Takeaways: When to Use a Lathe Faceplate

- A lathe faceplate is used when turning a workpiece that cannot be held by a chuck.

- Faceplates are ideal for holding irregularly shaped or asymmetrical workpieces.

- Using a faceplate allows for greater control and stability while turning the workpiece.

- Faceplates are commonly used for turning bowls, platters, or large diameter workpieces.

- When using a faceplate, it’s important to securely attach the workpiece using screws or bolts.

Frequently Asked Questions

In this section, we have compiled some common questions regarding the usage of a lathe faceplate.

Q: What is a lathe faceplate and when should I use it?

A: A lathe faceplate is a circular metal plate that attaches to the headstock of a lathe. It is used when working with larger or irregularly shaped workpieces that cannot be held by the lathe’s standard chuck. The faceplate provides a secure and stable platform for mounting the workpiece, allowing for precision turning and shaping.

There are several situations when you may need to use a lathe faceplate. One instance is when you are working with a large diameter piece that exceeds the capacity of the lathe chuck. Another scenario is when you are turning a workpiece with uneven dimensions, such as irregularly shaped bowls or platters. In these cases, the faceplate provides a reliable means of securing the workpiece for safe and accurate machining.

Q: How do I attach a workpiece to a lathe faceplate?

A: Attaching a workpiece to a lathe faceplate involves a simple process. First, ensure that the faceplate is clean and free of any debris or dirt. Then, place the workpiece onto the faceplate, aligning it with the center hole. Use several screws or bolts to secure the workpiece to the faceplate, ensuring that it is firmly held in place. It is important to distribute the screws evenly around the workpiece to maintain balance and prevent any wobbling during machining.

Additionally, it is advisable to use a small center punch to mark the exact center of the workpiece before attaching it to the faceplate. This will allow for precise alignment and better accuracy in your turning or shaping processes.

Q: What are the advantages of using a lathe faceplate?

A: There are several advantages to using a lathe faceplate. First, it provides a secure and stable platform for mounting large or irregularly shaped workpieces. This is especially useful when working with materials that are difficult to hold with a lathe chuck. The faceplate allows for precise turning and shaping, ensuring accurate results.

Another advantage is that the faceplate allows you to work with larger diameter workpieces that exceed the capacity of the lathe chuck. This expands the range of projects you can undertake on your lathe. Additionally, the faceplate’s solid connection to the lathe headstock provides increased stability and reduces vibration during machining, resulting in smoother cuts and a better overall finish.

Q: Are there any limitations to using a lathe faceplate?

A: While a lathe faceplate is a versatile tool, there are some limitations to keep in mind. One limitation is that using a faceplate requires more setup time compared to using a lathe chuck. Attaching and securing the workpiece to the faceplate involves additional steps, which may be time-consuming.

Additionally, when working with a faceplate, you need to ensure that the workpiece is properly balanced. If the workpiece is not balanced, it can cause the lathe to vibrate, resulting in poor machining results. Balancing the workpiece may require extra effort and skill, especially when working with irregularly shaped or heavy materials.

Q: Can I use a lathe faceplate for all projects?

A: While a lathe faceplate is a useful tool, it may not be necessary for every project. For small or symmetrical workpieces that can be securely held by the lathe chuck, using a faceplate may not be required. The lathe chuck provides a quick and convenient method for holding such workpieces.

However, when working with larger or irregularly shaped workpieces, a lathe faceplate becomes essential. It provides a reliable means of securing these workpieces for safe and precise machining. So, when considering whether to use a lathe faceplate, evaluate the size and shape of your workpiece and choose the appropriate holding method accordingly.

Lathe Tutorial P 11 Faceplate Set Up

Summary

When using a lathe faceplate, it’s important to consider a few key factors. First, make sure the workpiece is too big or irregularly shaped for other machining methods. The faceplate provides stability and grip in these situations. Second, check if the workpiece requires face turning or heavy-duty machining. The faceplate can handle heavy loads and allows for precise machining on large, heavy objects. Lastly, keep in mind that the faceplate should be used when other options like chucks or collets are not suitable. Overall, the lathe faceplate is a versatile tool for tackling challenging workpiece sizes and shapes.

In conclusion, the lathe faceplate is a helpful tool for handling big, irregularly shaped workpieces that require face turning or heavy machining. It should be used when other options are not suitable, and it provides stability and precision for working on large objects. Remember these tips to make the most out of using a lathe faceplate.