Are you curious about where drill presses are manufactured? Well, you’ve come to the right place! In this article, we’ll explore the fascinating world of drill press production and uncover the countries that play a significant role in their manufacturing. So, let’s dive in and satisfy our curiosity!

When it comes to drilling presses, different countries have emerged as powerhouses in their production. From the United States to China and Germany to Taiwan, there’s a global network of manufacturers that contribute to this industry. Each country brings its own unique expertise and innovation to the table, making the manufacturing landscape diverse and exciting.

So, if you’ve ever wondered where your trusty drill press comes from, join us as we embark on a journey to uncover the origins and manufacturing hotspots of these essential tools. Get ready to be amazed by the international collaboration and expertise that goes into making the drill presses we rely on every day!

Where Are Drill Presses Manufactured?

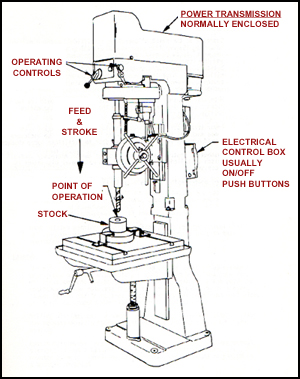

Drill presses are versatile tools used in woodworking, metalworking, and various other industries. But have you ever wondered where these essential machines are manufactured? In this article, we will delve into the world of drill press production and explore the different countries known for their manufacturing capabilities. From the renowned industrial hubs to emerging players in the market, we will uncover the origins of these powerful machines and provide you with a comprehensive understanding of where drill presses are made.

The Manufacturing Landscape of Drill Presses

1. The United States

When it comes to drill press manufacturing, the United States stands as one of the pioneers in the industry. American-made drill presses are known for their exceptional quality and durability. Many reputable brands such as Delta, Jet, and Powermatic have their manufacturing facilities in the U.S. These companies prioritize precision engineering, innovative designs, and stringent quality control measures to deliver reliable and efficient drill presses.

The United States boasts a rich history in manufacturing, providing the foundation for the production of high-quality drill presses. American manufacturers often source their components from local suppliers, ensuring that each drill press is made with top-notch materials. With advanced technology, skilled craftsmanship, and strict adherence to safety standards, drill presses manufactured in the United States are sought after by professionals and enthusiasts alike.

2. Germany

Known for its precision engineering and meticulous attention to detail, Germany has established itself as a prominent player in the drill press manufacturing industry. German-made drill presses are renowned for their exceptional performance, accuracy, and durability. Brands like Bosch, Metabo, and Fein have gained global recognition for their high-quality offerings.

German manufacturers follow strict quality control procedures, ensuring that every drill press meets the highest standards. They invest in research and development to embrace cutting-edge technologies, resulting in innovative features that enhance user experience. With a focus on craftsmanship and engineering excellence, drill presses from Germany are favored by professionals who value precision and reliability.

3. China

China has emerged as a dominant player in the global manufacturing industry, including the production of drill presses. The country’s manufacturing capabilities, cost-effectiveness, and vast production capacity have attracted many international brands to set up their production facilities in China. It has become a manufacturing hub for both affordable and high-performance drill presses.

While Chinese-made drill presses were once associated with lower quality, the country has made significant strides in improving manufacturing processes and product standards. Chinese manufacturers now offer a wide range of drill presses, catering to different price points and requirements. Many well-known brands, including Wen, Craftsman, and Central Machinery, have established manufacturing partnerships or factories in China to capitalize on its manufacturing prowess.

4. Taiwan

Taiwan is renowned for its precision engineering and expertise in manufacturing machine tools, making it a significant player in the drill press industry. Taiwanese manufacturers apply advanced technology and strict quality control measures to produce reliable and high-performing drill presses. Brands like YI-CHANG, HANKOOK, and YANG IRON are recognized for their precision and craftsmanship.

Taiwanese drill presses often offer a combination of affordability and quality, making them popular choices for both professional and hobbyist users. These manufacturers invest in research and development to continuously improve their offerings, ensuring that each drill press meets the evolving needs of the market. With a focus on precision, performance, and value, Taiwan has become a notable manufacturing destination for drill presses.

5. Japan

Japan has a longstanding reputation for excellence in manufacturing, and this extends to the production of drill presses. Japanese-made drill presses are known for their precision, reliability, and innovative features. Brands like Makita, Kawasaki, and Hitachi deliver drill presses that are lauded for their durability and exceptional performance.

Japanese manufacturers prioritize customer satisfaction and invest heavily in research and development to stay at the forefront of innovation. Their drill presses often incorporate advanced technologies and ergonomic designs, ensuring ease of use and accurate drilling operations. With a strong emphasis on quality and craftsmanship, Japanese drill presses are trusted by professionals in various industries.

6. Other Manufacturing Hubs

While the aforementioned countries represent significant players in drill press manufacturing, there are other notable manufacturing hubs around the world. Countries like Italy, Switzerland, India, and South Korea have their own manufacturing capabilities and contribute to the global supply of drill presses. Each region brings its unique approach to production and adds to the diverse range of drill presses available in the market.

These manufacturing hubs often specialize in specific types of drill presses or cater to niche markets. For example, Italy is known for producing high-end, artisanal drill presses, while India offers more affordable options without compromising on quality. South Korea, on the other hand, focuses on technological advancements and compact designs. By diversifying the manufacturing landscape, these countries provide a wide array of options for consumers worldwide.

Drill Press Manufacturing: Factors to Consider

When assessing where drill presses are manufactured, it is essential to consider various factors that influence the production process and the quality of the final product. Some key considerations include:

1. Cost of Production

Manufacturing costs play a crucial role in determining the location of drill press production. Countries with lower labor and operational costs often attract manufacturers looking to produce affordable drill presses. China, for instance, has competitive manufacturing costs due to its large labor force and infrastructure capabilities. On the other hand, countries with higher labor costs, such as Germany and the United States, may focus on producing premium drill presses.

1.1 Labor Costs

Labor costs directly impact the overall manufacturing expenses. Countries with lower wages tend to have more cost-effective production processes. China and Taiwan, for instance, offer competitive labor rates, making them favorable destinations for manufacturing drill presses. However, it is important to note that lower labor costs do not indicate lower quality, as these countries have also made significant advancements in manufacturing technologies and processes.

2. Manufacturing Expertise

The expertise and experience of a country’s manufacturing industry contribute to the overall quality and precision of drill presses. Countries with a long-standing tradition of engineering excellence, such as Germany and Japan, are well-known for manufacturing high-quality drill presses. Their expertise in precision engineering and adherence to strict quality control measures ensure reliable and durable products.

2.1 Legacy of Manufacturing

A country’s manufacturing legacy often influences its expertise in specific industries. For example, Germany’s reputation for precision engineering and craftsmanship stems from its rich manufacturing heritage. This legacy ensures that the manufacturing industry is supported by a skilled workforce and a robust infrastructure, further enhancing the quality of drill presses produced.

3. Technological Advancements

The level of technological advancements within a country significantly impacts the manufacturing processes and capabilities. Countries with advanced technology infrastructure can adopt innovative techniques and produce drill presses with enhanced features and functionality. Japan, for instance, is known for its technological prowess, allowing manufacturers to incorporate cutting-edge technologies into their drill press designs.

3.1 Research and Development Investments

Investments in research and development (R&D) drive technological advancements in manufacturing. Countries that prioritize R&D allocate resources to enhance production techniques, develop new materials, and improve overall product performance. These investments contribute to the development of advanced drill presses that cater to the evolving needs of users.

Choosing the Right Drill Press

Now that we have explored the manufacturing landscape of drill presses, it’s essential to consider your specific requirements when choosing the right drill press for your needs. Factors to take into account include:

1. Purpose and Intended Use

Consider the type of drilling tasks you will undertake and the materials you will be working with. Different drill presses are designed for specific applications, such as woodworking or metalworking. Make sure to choose a drill press that aligns with your intended use.

2. Power and Performance

Assess the power and performance capabilities of the drill press. Consider factors such as motor horsepower, drilling capacity, and variable speed options. Ensure that the drill press can handle the materials and projects you have in mind.

3. Build Quality and Durability

Check for the overall build quality and durability of the drill press. Look for robust construction, high-quality materials, and precision engineering. A well-built drill press will offer longevity and reliable performance.

4. Safety Features

Safety should be a top priority when working with a drill press. Look for features such as an adjustable depth stop, safety guards, and emergency stop buttons to ensure a secure working environment.

5. Budget

Consider your budget and the overall value offered by the drill press. Assess the features, performance, and reputation of the brand to make an informed decision that aligns with your financial constraints.

By taking these factors into account, you can select a drill press that suits your needs and offers a reliable and efficient drilling experience.

In conclusion, drill presses are manufactured in various countries around the world, each with its unique manufacturing capabilities and specialties. Countries like the United States, Germany, China, Taiwan, and Japan have established themselves as influential players in the drill press industry. The location of production depends on factors such as manufacturing costs, expertise, technological advancements, and legacy in manufacturing. By understanding the manufacturing landscape and considering your specific requirements, you can choose the right drill press that meets your needs and ensures optimal performance. So, whether you’re a professional carpenter or a DIY enthusiast, explore the diverse range of drill presses available and unleash the power of precision drilling.

Key Takeaways: Where are Drill Presses Manufactured?

- Drill presses are manufactured in various countries around the world.

- China is one of the largest producers of drill presses.

- Other countries like the United States, Germany, and Taiwan also manufacture drill presses.

- The country of origin can affect the quality and price of a drill press.

- When buying a drill press, it’s important to consider the manufacturing country and its reputation for producing reliable machinery.

Frequently Asked Questions

Welcome to our frequently asked questions section about the manufacturing of drill presses. Here, we’ll answer some common queries related to where drill presses are manufactured and provide you with valuable insights. Explore the answers below to get a better understanding of the topic!

1. What countries are known for manufacturing drill presses?

Drill presses are manufactured in various countries around the world. Some of the prominent countries known for producing drill presses include the United States, Germany, China, and Taiwan. Each of these countries has a reputation for producing high-quality drill presses that meet different needs and preferences.

The United States is known for its precision engineering and advanced technology, which leads to the production of reliable and durable drill presses. Germany is renowned for its engineering expertise, delivering precision and superior performance in their machines. China and Taiwan have emerged as major players in manufacturing affordable drill presses while maintaining decent quality standards.

2. Are all drill presses made in the country where the brand is based?

No, drill presses are not always manufactured in the same country where the brand is based. Many drill press brands have their headquarters in one country but manufacture their products in different locations globally. This strategy allows brands to take advantage of cost-effective manufacturing facilities, expertise, and resources available in various countries.

Some manufacturers may have production facilities in multiple countries, strategically distributing manufacturing tasks based on each country’s strengths. For example, a brand based in the United States may have some models manufactured domestically, while others are produced in countries like China or Taiwan to improve cost-efficiency or cater to specific markets.

3. Why do some drill presses have “Made in” labels from different countries?

When you come across drill presses with “Made in” labels from different countries, it’s typically because different components of the drill press are sourced from various locations worldwide. Manufacturers often aim to optimize the production process by sourcing components from countries that specialize in specific parts.

For example, a drill press may have its motor manufactured in Germany for its excellent engineering standards, while the body is produced in China for cost efficiency. These components are then brought together for assembly in another location. So, even though a drill press may have different country labels, it does not compromise the overall quality or performance of the machine.

4. Can you find high-quality drill presses manufactured in developing countries?

Absolutely! While it’s true that some of the well-established and renowned drill press manufacturers are located in developed countries, there are also high-quality drill presses manufactured in developing countries. The global manufacturing landscape has evolved, and developing nations now have the capability to produce top-notch drill presses.

Improvements in technology, access to skilled labor, and investments in manufacturing facilities have enabled developing countries to meet international quality standards. Countries like China, Taiwan, and India have emerged as significant players in the manufacturing sector, producing drill presses that offer excellent performance, durability, and value for money.

5. Can I determine the quality of a drill press based on its country of origin?

While the country of origin can sometimes provide certain insights into the quality of a drill press, it is not the sole determining factor. The quality of a drill press depends on various elements, including the manufacturer’s expertise, the processes in place, and the overall attention to detail during production.

It’s important to conduct thorough research, read customer reviews, and consider reputable brands when assessing the quality of a drill press. Brands with a strong track record and positive customer feedback are generally more reliable indicators of quality than the country where the drill press is manufactured.

Summary

Drill presses are manufactured all over the world, with some of the major production countries being China, Taiwan, and the United States. Different manufacturers have their own factories and assembly plants in these locations. Many well-known tool companies, such as Craftsman and Delta, have their drill presses made in China and Taiwan, while others like Jet and Powermatic produce them in the United States. So, depending on the brand, drill presses can be made in different countries.

However, it’s important to note that where a drill press is manufactured doesn’t necessarily determine its quality. Some drill presses made in China or Taiwan are of great quality, while others may not be as reliable. On the other hand, drill presses made in the United States generally have a reputation for being sturdy and durable. Ultimately, when choosing a drill press, it’s crucial to consider factors such as brand reputation, customer reviews, and specific model features rather than solely focusing on the manufacturing country.