Jet planes are wonders of engineering and aviation, soaring through the sky with their sleek forms and powerful engines. Ever wondered where these incredible machines are made? Let’s dive into the world of jet plane manufacturing and explore the epicenter of their creation.

When it comes to creating these marvels of modern technology, it’s not just one place that brings them to life. Jet planes are made in various locations around the world, with each country contributing its expertise and craftsmanship. From the United States to Europe and beyond, let’s take a journey to discover where these incredible machines are born.

So, buckle up and join us as we explore the fascinating world of jet plane manufacturing. Whether you’re a budding aviation enthusiast or simply curious about these magnificent flying machines, we’ve got an exciting adventure ahead. Get ready to take off and dive into the realm of where jet planes are made!

Where are Jet Planers Made: A Deep Dive into the Manufacturing Process

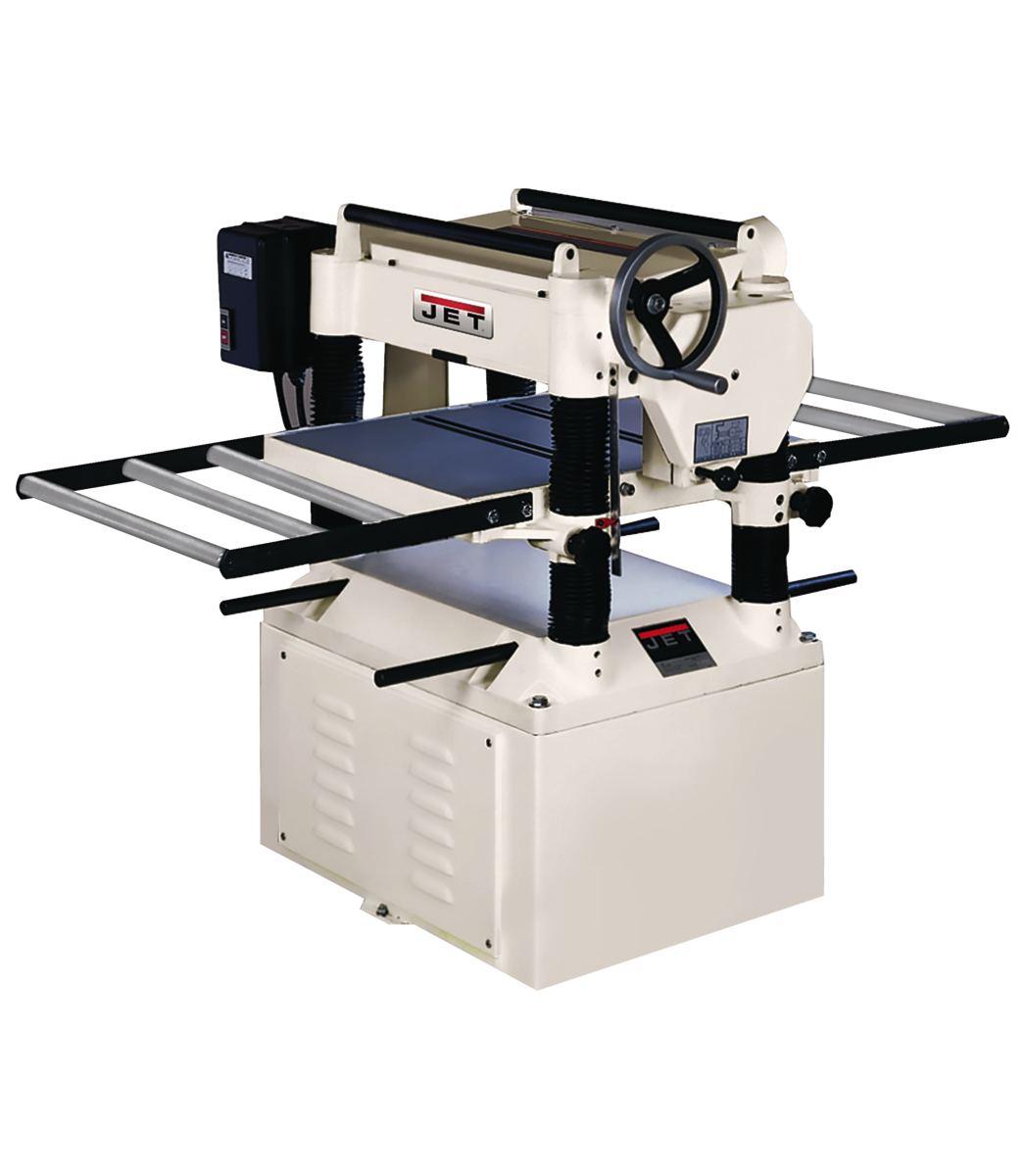

Jet planers are powerful machines that find application in various industries such as woodworking, construction, and metalworking. If you’ve ever wondered where these workhorses are made, you’ve come to the right place. In this article, we will explore the manufacturing process behind jet planers, the components that go into their production, and the factors that contribute to the quality and reliability of these machines.

1. The Manufacturing Process

Jet planers are typically manufactured in specialized facilities using advanced machinery and production techniques. The process begins with the design phase, where engineers and technicians develop detailed blueprints and specifications for the planers. These blueprints are then used to create the molds and tooling necessary for production.

Once the mold is ready, the manufacturing process moves on to the production line. Here, various components such as the frame, motor, cutterhead, and feed rollers are fabricated, assembled, and tested. The frame, typically made of sturdy materials like cast iron or steel, serves as the foundation of the planer and provides stability and durability.

The motor, the heart of the machine, is installed next. Jet planers often feature powerful induction motors that generate significant horsepower to tackle even the toughest cutting tasks. The cutterhead, responsible for removing material and creating a smooth finish, is precision-machined and fitted with high-quality knives. Finally, the feed rollers, driven by the motor, ensure a steady and uniform feed rate.

2. Components and Quality

The components used in the manufacturing of jet planers play a crucial role in determining their quality and performance. Top-tier planers are crafted using premium materials and undergo stringent quality control measures throughout the production process.

One key component is the cutterhead, where high-quality knives are crucial. These knives are typically made of high-speed steel (HSS) or carbide, known for their durability and ability to maintain sharpness over extended periods. The feed rollers, usually made of rubber or polyurethane, need to have excellent grip to ensure the workpiece is fed consistently and securely.

The motor is another vital component. Jet planers often utilize robust induction motors that provide reliable power and smooth operation. These motors are designed to withstand heavy usage and minimize vibrations for enhanced precision and longevity.

The frame of the planer is equally important. It should be made from durable materials like cast iron or steel, which provide stability and help dampen vibrations during operation. A sturdy frame ensures accurate and consistent results, even under demanding conditions.

3. Factors Influencing Production

Several factors influence where jet planers are made. Manufacturing facilities are often strategically located near raw material suppliers to minimize transportation costs and ensure a steady supply chain. Economic considerations, such as labor costs and government incentives, also play a role in determining the manufacturing location.

Moreover, manufacturers prioritize quality control and compliance with safety standards during the production of jet planers. These machines undergo rigorous testing and inspection to meet industry requirements and ensure customer satisfaction. By implementing robust quality control measures, manufacturers can guarantee that only top-quality planers reach the market.

In conclusion, jet planers are made through a meticulous manufacturing process that involves designing, fabricating, assembling, and testing various components. The quality of these components, such as the cutterhead, motor, and frame, greatly influences the performance and durability of the planers. Manufacturing locations are determined by factors like raw material availability, cost considerations, and adherence to quality standards. Overall, the manufacturing process and the components used contribute to the high-quality and reliability of jet planers in various industrial applications.

Where are Jet Planes Made? – Key Takeaways

1. Jet planes are made in various countries around the world, including the United States, France, Germany, and Russia.

2. Boeing and Airbus are two major manufacturers of jet planes, with Boeing being based in the United States and Airbus in France.

3. The United States is known for producing some of the most advanced military jet planes, like the F-16 and F-35.

4. Germany is famous for its engineering prowess, and companies like Airbus and Dassault Aviation have manufacturing facilities there.

5. Russia is renowned for its aerospace industry, and manufacturers like Sukhoi and MiG produce jet planes in the country.

Frequently Asked Questions

When it comes to jet planes, there is often curiosity about where they are made. Here are some common questions and answers regarding the production locations of jet planes.

1. What countries are known for manufacturing jet planes?

Several countries are renowned for manufacturing jet planes. The United States, with companies like Boeing and Lockheed Martin, is a major producer. Other significant players include Airbus in France, Embraer in Brazil, and Bombardier in Canada.

These countries have established themselves as leading manufacturers due to their expertise, infrastructure, and investment in the aerospace industry. Their production facilities contribute to the global supply of jet planes.

2. Can you provide specific examples of jet plane manufacturers and their locations?

Certain jet plane manufacturers have specific locations where they carry out production. For instance, Boeing, one of the largest aircraft manufacturers globally, has manufacturing facilities in Seattle, Washington, and Charleston, South Carolina, in the United States.

Airbus, on the other hand, has manufacturing sites in countries such as France, Germany, Spain, and the United Kingdom, allowing it to serve both the European market and customers worldwide. These locations host various stages of the manufacturing process, including assembly lines and final assembly plants.

3. Are there any emerging countries in the jet plane manufacturing industry?

Absolutely! The aerospace industry is a competitive and dynamic field, with emerging countries making their mark in jet plane manufacturing. For example, China has been investing heavily in its aviation sector, with companies like Commercial Aircraft Corporation of China (COMAC) producing their own passenger jets.

India also has ambitions to become a significant player in the aerospace industry. With initiatives like the “Make in India” campaign, the country aims to promote domestic manufacturing of jet planes and attract global investment to establish production facilities.

4. Do jet plane manufacturers have collaborations or partnerships across countries?

Collaborations and partnerships between jet plane manufacturers across countries are common in the industry. Such collaborations serve various purposes, including sharing expertise, resources, and cost-sharing.

For example, Airbus formed a partnership between France, Germany, Spain, and the UK, fostering collaboration between different countries’ aerospace industries. This allows them to pool resources and expertise to manufacture highly sophisticated and technologically advanced jet planes.

5. How does the manufacturing location of jet planes impact the global aviation industry?

The manufacturing location of jet planes plays a crucial role in the global aviation industry. It determines factors such as the economic impact on the manufacturing country, job creation, and the ability to meet the growing demand for air travel.

Furthermore, the manufacturing location influences the overall competitiveness of jet plane manufacturers. As countries invest in their aerospace industries, they enhance innovation, technology, and production standards, ultimately driving the advancement of the global aviation industry as a whole.

Summary

Jet planes are made in different countries, including the United States, Europe, and Asia. They require a team of engineers, designers, and workers to build them. The manufacturing process involves assembling various parts and conducting rigorous testing to ensure safety and performance. The important thing is that no matter where they are made, jet planes enable us to travel quickly and safely around the world.

Jet planes are built in different parts of the world by teams of experts. They undergo rigorous testing to ensure safety and performance before being used for travel. These amazing machines allow us to explore the world and connect with people from different countries. So, the next time you fly on a jet plane, think about the incredible effort that went into making it!