Are you curious about where Laguna bandsaws are made? Well, let me take you on a journey to uncover the origins of these powerful woodworking tools. From their humble beginnings to their current manufacturing process, we’ll explore the story behind these popular bandsaws. So, buckle up and let’s dive into the world of Laguna bandsaws!

In the world of woodworking, Laguna bandsaws have carved out a special place for themselves. But have you ever wondered where these amazing machines are actually made? It turns out that the birthplace of Laguna bandsaws is no other than the United States of America. Yes, you heard it right – these precision tools are proudly made right here in the USA.

Laguna Tools, the company that produces these bandsaws, has its headquarters and manufacturing facilities located in Irvine, California. This is where skilled craftsmen and technicians work diligently to bring these high-quality bandsaws to life. So, the next time you see a Laguna bandsaw in action, remember that it was crafted with care and precision right here in the USA.

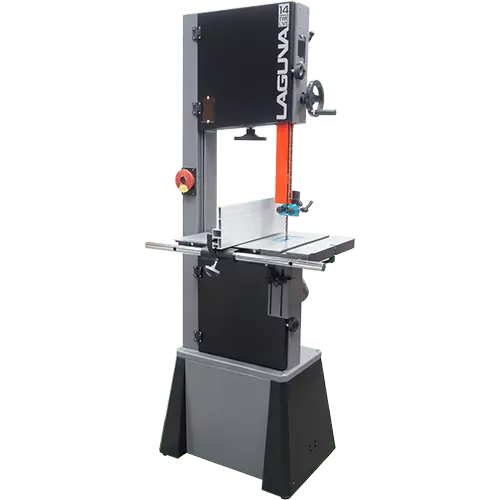

Where are Laguna Bandsaws Made? Unveiling the Origin and Craftsmanship Behind Your Favorite Woodworking Tool

When it comes to woodworking tools, Laguna Bandsaws have earned a reputation for their exceptional quality and performance. But have you ever wondered where these prized tools are made? In this article, we dive deep into the origins and craftsmanship behind Laguna Bandsaws. From the manufacturing process to the dedication of the skilled artisans, we uncover the secrets that make these bandsaws stand out from the competition.

The Birthplace of Excellence: The Laguna Bandsaw Factory in Italy

If you’ve ever marveled at the precision and craftsmanship of a Laguna Bandsaw, you can thank the skilled artisans in Italy. Nestled in the picturesque town of Pesaro, the Laguna Bandsaw factory is the birthplace of excellence. It is here that every Laguna Bandsaw is meticulously crafted by a team of talented and experienced woodworkers.

The Manufacturing Process: The journey of a Laguna Bandsaw begins with selecting the highest quality materials. From the cast iron frame to the precision components, every part of the bandsaw is carefully chosen to ensure durability and performance. Skilled craftsmen then assemble these components by hand, meticulously aligning and fine-tuning each element to guarantee optimal functionality.

Artistry and Attention to Detail: What sets Laguna Bandsaws apart is the dedication to artistry and attention to detail. Each bandsaw is hand-finished to perfection, with the artisans meticulously inspecting every inch of the machine. From smoothing the edges to polishing the surface, they ensure that every Laguna Bandsaw is not only a powerful tool but also a work of art.

Embracing Innovation: While Laguna Bandsaws stay true to traditional craftsmanship, they also embrace innovation. The factory is equipped with state-of-the-art technology that enhances efficiency and precision. From computer-aided design software to automated machinery, the artisans are able to blend the best of both worlds – traditional craftsmanship and cutting-edge technology.

From the Shores of Italy to Woodworking Workshops Worldwide

Once the Laguna Bandsaws are meticulously crafted in Italy, they embark on a journey to woodworking workshops worldwide. These exceptional tools are not just revered in their birthplace but are sought after by woodworkers and craftsmen around the globe.

The Global Distribution Network: Laguna Bandsaws are made available to woodworkers worldwide through an extensive network of distributors and retailers. Whether you’re in North America, Europe, Asia, or any other part of the world, you can easily find a Laguna Bandsaw that suits your woodworking needs.

International Reputation: Laguna Bandsaws have gained an international reputation for their exceptional quality and performance. Woodworking professionals and enthusiasts trust the brand for its reliability, precision, and durability. The craftsmanship and attention to detail that go into each bandsaw have made Laguna a beloved name in the woodworking community.

Customer Service and Support: Laguna takes pride in providing excellent customer service and support to its customers worldwide. From answering technical queries to providing after-sales assistance, the company ensures that woodworkers have a seamless experience with their bandsaws. This commitment to customer satisfaction has contributed to Laguna’s success and loyalty among its global clientele.

Benefits of Using a Laguna Bandsaw: Unlocking the Potential for Masterful Woodworking

Now that we’ve explored the origins and craftsmanship behind Laguna Bandsaws, let’s delve into the benefits of using these exceptional tools. Whether you’re a professional woodworker or a hobbyist, a Laguna Bandsaw can elevate your woodworking projects to new heights.

Precision and Accuracy: Laguna Bandsaws are renowned for their precision and accuracy. The powerful motors, robust construction, and finely-tuned components allow for smooth and precise cuts, even through thick hardwoods. This level of precision enables woodworkers to create intricate designs and achieve professional-grade results.

Resawing Capabilities: Resawing refers to the process of cutting thin slices from a larger piece of wood. Laguna Bandsaws excel in this area, allowing woodworkers to create veneers, book-matched panels, and other decorative elements with ease. The precision of the bandsaw ensures consistent thickness and minimizes waste, making it an ideal tool for resawing projects.

Versatility and Flexibility: Laguna Bandsaws come in various sizes and configurations, catering to different woodworking needs. From compact models for hobbyists to industrial-grade machines for professional workshops, there’s a Laguna Bandsaw for every application. The ability to choose a bandsaw that suits your specific requirements ensures that you have the flexibility to tackle a wide range of projects.

Durability and Longevity: Crafted with the finest materials and assembled with meticulous care, Laguna Bandsaws are built to last. These machines can withstand the demands of daily use in a woodworking workshop, ensuring that you have a reliable tool that will serve you for years to come. The durability and longevity of Laguna Bandsaws make them a wise investment for any woodworker.

Unveiling the Craftsmanship: The Essence of Laguna Bandsaws

Introduction: Laguna Bandsaws have become a symbol of excellence in the woodworking community. From their precise cuts to their exceptional durability, these bandsaws have earned the trust and admiration of woodworkers worldwide. In this section, we will take a closer look at the craftsmanship behind Laguna Bandsaws, exploring the key features and design elements that set them apart.

1. The Heart of Precision: The Laguna Bandsaw Blade

When it comes to achieving precise cuts, the blade of a bandsaw plays a crucial role. Laguna Bandsaws are carefully engineered to accommodate high-quality blades that are razor-sharp and designed for optimal performance. These bandsaw blades are made from durable materials such as high carbon steel or carbide, ensuring longevity and consistent cutting power.

The Laguna Bandsaw blades are crafted with precision, utilizing advanced manufacturing techniques to achieve the perfect balance between flexibility and rigidity. This allows the blades to effortlessly maneuver through different types of wood, providing clean and accurate cuts every time. Whether you’re slicing through hardwood or making intricate curved cuts, the Laguna Bandsaw blade delivers exceptional results.

Furthermore, Laguna offers a wide range of blade options, catering to various woodworking needs. From resaw blades for thick timber to fine-tooth blades for detailed work, woodworkers can choose the perfect blade to suit their specific projects. The versatility and precision of the Laguna Bandsaw blade make it an indispensable tool in any woodworking workshop.

Design Features and Innovations:

Alongside the exceptional craftsmanship, Laguna Bandsaws boast a range of design features and innovations that enhance their usability and performance. Let’s explore some of these key elements:

- Sturdy Construction: Laguna Bandsaws are built with robust frames and structures, ensuring stability and reducing vibrations. This allows for precise cuts and minimizes the risk of accidents or inaccuracies.

- Tensioning System: The blade tensioning system in Laguna Bandsaws is user-friendly and efficient. Woodworkers can easily adjust the tension of the blade to achieve the optimal balance between flexibility and cutting power.

- Table and Fence Design: The tables and fences in Laguna Bandsaws are engineered for accuracy and ease of use. They provide ample support for the workpiece, allowing woodworkers to achieve precise cuts while maintaining control and stability.

- Dust Collection: Laguna Bandsaws are designed with integrated dust collection systems, ensuring a cleaner and safer working environment. The efficient dust collection prevents debris from obstructing the blade and reduces the risk of respiratory issues.

- Quick-Release Blade Change: Swapping out blades in a Laguna Bandsaw is a breeze, thanks to their quick-release blade change systems. This feature allows woodworkers to save time and maintain productivity by swiftly switching between different blade types.

- Safety Features: Laguna Bandsaws prioritize safety with features such as blade guards, emergency stop buttons, and anti-kickback mechanisms. These elements provide a layer of protection and peace of mind for woodworkers, ensuring they can focus on their craft without worry.

2. The Symphony of Motion: The Laguna Bandsaw Motor

Behind every precise cut and powerful performance of a Laguna Bandsaw lies the heart of the machine – the motor. The motors in Laguna Bandsaws are carefully selected to deliver optimal power and efficiency. Whether you’re resawing a thick piece of hardwood or creating intricate curves, the Laguna Bandsaw motor provides the necessary torque and speed for flawless execution.

Laguna offers a range of motor options to cater to different woodworking needs. From compact models with smaller motors for hobbyists to industrial-grade machines with high-powered motors for professional workshops, there’s a Laguna Bandsaw motor that suits every application.

One of the standout features of Laguna Bandsaw motors is their quiet operation. Designed with noise reduction in mind, these motors minimize disruptions in the workshop, allowing woodworkers to focus on their craft without distractions. The smooth and silent performance of Laguna Bandsaw motors adds to the overall experience and satisfaction of using these exceptional tools.

Efficiency and Control: The Drive System

Working in harmony with the motor, the drive system in Laguna Bandsaws ensures efficient power distribution and precise control over the cutting process. The drive system transfers the rotational motion from the motor to the blade, allowing for smooth and accurate cuts.

Laguna Bandsaws incorporate different drive systems, including belt drives and direct drives. Belt drives provide flexibility, allowing for speed adjustments and accommodating different blade sizes. Direct drives, on the other hand, offer immediate power transfer and maximize efficiency.

Woodworkers can choose the drive system that best suits their needs and preferences, be it for versatility or focused power. The efficient drive systems in Laguna Bandsaws contribute to their exceptional performance and reliability, perfecting every cut and ensuring the best possible woodworking experience.

Mastering Your Craft: Tips and Tricks for Using Laguna Bandsaws

Introduction: Now that we’ve explored the origins, craftsmanship, and key features of Laguna Bandsaws, let’s dive into some tips and tricks for getting the most out of these exceptional tools. By mastering your craft and harnessing the full potential of your Laguna Bandsaw, you can take your woodworking projects to new heights of precision and artistry.

1. Blade Selection: Choosing the Right Blade for the Job

One of the crucial factors in achieving excellent results with your Laguna Bandsaw is selecting the right blade for the specific task at hand. Here are some pointers to keep in mind when choosing a blade:

- Consider the Wood Type: Different blade types are suitable for various wood types. For example, a fine-tooth blade is ideal for cutting hardwoods, while a skip-tooth blade is better for softer woods.

- Thickness and Width: The thickness and width of the wood you’re working with should also influence your blade choice. Thicker or wider boards may require blades with larger teeth or a greater tooth set.

- Curved Cuts vs. Straight Cuts: If you’re making intricate curved cuts, a blade with a narrow width and a higher number of teeth per inch (TPI) will yield better results. For straight cuts, a wider blade with fewer TPI can be more efficient.

- Specialty Blades: Laguna Bandsaws offer specialty blades for specific applications such as resawing, veneer cutting, or scrollwork. These blades are designed to excel in their respective tasks and can significantly enhance your woodworking projects.

By selecting the right blade for each project, you can optimize your Laguna Bandsaw’s performance and achieve clean, precise cuts with ease.

Tensioning and Tracking: Fine-Tuning the Blade

Once you’ve chosen the appropriate blade, it’s essential to properly tension and track it on your Laguna Bandsaw. Here are some tips for achieving optimal tension and tracking:

- Tensioning: Follow the manufacturer’s guidelines for tensioning the blade. Over-tensioning can lead to premature blade wear, while under-tensioning can result in poor performance and inaccurate cuts.

- Tracking: Adjust the blade tracking using the tracking knob or adjustment mechanism on your bandsaw. The blade should run smoothly and centered on the wheels without any wobbling or veering off to one side.

- Blade Guides: Ensure that the blade guides are properly aligned and adjusted. They should provide support and control to the blade, minimizing deflection and enhancing cutting accuracy.

Taking the time to properly tension and track your blade will ensure optimal performance and extend its lifespan, allowing you to make the most of your Laguna Bandsaw.

2. Safety First: Best Practices for Working with Laguna Bandsaws

While Laguna Bandsaws are designed with safety features, it’s vital to prioritize safety precautions during every woodworking session. Here are some best practices to follow:

- Wear Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety glasses, hearing protection, and a dust mask or respirator. This protects you from potential hazards such as flying debris, loud noise, and dust particles.

- Maintain a Clean Workspace: Keep your bandsaw area organized and free from clutter. This minimizes the risk of accidents and ensures smooth operation.

- Properly Position the Workpiece: Secure the workpiece firmly against the fence and the table, maintaining control and stability throughout the cutting process. This reduces the chances of kickback and allows for accurate cuts.

- Feed Rate: Avoid forcing the workpiece into the blade. Instead, let the blade do the work at the appropriate feed rate. Pushing too hard can strain the motor and lead to less precise cuts.

- Blade Maintenance: Regularly inspect and clean your bandsaw blade to remove pitch or resin buildup. This not only improves performance but also prevents potential hazards such as blade slippage or binding.

By incorporating these safety practices into your woodworking routine, you can ensure a safe and enjoyable experience with your Laguna Bandsaw.

The Woodworker’s Secret Weapon: Laguna Bandsaws

Introduction: From their exquisite craftsmanship to their exceptional performance, Laguna Bandsaws have become a secret weapon in the hands of woodworkers around the world. Whether you’re a seasoned professional or a passionate hobbyist, these bandsaws offer unparalleled precision, versatility, and longevity.

The Art of Excellence: Crafted in Italy

Italian Craftsmanship: The Laguna Bandsaw factory in Pesaro, Italy, is the birthplace of excellence. Skilled artisans meticulously handcraft each bandsaw, selecting the highest quality materials and incorporating innovative technology. The result is a machine that not only performs flawlessly but also exhibits the artistry of traditional craftsmanship.

Global Distribution: Laguna Bandsaws have gained international recognition and are available through a wide network of distributors. Woodworkers worldwide have access to these exceptional tools, allowing them to elevate their craft and achieve professional-grade results.

Unlocking Woodworking Potential: Benefits of Using Laguna Bandsaws

Precision and Accuracy: Laguna Bandsaws are renowned for their precise cuts and accurate performance. They enable woodworkers to create intricate designs and achieve professional-grade results with ease.

Versatility and Flexibility: With a wide range of models and configurations, Laguna Bandsaws cater to various woodworking needs. From compact tools for hobbyists to industrial-grade machines, there’s a bandsaw for every application.

Durability and Longevity: Crafted with the finest materials and designed for robustness, Laguna Bandsaws are built to last. These machines withstand the demands of daily use in woodworking workshops, ensuring that woodworkers have a reliable tool for years to come.

Master the Craft with Laguna Bandsaws

Introduction: Laguna Bandsaws are a woodworker’s best friend, offering precision, versatility, and durability. Let’s explore some expert tips and tricks to help you master your craft with these exceptional tools.

1. Choosing the Right Blade for the Job

When it comes to using Laguna Bandsaws, selecting the right blade is crucial for achieving clean and accurate cuts. Consider the type of wood you’re working with, the thickness of the material, and the desired cut. This will help you choose the appropriate blade type, width, and tooth configuration for the task at hand.

Pro Tip: Keep a variety of blades in your workshop to tackle different woodworking projects. This allows you to optimize the performance of your Laguna Bandsaw for each specific application.

2. Mastering Tensioning and Tracking

Properly tensioning and tracking the blade on your Laguna Bandsaw ensures optimal performance and prolongs the life of the blade. Follow the manufacturer’s guidelines for tensioning, and regularly check the blade for proper tracking. Make any necessary adjustments using the tensioning knob or adjustment mechanism on your bandsaw.

Pro Tip: Consider investing in a blade tension gauge to ensure consistent tensioning and achieve the best results with your bandsaw.

3. Safety First: Best Practices for Working with Laguna Bandsaws

Using any power tool requires prioritizing safety. When working with Laguna Bandsaws, always wear appropriate personal protective equipment, keep your workspace clean and organized, and follow proper feeding techniques to avoid accidents or injuries.

Pro Tip: Familiarize yourself with the safety features of your Laguna Bandsaw and conduct regular maintenance to keep the machine in optimal working condition.

With these expert tips and tricks, you can unlock the full potential of your Laguna Bandsaw and take your woodworking skills to the next level.

Where Are Laguna Bandsaws Made?

In a nutshell, Laguna bandsaws are made in Taiwan.

Key Takeaways:

- Laguna bandsaws are produced in Taiwan.

- Taiwan has a strong reputation for manufacturing quality machinery.

- The country has a skilled workforce and advanced manufacturing technologies.

- Laguna bandsaws benefit from Taiwanese craftsmanship and expertise.

- Customers can expect reliable and high-quality bandsaws from Laguna.

Frequently Asked Questions

Looking to find out where Laguna bandsaws are made? We’ve got answers to all your questions!

1. Are Laguna bandsaws manufactured in the United States?

Yes, Laguna bandsaws are manufactured in the United States. The company was founded in 1983 in Irvine, California. Since then, they have continued to produce their bandsaws domestically. By manufacturing their products in the United States, Laguna ensures quality control and supports local employment.

2. Do Laguna bandsaws have any international manufacturing facilities?

No, Laguna bandsaws do not have any international manufacturing facilities. All their manufacturing takes place in the United States. However, they do have a global presence through their network of dealers and distributors, allowing their bandsaws to be available worldwide.

3. Are all components of Laguna bandsaws sourced from the United States?

While a majority of the components that go into making Laguna bandsaws are sourced from the United States, there are certain parts that may be sourced internationally. These components are carefully selected to meet Laguna’s high standards and specifications. However, the final assembly of the bandsaws takes place in the United States, ensuring quality control.

4. How does manufacturing in the United States benefit Laguna bandsaws?

Manufacturing in the United States allows Laguna to maintain high-quality control over their bandsaws. By overseeing the entire production process domestically, they can ensure that each bandsaw meets their rigorous standards before it reaches the customer. Additionally, manufacturing locally supports the American economy and provides jobs within the community.

5. Are there any specific features or characteristics that differentiate Laguna bandsaws made in the United States?

Laguna bandsaws made in the United States are known for their superior craftsmanship and attention to detail. The company is dedicated to using high-quality materials and advanced manufacturing techniques to produce bandsaws that are reliable, durable, and precise. Made with precision, Laguna bandsaws made in the United States are trusted by professionals and woodworking enthusiasts alike.

LT Series Industrial Bandsaw Line | Laguna Tools

Summary

So, where are Laguna bandsaws made? Well, they are made in the USA and Italy. The company has factories in California and Italy where they produce their bandsaws.

When it comes to quality, Laguna bandsaws are highly regarded by professionals and hobbyists alike. They are known for their precision, durability, and innovative features. Plus, the fact that they are made in the USA and Italy further ensures their craftsmanship.

If you’re looking for a reliable bandsaw, you can trust Laguna to deliver a high-quality product. Whether you’re a woodworker or a metalworker, their bandsaws are designed to meet your needs and help you create amazing projects.