Hey there! So you’re wondering where Norwood bandsaw mills are made, huh? Well, let me tell you, these mills have quite the interesting story behind them.

You know, Norwood is all about creating top-notch, high-quality bandsaw mills that are loved by professionals and DIY enthusiasts alike. But have you ever wondered where these incredible machines are actually manufactured?

Well, my curious friend, in this article, we’re going to dive deep into the origins of Norwood bandsaw mills and find out exactly where they are made. Get ready for a fascinating journey into the world of woodworking machinery!

Where Are Norwood Bandsaw Mills Made?: A Deep Dive into the Manufacturing Process

Are you in the market for a bandsaw mill and curious about where Norwood bandsaw mills are made? Look no further! In this article, we’ll take a close look at the manufacturing process behind Norwood bandsaw mills and explore the various factors that contribute to their exceptional quality and performance. Whether you’re a woodworking enthusiast or a professional looking to invest in a reliable and efficient mill, understanding the origins of your equipment is essential. Join us as we venture into the world of Norwood bandsaw mills and the locations where they are manufactured.

Canadian Craftsmanship: Where Norwood Bandsaw Mills Are Made

Description: One of the primary locations where Norwood bandsaw mills are made is Canada. Renowned for its fine craftsmanship and attention to detail, Canada is home to Norwood’s manufacturing facilities. With a rich history in woodworking traditions and a commitment to excellence, the Canadian manufacturing sector is highly regarded worldwide. Let’s delve into the specific regions in Canada where Norwood bandsaw mills are carefully crafted.

Regional Manufacturing: Quebec, Ontario, and British Columbia

Description: Quebec, Ontario, and British Columbia are the key regions in Canada where Norwood bandsaw mills are made. In Quebec, the heart of Norwood’s manufacturing operations, you’ll find state-of-the-art facilities equipped to produce these high-quality mills. Similarly, Ontario and British Columbia boast manufacturing sites that contribute to the production process. Each region brings its own expertise to the table, making use of local resources and skilled workers to create top-notch bandsaw mills.

Quebec’s Manufacturing Expertise and Norwood Bandsaw Mills

Description: Quebec’s manufacturing expertise plays a crucial role in the production of Norwood bandsaw mills. With a long-standing tradition of craftsmanship and an abundance of natural resources, Quebec offers an ideal setting for wood-based industries. Norwood’s facilities in Quebec employ skilled technicians and utilize cutting-edge machinery to ensure the highest standards of quality. The meticulous attention to detail and commitment to excellence make Quebec an integral part of Norwood’s manufacturing process.

Unwavering Quality Control: The Norwood Manufacturing Process

Description: When it comes to Norwood bandsaw mills, every step of the manufacturing process is carefully monitored to maintain the highest level of quality control. From sourcing materials to the final inspection, Norwood’s manufacturing process is a well-oiled machine. In this section, we’ll explore the key stages of production that contribute to the exceptional performance and durability of Norwood bandsaw mills.

Material Selection: Choosing the Finest Components

Description: The first stage of the manufacturing process involves selecting the finest components for Norwood bandsaw mills. From the frame to the blades, every part is carefully chosen to ensure superior quality and longevity. High-grade steel and durable materials are selected to withstand the demanding tasks performed by bandsaw mills. By using only the best materials, Norwood guarantees that their products will stand the test of time.

Precision Machining: Transforming Materials into Performance

Description: Precision machining is a vital step in the manufacturing process. Skilled technicians operate cutting-edge machinery to transform selected materials into components that deliver optimal performance. Every cut and every measurement is meticulously executed to ensure precise fitting and seamless assembly. Norwood’s commitment to precision machining results in bandsaw mills that operate smoothly and efficiently.

Assembly: The Art of Putting It All Together

Description: The assembly process is where all the carefully crafted components come together to form a Norwood bandsaw mill. Expert technicians meticulously follow detailed instructions and utilize specialized tools to assemble the mills with utmost precision. Each step of the assembly process is closely monitored to ensure that the final product meets Norwood’s strict quality standards.

The Benefits of Norwood Bandsaw Mills

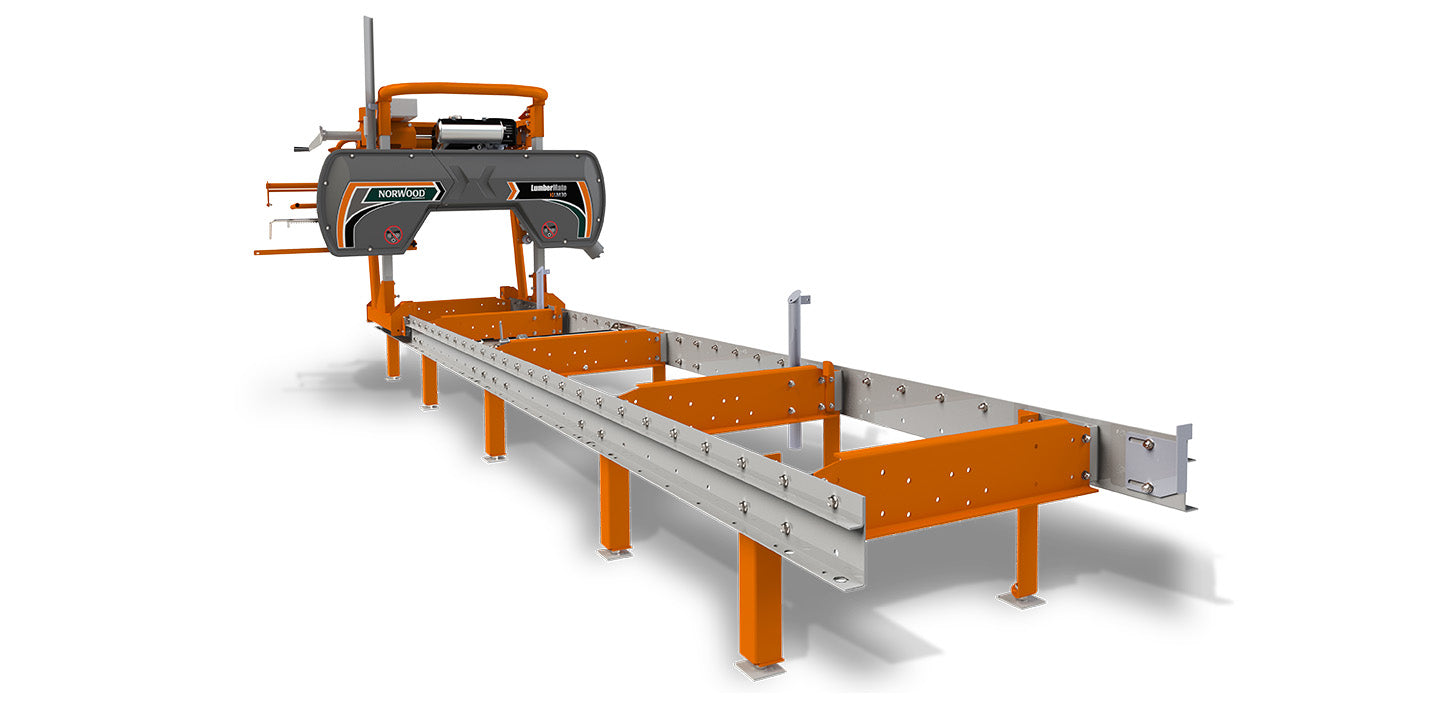

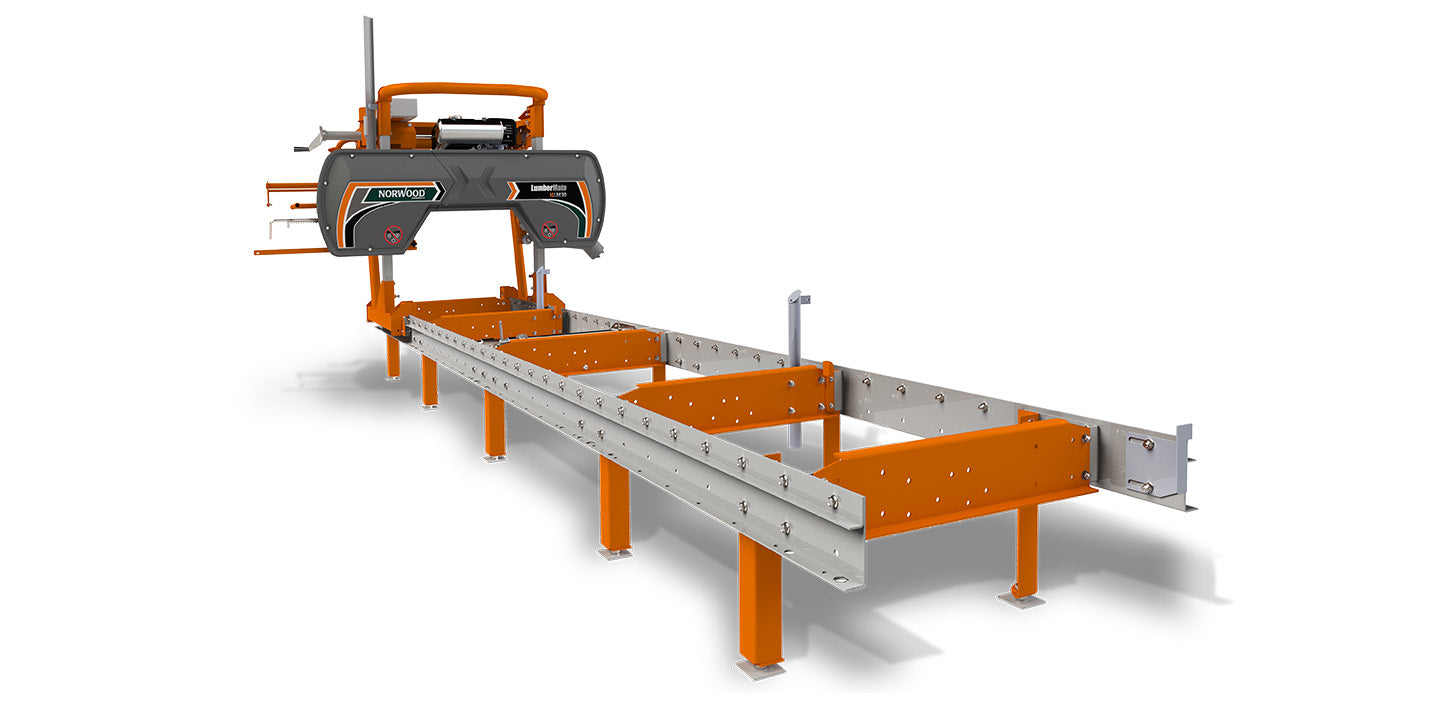

Description: Now that we’ve explored where Norwood bandsaw mills are made and the meticulous manufacturing process behind them, let’s take a moment to highlight the benefits of these exceptional machines. From their durability and precision to their versatility and ease of use, Norwood bandsaw mills offer a myriad of advantages for both hobbyists and professionals in the woodworking industry.

Durability and Longevity: Built to Last

Description: One of the standout features of Norwood bandsaw mills is their durability and longevity. Crafted with top-grade materials and manufactured under strict quality control, these mills are built to withstand the test of time. Whether you’re tackling large-scale projects or working on smaller tasks, Norwood bandsaw mills offer the reliability and longevity you need.

Precision and Accuracy: Consistently Exceptional Results

Description: When it comes to precision and accuracy, Norwood bandsaw mills set the standard. The carefully machined components and meticulous assembly process ensure that each cut is precise and accurate, resulting in consistently exceptional results. Whether you’re cutting through hardwood or softwood, Norwood bandsaw mills deliver the precision you demand.

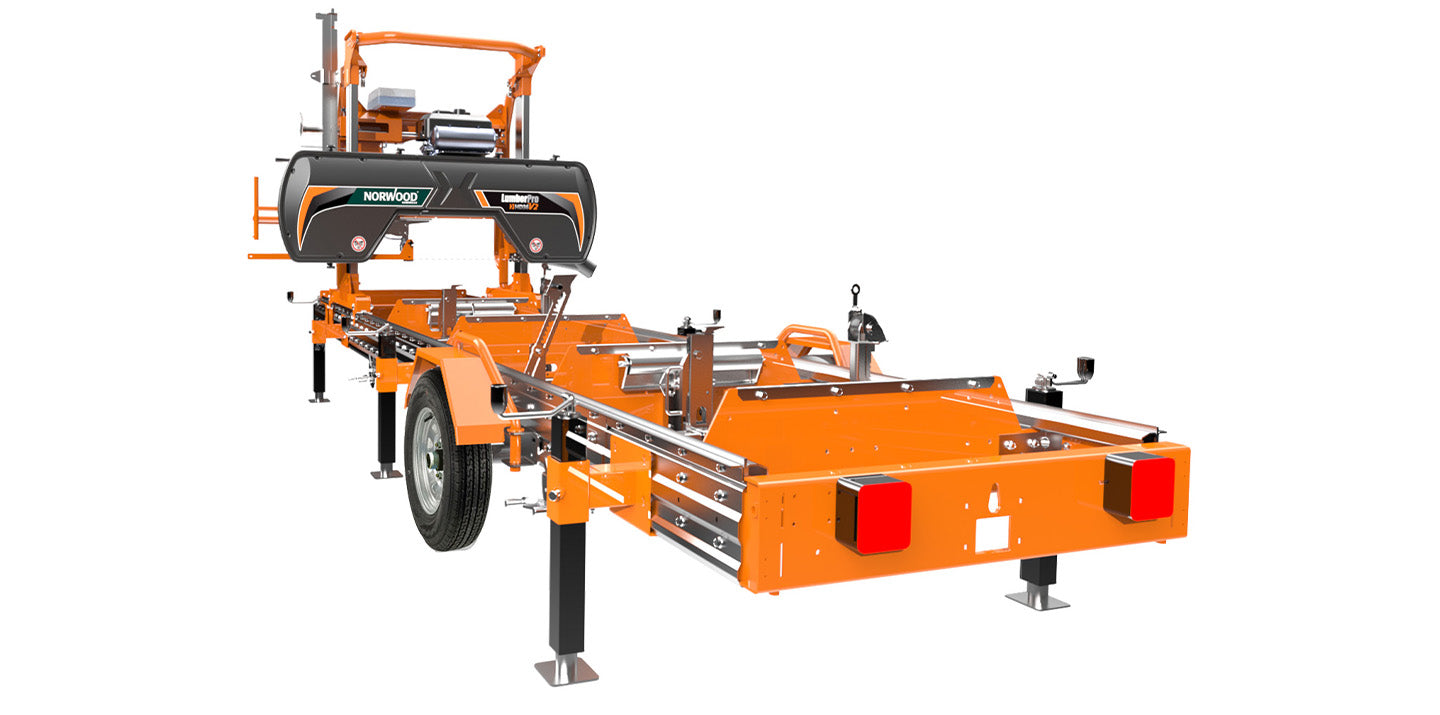

Versatility and Flexibility: Adaptable to Various Projects

Description: No matter the scale or complexity of your woodworking projects, Norwood bandsaw mills offer the versatility and flexibility needed to tackle them all. With adjustable features and customizable options, these mills can be tailored to meet your specific requirements. From large, heavy-duty operations to intricate detail work, Norwood bandsaw mills are up to the task.

User-Friendly Design: Easy to Use and Maintain

Description: While Norwood bandsaw mills are packed with advanced features and capabilities, their user-friendly design ensures that they are easy to use and maintain. Whether you’re a seasoned professional or a hobbyist just starting out, these mills are designed to be intuitive and hassle-free. Plus, Norwood provides comprehensive support and resources to help users get the most out of their equipment.

Cost-Effective Solution: Great Value for Your Investment

Description: Investing in a Norwood bandsaw mill is a cost-effective solution for woodworking enthusiasts and professionals alike. With their exceptional quality and durability, these mills offer great value for your investment. You can count on Norwood bandsaw mills to deliver reliable performance for years to come, making them a wise choice for any woodworker.

Additional Factors to Consider

Description: As you explore the world of Norwood bandsaw mills, there are a few additional factors worth considering. Beyond their manufacturing process and the benefits they offer, these factors can further aid you in making an informed decision about which Norwood bandsaw mill is right for you.

Accessories and Add-Ons: Enhancing the Milling Experience

Description: To enhance your milling experience, Norwood offers a range of accessories and add-ons that can be incorporated into your bandsaw mill setup. From blade sharpeners and bed extensions to log handling tools and more, these additional features can increase efficiency and expand your milling capabilities.

Customer Support and Resources: Assistance at Every Step

Description: Norwood takes pride in providing exceptional customer support and resources to help users maximize their bandsaw mill experience. From detailed instructional videos and manuals to a responsive customer service team, Norwood ensures that you have the assistance you need at every step of the way.

Comparison with Other Brands: Making an Informed Choice

Description: When considering Norwood bandsaw mills, it’s essential to compare them with other brands in the market. By evaluating the features, performance, and customer reviews of different bandsaw mills, you can make an informed choice that aligns with your specific needs and preferences.

In conclusion, Norwood bandsaw mills are manufactured in Canada, primarily in Quebec, Ontario, and British Columbia. These mills go through a meticulous manufacturing process that ensures the highest level of quality control. The result is a range of bandsaw mills that offer durability, precision, versatility, user-friendliness, and excellent value for your investment. With accessories, customer support, and comparisons with other brands to consider, you can confidently choose a Norwood bandsaw mill that meets your woodworking requirements. So, why wait? Explore the world of Norwood bandsaw mills and enhance your woodworking journey today!

Key Takeaways: Where are Norwood bandsaw mills made?

- Norwood bandsaw mills are made in Canada, specifically in the town of Hawkestone, Ontario.

- Norwood is proud to manufacture their mills locally, ensuring high-quality craftsmanship.

- By producing their mills in Canada, Norwood supports the local economy and creates job opportunities.

- Hawkestone, Ontario is a small town known for its manufacturing industry, making it an ideal location for Norwood’s production facility.

- When you buy a Norwood bandsaw mill, you can have peace of mind knowing it was made with care in Canada.

Frequently Asked Questions

Here are some common questions about the origin of Norwood bandsaw mills:

1. Can you tell me where Norwood bandsaw mills are manufactured?

Norwood bandsaw mills are proudly manufactured in North America, with their main manufacturing facility located in the province of Ontario, Canada. They have been producing high-quality bandsaw mills for over 25 years.

Their state-of-the-art manufacturing facility houses a skilled team of engineers, fabricators, and technicians who work diligently to ensure that each mill meets the strict quality standards set by Norwood. The company takes pride in its Canadian heritage and is committed to supporting the local economy.

2. Are Norwood bandsaw mills made entirely in Canada?

Yes, Norwood bandsaw mills are made entirely in Canada. In addition to their location in Ontario, Canada, where the main manufacturing facility is situated, Norwood sources many of the components and materials for their mills from Canadian suppliers.

By manufacturing their mills locally, Norwood can closely monitor the production process and maintain the highest level of quality control. It also allows them to support local jobs and contribute to the Canadian economy, which is something Norwood takes great pride in.

3. Are Norwood bandsaw mills made with international components?

Yes, Norwood bandsaw mills are made with a combination of international and domestic components. While the main manufacturing facility is in Canada, Norwood sources some components from trusted international suppliers.

The selection of international components is based on stringent quality standards to ensure that every Norwood mill is built to last. Norwood has established strong partnerships with these global suppliers to ensure the highest quality and reliability of their bandsaw mills.

4. Do Norwood bandsaw mills come with a warranty?

Yes, Norwood bandsaw mills come with a comprehensive warranty to provide customers with peace of mind. They offer a 2-year limited warranty, which covers any defects in materials or workmanship from the date of purchase.

Customers can rest assured that Norwood stands behind the quality of their mills and will rectify any issues that arise within the warranty period. This warranty reflects their commitment to delivering reliable and durable bandsaw mills to their customers.

5. Can I visit the Norwood manufacturing facility?

Unfortunately, Norwood does not offer public tours of their manufacturing facility. The facility is strictly dedicated to production and does not accommodate public visits.

However, Norwood provides comprehensive information about their mills on their website, including detailed specifications, videos, and customer testimonials. They also have a dedicated customer support team that is available to assist with any questions or inquiries regarding their bandsaw mills.

Summary

If you’re wondering where Norwood bandsaw mills are made, the answer is Canada. Norwood is a Canadian company that manufactures their bandsaw mills in their own factory.

These mills are known for their quality and durability, and they are designed to be easy to use. Whether you’re a professional woodworker or just starting out, a Norwood bandsaw mill could be a great investment for your woodworking projects.