Ah, the Channel Tunnel boring machines. Have you ever wondered where these massive machines are currently digging deep below the English Channel? Let’s embark on a fascinating journey to discover their whereabouts!

Deep beneath the surface, where the land meets the sea, lies an engineering marvel known as the Channel Tunnel. This remarkable tunnel connects the United Kingdom to mainland Europe, enabling people and goods to travel between the two with ease. But have you ever stopped to think about how this tunnel was built in the first place?

Well, my young curious minds, it all began with the mighty Channel Tunnel boring machines! These colossal machines, aptly named because of their ability to bore through mountains and solid rock, played a crucial role in constructing this awe-inspiring tunnel. But where are they now? Let’s find out, shall we?

Exploring the Location of Channel Tunnel Boring Machines

Channel Tunnel Boring Machines (TBMs) play a crucial role in the construction of the Channel Tunnel, connecting the United Kingdom and France. In this article, we will dive deep into the whereabouts of these impressive machines and shed light on their purpose, operation, and significance in this engineering feat.

The Journey Begins: Where Are the Channel Tunnel Boring Machines?

The Channel Tunnel Boring Machines are primarily located at two major sites: one in the United Kingdom and the other in France. In the UK, the TBMs are stationed at the Shakespeare Cliff site in Kent, while in France, they are situated at the Sangatte site near Calais.

The reason for having separate locations for the TBMs is to avoid the challenges of transportation and facilitate efficient operation. The TBM components, weighing hundreds of tons, are massive and require careful handling. By having them stationed near the tunnel entrances in both countries, the construction process becomes more streamlined and time-efficient.

Additionally, these locations provide sufficient space for the assembly, disassembly, and maintenance of the TBMs. These sites are equipped with the necessary infrastructure and facilities that support the operation and monitoring of the machines throughout the construction process.

The Secrets Unveiled: Inside the Channel Tunnel Boring Machines

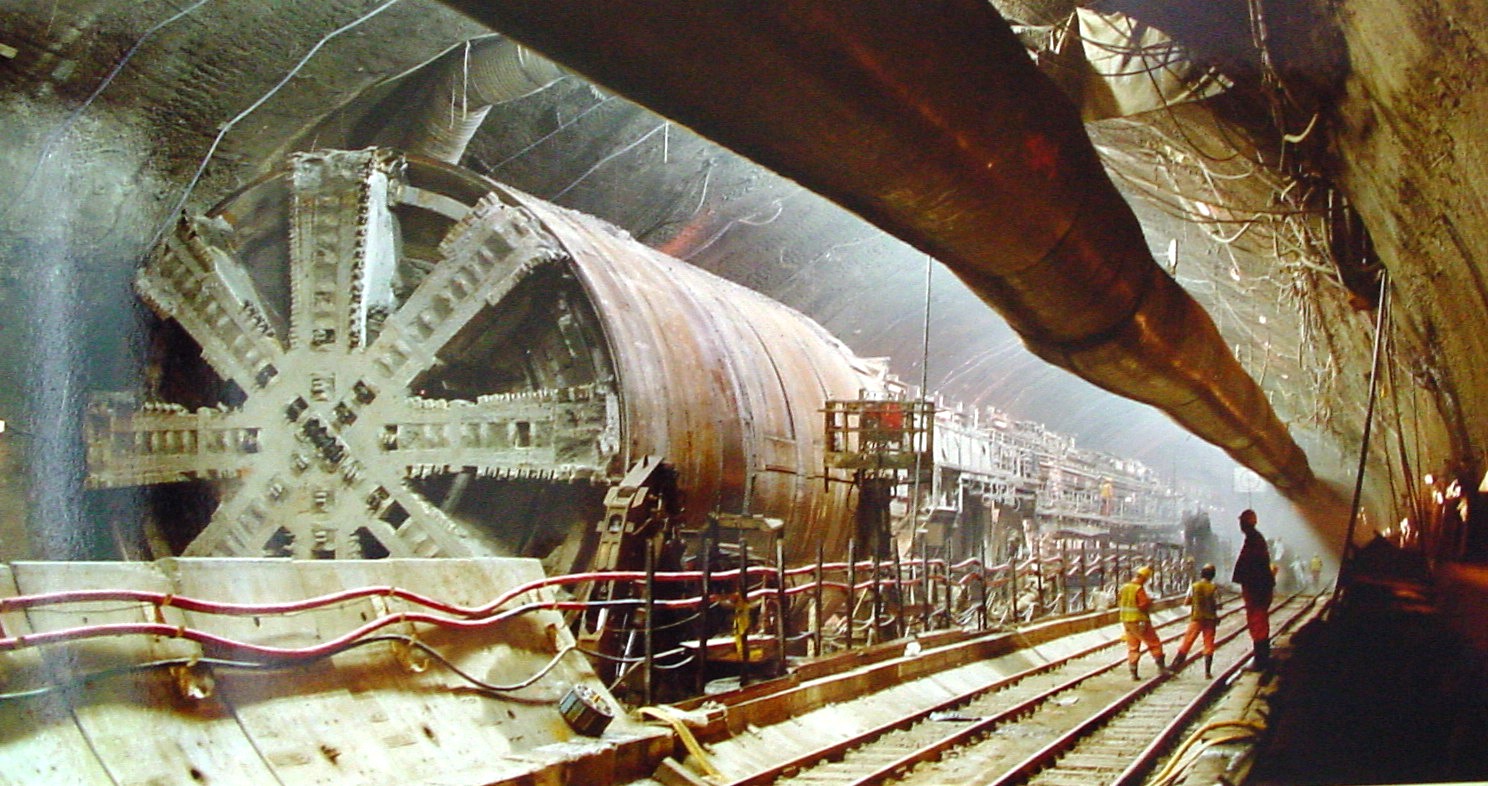

Channel Tunnel Boring Machines are engineering marvels that consist of various sophisticated components and systems. Let’s take a closer look at what goes on inside these colossal machines:

1. Cutter Head

The cutter head is the foremost part of the TBM that leads the way in excavating the tunnel. It is equipped with countless cutting tools, such as disc cutters and roller cutters, which break apart the rock or soil as the TBM progresses forward.

The cutter head rotates at a slow but steady pace, exerting immense force to create the tunnel cavity. It is designed to withstand the high pressure and wear and tear experienced during the excavation process.

Furthermore, the cutter head also includes systems for slurry management, which helps to stabilize the tunnel face and remove the excavated material.

2. Shield

The shield is the main body of the TBM that houses the operator’s cabin, control systems, and backup systems. It provides a protective enclosure for the workers and equipment inside the TBM.

The shield is designed to ensure the stability and integrity of the tunnel during excavation. It supports the weight of the TBM and effectively distributes the load to maintain the structural strength of the tunnel walls.

Additionally, the shield also incorporates systems for ventilation, communication, and power supply, ensuring a safe and functional working environment within the TBM.

3. Conveyer System

The conveyer system plays a vital role in transporting the excavated material from the TBM to the surface. It consists of a series of conveyer belts or screw conveyers that move the spoil away from the TBM.

This system allows for efficient removal of the excavated material, preventing congestion and enabling a smooth operation of the TBM. It also aids in maintaining a clean and organized working environment within the TBM.

Moreover, the conveyer system can be designed to handle different types of soil or rock, ensuring the versatility and adaptability of the TBM during the construction process.

4. Thrust System

The thrust system is responsible for pushing the TBM forward as it excavates the tunnel. It exerts considerable force to propel the TBM and withstand the resistance offered by the surrounding soil or rock.

This system consists of hydraulic jacks or cylinders that generate the necessary thrust, allowing the TBM to steadily advance. The thrust force is carefully calibrated to prevent excessive pressure on the tunnel walls, ensuring the stability and safety of the construction process.

Additionally, the thrust system also provides a means for monitoring and adjusting the advance rate of the TBM to optimize productivity and efficiency.

The Advancements Continue: Where Are the Channel Tunnel Boring Machines Headed?

As the Channel Tunnel Boring Machines continue their journey through the tunnel, their destinations vary depending on the specific construction phase. After completing the excavation work, the TBMs are disassembled and transported back to their respective sites for maintenance and refurbishment.

However, the future of these remarkable machines doesn’t end with the construction of the Channel Tunnel. TBMs are highly valuable assets that can be repurposed and used for other tunneling projects worldwide.

Many TBMs used in the Channel Tunnel project have found new homes in various parts of the world, contributing to the construction of tunnels for transportation, infrastructure, and utility purposes. These machines continue to demonstrate their efficiency, reliability, and ability to overcome complex engineering challenges.

Embracing the Marvel of Engineering: Innovations and Future Possibilities

The Channel Tunnel Boring Machines are just one example of the incredible innovations in the field of engineering. As technology continues to evolve, new advancements are being made with the aim of enhancing the efficiency and sustainability of tunnel construction.

Some of the future possibilities include the development of more compact and versatile TBMs that can navigate through tight spaces and challenging terrains. The integration of automation and artificial intelligence in the operation of TBMs is also an area of ongoing research, which promises significant improvements in productivity and safety.

With each new project, engineers strive to push the boundaries of what is possible, ensuring that tunneling becomes more efficient, sustainable, and cost-effective. The Channel Tunnel Boring Machines have set the stage for these advancements, leaving a lasting impact on the world of engineering.

In conclusion, Channel Tunnel Boring Machines are strategically located in both the United Kingdom and France, near the tunnel entrances, to streamline the construction process. These impressive machines consist of various components such as the cutter head, shield, conveyer system, and thrust system, all playing a crucial role in the excavation and transportation of materials. After their role in the Channel Tunnel project concludes, these TBMs find new opportunities worldwide. As the engineering field continues to advance, innovations and future possibilities for TBMs emerge, promising to redefine tunneling as we know it.

Key Takeaways – Where are the Channel Tunnel Boring Machines?

- The Channel Tunnel Boring Machines are located in England and France.

- They are used to create tunnels under the English Channel.

- The machines are massive, weighing thousands of tonnes.

- They are operated by skilled engineers who control their movement.

- The tunnel boring machines work day and night to excavate tunnels.

Frequently Asked Questions

Welcome to our FAQ section where we answer the most commonly asked questions about the Channel Tunnel Boring Machines!

1. How deep are the Channel Tunnel Boring Machines going underground?

The Channel Tunnel Boring Machines typically dig tunnels at depths of around 40 meters or 130 feet below ground level. This depth is necessary to ensure stability and to allow the tunnel to pass beneath the English Channel.

The machines operate in highly pressurized conditions underground and are designed to excavate through different types of soil and rock formations, ensuring the tunnel’s stability and durability.

2. How long are the Channel Tunnel Boring Machines?

The Channel Tunnel Boring Machines are truly mammoth in size! They can reach lengths of over 150 meters or approximately 492 feet. These colossal machines are specially designed to excavate tunnels on a large scale and are equipped with various cutting tools to remove soil and rock as they progress.

As they move forward, the TBM sections are assembled to form a complete tunnel by pushing against the tunnel wall already constructed. It’s an impressive operation to witness!

3. How many Channel Tunnel Boring Machines were used to construct the tunnel?

A total of eleven Channel Tunnel Boring Machines, or TBMs, were used during the construction of the Channel Tunnel. Six machines were used to dig the tunnels beneath the English Channel from the UK side, while five machines were used from the French side.

The TBMs operated simultaneously, digging separate tunnels for the North Bound and South Bound tracks to expedite the construction process. Each machine had a specific role, whether excavating the main tunnels or creating service tunnels alongside them.

4. Where are the Channel Tunnel Boring Machines now?

After completing their remarkable task of excavating the Channel Tunnel, most of the Channel Tunnel Boring Machines were dismantled underground and left disused beneath the English Channel.

However, two TBMs named “Phoebus” and “Brigitte” were saved and later exhibited at the Eurotunnel exhibition center in Folkestone, England. Visitors can marvel at these colossal machines and learn about their remarkable engineering feats.

5. Can the Channel Tunnel Boring Machines be reused for other projects?

Due to the sheer size and complexity of the Channel Tunnel Boring Machines, it is relatively rare for them to be reused for other projects. Most TBMs are specifically designed for a particular tunneling project and may not be suitable for different environments or geologies.

However, some components or parts of the TBMs can be refurbished and repurposed for other tunnelling projects to reduce costs and environmental impact. Recycling and repurposing components is a common practice in the construction industry!

How the world’s longest underwater tunnel was built – Alex Gendler

Summary

So, to sum it up, the Channel Tunnel boring machines (TBMs) can be found underground. These massive machines help build tunnels by digging through soil and rock. Currently, there are 11 TBMs working on different projects around the world.