Attention all aspiring DIYers and nail gun enthusiasts! Have you ever wondered where to oil your trusty Porter Cable nail gun? Look no further because we’ve got the answer you’ve been searching for. In this guide, we’ll walk you through the importance of oiling your nail gun and exactly where you should apply that much-needed lubrication. So, grab your tool belt and get ready to dive into the world of Porter Cable nail gun maintenance!

When it comes to keeping your nail gun in optimal condition, oiling is crucial. A well-lubricated nail gun not only enhances its performance but also extends its lifespan. But you might be wondering, where exactly should you oil your Porter Cable nail gun? Don’t worry, we’ve got you covered. In this guide, we’ll break down the step-by-step process, ensuring that you’ll never miss a spot that needs a little TLC.

So, how do you know which parts of your nail gun require oiling? From the trigger mechanism to the piston, each component plays a vital role. By following our expert tips and tricks, you’ll learn exactly where to apply oil and how often to do so. With our help, you’ll keep your Porter Cable nail gun humming along smoothly, ready to tackle any woodworking project you throw its way. So, get ready to become a nail gun maintenance pro!

1. Disconnect the nail gun from the power source.

2. Locate the oil cap on the side of the nail gun.

3. Remove the oil cap and set it aside.

4. Apply a few drops of oil into the cap.

5. Dip a small brush into the oil and brush it onto the moving parts of the nail gun.

6. Replace the oil cap and tighten it securely.

Regular oiling will extend the lifespan of your Porter Cable nail gun and ensure optimal performance.

Where Do You Oil a Porter Cable Nail Gun?

When it comes to maintaining your Porter Cable nail gun, one of the most important steps is oiling it regularly. Oiling your nail gun helps to keep it running smoothly and prevents it from getting damaged. However, knowing where to oil your Porter Cable nail gun can be a bit tricky if you’re new to using one. In this article, we’ll explore the different parts of a Porter Cable nail gun that require oiling and provide you with a step-by-step guide on how to properly oil your nail gun to ensure its longevity and optimal performance.

The Benefits of Regularly Oiling Your Porter Cable Nail Gun

Before we dive into the specifics of where to oil your Porter Cable nail gun, let’s first discuss the various benefits of regularly oiling it:

- Improved Performance: Oiling your nail gun reduces friction within the tool, allowing it to operate more smoothly and efficiently.

- Increased Lifespan: By keeping your nail gun properly lubricated, you can prevent premature wear and tear, extending its lifespan.

- Reduced Jamming: A well-oiled nail gun is less likely to jam, preventing unnecessary delays and frustration during your projects.

- Cost Savings: Regular maintenance, including oiling, can help you avoid costly repairs or the need for a new nail gun.

1) Understanding the Anatomy of a Porter Cable Nail Gun

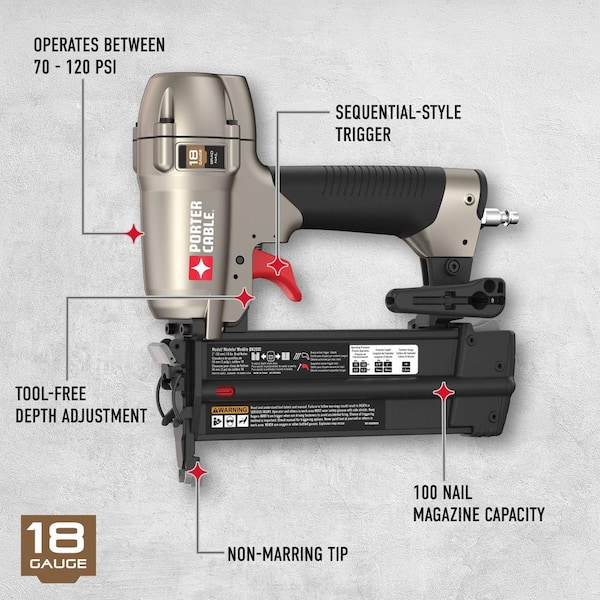

Before we get into the specifics of where to oil your Porter Cable nail gun, it’s essential to have a basic understanding of its anatomy. A typical Porter Cable nail gun consists of the following key parts:

- Magazine: This is where the nails are loaded.

- Contact Trip or Sequential Trigger: The trigger mechanism that allows you to shoot nails.

- Piston and Cylinder: The piston pushes the nail into the material, while the cylinder houses the piston.

- Air Inlet: The point where the air hose is connected to supply air to power the nail gun.

- Oiling Point(s): These are the specific areas of the nail gun that require oiling for proper maintenance and performance.

Now that we have a basic understanding of the different parts, let’s move on to the specific areas where you should be oiling your Porter Cable nail gun.

2) Where to Oil Your Porter Cable Nail Gun: Step-by-Step Guide

To properly oil your Porter Cable nail gun, follow these steps:

Step 1: Safety First

Before you begin, always remember to disconnect the nail gun from the power source or air supply to ensure your safety.

Step 2: Locate the Oiling Points

Refer to your Porter Cable nail gun’s user manual to identify the specific areas where oil should be applied. Typically, you’ll find two main oiling points: the air cylinder and the driver blade. These areas are usually marked with an oil symbol or indicated in the user manual.

Step 3: Apply the Oil

Using a high-quality air tool oil or a specific oil recommended by Porter Cable, apply a few drops of oil to each of the identified oiling points. Avoid over-oiling, as this can lead to residue buildup or other issues. A few drops are usually sufficient to lubricate the parts effectively.

Step 4: Cycle the Nail Gun

To distribute the oil evenly and ensure proper lubrication, cycle the nail gun multiple times without firing any nails. This helps to spread the oil throughout the internal components of the nail gun and ensures smooth operation.

Step 5: Wipe off Excess Oil

After oiling and cycling the nail gun, wipe off any excess oil using a clean, lint-free cloth. This prevents the accumulation of excess oil, which can attract debris or cause other issues.

And that’s it! By following these steps and properly oiling your Porter Cable nail gun, you’ll be able to maintain its performance and ensure its longevity.

Tips for Proper Nail Gun Maintenance

In addition to regular oiling, here are some additional tips to keep your Porter Cable nail gun in top shape:

1) Clean the Nail Gun

Regularly clean your nail gun to remove any dirt, debris, or sawdust that may have accumulated. Use compressed air or a brush to clean the magazine, driver blade, and other parts. This helps to prevent jamming and ensures smooth operation.

2) Use the Right Nails

Always use the correct nails recommended by Porter Cable for your nail gun. Using the wrong nails can damage the gun or result in misfires. Consult your user manual or the manufacturer’s website for information on compatible nail sizes and types.

3) Store Properly

When not in use, store your nail gun in a clean, dry place. Protect it from extreme temperatures, moisture, and dust. Consider using a dedicated case or toolbox to keep it safe and organized.

By following these maintenance tips and regularly oiling your Porter Cable nail gun, you’ll ensure its optimal performance and enjoy years of reliable service.

Conclusion

Regularly oiling your Porter Cable nail gun is crucial for maintaining its performance and prolonging its lifespan. By understanding the different parts of the nail gun that require oiling and following the step-by-step guide provided in this article, you’ll be able to keep your nail gun running smoothly and prevent any potential damage. Remember to also follow the additional maintenance tips to ensure your nail gun stays in top shape. Happy nailing!

Key Takeaways: Where do you oil a Porter Cable nail gun?

- The oil for lubricating a Porter Cable nail gun should be applied to the air fitting regularly.

- Look for a small oil port or nipple on the nail gun and apply a few drops of oil into it.

- It is important to read the user manual to understand the specific oiling instructions for your particular model of Porter Cable nail gun.

- Regularly oiling the nail gun helps to ensure smooth operation and prolong its lifespan.

- Remember to use the recommended oil type specified by Porter Cable for optimal performance.

Frequently Asked Questions

Welcome to our Frequently Asked Questions section where we provide answers to common queries regarding oiling a Porter Cable nail gun. Whether you’re a seasoned carpenter or a DIY enthusiast, understanding how to properly oil your nail gun is vital for its performance and longevity. Read on to find answers to your questions and ensure your nail gun delivers optimal results.

1. Why is it important to oil a Porter Cable nail gun?

Oiling your Porter Cable nail gun is essential for its smooth operation and to prevent potential damage. The nail gun consists of several moving parts that require lubrication to reduce friction and heat generated during operation. Regular oiling helps to maintain the integrity of these parts, ensuring the tool’s reliability and extending its lifespan.

Additionally, oiling your nail gun helps in reducing the chances of jamming and misfires, resulting in more effective and accurate nail placements. So, make sure to incorporate regular oiling into your maintenance routine to keep your Porter Cable nail gun in top-notch condition.

2. Where should I oil my Porter Cable nail gun?

When it comes to oiling your Porter Cable nail gun, focus on two key areas: the air fitting and the driver blade. Begin by applying a few drops of pneumatic tool oil to the air fitting, which connects the tool to the air compressor. This lubricates the inner components and helps maintain smooth airflow.

Next, move on to the driver blade or piston. Apply a small amount of oil to the exposed area near the front of the nail gun, ensuring the blade is well-lubricated. It’s important not to over-oil, as excess oil can attract dust and debris. A few drops applied regularly is sufficient to keep your Porter Cable nail gun running smoothly.

3. How frequently should I oil my Porter Cable nail gun?

The frequency of oiling your Porter Cable nail gun depends on the amount of use it gets. As a general rule, it’s recommended to oil the tool every 200 to 300 nails or after about three to four hours of continuous use. However, if you notice any signs of decreased performance, such as increased jamming or misfires, consider oiling your nail gun more frequently.

Keep in mind that regular maintenance routines can vary based on the type of nail gun and manufacturer’s recommendations. Consulting your tool’s user manual will provide specific guidelines on how often to oil your Porter Cable nail gun for optimal performance.

4. Can I use any type of oil to lubricate my Porter Cable nail gun?

No, it is important to use the recommended type of oil for your Porter Cable nail gun. Using the wrong lubricant can cause damage to the internal components and affect the tool’s performance. It is advisable to use a high-quality pneumatic tool oil specifically designed for nail guns.

These oils are formulated to withstand the high demands of pneumatic tools and provide the necessary lubrication to keep the moving parts running smoothly. Using a non-compatible oil can lead to increased wear and tear, decreased lifespan, and potential malfunctions.

5. Are there any other maintenance tips for my Porter Cable nail gun?

Apart from regular oiling, there are other maintenance practices to ensure your Porter Cable nail gun stays in optimum condition. Keep the tool clean by regularly removing any sawdust or debris that may accumulate on the surface or inside the nail gun. Use a soft brush or compressed air to clean hard-to-reach areas.

Also, periodically inspect the tool for any signs of wear, damage, or loose parts. If you notice any issues, consult the user manual or contact a professional for assistance. Lastly, store your nail gun in a clean and dry environment when not in use to prevent dust and moisture accumulation.

Summary

So, to sum it up, oiling a Porter Cable nail gun is important for keeping it running smoothly. You’ll want to oil it before and after each use to prevent damage and ensure optimal performance. Don’t forget to use the correct oil and follow the manufacturer’s instructions to get the best results. Keep your nail gun well-oiled, and you’ll be all set for your next project!

In conclusion, oiling your Porter Cable nail gun regularly is key to its longevity and functionality. By following the simple steps outlined in the article, you can keep your nail gun in great shape and avoid any potential issues down the line. So, make sure to give your nail gun the care it deserves, and happy nailing!