Have you ever wondered where plywood goes once it’s made? Well, let me tell you, plywood is a versatile material that finds its way into countless applications. From construction sites to furniture factories and even art studios, plywood plays a vital role in our lives. So, let’s dive in and explore the fascinating journey of plywood and where it ends up!

To start off, plywood is frequently used in the construction industry. Its strength, durability, and affordability make it a popular choice for building projects. Whether it’s used for framing, roofing, or flooring, plywood provides a sturdy foundation for structures of all sizes. So, the next time you pass by a construction site, remember that plywood is likely playing a crucial role behind the scenes.

But plywood doesn’t stop at construction sites. It also finds its way into the world of furniture making. From cabinets and bookshelves to tables and chairs, plywood is often used as a core material. Its ability to be easily shaped and its stability make it ideal for creating beautiful and functional pieces of furniture. So, the desk you’re sitting at or the shelves in your bedroom might just owe their existence to plywood.

Now, let’s not forget about the creative side of things. Plywood is a favorite among artists and designers due to its versatility and aesthetic appeal. It can be painted, carved, or even laser-cut to create unique works of art. So, whether you’re admiring a sculpture in a gallery or gazing at a captivating piece of wall art, there’s a chance that plywood played a part in its creation.

From construction sites to furniture factories and art studios, plywood has a wide range of applications. Its strength, affordability, and adaptability make it an indispensable material in various industries. So, the next time you encounter plywood, take a moment to appreciate its journey and the important role it plays in our everyday lives. Let’s dive in and explore where plywood goes!

Where Does Plywood Go? Exploring the Many Uses of Plywood

In this article, we will delve into the versatile world of plywood and explore its many applications. From construction to furniture making, plywood is a material that is widely used in various industries. Whether you’re a DIY enthusiast or a professional contractor, understanding where plywood goes can give you valuable insights into its potential uses and benefits. Join us as we uncover the fascinating journey of plywood and discover how it shapes our world.

The Construction Industry: Plywood as a Building Staple

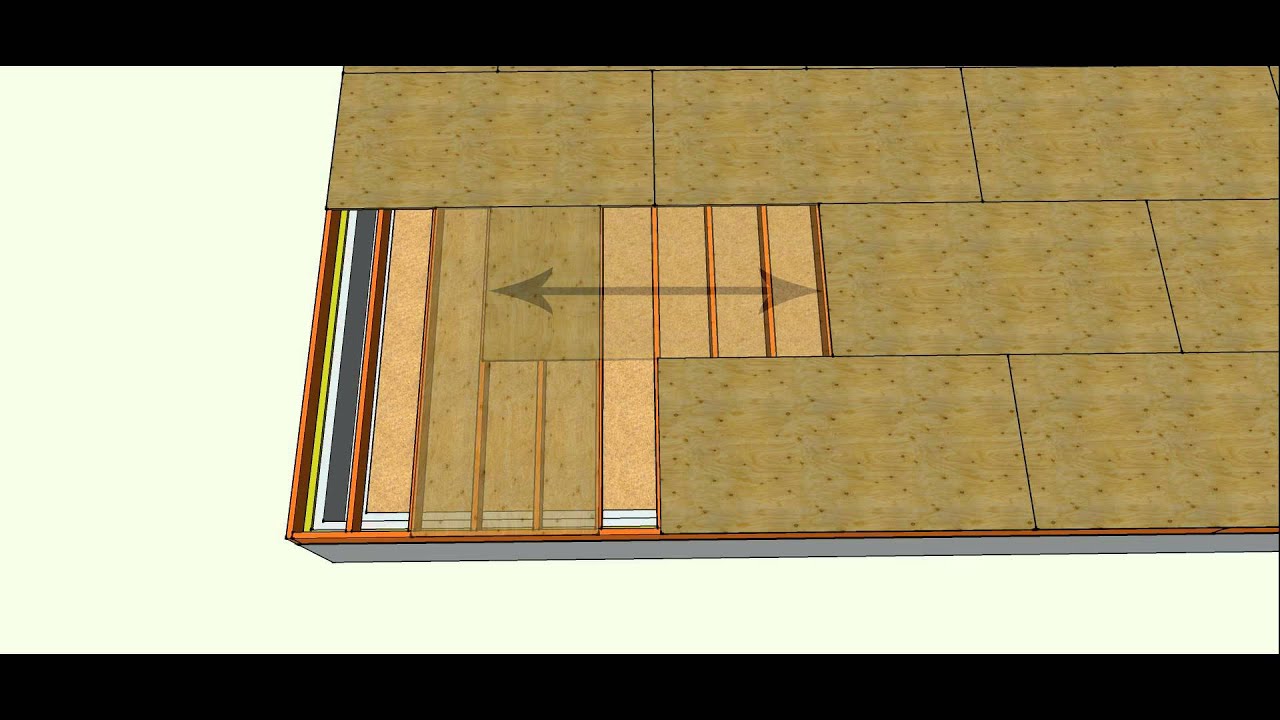

Plywood plays a crucial role in the construction industry, serving as a foundational material in various applications. One of the primary uses of plywood in construction is for sheathing, which provides structural support and rigidity to buildings. Plywood panels are often used as a base for roofs, walls, and floors, offering durability and stability.

Another common use of plywood in construction is for formwork. Plywood sheets are used to create temporary molds or frameworks that hold concrete in place during the pouring and drying process. This formwork ensures that the concrete sets in the desired shape and prevents any deformation or collapse during construction.

Furthermore, plywood is utilized in creating interior finishes such as cabinets, countertops, and doors. It provides versatility in design and can be easily shaped, allowing for intricate and customized creations. From commercial buildings to residential homes, plywood finds its way into numerous construction projects.

Furniture Making: Plywood’s Role in Design and Functionality

Plywood is a go-to material for furniture makers due to its strength, flexibility, and affordability. It is often used to create the structural components of furniture, including the frames, shelves, and drawers. By utilizing plywood, furniture manufacturers can achieve sturdy and reliable pieces that can withstand everyday use.

Beyond its structural benefits, plywood also offers design possibilities. Its layered composition gives it a distinctive and visually appealing grain pattern, adding an aesthetic touch to furniture pieces. Additionally, plywood can be easily veneered or laminated to achieve different finishes, providing versatility in creating unique designs and styles.

From chairs to tables to cabinets, plywood can be found in a wide range of furniture pieces. Its affordability and versatility make it a popular choice for both mass-produced items and one-of-a-kind designs in the furniture industry.

Marine Applications: The Waterproof Strength of Plywood

When it comes to marine applications, such as boat construction and dock building, plywood takes on a special role. Marine-grade plywood is specifically engineered to withstand exposure to water and provide superior durability in harsh marine environments.

The layers of marine plywood are bonded together with waterproof adhesive, ensuring that the wood does not delaminate or deteriorate when exposed to moisture. This makes it an ideal choice for boat hulls, decks, and other components that come into direct contact with water.

The strength and resistance to rot and decay make marine plywood a reliable material for marine structures like docks and piers. Its ability to withstand constant exposure to water and harsh weather conditions ensures that these structures can endure for extended periods without compromising on safety and stability.

Transportation Industry: Plywood for Efficient Packaging and Storage

In the transportation industry, plywood finds its use in packaging and storage solutions. Plywood crates and pallets are commonly used for shipping and transporting goods, thanks to their strength and durability. These plywood containers offer secure protection for the products during transit, minimizing the risk of damage.

Moreover, plywood is often used for shelving and racking systems in warehouses and storage facilities. Its load-bearing capacity and resistance to warping or bending make it ideal for supporting heavy items and optimizing storage space. Whether it’s in a truck, a warehouse, or a shipping container, plywood proves its worth in the transportation industry.

Additionally, plywood is used in the construction of specialty vehicles such as trailers and RVs. Its lightweight yet strong composition makes it an excellent choice for constructing the framework and interior components of these vehicles, ensuring durability and maximizing fuel efficiency.

Art and Design: Plywood as a Canvas for Creativity

Plywood’s unique attributes also make it a popular choice in the world of art and design. Artists and designers often use plywood as a canvas for various forms of expression, including paintings, sculptures, and installations.

The texture and grain patterns of plywood add depth and character to artistic creations, allowing artists to explore different techniques and mediums. Plywood’s affordability and accessibility also make it a go-to material for emerging artists or those working on large-scale projects.

Furthermore, plywood is used in architectural models and prototypes. Its lightweight nature and ease of manipulation make it an ideal material for creating accurate and detailed representations of architectural designs.

DIY Projects: Plywood for the Home Handyman

For the avid DIY enthusiast or home handyman, plywood opens up a world of possibilities. From simple home renovations to elaborate woodworking projects, plywood is a versatile material that can bring your ideas to life.

Common DIY projects involving plywood include building shelves, bookcases, and storage solutions. Plywood’s affordability and ease of customization make it an excellent choice for crafting functional and stylish additions to your home.

Besides furniture, plywood can be used for decorative elements such as wall paneling, headboards, and backsplashes. Its unique appearance and ability to blend well with different styles make it a popular material for adding character and charm to living spaces.

Plywood in Modern Architecture: Pushing Boundaries and Innovations

As technology and architectural design advance, plywood continues to play a significant role in pushing boundaries and facilitating innovative solutions.

Plywood as Structural Expression and Efficiency

In contemporary architecture, plywood is often used to create unique and expressive structural elements. Plywood’s flexibility allows architects to design intricate forms that can be efficiently constructed using this material.

From curved ceilings to eye-catching facades, plywood provides a cost-effective and sustainable alternative to other construction materials. Its lightweight yet robust properties make it an ideal choice for creating lightweight structures that minimize material consumption while maximizing structural integrity.

Sustainable Building Practices with Plywood

With growing concerns over environmental sustainability, plywood emerges as a frontrunner in enabling greener building practices. Plywood is made from renewable resources, such as fast-growing trees, and the production process involves minimal energy consumption.

Moreover, plywood can be sourced from responsible forestry practices, ensuring that new trees are planted to replace those harvested. By using plywood in construction, architects and builders can reduce their carbon footprint and contribute to the promotion of sustainable practices in the industry.

Innovative Plywood Composites

Plywood composites, such as cross-laminated timber (CLT), are gaining popularity in modern architecture. CLT panels consist of multiple layers of plywood that are cross-bonded and pressed together, resulting in an incredibly strong and stable building material.

CLT offers excellent load-bearing capabilities and can be used in various applications, including walls, floors, and roofs. Its prefabricated nature allows for efficient and precise construction, reducing building time and costs.

The Future of Plywood: Advancements and Exciting Possibilities

While plywood has a long history and well-established applications, its future holds promising advancements and possibilities.

Technological Innovations in Plywood Production

Advancements in production techniques and technologies enable plywood manufacturers to create stronger, more durable, and sustainable products. From enhanced bonding methods to improved water-resistant coatings, these innovations further enhance the performance and versatility of plywood.

New research and development efforts are also focused on developing alternative materials that mimic the strengths and characteristics of plywood while providing additional benefits. These materials include engineered wood products like laminated veneer lumber (LVL) and oriented strand board (OSB).

Plywood in Renewable Energy Solutions

Renewable energy technologies, such as wind turbines and solar panels, are becoming increasingly prevalent in the fight against climate change. Plywood has the potential to play a role in these renewable energy solutions.

Plywood’s light weight and structural integrity make it an ideal material for constructing wind turbine blades. Its flexibility and durability can withstand the forces exerted by the wind, ultimately contributing to more efficient and sustainable energy generation.

Design and Architectural Innovations with Plywood

In the realm of design and architecture, plywood continues to inspire innovative solutions. Designers and architects are exploring new ways to manipulate plywood and push its limits, resulting in unique structures, installations, and furniture pieces.

Plywood’s versatility and adaptability make it an excellent material for creating sustainable, affordable, and aesthetically pleasing spaces. From temporary installations to permanent buildings, plywood’s potential in design and architecture is boundless.

Essential Tips for Working with Plywood

Working with plywood – whether it’s for construction, furniture making, or DIY projects – requires some know-how to achieve the best results. Here are some essential tips to keep in mind when working with this versatile material:

1. Choose the Right Grade:

Plywood comes in various grades, ranging from A to D, with A being the highest quality. Consider the intended use of the plywood and select the grade accordingly, ensuring it meets the required strength and appearance standards.

2. Handle with Care:

Plywood, especially the edges, is susceptible to damage. Be cautious when transporting and storing it to prevent dents, chips, or moisture absorption. Use edge protectors and store plywood in a dry and flat position.

3. Proper Cutting Techniques:

When cutting plywood, ensure clean and precise cuts by using a sharp blade or a specialized plywood blade. Maintain firm support underneath the plywood to avoid splintering or tear-out on the underside of the cut.

4. Use Appropriate Fasteners:

Choose the right type of fasteners, such as screws or nails, for your plywood project. Consider the thickness of the plywood, the material you’re fastening it to, and the intended load-bearing capacity.

5. Allow for Expansion and Contraction:

Plywood expands and contracts with changes in humidity and temperature. Leave small gaps or use appropriate spacing techniques to accommodate this movement and prevent warping or buckling.

6. Apply Protective Finishes:

If the plywood will be exposed to the elements or high moisture levels, apply suitable finishes or sealants to protect it from water damage, rot, and decay. Consult with a professional for the best products for your specific application.

7. Practice Safe Handling:

Wear appropriate safety gear, such as goggles and gloves, when working with plywood. Follow all safety guidelines and use proper techniques for cutting, routing, and sanding the material.

8. Maintain Clean Edges:

Clean, smooth edges enhance the appearance of plywood projects. Use sandpaper or a router with a flush-trim bit to achieve clean and crisp edges before applying any finishes or joining techniques.

By keeping these tips in mind, you can ensure successful outcomes and maximize the benefits of working with plywood in your projects.

Key Takeaways: Where Does Plywood Go?

Plywood commonly goes to the following places:

- Construction sites for structural applications.

- Cabinetry and furniture manufacturing.

- Interior and exterior home and building renovations.

- Transportation industry for vehicle interiors.

- Art and crafts projects.

Frequently Asked Questions

Curious to know where plywood goes? We’ve got you covered! Here are answers to commonly asked questions about the destinations of plywood.

1. What are some common applications for plywood?

Plywood is a versatile material that finds its way into various projects and industries. One of the most common uses is in construction, where it is used for sheathing buildings, subflooring, and roofing. It is also prevalent in furniture-making, providing a sturdy and cost-effective option for shelves, cabinets, and tables. Additionally, plywood is often used for making boat hulls, packaging crates, and even musical instruments like guitars and pianos.

While these are just a few examples, the possibilities are vast. Plywood’s strength, durability, and affordability make it a go-to choice for many applications across different sectors.

2. How is plywood utilized in the transportation industry?

Plywood plays a vital role in the transportation industry. It is commonly used for truck and trailer flooring due to its resilience and load-bearing capacity. Plywood provides a stable surface to support heavy cargo during transit. Additionally, plywood serves as a protective barrier for goods, preventing damage from shifting or impacts during transportation.

Besides truck flooring, plywood is also used in the construction of shipping containers and railway carriages. Its strength and durability help withstand the rigors of transportation, ensuring the safe delivery of goods.

3. What about the application of plywood in interior design projects?

Plywood has gained popularity in interior design and architectural projects for its natural aesthetic appeal and versatility. It is often used for wall paneling, creating a warm and inviting ambiance. Designers also utilize plywood for crafting unique furniture pieces like chairs, tables, and shelving units.

Another exciting application of plywood in interior design is in creating custom-built cabinetry and storage solutions. Plywood’s flexibility allows for interesting and innovative designs that perfectly fit a space.

4. Are there any specific uses for plywood in the arts and crafts world?

Absolutely! Plywood remains a favorite material among artists and crafters due to its flexibility and ease of use. It serves as a base for painting, providing a smooth and sturdy surface to work on. Plywood is also frequently used for creating sculptures, models, and prototypes due to its ability to be easily shaped and carved.

Plywood’s affordability compared to other art materials makes it an attractive option for artists, enabling them to experiment and bring their creative ideas to life.

5. Where does plywood go after its useful lifespan?

When plywood reaches the end of its useful lifespan, it can be recycled or repurposed. Recycling involves breaking down used plywood into wood fibers and reusing them to create new products or energy. Repurposing can involve transforming old plywood into furniture, decorative elements, or even firewood.

Another option is to dispose of plywood in a responsible manner, such as taking it to waste management facilities that can handle wood waste. Proper disposal ensures that the plywood does not end up in landfills or contribute to environmental pollution.

5 Mistakes Buying Plywood – Don’t Waste Your Money!

Summary

So, to sum it all up, plywood is a versatile material made from layers of wood glued together. It is used in many different ways, like making furniture, building houses, and even in the transportation industry. Plywood is strong, durable, and cost-effective, making it a popular choice for construction projects.

But where does plywood go after it’s used? Well, it can be recycled or repurposed into new products, reducing waste and helping the environment. So remember, next time you see plywood, think about all the places it can go and the many ways it can be used!