Hey there! Are you curious about where the depth stop is located on a drill press? Well, let’s dive right in and find out!

When you’re using a drill press, it’s essential to know how to control the depth of your drilling. That’s where the depth stop comes in handy. But where exactly can you find it on a drill press?

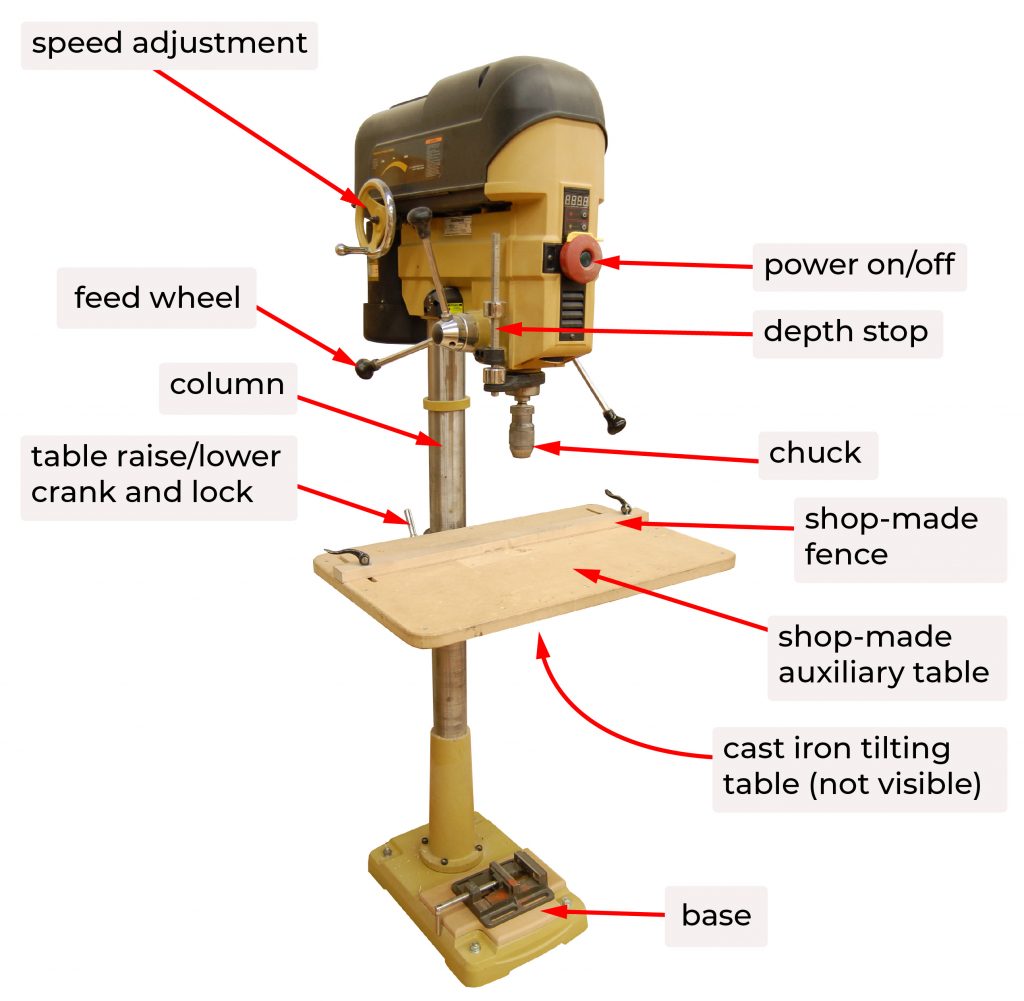

The depth stop is typically located on the side of the drill press, near the spindle. It’s a mechanism that allows you to set a predetermined depth for your drilling operations. By adjusting the depth stop, you can ensure that your drill bit only goes as deep as you want it to.

So, the next time you’re using a drill press and need to control the depth of your drilling, look for the depth stop on the side near the spindle. It’s a nifty feature that makes your drilling tasks a breeze! Now, let’s explore some more fascinating aspects of using a drill press.

Where is the Depth Stop Located on the Drill Press?

When using a drill press, understanding the different features and components is crucial for optimal performance and safety. One such feature is the depth stop, which allows you to control the depth of your drill hole. In this article, we will explore the location of the depth stop on a drill press, its functionality, and how to use it effectively.

Understanding the Depth Stop

The depth stop is a mechanism on the drill press that enables you to set a specific depth for your drilling operations. It consists of a stop rod or collar that can be adjusted vertically to limit the travel of the quill, thus controlling the depth of the drill hole. This feature is especially useful when you need to create consistent and precise holes of a specific depth.

The depth stop on a drill press is typically located on the column or the side of the drill press head. Its position may vary depending on the model and manufacturer, but it is generally within easy reach and clearly marked for user convenience. Some drill presses may have a threaded depth stop rod that can be manually adjusted, while others might feature a depth stop lever or handle for quick adjustments.

Locating the Depth Stop on Different Drill Press Models

While the exact location of the depth stop may differ from one drill press model to another, it is typically positioned within reach of the user for easy access and adjustments. Here are three commonly used drill press models and their respective depth stop locations:

1. Benchtop Drill Press:

In most benchtop drill presses, the depth stop can be found on the side of the drill press head. It is often operated by a depth stop lever or handle, which allows you to quickly set and adjust the desired drilling depth.

Keep in mind that the depth stop might be positioned at different heights along the head column, depending on your specific model. Refer to your drill press manual for precise instructions on locating and using the depth stop.

2. Floor Standing Drill Press:

On floor standing drill presses, the depth stop is usually located on the column, similar to the benchtop models. You’ll typically find it on the side or front of the column, where it is easily accessible during drilling operations.

Again, the depth stop might be operated by a lever, handle, or even a threaded rod for adjustments. Consult your drill press manual for accurate information on locating and utilizing the depth stop on your specific model.

3. Magnetic Drill Press:

Magnetic drill presses, also known as mag drills, are a specialized type of drill press used primarily for metalworking applications. The depth stop on these machines is typically located on the back or side of the drill press head.

Mag drills often feature a threaded depth stop rod that can be adjusted manually by rotating it clockwise or counterclockwise. This allows you to set precise drilling depths for consistent results. Consult your magnetic drill press manual for detailed instructions on locating and operating the depth stop.

Tips for Using the Depth Stop Effectively

To make the most out of your drill press and its depth stop feature, consider the following tips:

1. Measure and Mark:

Prior to drilling, measure and mark the desired depth on your workpiece using a ruler, caliper, or depth gauge. This will ensure accurate and consistent hole depths across multiple pieces.

2. Adjust the Depth Stop:

Locate the depth stop on your drill press and adjust it to match the marked depth on your workpiece. Use the depth stop lever, handle, or threaded rod, depending on your drill press model, to set the desired drilling depth.

3. Test and Adjust:

Before drilling into your actual workpiece, perform a test run on a scrap piece of material. Check if the hole depth matches your expectations. If necessary, make minor adjustments to the depth stop until you achieve the desired result.

By following these tips and familiarizing yourself with the location and functionality of the depth stop, you can enhance the precision and accuracy of your drilling operations with a drill press.

Additional Information on Drill Press Components

Now that we have covered the location and use of the depth stop on a drill press, let’s delve into other essential components that contribute to the functionality and performance of this versatile tool.

Main Components of a Drill Press

A drill press consists of several key components, each serving a specific purpose in the drilling process. Understanding these components is essential for safe and effective use of the drill press. Let’s explore these components in more detail:

1. Base:

The base of a drill press provides stability and support for the entire machine. It is typically made of cast iron or steel and should be securely bolted to a workbench or mounted on a stable surface to prevent movement during operation.

2. Column:

The column is the vertical support structure that connects the base to the drill head. It houses various mechanisms, including the depth stop, that allow for height adjustments and column rotation for angled drilling.

3. Drill Head:

The drill head houses the motor, spindle, and chuck assembly. It is responsible for the rotational movement of the drill bit and contains the depth stop, speed control, and other features for precise drilling operations.

4. Spindle:

The spindle is the rotating shaft that holds the drill chuck and connects to the motor. It provides the necessary power and torque to rotate the drill bit during drilling.

5. Chuck:

The chuck is a mechanical device that holds and tightens the drill bit in place. It allows for easy attachment and detachment of various drill bits, depending on the drilling requirements.

6. Table:

The table is a flat, adjustable surface located below the drill head. It provides a stable platform for holding the workpiece during drilling operations. The table can be tilted, raised, or lowered to accommodate drilling at different angles or depths.

7. Depth Gauge:

The depth gauge is a measurement device that helps you determine the depth of the drill hole. It is often built into the depth stop mechanism and allows for precise depth adjustments.

8. Speed Control:

Many drill presses feature a speed control mechanism that allows you to adjust the rotational speed of the drill bit. This is especially useful when working with different materials or needing to drill at various speeds for optimal results.

Conclusion

Knowing the location of the depth stop on a drill press is fundamental for achieving accurate and consistent drilling depths. By understanding the components and functionality of a drill press, you can optimize your drilling operations and ensure safe and precise results.

Remember to consult your drill press manual for specific instructions on locating and using the depth stop on your particular model. Practice measuring, marking, and adjusting the depth stop on scrap materials to familiarize yourself with the process before working on your actual project.

With proper knowledge and practice, you can make the most out of your drill press and elevate your woodworking, metalworking, or any other drilling projects to new heights of precision and quality.

Key Takeaways: Where is the Depth Stop Located on the Drill Press?

- The depth stop on a drill press is usually located on the side or front of the drill press head.

- It is a small adjustable collar or rod that controls the depth of the drill bit.

- By setting the depth stop, you can ensure that the drill bit only goes to a specific depth, preventing over-drilling.

- Depth stops are often marked with measurements for easy reference.

- It is important to familiarize yourself with the location and operation of the depth stop on your specific drill press model.

Frequently Asked Questions

Welcome to our Frequently Asked Questions section about drill presses! Here, we’ll answer some common questions to help you better understand where the depth stop is located on a drill press.

1. How can I locate the depth stop on my drill press?

Locating the depth stop on a drill press is relatively easy. Most drill presses have a depth stop rod or shaft that is positioned on the side of the drill press column. It is usually attached to a tightening mechanism that allows you to adjust the depth. Look for a knurled or textured knob that you can twist to tighten or loosen the depth stop. If you’re having trouble finding it, refer to your drill press manual for guidance.

Once you’ve located the depth stop, make sure it is adjusted to the desired depth. Tighten the knurled knob to secure the depth stop in place. This will ensure that the drill bit stops drilling at the desired depth, preventing it from going too deep.

2. Can the location of the depth stop vary on different drill presses?

Yes, the location of the depth stop can vary among different drill press models. While it is commonly found on the side of the drill press column, some models may have it located on the front, near the drill chuck, or even on the quill. To determine the specific location on your drill press, consult the user manual provided by the manufacturer.

It’s important to note that the design and placement of the depth stop can also depend on the size and type of drill press. Larger drill presses may have more intricate depth stop mechanisms, while smaller models may have simpler setups. Familiarize yourself with the layout of your particular drill press to locate the depth stop accurately.

3. What is the purpose of the depth stop?

The depth stop on a drill press serves a crucial purpose – it allows you to control the drilling depth. By setting the depth stop to a specific position, you can ensure that the drill bit does not go beyond that depth. This is particularly useful when working on projects that require consistent hole depths or when you want to prevent drilling through a workpiece entirely.

The depth stop helps you achieve precision and accuracy in your drilling, saving you time and effort in measuring and marking the desired drilling depth. Whether you’re working on woodworking projects, metal fabrication, or any other drilling task, the depth stop provides a convenient way to regulate and limit the depth of your holes.

4. Can I adjust the depth stop to different depths?

Yes, you can adjust the depth stop on most drill presses to accommodate different drilling depths. The depth stop is typically adjustable, allowing you to set it to various positions according to your specific requirements. By loosening the knurled or textured knob, you can slide the depth stop rod or shaft up or down to the desired depth.

When adjusting the depth stop, make sure to measure and mark the drilling depth accurately beforehand. This will help you set the depth stop at the precise position you need. Once you’ve adjusted the depth stop, tighten the knob to secure it in place. Remember to always test the depth stop by drilling a test hole to ensure it is correctly set before proceeding with your project.

5. Are depth stops available on all drill presses?

While depth stops are a common feature on most drill presses, it’s essential to check the specifications of the drill press you intend to purchase or use. Smaller, portable drill presses or specialty models may not come equipped with a depth stop. If drilling depth control is a significant requirement for your projects, ensure the drill press you choose has a depth stop feature.

If your drill press doesn’t include a built-in depth stop, there are aftermarket depth stop attachments available that can be installed to provide similar functionality. These attachments typically clamp onto the drill press column and provide adjustable depth control. You can explore these options if you need depth stop capabilities on a drill press that doesn’t come with one.

Summary

So, to sum it up, the depth stop on a drill press is a really handy feature. It helps you control how deep you drill holes, so you don’t go too far. The depth stop is usually located on the side of the drill press and can be adjusted to different depths. Just make sure to tighten it securely before you start drilling. Remember, safety first!

In conclusion, the depth stop is a crucial part of a drill press that helps you control the depth of your holes. By using this feature effectively and following safety guidelines, you can ensure accurate and controlled drilling every time. So go ahead, put your newfound knowledge to use and have fun with your drill press adventures!