Hey there! Ready to dive into the exciting world of lathes? You might be wondering, “Where is the headstock on a lathe?” Well, let’s uncover this fascinating piece of machinery together!

If you’re new to lathes, the headstock is an essential part that you shouldn’t miss. Located at one end of the lathe, it’s like the brain of the operation. The headstock holds the main spindle, which rotates the workpiece, making it spin and allowing you to shape and mold it according to your creativity.

Now, you’re probably wondering where exactly the headstock is situated. Picture this: when you stand in front of a lathe, facing the machine, the headstock is typically on the left side. It’s the part that holds the spindle and enables you to secure and rotate the workpiece. So, it’s pretty important!

So, the headstock on a lathe is like the captain of the ship, directing the movement and rotation of your project. Without it, a lathe wouldn’t be much of a lathe at all! Let’s keep exploring to uncover more fascinating things about lathes and their amazing components! So, let’s get started, shall we?

Looking for the headstock on a lathe? The headstock is typically located on one end of the lathe bed. It houses the motor and spindle, and is responsible for rotating the workpiece. To find the headstock, simply look for the end of the lathe opposite to where you feed the material in. It’s usually marked and easily identifiable. Happy turning!

Where is the Headstock on a Lathe?

A lathe is a versatile machine used in woodworking, metalworking, and other industries. It consists of various components that work together to perform different operations. One of the crucial parts of a lathe is the headstock. In this article, we will explore what the headstock is, its purpose, and where it is located on a lathe.

Understanding the Headstock

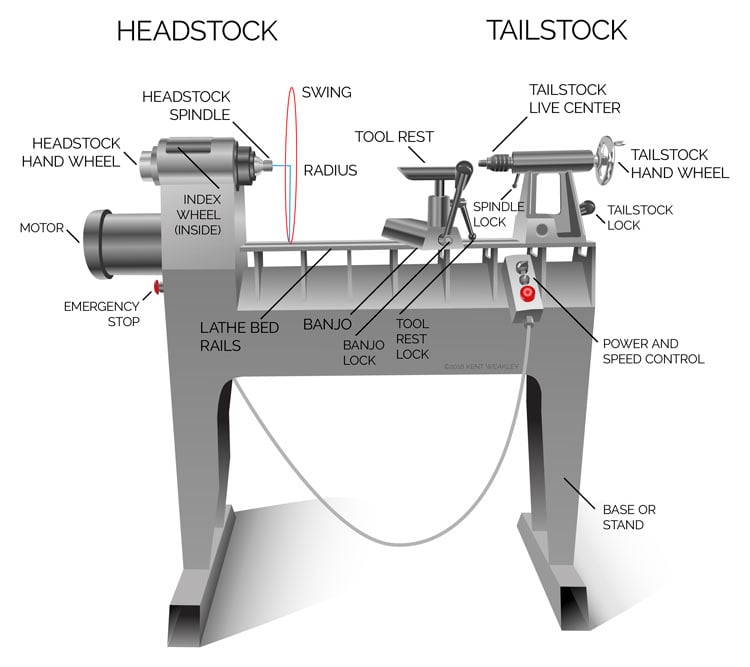

The headstock is an integral part of a lathe that houses the main spindle. It is typically positioned at one end of the lathe bed, opposite to the tailstock. The primary function of the headstock is to hold and rotate the workpiece. It is equipped with a motor that provides the necessary power for the spindle to rotate at different speeds.

The headstock is also responsible for providing the necessary support and stability to the workpiece during machining operations. It holds various accessories, such as chucks or faceplates, which are used to secure the workpiece firmly in place. The headstock is designed to withstand high forces and vibrations generated during cutting or shaping operations.

Overall, the headstock plays a vital role in the functionality and precision of a lathe. Its position and design are crucial factors that determine the performance and capabilities of the machine.

The Location of the Headstock

As mentioned earlier, the headstock is usually positioned at one end of the lathe bed. It is placed opposite to the tailstock, which is where the workpiece is supported on the other end. The headstock is fixed and secured to the bed, ensuring stability and alignment during use.

On most conventional lathes, the headstock is located on the left-hand side of the lathe when facing the machine from the operator’s perspective. The spindle, which is part of the headstock, protrudes out and is accessible for attaching various tools and accessories.

The headstock is typically mounted on precision bearings to minimize axial and radial play. This ensures smooth and accurate rotation of the workpiece, resulting in precise machining operations.

Advantages of a Well-Positioned Headstock

A well-positioned headstock offers several advantages in lathe operations. Firstly, it allows for easy access to the workpiece during setup and machining. The operator can conveniently attach or remove tools, chucks, or faceplates without any obstructions.

Secondly, the correct placement of the headstock ensures better stability and support for the workpiece. This results in improved precision and accuracy during cutting, shaping, or turning operations. A properly positioned headstock minimizes vibrations and eliminates any flexing that could lead to inaccuracies in the finished workpiece.

Lastly, a well-designed headstock allows for smooth and efficient belt changes. Belt-driven lathes require different speed settings for various materials and machining processes. An easily accessible headstock enables the operator to change belts quickly, reducing downtime and improving productivity.

Choosing the Right Headstock Design

When it comes to selecting a lathe, the design and quality of the headstock play a crucial role. Different lathes offer varying headstock configurations to suit specific applications. Here are a few key considerations when choosing the right headstock design:

1. Single or Multiple Speeds

Some lathes offer a single fixed speed, while others provide multiple speed settings. Determine whether your work requires a fixed or variable speed headstock based on the materials and operations you will be performing.

2. Hollow Spindle

If you need to work with longer or larger diameter workpieces, consider a lathe with a hollow spindle. This feature allows for through-hole machining, enabling the use of longer stock or the passage of bar stock for more extensive projects.

3. Quick-Change Chucks

Look for a lathe with a headstock that offers quick-change chuck options. This feature allows for faster and more efficient tool changes, reducing downtime and maximizing productivity.

4. Compatibility with Accessories

Consider the compatibility of the headstock with various accessories such as faceplates, collets, or mandrels. Ensure that the headstock can accommodate the accessories you require for your specific projects.

5. Durability and Precision

A high-quality, well-constructed headstock is essential for achieving accurate and precise results. Look for a lathe with a robust and durable headstock that offers precise spindle alignment and minimal play.

Tips for Maintaining the Headstock

To ensure optimal performance and longevity of the headstock on your lathe, follow these essential maintenance tips:

1. Regular Lubrication

Proper lubrication of the headstock is crucial to reduce friction and heat buildup. Follow the manufacturer’s recommendations for lubricating the bearings, gears, and other moving parts of the headstock.

2. Cleaning and Inspection

Regularly clean the headstock and inspect it for any signs of damage, wear, or misalignment. Check for loose or worn-out components that could affect the performance of the headstock.

3. Belt Tension Adjustment

If your lathe has a belt-driven headstock, regularly check and adjust the tension of the belts. Proper tension ensures smooth and efficient power transmission, resulting in consistent speed and torque.

4. Balance the Spindle

Periodically balance the spindle, especially if you frequently work with larger or heavier workpieces. Imbalanced spindles can cause vibrations, reduce precision, and put excessive stress on the lathe components.

5. Seek Professional Assistance if Needed

If you encounter any issues or suspect a problem with the headstock, do not attempt to fix it yourself unless you have the necessary expertise. Contact a qualified technician or lathe specialist to diagnose and repair any headstock-related problems.

In conclusion, the headstock is a critical component of a lathe that plays a significant role in its functionality and performance. It holds and rotates the workpiece, providing stability and support during machining operations. Understanding the importance of the headstock and its correct placement can help optimize lathe operations, ensuring accuracy, precision, and productive outcomes.

Key Takeaways: Where is the Headstock on a Lathe?

- The headstock is an essential part of a lathe machine.

- It is located at the left end of the lathe bed.

- The headstock houses the main spindle, which rotates the workpiece.

- The main spindle is driven by a motor and can be adjusted for different speeds.

- The headstock also houses various components like gears and belts for power transmission.

Frequently Asked Questions

Welcome to our FAQ section where we’ll answer some common questions about the headstock on a lathe. Read on to learn more!

1. What is the purpose of the headstock on a lathe?

The headstock is a crucial component of a lathe that holds the workpiece and provides power to rotate it. It is typically located at the left end of the lathe bed. The primary purpose of the headstock is to hold the spindle, which is responsible for rotating the workpiece at various speeds. It also houses the gears and belts that transmit power from the motor to the spindle.

Additionally, the headstock usually has a chuck or other holding mechanism that securely grips the workpiece, allowing it to be machined or shaped as required. Without the headstock, a lathe would be unable to rotate the workpiece, making it impossible to perform turning, facing, or other machining operations.

2. What are the common parts of a lathe’s headstock?

A lathe’s headstock typically consists of several important parts. These include the spindle, chuck or faceplate, pulleys or belts, and the motor. The spindle is the central component and is directly connected to the motor, rotating the workpiece.

The chuck or faceplate is used to hold the workpiece securely in place while it is being machined. Different types of chucks can be used, depending on the shape, size, and requirements of the workpiece. Pulleys or belts are responsible for transferring power from the motor to the spindle, and they can be adjusted to change the speed at which the workpiece rotates.

3. Can the headstock be moved or adjusted on a lathe?

In most traditional lathes, the headstock is fixed and cannot be moved or adjusted along the bed. However, some modern lathes may have a movable headstock, allowing for greater flexibility in positioning the workpiece. This can be particularly useful when working on longer or larger pieces that require additional support or a different angle of approach.

If you require a movable headstock, it’s important to check the specifications of the lathe you’re considering to ensure it offers this feature. Remember that a movable headstock may come at an additional cost and may not be necessary for all types of lathe work.

4. How does the headstock affect the precision of the lathe?

The headstock plays a critical role in maintaining the overall precision of a lathe. It must be constructed with high accuracy to ensure that the spindle runs true and straight. Any misalignment or wobbling in the headstock can result in inaccuracies in the machined workpiece.

The quality and stability of the bearings used in the headstock also contribute to the precision of the lathe. High-quality bearings minimize vibration and ensure smooth rotation, which is essential for achieving accurate and consistent results. Regular maintenance and lubrication of the headstock are necessary to maintain its precision over time.

5. Can the headstock be upgraded or replaced on a lathe?

In some cases, it is possible to upgrade or replace the headstock on a lathe. This can be done to enhance the lathe’s capabilities or to accommodate specific requirements. However, it is important to note that upgrading or replacing the headstock may require professional assistance, especially if it involves modifying or adapting other components of the lathe.

Before considering any modifications or replacements, it’s advisable to consult the lathe manufacturer or a professional lathe technician. They can provide guidance on the compatibility of different headstock options and ensure that the lathe’s overall performance and safety are not compromised.

Summary

So, to sum it up, the headstock on a lathe is the part where the workpiece is held. It’s usually at one end of the lathe, opposite the tailstock. The headstock houses the spindle, which rotates the workpiece to perform various machining operations. It’s an important component for turning, shaping, and cutting materials like wood or metal.

Remember, the headstock is fixed in place, while the tailstock can move along the lathe bed. This allows for different lengths of workpieces to be accommodated. Knowing where the headstock is and how it functions is key to using a lathe properly. Just be sure to always follow safety guidelines when working with lathes to avoid accidents. Happy turning!