Looking to remove material on keyways? Wondering which chisel is the right tool for the job? Well, you’ve come to the right place! In this guide, we’ll explore the world of chisels and discover the perfect tool to tackle those keyway removal tasks. Whether you’re a beginner or a seasoned DIY enthusiast, we’ve got you covered!

Now, you might be thinking, why do I need a special chisel for removing material on keyways? Great question! Keyways are narrow slots or grooves found in various mechanical components, such as gears or pulleys. And to efficiently remove material from these tight spaces, you need a chisel specifically designed for the task.

So, sit tight and get ready to uncover the secrets of the perfect chisel for keyway removal. By the end of this guide, you’ll have all the knowledge you need to make an informed decision and get the job done like a pro. Let’s dive in!

Which Chisel is Used for Removing Material on Keyways?

When it comes to removing material on keyways, choosing the right chisel is crucial. Keyways are narrow slots or grooves in mechanical components, such as shafts or gears, that accommodate keys to prevent slippage. Removing material from keyways requires precision and finesse, as any mistakes can compromise the integrity of the component. In this article, we will explore the different types of chisels used for removing material on keyways and how to select the appropriate one for your specific application.

Types of Chisels for Removing Material on Keyways

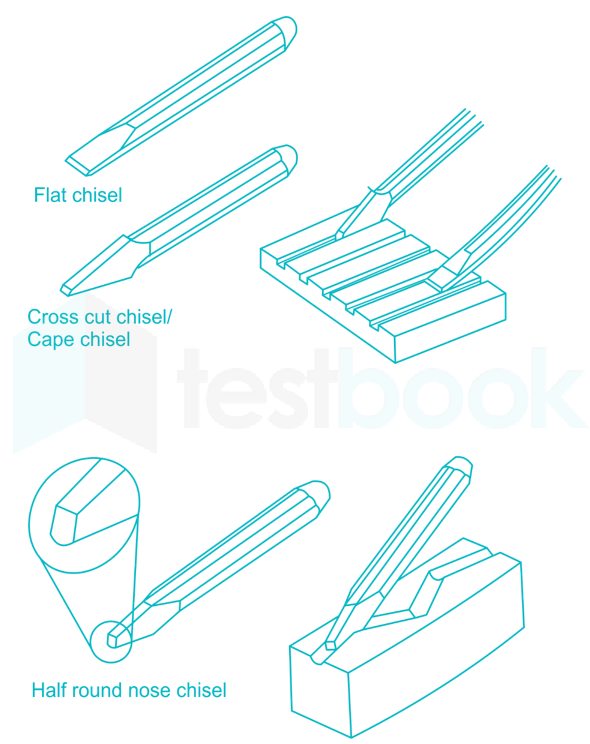

There are several types of chisels that can be used for removing material on keyways. Each chisel has its own unique design and purpose, making it suitable for specific applications. Let’s take a closer look at the most commonly used chisels:

1. Flat Chisels

Flat chisels, also known as straight chisels, are the most versatile chisels used for removing material on keyways. They feature a flat cutting edge and a straight blade, making them ideal for general purpose work. With a flat chisel, you can remove material in a controlled manner, ensuring the keyway is clean and precise. It is important to note that flat chisels come in various sizes, so selecting the appropriate width is crucial for the specific keyway size you are working on.

When using a flat chisel, it is recommended to position the chisel at a slight angle to prevent it from getting stuck in the keyway. This will allow you to make controlled and precise movements as you remove the material. Additionally, you should always wear safety goggles and gloves to protect yourself from any potential flying debris.

2. Cape Chisels

Cape chisels, also known as half-round chisels, are another commonly used option for removing material on keyways. These chisels have a curved cutting edge, which can be beneficial for working on curved or irregularly-shaped keyways. The curved blade allows for better maneuverability and control, ensuring that you can remove material accurately and efficiently.

When using a cape chisel, it is important to align the curved cutting edge with the contour of the keyway. This will ensure that you are removing material precisely and avoiding any unintended damage to the surrounding area. As with any chisel, it is essential to use proper safety precautions when using a cape chisel, including wearing protective gear and using caution during the removal process.

3. Round-Point Chisels

Round-point chisels, as the name suggests, have a rounded cutting edge. These chisels are particularly useful for removing material in tight corners or hard-to-reach areas within a keyway. The rounded tip allows for more precise and controlled movements, ensuring that material is removed without causing any damage to the surrounding components.

When using a round-point chisel, it is important to exercise caution and patience. Due to the rounded tip, the cutting action may be slower compared to flat or cape chisels. However, this slower pace allows for greater control and accuracy, especially in confined spaces. Always work in a well-lit area and wear appropriate safety gear to protect yourself from any potential hazards.

Selecting the Right Chisel for Your Application

Choosing the right chisel for removing material on keyways depends on various factors, including the material of the component, the size of the keyway, and the level of precision required. Here are some key considerations to help you select the appropriate chisel:

1. Material Compatibility

Consider the material of the component you are working on. Different materials may require different chisels for optimal results. For example, softer materials, such as aluminum, may require a chisel with a sharper cutting edge to effectively remove material, while harder materials, such as steel, may require a more robust and durable chisel.

Research the properties of the component material and consult with professionals or expert resources to determine the most suitable chisel for your specific application.

2. Keyway Size and Shape

The size and shape of the keyway play a crucial role in selecting the right chisel. Ensure that the width of the chisel is appropriate for the size of the keyway. Using a chisel that is too narrow or too wide can result in inefficient material removal or damage to the keyway itself.

If the keyway has irregular contours or curves, consider using a cape chisel or a round-point chisel to achieve more precise removal of material.

3. Level of Precision

Consider the level of precision required for your specific application. If you need to remove material with utmost accuracy, a chisel with a finer cutting edge, such as a flat chisel with a narrower width, might be preferable. However, if the application allows for slightly more tolerance, a broader chisel may be more suitable.

Assess the requirements of your application and consult with experienced professionals or colleagues to determine the appropriate level of precision for material removal.

Alternative Tools and Techniques for Removing Material on Keyways

In addition to chisels, there are alternative tools and techniques that can be used to remove material on keyways. These include:

1. Milling

Milling is a machining process that uses rotary cutters to remove material from a workpiece. It can be a highly precise and efficient method for removing material on keyways. Milling machines equipped with appropriate attachments can be used to achieve accurate and consistent results.

Remember that milling requires specialized equipment and knowledge, so it may not be feasible for all applications.

2. Grinding

Grinding is another technique that can be used to remove material on keyways. It involves the use of abrasive wheels to grind away material and create the desired shape. This method requires caution and precision, as excessive grinding can lead to overheating and damage to the component.

Ensure that you have the proper safety equipment and follow grinding best practices to achieve optimal results safely.

3. Broaching

Broaching is a specialized process that involves using a broach, a multi-toothed tool, to remove material in a single pass. It can be an efficient method for removing material on keyways, especially for larger batch productions.

However, broaching requires specialized equipment and expertise, so it may not be a viable option for all applications.

In conclusion, selecting the right chisel for removing material on keyways is essential for precision and efficient work. Flat chisels, cape chisels, and round-point chisels are the most commonly used types for this purpose. Consider the material compatibility, keyway size and shape, and level of precision required when selecting a chisel. Additionally, alternative methods such as milling, grinding, and broaching can be viable options depending on your specific application. Always prioritize safety and consult with experts or professionals for guidance on the most suitable approach.

Key Takeaways: Which Chisel is Used for Removing Material on Keyways?

- A keyway is a slot or groove made on a shaft or hub to fit a key, which prevents relative rotation between the two.

- A flat chisel, also known as a cape chisel, is typically used for removing material on keyways.

- Flat chisels have a wide cutting edge that allows for effective material removal on keyways.

- When using a flat chisel on a keyway, it’s important to strike the chisel with a hammer in a controlled manner to prevent damage to the keyway.

- Always use safety goggles and gloves when working with chisels to protect yourself from any potential injuries.

Frequently Asked Questions

If you’re wondering about the right chisel for removing material on keyways, we’ve got you covered. Here are some commonly asked questions about this topic:

1. What type of chisel is best for removing material on keyways?

A keyway is a narrow groove used to transmit torque between a rotating shaft and a member attached to it. When it comes to removing material on keyways, the most suitable chisel is the keyway chisel. This type of chisel is specifically designed with a narrow profile to fit into the confined spaces of keyways. It allows for precise and controlled material removal.

Keyway chisels typically have a straight cutting edge with a thin blade, allowing them to access and remove material from the keyway without damaging the surrounding area. They are available in various widths to accommodate different keyway sizes. When using a keyway chisel, it’s important to work slowly and carefully to avoid any unintended damage to the keyway or adjacent surfaces.

2. How do I use a keyway chisel to remove material on a keyway?

The first step in using a keyway chisel is to secure the workpiece firmly in place, ensuring it doesn’t move during the chiseling process. It’s essential to wear appropriate safety gear, such as safety glasses and gloves, to protect yourself from flying debris.

To remove material using a keyway chisel, carefully position the chisel at the edge of the keyway, aligning it with the material you want to remove. Apply controlled downward pressure on the chisel handle, using a mallet or hammer. Make sure to strike the chisel with precision to avoid damaging the keyway or creating excess chipping.

Work your way along the keyway, removing small amounts of material at a time. Take breaks to analyze your progress and ensure you’re staying on track. Keep in mind that patience and precision are key when using a keyway chisel, as you want to remove material without compromising the structural integrity of the keyway or adjacent surfaces.

3. Can I use a different type of chisel for removing material on keyways?

While there are other types of chisels available, such as bevel-edge chisels and mortise chisels, it’s generally not recommended to use them for removing material on keyways. These chisels are designed for different types of woodworking applications and may not have the appropriate size or shape to fit into keyways.

Keyway chisels have specific characteristics, including the narrow profile and thin blade, that make them the best choice for this task. Attempting to use a different type of chisel may result in difficulty accessing the keyway or causing damage to the surrounding areas.

4. What safety precautions should I take when using a keyway chisel?

When using a keyway chisel, it’s crucial to prioritize safety. Make sure to wear safety glasses to protect your eyes from flying debris, as well as gloves to safeguard your hands. Additionally, use caution when striking the chisel with a mallet or hammer to avoid injury.

Before starting, secure the workpiece firmly to prevent unexpected movement. Take frequent breaks to rest and assess your progress, ensuring you’re still working in a controlled manner. Following these safety precautions will help minimize the risk of accidents or injuries while using a keyway chisel.

5. Can I use a power tool instead of a chisel to remove material on keyways?

While power tools, such as rotary tools or die grinders, can be used to remove material on keyways, they may not offer the same level of precision as a keyway chisel. Power tools are generally more aggressive and may remove material quickly, but they may also be more prone to causing unintentional damage to the surrounding areas.

If precision and control are of utmost importance, using a keyway chisel by hand is recommended. However, if you have experience and confidence in using power tools, you can explore using them on keyways. Remember to exercise caution and work slowly to avoid compromising the integrity of the keyway or causing damage to adjacent surfaces.

Summary

So, if you want to remove material on keyways, you should use a flat chisel. It’s the best tool for the job because of its shape, size, and durability. Remember to always work carefully and use proper safety precautions when using chisels or any other tools.