Have you ever wondered which way a lathe turns? Well, you’re in the right place! Let’s dive into the world of lathes and uncover the answer together.

Imagine this: you’re in a workshop, surrounded by tools and machinery, and you come across a lathe. It’s this fascinating device used for shaping and smoothing wood, metal, and other materials. But here’s the million-dollar question: which direction does it turn?

Now, you might be thinking, “Why does it even matter?” Well, knowing the direction a lathe turns is crucial for several reasons. It affects the quality of the finished product, tool life, and safety. So, let’s unravel this mystery and discover the answer.

Which Direction Does a Lathe Turn? Understanding the Basics

Lathe machines are an essential tool in the world of manufacturing, woodworking, and metalworking. They are power tools that rotate an object on its axis while various cutting tools shape, cut, or drill it. One common question that often arises is, “Which direction does a lathe turn?” In this article, we will delve into the details and unravel the mystery behind the direction of a lathe’s rotation.

Understanding the Mechanics of a Lathe

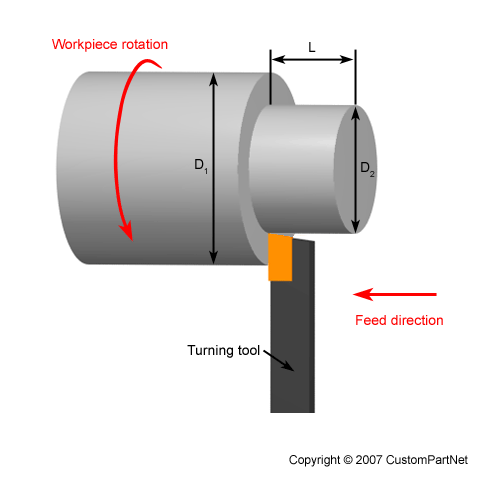

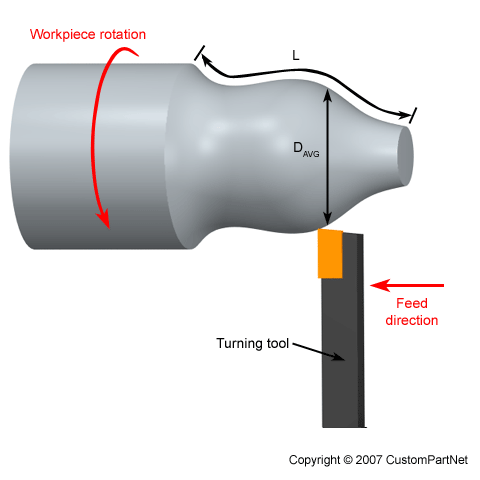

Before we dive into the direction of a lathe’s rotation, let’s first understand the basics of a lathe machine. A lathe consists of several key components, including the headstock, bed, tailstock, carriage, and toolpost. The headstock contains the motor, gearbox, and spindle, which holds the workpiece. The bed is the horizontal beam on which the other components of the lathe are mounted, ensuring stability and precision. The tailstock acts as a support for the opposite end of the workpiece, while the carriage holds the cutting tools and moves along the bed to shape the workpiece.

The Role of the Motor in Determining the Direction of a Lathe’s Rotation

The direction in which a lathe turns is determined by the motor’s rotation. Lathe machines usually come with either an AC (alternating current) motor or a DC (direct current) motor. In the case of an AC motor, the rotation direction can typically be reversed by swapping the positions of the phase wires. On the other hand, DC motors have a specific rotation direction determined by the design of the motor itself.

Now that we have a basic understanding of lathe mechanics, let’s explore the direction of rotation in more detail.

Clockwise Rotation and Its Applications

Clockwise rotation refers to the movement of a lathe in the same direction as the hands of a clock, i.e., from left to right when facing the lathe. This direction is commonly used for operations such as turning, facing, and tapering. These operations involve removing material from the workpiece to create desired shapes or dimensions. Clockwise rotation is often the default direction for many lathe machines, especially those used in traditional turning applications.

The advantages of clockwise rotation include better chip clearance, reduced tool wear, and improved surface finish. However, it’s important to note that not all lathe machines rotate in the clockwise direction by default. Some lathe machines have reversible motors or may require manual adjustments to switch the rotation direction between clockwise and counterclockwise.

Counterclockwise Rotation and Its Applications

Counterclockwise rotation, as the name suggests, refers to the movement of a lathe in the opposite direction of the hands of a clock, i.e., from right to left when facing the lathe. This direction is often used for operations such as threading, knurling, and parting-off. Threading involves cutting grooves into the workpiece to create screw threads, while knurling creates a patterned texture on the workpiece’s surface. Parting-off is the process of cutting off a finished piece from the remaining stock.

Counterclockwise rotation is necessary for these operations because it ensures that the cutting tools engage with the workpiece correctly, creating the desired threads or patterns. Some lathe machines have specialized features and controls to facilitate counterclockwise rotation, while others may require manual adjustments or additional accessories.

The Importance of Understanding the Direction of a Lathe’s Rotation

Understanding the direction of a lathe’s rotation is crucial for safe and efficient operation. Using the wrong rotation direction can lead to poor cutting performance, tool breakage, or even damage to the workpiece or the lathe itself. Therefore, it is essential to consult the lathe’s manual or seek guidance from experienced operators before operating a lathe.

In conclusion, the direction in which a lathe rotates depends on the motor’s design and can be clockwise or counterclockwise. This rotation direction determines the type of operations the lathe can perform, such as turning, facing, threading, and parting-off. Understanding these nuances is vital for achieving accurate results and ensuring the longevity of both the lathe machine and the workpiece. Whether you’re a beginner or an experienced lathe operator, always double-check the rotation direction and follow proper safety protocols to make the most of this versatile tool.

Key Takeaways: Which Direction Does a Lathe Turn?

- A lathe turns in two directions: clockwise and counterclockwise.

- The direction depends on the type of lathe and the specific operation being performed.

- In general, most lathes turn clockwise when viewed from the operator’s perspective.

- However, some lathes, such as screw-cutting lathes, may turn counterclockwise for certain tasks.

- It is important to consult the lathe’s manual or seek guidance from an experienced operator for the correct direction when using a lathe.

Frequently Asked Questions

Curious about the direction a lathe turns? Look no further! We’ve compiled a list of commonly asked questions to help clarify this topic. Read on to learn more!

Q: What direction does a lathe typically turn?

A: Lathes usually turn in the clockwise direction. When viewed from the headstock side, the workpiece rotates from left to right. This rotation is the standard convention for most lathes.

However, it’s important to note that certain lathes, such as screw-cutting lathes, operate in the opposite direction. These lathes turn counterclockwise, or from right to left, when viewed from the headstock side. Always refer to the manufacturer’s instructions or consult an expert if unsure about the specific lathe model you are using.

Q: Why do lathes turn in a particular direction?

A: The direction in which lathes turn is a result of industry standards and practicality. Most lathes are designed to turn clockwise to align with the rotation direction of the cutting tools. This allows the cutting tools to engage the workpiece more efficiently for smoother cuts and improved safety.

Additionally, the clockwise rotation of lathes enables a better chip evacuation system, as the chips are expelled away from the operator. This setup helps prevent the chips from interfering with the cutting operation, reducing the risk of injury and improving overall productivity.

Q: Can lathes be reversed to turn in the opposite direction?

A: Yes, many modern lathes are equipped with a feature called “reverse spindle rotation.” This feature allows the lathe to turn in the opposite direction, counterclockwise, compared to its default clockwise rotation. Reversing the rotation can be useful when performing specific tasks that require a different cutting approach or when threading certain materials.

However, not all lathes come with this feature, especially older models. If you specifically require a lathe with reverse rotation capabilities, make sure to check with the manufacturer or supplier before making a purchase.

Q: Are there any safety considerations when using a lathe?

A: Absolutely! Safety is paramount when operating any machinery, including lathes. Some essential safety measures to follow include wearing appropriate personal protective equipment (PPE), such as safety glasses, gloves, and a face shield. It’s also crucial to secure the workpiece properly and use the appropriate cutting tools for the task at hand.

Furthermore, make sure to familiarize yourself with the lathe’s emergency stop feature and proper shutdown procedures. Always keep the lathe clean and free from clutter to ensure smooth operations. Lastly, proper training and understanding of the lathe’s manual are vital to minimize the risk of accidents and ensure safe usage.

Q: Can a lathe be used to turn different materials?

A: Yes, lathes can be used to turn a wide range of materials, including wood, metal, plastic, and even certain composites. However, it’s crucial to select the appropriate lathe for the specific material you intend to work with.

Wood lathes, for example, are specially designed with features that cater to the unique properties of wood, such as variable speed control and specific tool rests. On the other hand, metal lathes are built to withstand the higher forces and demands of metalworking. Choosing the right lathe for the material you are working with ensures optimal performance, accuracy, and safety.

Summary

When using a lathe, it’s important to know which direction it turns. Most lathes turn clockwise, but some can turn counterclockwise. To determine the direction, check the rotation arrow on the lathe or consult the user manual.

It’s crucial to understand the direction because it affects the cutting and shaping of the material. Always double-check before starting the lathe to avoid accidents and ensure accurate results. So, remember to identify the correct direction and stay safe while working with a lathe!