If you’ve ever wondered which direction is stronger when it comes to plywood, you’re in the right place! Plywood, a versatile building material, has its different strength properties based on how the plies are arranged. So, let’s dive in and explore the fascinating world of plywood strength!

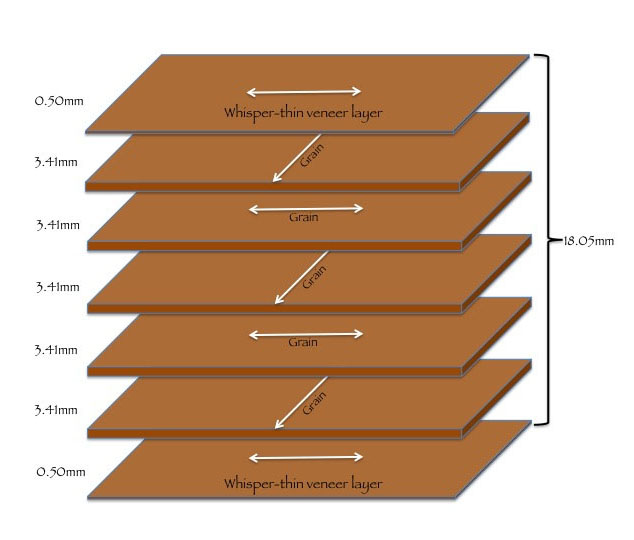

When it comes to plywood, the direction in which it is stronger depends on the arrangement of its layers. Plywood consists of several thin layers of wood called plies, which are glued together. Each ply is oriented at a right angle to the adjacent ones, creating a cross-grain pattern. This arrangement gives plywood its strength and stability.

In general, plywood tends to be stronger in the direction across the grain, also known as the short direction. However, there are also cases where plywood can be stronger along the grain, also known as the long direction. Understanding the strength characteristics of plywood can help you make informed decisions when choosing the right material for your projects. So, let’s delve deeper into the factors that determine plywood strength and discover some practical tips along the way!

Which Direction is Plywood Stronger?

When it comes to plywood, understanding its strength and properties is crucial for making informed decisions in construction and woodworking projects. One common question that often arises is, “Which direction is plywood stronger?” In this article, we will delve into the topic in detail, exploring the factors that determine plywood strength and providing valuable insights for those seeking answers.

Understanding Plywood Strength

Before we dive into the specifics of plywood strength in different directions, let’s first understand the composition of this versatile material. Plywood is made by gluing together several layers of thin wood veneers with the grain direction alternating at 90-degree angles. This alternating grain pattern gives plywood its exceptional strength and stability.

The Longitudinal Direction (With the Grain)

When plywood is oriented with the grain direction running perpendicular to the supports or load-bearing elements, it exhibits significant strength. In this configuration, the continuous grain alignment enhances the material’s ability to carry weight and withstand bending forces. Plywood’s strength in the longitudinal direction makes it suitable for floor joists, beams, and other structural elements.

Furthermore, the continuous grain direction also allows for better nail and screw retention, ensuring a secure bond between the plywood and other materials. This added strength makes plywood an ideal choice for subflooring and decking applications, where durability and load-bearing capacity are essential.

The Cross-Grain Direction

While plywood is strongest when loaded in the longitudinal direction, it still possesses considerable strength when loaded in the cross-grain direction. The alternating grain pattern helps distribute the stress and prevents cracks from propagating through the material. However, compared to the longitudinal direction, plywood’s strength in the cross-grain direction is relatively lower.

Despite this, plywood used in applications where the grain runs parallel to the supports, such as wall sheathing or cabinet backing, still provides ample strength and stability. It is crucial to note that proper support and fastening techniques should be employed to maximize the material’s strength and longevity.

Factors Impacting Plywood Strength

While the grain direction plays a significant role in plywood strength, other factors can influence its overall performance:

1. Plywood Grade:

Plywood is available in various grades, each designed for specific applications. Higher-grade plywood tends to have fewer voids and defects, contributing to its overall strength.

2. Thickness:

The thickness of plywood affects its load-bearing capacity. Thicker plywood can withstand heavier loads compared to thinner counterparts.

3. Species of Wood:

The species of wood used in plywood also impacts its strength. Different wood species have varying intrinsic properties that contribute to the overall strength and performance of the plywood.

4. Adhesive Quality:

The adhesive used to bond the plywood layers together plays a crucial role in its strength and durability. High-quality adhesives ensure a strong bond between the layers, enhancing the plywood’s overall strength.

5. Moisture Content:

Moisture can significantly impact the strength and integrity of plywood. Excessive moisture can lead to warping, delamination, and reduced strength. It is essential to store and use plywood in appropriate environments to maintain its strength.

Benefits of Using Plywood in Different Directions

Now that we have gained insight into the strength of plywood in different directions, let’s explore the benefits of using plywood in specific orientations:

1. Longitudinal (With the Grain) Orientation:

– Enhanced load-bearing capacity

– Better resistance to bending forces

– Secure nail and screw retention

2. Cross-Grain Orientation:

– Ample strength for applications parallel to the supports

– Even distribution of stress

– Suitable for wall sheathing and cabinet backing

Tips for Maximizing Plywood Strength

Here are some tips to ensure you maximize the strength and durability of plywood in your projects:

1. Choose the Appropriate Grade:

Select the right grade of plywood based on your specific application. Higher grades typically offer better strength and fewer defects.

2. Orient the Plywood Correctly:

Understand the load-bearing requirements and orient the plywood with the grain direction to align with the supports or load-bearing elements.

3. Utilize Proper Fastening Techniques:

Use appropriate nails, screws, or adhesives to fasten the plywood securely to ensure optimal load-bearing capacity and structural integrity.

4. Protect Plywood from Moisture:

Prevent exposure to excessive moisture, as it can weaken the plywood. Use appropriate sealants or coatings to protect the plywood when necessary.

5. Support Plywood Adequately:

Ensure proper support for plywood to prevent sagging or failure. Use additional supports or reinforcement when necessary, especially in applications with heavy loads.

Conclusion

Plywood exhibits considerable strength in both the longitudinal and cross-grain directions, with its maximum strength realized when loaded with the grain (longitudinal direction). Understanding the grain direction and other factors influencing plywood strength allows for informed decisions in construction and woodworking projects. By selecting the right grade, orienting the plywood correctly, and employing proper fastening techniques, you can maximize its strength and durability. So, next time you ask, “Which direction is plywood stronger?” you’ll have the knowledge to make an educated choice.

Key Takeaways: Which Direction is Plywood Stronger?

- Plywood is stronger in one direction than another.

- The direction of the grain in each layer determines the strength.

- Plywood is typically stronger along the length than across the width.

- Longitudinal strength refers to the strength along the length of the plywood.

- Cross-sectional strength refers to the strength across the width of the plywood.

Frequently Asked Questions

Welcome to our Frequently Asked Questions section where we answer common inquiries about the strength of plywood in different directions.

What direction is plywood stronger?

Plywood gets its strength from the direction of the wood grain in its layers. The strength of plywood can vary depending on the orientation of the grain. In general, plywood is strongest when force is applied perpendicular to the layers or across the face grain.

When force is applied parallel to the grain, plywood is not as strong. Therefore, plywood is typically stronger in the cross-grain direction compared to the long-grain direction. This is due to the way the layers are arranged during the manufacturing process.

Does plywood have a weaker direction?

Yes, plywood does have a weaker direction. The long-grain direction is generally considered the weaker direction in plywood. When force is applied parallel to the grain, the layers of plywood can separate, causing the plywood to weaken.

However, it’s important to note that even in the weaker direction, plywood still possesses considerable strength. It is a versatile and durable material when used in construction and various woodworking projects.

Can plywood be used in all directions?

Plywood can be used in all directions, depending on the specific application and load-bearing requirements. While plywood is strongest in the cross-grain direction, it can still provide ample strength in the long-grain direction when used appropriately.

The decision of which direction to use plywood depends on several factors, such as the design, load distribution, and the specific forces it will experience. Consulting with a professional or referring to engineering guidelines can help determine the best orientation for plywood in a particular project.

Are there specific applications where the direction of plywood matters?

Yes, the direction of plywood does matter in certain applications. For example, in flooring installations, plywood is typically laid perpendicular to the floor joists to provide better support and distribute the load more evenly.

Similarly, in cabinet or furniture making, the direction of plywood may be crucial for structural integrity and aesthetic purposes. By understanding the properties and directional strength of plywood, craftsmen and builders can maximize its performance and create long-lasting, reliable structures.

Does plywood have a uniform strength in all sizes and thicknesses?

No, the strength of plywood can vary depending on its size and thickness. Generally, thicker plywood tends to be stronger and more rigid compared to thinner plywood.

Moreover, larger sizes of plywood panels may have reduced strength at the edges due to the potential for splitting or delamination. It is important to consider these factors when selecting plywood for a specific project and consult load calculations or engineering specifications when required.

Direction of Face Grain of Plywood – Floor and Roof Building Installation

Summary

So, which direction is plywood stronger? It turns out that plywood is stronger along the grain, meaning that the long edges of the plywood have more strength. This is because the grain of the wood runs parallel to those edges. However, it’s important to note that plywood is still a strong and versatile material, regardless of the direction of the grain.

In addition, the orientation of the plywood also affects its strength. When installed correctly, with the grain direction perpendicular to the support structure, plywood can provide excellent strength and stability. So, whether you’re using plywood for building furniture, constructing walls, or any other project, understanding the direction of its strength can help you make the most out of this useful material.