Have you ever wondered which hole making process cannot be done on a drill press machine? Well, you’re in the right place to find out! In this article, we’ll explore the limitations of drill press machines and discover the hole making techniques that go beyond their capabilities. So, let’s dive in and expand our knowledge about the fascinating world of hole making!

When it comes to drilling holes, drill press machines are usually our go-to tools. They offer precision, stability, and ease of use. But did you know that there are some hole making processes that can’t be accomplished using these machines? That’s right! While drill presses excel at many tasks, there are certain techniques that require alternative methods. Let’s explore these unconventional hole making processes and understand why they can’t be performed on a drill press machine.

Are you ready to go beyond the limits of a drill press machine? In this article, we’ll delve into the world of hole making techniques, uncovering the ones that defy the capabilities of a drill press. By understanding these limitations, you’ll broaden your understanding of hole making and discover alternative methods that can help you tackle any project with finesse. So, let’s get started and explore the fascinating world of hole making beyond the drill press!

While a drill press machine is versatile, there is one hole making process it cannot perform: square hole drilling. The drill press is designed to create round holes, and its rotating bit cannot accommodate the geometry required for square holes. However, there are specialized tools, such as mortising machines or broaching machines, that can be used for square hole drilling. So, if you need to create square holes, you will need to explore alternative hole making methods.

Which Hole Making Process Cannot Be Done on a Drill Press Machine?

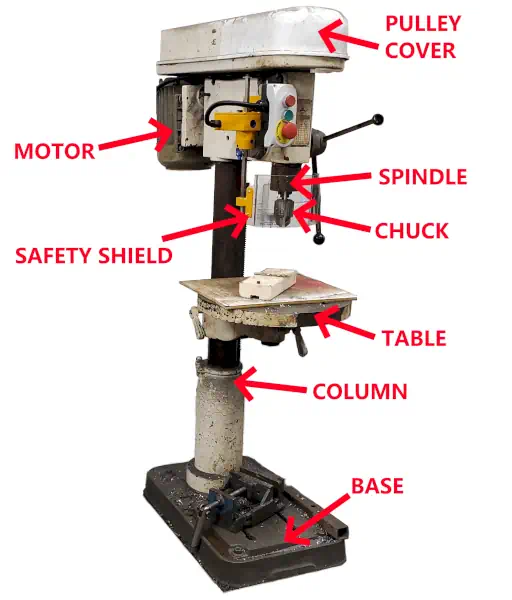

When it comes to creating holes, a drill press machine is an essential tool in any workshop. It provides accuracy, speed, and control for a wide range of hole making processes. However, there are certain hole making processes that cannot be done on a drill press machine. In this article, we will explore these processes in detail and understand why a drill press machine is not suitable for them.

1. Boring Large Holes

A drill press machine is not designed to bore large holes. The drill bit used in a drill press machine is thin and can only create holes within a certain diameter range. If you need to create a large hole, you would need a specialized tool such as a hole saw or a boring machine. These tools have larger cutting surfaces and can remove more material, allowing you to create holes of various sizes.

Boring large holes requires a different set of tools and techniques compared to drilling small holes. The drill press machine lacks the power and stability necessary to bore large holes effectively. Additionally, the speed and torque of a drill press machine may not be suitable for larger hole making processes, which can lead to inefficiency and potential damage to the machine or workpiece.

In summary, if you need to bore large holes, it is best to use a specialized tool rather than a drill press machine.

2. Tapping Threads

Tapping threads is a common process used to create internal threads in a hole. While it is possible to tap threads using a drill press machine, it is not recommended. The main reason is that a drill press machine lacks the necessary control and precision required for tapping threads.

Tapping requires a different type of cutting tool called a tap. The tap is designed to cut threads into the material as it rotates. To tap threads accurately, it is crucial to maintain a perpendicular angle between the tap and the workpiece. A drill press machine may not provide the necessary control and alignment required for accurate threading.

Furthermore, the speed and torque of a drill press machine may not be suitable for tapping threads, especially in harder materials. Incorrect speed or torque can lead to broken taps or damaged threads, resulting in costly mistakes and potential workpiece damage.

If you need to tap threads, it is recommended to use a tapping machine or a handheld tapping tool that is specifically designed for this process.

3. Countersinking

Countersinking is a hole making process that involves widening the mouth of a hole to accommodate a countersunk screw or bolt. While a drill press machine can drill a hole, it is not designed for countersinking.

Countersinking requires a specialized tool called a countersink bit. This bit has a conical shape with a wider diameter at the top to create the countersunk shape. The angle of the countersink bit is also important as it determines the angle at which the screw or bolt will sit flush with the surface.

A drill press machine typically uses straight drill bits, and it lacks the angle adjustment required for countersinking. Additionally, the speed and depth control of a drill press machine may not be as precise for countersinking, resulting in inconsistent or improper countersinks. It is best to use a dedicated countersinking tool or a handheld countersink tool for this process.

4. Reaming

Reaming is a process used to refine the diameter and finish of a drilled hole. While a drill press machine can create a hole, it is not suitable for reaming.

Reaming requires a reamer, which is a cutting tool designed specifically for this process. The reamer removes a small amount of material from the hole, resulting in improved accuracy and surface finish. The reaming process is typically performed after drilling to achieve a precise and smooth hole.

A drill press machine lacks the necessary control and precision required for reaming. The speed and torque may not be suitable, and the lack of fine depth adjustment can result in inaccuracies. It is recommended to use a reaming machine or a handheld reaming tool for this process.

5. Broaching

Broaching is a hole making process that involves using a specialized cutting tool called a broach to create a hole with a specific shape or profile. This process is typically used for keyways or splines. A drill press machine is not suitable for broaching due to several reasons.

Broaching requires a high level of precision and control to ensure the desired shape and size of the hole. A drill press machine may lack the necessary rigidity and stability to handle the forces involved in broaching. The speed and torque of the drill press machine may also not be suitable for broaching, leading to potential tool breakage or workpiece damage.

Moreover, broaching requires specialized cutting tools and fixturing to hold the workpiece securely during the cutting process. A drill press machine may not be designed to accommodate these requirements, making it unsuitable for broaching.

For broaching processes, it is best to use a broaching machine or seek the assistance of a professional with the necessary equipment and expertise.

6. Shaping and Forming

A drill press machine is primarily designed for drilling holes and lacks the capability to shape or form holes in any significant way. Shaping and forming holes require specialized tools such as milling machines, lathes, or CNC machines.

Milling machines are used to create complex shapes and profiles by removing material from the workpiece using rotating cutting tools. Lathes, on the other hand, are used to rotate the workpiece while stationary cutting tools shape and form the material. CNC machines are capable of automated shaping and forming processes and are widely used in advanced manufacturing industries.

If you require shaped or formed holes, it is best to consult with a professional or utilize the appropriate machinery for the specific process.

7. Laser Cutting

Laser cutting involves using a high-powered laser beam to cut through materials and create precise holes or shapes. While a drill press machine is a versatile tool, it is not capable of laser cutting.

Laser cutting machines use advanced technology to produce clean and accurate cuts in various materials, including metal, plastic, and wood. The laser beam can be controlled with precision to create holes of different shapes and sizes. The process is fast, efficient, and highly accurate.

Laser cutting requires specialized equipment and expertise, and it is best to consult with a professional or utilize laser cutting services for this process.

Additional Information

8. Benefits of Using a Drill Press Machine for Hole Making

Increased Accuracy

A drill press machine provides increased accuracy compared to handheld drills. It offers precise control over drilling depth and angle, ensuring consistent and accurate holes.

Enhanced Safety

Using a drill press machine reduces the risk of accidents and injuries compared to handheld drills. The machine is designed with safety features such as clamps and guards to protect the operator.

Efficient and Time-Saving

A drill press machine allows for efficient and quick hole making processes. The machine’s consistent drilling speed and depth control enable faster completion of tasks.

Versatility

While a drill press machine may have limitations for certain hole making processes, it is still a versatile tool that can handle a wide range of drilling tasks. It is suitable for various materials, including wood, metal, and plastic.

9. Drill Press Machine vs. Handheld Drills

A Comparison of Features and Benefits

Table: Comparison of Drill Press Machine and Handheld Drills

| Features | Drill Press Machine | Handheld Drill |

|---|---|---|

| Accuracy | High | Medium |

| Speed Control | Precise | Variable |

| Drilling Depth Control | Precise | Variable |

| Stability | High | Low |

| Power | High | Variable |

| Size and Portability | Large and Stationary | Compact and Portable |

While a drill press machine offers increased accuracy and control, handheld drills provide greater portability and flexibility. The choice between the two depends on the specific requirements of the project and the preference of the user.

10. Tips for Effective Hole Making with a Drill Press Machine

1. Use the Right Drill Bit

Ensure you are using the appropriate drill bit for the material you are drilling. Different drill bits are designed for specific materials, such as wood, metal, or concrete.

2. Secure the Workpiece

Always secure the workpiece firmly before drilling to prevent movement or slipping during the drilling process. This will help ensure accurate and clean holes.

3. Adjust Speed and Depth

Set the appropriate drilling speed and depth according to the material and hole size. Refer to the manufacturer’s guidelines for recommended settings.

4. Lubricate the Drill Bit

If you are drilling through metal or tougher materials, consider using a lubricant to reduce friction and heat buildup. This will extend the life of your drill bit and improve drilling efficiency.

5. Clear Chips and Debris

Regularly clear the chips and debris from the drilling area to maintain a clean and efficient operation. This will prevent clogging and ensure smooth drilling.

11. Conclusion

A drill press machine is an invaluable tool for a wide range of hole making processes. However, there are certain processes that require specialized tools and techniques. For boring large holes, tapping threads, countersinking, reaming, broaching, shaping and forming, and laser cutting, it is best to use dedicated tools or seek professional assistance. Understanding the limitations of a drill press machine will help you make informed decisions and achieve the desired results in your hole making projects.

Key Takeaways: Which Hole Making Process Cannot Be Done on a Drill Press Machine?

Key Takeaways:

- 1. Counterboring cannot be done on a drill press machine.

- 2. Tapping threads cannot be done on a drill press machine.

- 3. Reaming cannot be done on a drill press machine.

- 4. Boring large holes cannot be done on a drill press machine.

- 5. Honing cannot be done on a drill press machine.

Frequently Asked Questions

When it comes to hole making processes, there are certain tasks that cannot be performed on a drill press machine. Here are some common questions and answers regarding these limitations.

Can a drill press machine be used for tapping holes?

No, a drill press machine should not be used for tapping holes. Tapping is a process that involves creating internal threads, and it requires a different type of machine called a tapping machine or a tap and die set. These machines are specifically designed to handle the cutting and threading action required for tapping.

While a drill press machine may have the required rotational speed, it lacks the necessary control and alignment features needed for accurate tapping. Attempting to tap holes on a drill press machine can result in misaligned threads, damaged tools, and potential injury. It’s best to use the appropriate tool for tapping tasks.

Is it possible to perform counterboring on a drill press machine?

No, counterboring is not recommended on a drill press machine. Counterboring is a process of enlarging a portion of a hole to allow the head of a screw or fastener to sit flush with or below the surface of the material. It requires a specialized counterboring tool or a combination drill bit and counterbore. These tools provide the necessary cutting geometry and control to accurately create counterbores.

A drill press machine lacks the precision necessary for counterboring. It is primarily designed for drilling holes and doesn’t offer the required cutting features and alignment capabilities to create counterbores accurately. To achieve proper counterbores, it’s best to use the appropriate tools designed specifically for this purpose.

Can a drill press machine be used for reaming holes?

While a drill press machine can handle drilling tasks, it is not suitable for reaming holes. Reaming is a process used to improve the accuracy and surface finish of a drilled hole. It involves using a reamer, which has multiple cutting edges and is designed to remove a small amount of material to achieve precise dimensions.

A drill press machine lacks the required stability and control to properly perform reaming. The rotational speed and feed rate of a drill press machine may not be suitable for reaming, and it may result in poor surface finish and dimensional inaccuracies. It’s recommended to use a dedicated reaming machine or hand reamers for this specific task.

Is it safe to perform broaching on a drill press machine?

No, it is not safe to perform broaching on a drill press machine. Broaching is a process of creating precision keyways or splines in a workpiece using a broach tool. Broaching requires a high level of force and a machine specifically designed for this purpose to ensure proper cutting action.

Drill press machines do not have the necessary strength or rigidity needed for broaching. Attempting to perform broaching on a drill press machine can lead to tool breakage, damage to the workpiece, and risk of injury. It’s essential to use specialized broaching machines or broaching tools designed for this specific operation.

Can a drill press machine be used for countersinking?

Yes, a drill press machine can be used for countersinking. Countersinking is a process of creating a conical recess in a material to accommodate the head of a screw, allowing it to sit flush with or below the surface. Most drill press machines offer the capability to adjust the depth and angle of the countersink.

By using the appropriate countersink bit, the drill press machine can accurately create countersinks with consistent angles and depths. However, it’s important to ensure that the workpiece is securely clamped, the feed rate is controlled, and the correct cutting speeds are employed to achieve clean and precise countersinks.

Summary

So, to wrap it up, there are certain hole-making processes that cannot be done on a drill press machine. This is because drill press machines have limitations. For example, they cannot perform processes like tapping or countersinking holes. These tasks require specialized tools or machines to achieve the desired outcome. Therefore, it is important to be aware of the capabilities and limitations of a drill press machine when considering hole-making options.