When it comes to using power tools, safety should always be a top priority. So, which safety measures are acceptable when working with these powerful machines? Let’s dive in and find out!

First off, it’s important to understand that power tools can be dangerous if not used correctly. That’s why it’s crucial to wear appropriate protective gear, such as safety goggles, gloves, and earplugs, to keep yourself safe from flying debris and loud noises.

In addition to protective gear, always make sure to follow the manufacturer’s instructions for the specific power tool you’re using. These instructions will outline how to operate the tool safely and effectively, reducing the risk of accidents or injuries. Remember, safety should never be compromised when working with power tools.

- Wear protective gear, including safety glasses, gloves, and hearing protection.

- Read the tool’s instruction manual before use.

- Maintain a clean and organized work area.

- Avoid distractions and stay focused on the task.

- Disconnect the power and remove the battery before making adjustments or changing accessories.

- Never use a power tool if you are fatigued or under the influence of drugs or alcohol.

Follow these steps to ensure your safety when using power tools.

Which Safety Measures are Acceptable When Using Power Tools?

Power tools are essential for many projects, but they also pose significant risks if not handled properly. The key to using power tools safely lies in following the right safety measures. In this article, we will explore seven important safety measures that are acceptable when using power tools. By understanding and implementing these measures, you can minimize the risk of accidents and injuries while working with power tools.

1. Wear Appropriate Personal Protective Equipment

When using power tools, wearing the right personal protective equipment is crucial. This includes safety goggles or glasses to protect your eyes from flying debris, earplugs or earmuffs to minimize noise exposure, and gloves to provide a secure grip and protect your hands. In addition, if you are working with power tools that generate a lot of dust or particles, such as sanders or grinders, wearing a dust mask or respirator is necessary to prevent inhalation of harmful substances.

It is important to choose PPE that is specifically designed for the task at hand. For example, safety goggles or glasses should have side shields to prevent debris from entering the eyes from the sides. Gloves should fit properly and allow for dexterity, without being too loose or too tight. By wearing the right personal protective equipment, you can greatly reduce the risk of injuries and hazards associated with power tool use.

Furthermore, it is equally important to ensure that your clothing and accessories do not pose any risks. Avoid wearing loose clothing, long sleeves, or dangling jewelry that could get caught in the moving parts of the power tool. Tie back long hair and securely fasten any loose accessories. These small precautions can prevent accidents and ensure safe operation of power tools.

2. Familiarize Yourself with the Power Tool and Its User Manual

Before using any power tool, it is essential to take the time to read and fully understand the user manual provided by the manufacturer. The user manual contains vital information on the proper use, maintenance, and safety precautions specific to the particular power tool. It will guide you on how to operate the tool correctly, adjust settings, and change accessories.

By familiarizing yourself with the power tool and its user manual, you will gain valuable insights into its limitations and potential hazards. Understanding the tool’s capabilities and limitations will help you make informed decisions while using it, ensuring safe and efficient operation. Remember, each power tool is unique, and even experienced users should read the user manual for any new tool they are not familiar with.

In addition to reading the user manual, it is also advisable to seek training or guidance from experienced professionals or instructors, especially for complex or highly specialized power tools. Proper training will equip you with the necessary skills and knowledge to operate the tool safely and effectively.

3. Inspect the Power Tool and Its Accessories Before Use

Prior to using any power tool, it is vital to inspect it thoroughly, including all accessories and attachments. Look for any signs of damage, wear, or malfunction that could potentially compromise its safety and performance. Check the power cord or battery for any damage or exposed wires, and ensure that all switches, buttons, and controls are in working order.

If you notice any issues or abnormalities during the inspection, do not use the tool. It is crucial to address and repair any faults before using the power tool. Using a faulty tool can increase the risk of accidents, such as electrical shocks, tool malfunctions, or injuries. Regular maintenance and inspection of power tools are essential to ensure their safe and optimal operation.

Similarly, inspect the accessories and attachments, such as blades, drill bits, or sanding discs, for any signs of damage or wear. Ensure that they fit securely and are compatible with the power tool. Using damaged or ill-fitting accessories can result in accidents or damage to the workpiece. Always use the appropriate accessories recommended by the manufacturer to ensure safe and efficient operation.

4. Provide Adequate Lighting and Proper Workspace Setup

When using power tools, it is important to have adequate lighting in your workspace. Insufficient lighting can make it difficult to see the workpiece, increasing the risk of accidents and mistakes. Ensure that the area where you will be operating the power tool is well-lit, either with natural light or additional artificial lighting.

In addition to lighting, the setup of your workspace is crucial for safety. Clear any clutter or obstacles that may pose a tripping or falling hazard. Keep the work area clean and organized, with tools and materials properly stored. Use workbenches or sturdy surfaces to provide a stable base for operating the power tool.

Furthermore, if using power tools with long power cords, make sure they are properly secured to prevent tripping or entanglement. Avoid running cords across walkways or areas with high foot traffic. If necessary, use cord organizers or tape to secure cords to the floor or walls. An organized and well-prepared workspace promotes safe and efficient use of power tools.

5. Follow Proper Start-up and Shutdown Procedures

Every power tool has specific start-up and shutdown procedures that must be followed for safe operation. These procedures may include steps such as checking the power source, engaging safety switches or locks, or activating specific controls in a certain sequence.

Before starting the power tool, make sure it is securely placed on a stable surface or held firmly with appropriate clamps or supports. Check that the power source, whether it is a corded or cordless tool, is in good condition and provides the necessary voltage or charge.

When shutting down the power tool, always ensure that the tool is fully powered off and any moving parts have come to a complete stop. Return the tool to its designated storage location, away from any potential hazards or access by unauthorized individuals.

6. Use the Right Tool for the Job

Using the correct power tool for the specific task at hand is essential for safety and efficiency. Each power tool is designed for particular applications and materials, and using the wrong tool can lead to accidents, damage to the workpiece, or tool malfunctions.

Refer to the user manual or consult with experts to determine the appropriate power tool for your project. Consider factors such as the type of material, the size and complexity of the task, and any specific requirements or limitations. Using the right tool will not only ensure safe operation but also help achieve better results in less time.

It is important to note that modifications or improper use of power tools can compromise their safety and may void their warranty. Avoid using power tools for purposes other than their intended use, and refrain from altering their design or functionality without expert guidance. Stick to the recommended tools and techniques to maximize safety and performance.

7. Maintain Focus and Practice Good Ergonomics

When working with power tools, maintaining focus and concentration is vital. Avoid distractions such as loud music, phone calls, or conversations that can divert your attention away from the task at hand. Losing focus even for a moment can lead to accidents and injuries.

In addition to focus, practicing good ergonomics is crucial to prevent strains, fatigue, and long-term health issues. Maintain a proper posture while operating power tools, ensuring that your back is straight and your body is well-supported. Use tools and accessories with ergonomic features, such as handles with non-slip grips or adjustable heights.

Take regular breaks and stretch your muscles to prevent stiffness and discomfort. Listen to your body and be mindful of any pain or discomfort, as it may be a sign of poor ergonomics or overexertion. By practicing good ergonomics, you can minimize the risk of repetitive strain injuries and enhance your overall safety and well-being.

Additional Safety Tips for Using Power Tools

Using power tools safely requires attention to detail and adherence to proper procedures. To further enhance your safety, consider the following tips:

1. Conduct a Risk Assessment

Prior to starting any project involving power tools, conduct a risk assessment to identify potential hazards and take necessary precautions. This includes assessing the work area, the materials involved, and any specific risks associated with the tasks at hand. By being proactive and addressing potential risks, you can reduce the likelihood of accidents.

Benefits of Conducting a Risk Assessment:

- Identifying potential hazards and risks beforehand

- Implementing appropriate safety measures

- Minimizing the risk of accidents and injuries

2. Keep Emergency Contacts Handy

In case of an emergency or accident, it is important to have emergency contacts readily available. Keep a list of emergency phone numbers, including local hospitals, poison control centers, and fire departments, near your work area. This ensures quick access to help in case of any injuries or incidents.

3. Regularly Inspect and Maintain Power Tools

Routine inspection and maintenance of power tools are crucial for their safe and efficient operation. Regularly check for signs of wear, damage, or malfunctions, and address any issues promptly. Clean the tools and lubricate moving parts as recommended by the manufacturer. Proper maintenance not only extends the lifespan of your tools but also minimizes the risk of accidents.

Tips for Inspecting and Maintaining Power Tools:

1. Clean and remove debris from the tool after each use

Cleaning the tool regularly prevents build-up of dust and debris that can affect its performance and safety. Use compressed air or a soft brush to remove any particles from the tool’s surfaces and ventilation areas.

2. Lubricate moving parts regularly

Applying lubrication to moving parts, such as gears or bearings, helps reduce friction and wear. Refer to the user manual for the recommended lubrication intervals and types of lubricants to use.

3. Check power cords and batteries

Inspect the power cords or batteries for any signs of damage or deterioration. If any issues are found, replace or repair them immediately. Avoid using power tools with damaged cords or batteries, as it can lead to electrical hazards.

4. Sharpen or replace dull cutting tools

Dull cutting tools not only produce poor results but also increase the risk of accidents. Regularly inspect and sharpen cutting tools such as saw blades or drill bits. Replace any tools that are excessively worn or damaged.

4. Secure Workpieces and Use Clamps or Vices

When working with power tools, it is essential to secure the workpiece properly to prevent movement or shifting during operation. This can be achieved by using clamps, vices, or other suitable holding devices. Securely fasten the workpiece, ensuring that it is stable and immovable, before using the power tool.

5. Keep a First Aid Kit Nearby

Accidents can happen even with the utmost precautions. Having a first aid kit readily available in your workspace enables you to respond quickly to minor injuries and provide immediate care. Ensure that the first aid kit is fully stocked and includes necessary items such as bandages, disinfectant, and gloves.

Benefits of Having a First Aid Kit:

- Quick response to minor injuries

- Prompt provision of basic medical care

- Reducing the risk of infection or further complications

6. Never Work Under the Influence

Operating power tools while under the influence of alcohol, drugs, or medications that may impair your judgment or coordination is extremely dangerous. These substances can affect your reaction time, decision-making ability, and overall alertness, increasing the risk of accidents. Always work with power tools in a clear and sober state of mind.

7. Seek Professional Help for Complex or Specialized Tasks

If you have limited experience or are unsure about handling a particular task or power tool, it is advisable to seek professional help. Certain projects, such as electrical work or heavy machinery operation, may require specialized knowledge and skills. Contact a qualified professional or expert in the field to ensure the task is performed safely and correctly.

8. Always Disconnect Power before Making Adjustments or Repairs

When making adjustments, changing accessories, or performing repairs on a power tool, it is crucial to disconnect the power source first. Unplugging corded tools or removing the battery from cordless tools prevents accidental start-up or electrical shocks. Treat every adjustment or repair as a potentially hazardous situation and take the necessary precautions.

9. Store Power Tools Safely

Proper storage of power tools is essential for their longevity and safety. Store them in a dedicated space that is dry, clean, and away from areas with high humidity or extreme temperatures. Use the original carrying cases or invest in storage solutions that provide protection from dust, moisture, and accidental damage. Keep power tools out of reach of children and unauthorized individuals.

Benefits of Proper Storage:

- Preserving the lifespan and quality of power tools

- Preventing accidental damage or misuse

- Enhancing overall safety in the workspace

10. Practice Good Communication and Supervision

If you are working in a team or mentoring someone using power tools, clear and effective communication is vital. Provide clear instructions, discuss safety measures, and ensure that everyone is trained and aware of the potential risks associated with the task. Regularly supervise and monitor the work being performed, stepping in if you notice any unsafe practices or conditions.

By incorporating these safety measures and tips into your power tool usage, you can mitigate risks and ensure a safe working environment. Remember, safety should always be a top priority when using power tools. Prioritize protecting yourself and those around you by following these guidelines and promoting responsible and safe practices.

Key Takeaways: Which is Acceptable When Using Power Tools?

- Always wear appropriate safety gear, such as safety glasses, gloves, and ear protection.

- Use the correct tools for the job to ensure safety and effectiveness.

- Read and follow the manufacturer’s instructions before using any power tool.

- Ensure the power tool is in good condition, with no damage or defects.

- Never use power tools while under the influence of drugs or alcohol.

Frequently Asked Questions

When it comes to using power tools, it’s important to prioritize safety and follow the right practices. Here are some common questions and answers regarding which actions are acceptable when using power tools:

1. Can I wear loose clothing or jewelry while operating power tools?

No, it is not safe to wear loose clothing or jewelry when using power tools. They can get caught in the machinery and lead to accidents. It is recommended to wear snug-fitting clothes and remove any accessories that could potentially get tangled.

Always choose appropriate work attire that does not pose a risk of interference or entanglement with the power tool you are using. This simple precaution can help prevent accidents and injuries in the workshop.

2. Do I need to wear safety glasses when using power tools?

Yes, wearing safety glasses is crucial when using power tools. They protect your eyes from flying debris, sparks, and potential hazards. Even a small piece of material or debris can cause significant eye damage, so it’s important to prioritize eye protection at all times.

Investing in a good pair of impact-resistant safety glasses is a wise decision. Make sure they fit properly and provide adequate coverage for your eyes. Remember, your eyes are irreplaceable, so take the necessary precautions.

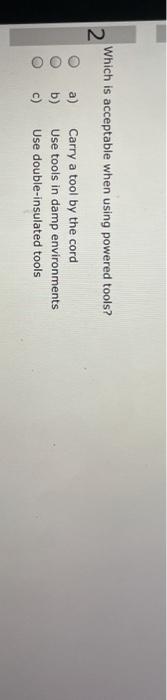

3. Is it acceptable to use power tools with wet hands?

No, it is never acceptable to use power tools with wet hands. Water conducts electricity, and using power tools with wet hands increases the risk of electrical shock or electrocution. Always ensure your hands are dry before handling any power tools.

If you need to use power tools in a damp environment, such as outdoors or in a workshop where fluids are present, make sure to wear appropriate protective gloves that are insulated against electricity.

4. Can I use power tools without a proper grip or stable footing?

No, it is crucial to maintain a proper grip and stable footing when using power tools. Having a secure grip on the tool allows for better control, reducing the risk of slips or accidental discharges. Additionally, having a stable footing ensures that you are balanced and less likely to lose control of the tool.

Always use both hands to operate power tools whenever possible and ensure that you have a solid, non-slip surface beneath your feet. Avoid working on ladders or unstable surfaces that can compromise your stability.

5. Is it acceptable to modify or remove safety features from power tools?

No, it is absolutely unacceptable to modify or remove safety features from power tools. These safety features are designed to protect you from potential harm. Altering or removing them can increase the risk of accidents and injuries.

If you find that a safety feature on your power tool is not functioning properly, it is recommended to have it repaired by a professional or replace the tool altogether. Always prioritize safety over convenience.

How to Start Using Power Tools for DIY Beginners | The DIY Mommy

Summary

Using power tools can be exciting, but safety should always come first. It’s important to wear protective gear such as goggles, gloves, and closed-toe shoes to prevent accidents. Always follow the manufacturer’s instructions and make sure you know how to properly operate the tool. Additionally, keep the work area clean and free of distractions to avoid injuries.

Remember that power tools should only be used by those who are old enough and responsible enough to handle them. Children under 18 should have adult supervision when using power tools. Lastly, be cautious and alert while using power tools, and seek help from an adult or professional if you’re unsure about anything. Safety should never be compromised when using power tools, so always take the necessary precautions to protect yourself and others.