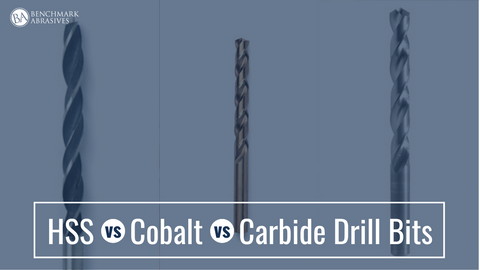

So you’re wondering, which is better: cobalt or carbide drill bits? Well, my friend, you’ve come to the right place! Let’s dive into the fascinating world of drill bits and explore the differences between these two popular options.

When it comes to choosing the right drill bit for your project, understanding the strengths and weaknesses of cobalt and carbide bits is crucial. Cobalt drill bits are known for their impressive durability and heat resistance. On the other hand, carbide drill bits are praised for their exceptional hardness and ability to drill through tough materials with ease.

But which one should you choose? That’s where things get interesting! In the following paragraphs, we’ll break down the pros and cons of both cobalt and carbide drill bits, helping you make an informed decision based on your specific needs. Let’s get started, shall we?

When it comes to drilling, both cobalt and carbide drill bits have their strengths. Cobalt drill bits are known for their durability and heat resistance, making them ideal for drilling through tough materials like stainless steel. On the other hand, carbide drill bits are great for drilling into hard materials like concrete and masonry. Cobalt bits are better for metalwork, while carbide bits excel in construction and masonry projects. Ultimately, the choice depends on the specific task at hand.

Which is Better: Cobalt or Carbide Drill Bits?

When it comes to drilling into tough materials like metal, choosing the right drill bit is crucial. Two popular options are cobalt and carbide drill bits. Both offer distinct advantages and are suited for different applications. In this article, we will compare cobalt and carbide drill bits in terms of strength, durability, versatility, and cost. By the end, you’ll have a clear understanding of which drill bit is better suited for your specific needs.

Strength and Durability

Cobalt drill bits are known for their exceptional strength and durability. They are made from high-speed steel (HSS) with added cobalt for enhanced performance. Cobalt drill bits can withstand high temperatures and are ideal for drilling into hard metals like stainless steel and cast iron. They have excellent chip clearance, allowing for smooth and efficient drilling. With proper care, cobalt drill bits can last longer than regular HSS drill bits.

On the other hand, carbide drill bits are made from a combination of tungsten carbide and cobalt. This unique composition gives them exceptional hardness and wear resistance. Carbide drill bits are perfect for drilling into hard materials such as concrete, masonry, and ceramics. They can also handle high-speed drilling without losing their sharpness. While carbide drill bits are generally more expensive than cobalt drill bits, their superior durability often justifies the investment.

In summary, cobalt drill bits offer excellent strength and durability for drilling into hard metals, while carbide drill bits are the go-to choice for tough materials like concrete and masonry.

Versatility and Application

When it comes to versatility, cobalt drill bits have a broader range of applications. They can be used for drilling into various materials, including wood, plastic, and softer metals. However, their true strength lies in drilling through tough metals like stainless steel, cast iron, and titanium. Cobalt drill bits also perform well in high-speed drilling, making them suitable for professional use.

Carbide drill bits, on the other hand, excel in specific applications. They are particularly effective in drilling into hard materials like concrete, brick, and tile. Carbide drill bits are commonly used in construction projects, where durable and precise drilling is required. It’s important to note that carbide drill bits should not be used on softer materials as they can cause damage or break.

In summary, cobalt drill bits offer versatility across various materials, while carbide drill bits are specialized for drilling into hard materials like concrete and masonry.

Cost Comparison

When it comes to the cost, cobalt drill bits are more affordable than carbide drill bits. This affordability makes them a popular choice for general drilling purposes. Cobalt drill bits are widely available and come in a range of sizes, making them suitable for both DIY enthusiasts and professionals. They offer good value for money and can handle most drilling tasks.

Carbide drill bits, however, are more expensive due to their superior durability and specialized applications. They are often used in professional settings where precision and longevity are crucial. While carbide drill bits may seem like a larger investment upfront, their extended lifespan makes them a cost-effective option in the long run for those who require their specific capabilities.

In summary, cobalt drill bits are more budget-friendly, while carbide drill bits offer long-term value for specialized applications.

Conclusion

In conclusion, choosing between cobalt and carbide drill bits ultimately depends on your specific drilling needs. If you primarily work with hard metals and require durability and strength, cobalt drill bits are a great choice. On the other hand, if you frequently drill into tough materials like concrete or brick, carbide drill bits are the better option. Consider your application, budget, and desired lifespan of the drill bits before making a decision. With the right drill bit in hand, you’ll be equipped to tackle any drilling project with ease.

Key Takeaways: Which is Better – Cobalt or Carbide Drill Bits?

- 1. Both cobalt and carbide drill bits have different properties and strengths.

- 2. Cobalt drill bits are better for drilling into hard metals like stainless steel.

- 3. Carbide drill bits are ideal for drilling into hard materials like concrete and masonry.

- 4. Cobalt drill bits are more durable and can withstand higher temperatures.

- 5. Carbide drill bits are more brittle but have excellent cutting performance.

Frequently Asked Questions

In the world of drilling, cobalt and carbide drill bits are both popular choices. Let’s explore the key differences and advantages of each in this set of frequently asked questions.

1. What are the main differences between cobalt and carbide drill bits?

Cobalt drill bits are made primarily of high-speed steel with added cobalt, which enhances their heat-resistance and hardness. On the other hand, carbide drill bits are made of carbide, a compound composed of carbon and other elements. Carbide drill bits are extremely durable and well-suited for working with hard materials like concrete or stone.

One of the main differences between the two is their purpose. Cobalt drill bits are typically used for drilling into metal, while carbide drill bits excel in drilling into hard materials like masonry. Cobalt drill bits are also more affordable compared to carbide drill bits.

2. Which type of drill bit is better for drilling into metal?

When it comes to drilling into metal, cobalt drill bits are the preferred choice. Thanks to the addition of cobalt, these bits are able to withstand high temperatures generated by the friction between the bit and the metal. Cobalt drill bits also have excellent hardness, allowing them to maintain sharpness even after prolonged use.

Carbide drill bits, while incredibly durable, are not as effective when it comes to drilling through metal. The hardness of carbide drill bits makes them ideal for tough materials like concrete, but they are prone to chipping or breaking when used on metal surfaces.

3. Are carbide drill bits suitable for drilling through concrete?

Absolutely! Carbide drill bits are specifically designed for drilling into hard materials, including concrete. The hardness and durability of carbide make it an excellent choice for this application. The sharpness and ability to withstand high impact forces allow carbide drill bits to effortlessly penetrate through concrete and other similar materials.

When using carbide drill bits for drilling into concrete, it’s important to use a hammer drill or rotary hammer for added power. This helps provide the necessary impact action to make the drilling process smoother and more effective.

4. Can cobalt drill bits be used on wood or other soft materials?

While cobalt drill bits are primarily designed for drilling into metal, they can also be used on softer materials like wood or plastic. However, it’s worth noting that cobalt drill bits may not deliver the same level of precision and efficiency as drill bits specifically designed for softer materials.

For drilling into wood, it’s recommended to use a drill bit specifically designed for wood, as they usually have a different shape and specially-designed flutes that effectively remove wood chips during drilling, resulting in cleaner holes.

5. Which type of drill bit is more cost-effective in the long run?

In terms of cost-effectiveness, cobalt drill bits have the edge. They are generally more affordable compared to carbide drill bits. However, it’s important to consider the specific application and material you will be working with. If your drilling needs primarily involve metal or softer materials, such as wood or plastic, cobalt drill bits will suffice.

On the other hand, if you frequently work with hard materials like concrete or stone, investing in carbide drill bits may be more cost-effective in the long run. Due to their exceptional durability, carbide drill bits tend to last longer and maintain their sharpness, resulting in fewer replacements and ultimately saving you money over time.

Summary

So, to sum it up, when it comes to drill bits, cobalt and carbide both have their pros and cons. Cobalt drill bits are great for drilling through tough materials like stainless steel and cast iron, while carbide drill bits are better for drilling into harder materials like concrete and masonry. Cobalt drill bits are more durable and can be resharpened, while carbide drill bits are known for their precision and sharpness. Ultimately, the choice between the two depends on the specific task at hand and the material you need to drill into.

In conclusion, cobalt and carbide drill bits are both useful tools, but for different purposes. If you’re working with tough metals, cobalt drill bits are your best bet, while if you need to drill into hard surfaces like concrete, carbide drill bits are the way to go. Remember to always consider the material, task, and personal preferences when selecting the right drill bit for your needs.