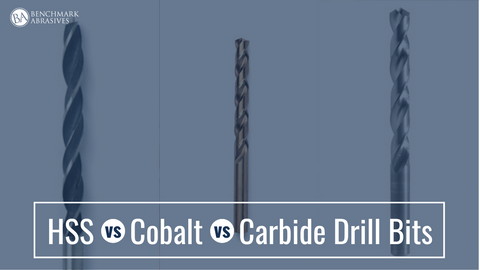

When it comes to drilling tasks, choosing the right tool can make a world of difference. So, which is better: cobalt or carbide drill bits? Let’s dive in and explore the unique characteristics of these two options to help you make an informed decision.

Cobalt drill bits are renowned for their durability and heat resistance. With their high cobalt content, they can tackle tough materials like stainless steel with ease. On the other hand, carbide drill bits are known for their incredible hardness, making them ideal for drilling through hard materials such as concrete and masonry.

Both cobalt and carbide drill bits have their strengths and weaknesses, so it’s important to understand their key features and applications before making a choice. Let’s break it down and discover which option could be the best fit for your drilling needs. Let’s get started!

If you’re deciding between cobalt and carbide drill bits, it’s important to consider their features. Cobalt drill bits are known for their durability and ability to withstand heat, making them ideal for tough materials like stainless steel. On the other hand, carbide drill bits are extremely hard and can handle even harder materials like concrete and masonry. Additionally, carbide bits have a longer lifespan and retain their sharpness for longer. Ultimately, the choice between cobalt and carbide drill bits depends on your specific needs and the materials you will be working with.

Which is Better: Cobalt or Carbide Drill Bits?

When it comes to drilling through tough materials, having the right drill bit can make all the difference. Two popular options that often come up in the debate are cobalt and carbide drill bits. Both have their strengths and are designed for specific applications. In this article, we will delve deeper into the characteristics, benefits, and best uses of cobalt and carbide drill bits to help you determine which is better suited for your needs.

Cobalt Drill Bits: The Strong and Versatile Option

Cobalt drill bits are famous for their strength and versatility. They are made from a unique blend of steel and cobalt alloy, which gives them exceptional hardness and heat resistance. Cobalt drill bits are designed to handle high-temperature applications and are often favored for drilling through tough materials like stainless steel, cast iron, and titanium.

One of the key advantages of cobalt drill bits is their ability to maintain their hardness even at high temperatures. This means they can withstand the heat generated during drilling without losing their sharpness or integrity. Cobalt drill bits also have a higher red hardness, meaning they can handle high-speed drilling without dulling quickly.

In addition to their strength, cobalt drill bits are also known for their versatility. They can be used on a wide range of materials, including metals like aluminum, copper, and brass, as well as hard plastics and wood. This makes them a popular choice for professionals and DIY enthusiasts alike, providing a reliable option for various drilling applications.

Carbide Drill Bits: The Durable and Precise Choice

Carbide drill bits, also known as cemented carbide or solid carbide drill bits, are renowned for their durability and precision. Unlike cobalt drill bits, which are made from an alloy, carbide drill bits are made from a compound of tungsten carbide particles held together by a binding agent, typically cobalt or nickel. This composition gives them exceptional hardness and wear resistance.

One of the primary advantages of carbide drill bits is their ability to maintain their cutting edge even after prolonged use. This makes them ideal for demanding drilling applications that require precision and accuracy, such as in manufacturing and engineering industries. Carbide drill bits are widely used for drilling through hard materials like concrete, brick, and tiles.

Carbide drill bits are especially effective in applications where high drilling speeds are required and where the material density is high. The hardness of the carbide tip allows for efficient drilling, reducing the need for excessive force. Additionally, carbide drill bits tend to produce cleaner, more precise holes, making them a popular choice in industries where accuracy is paramount.

Comparing Cobalt and Carbide Drill Bits

When comparing cobalt and carbide drill bits, it is important to consider the specific needs of the drilling task at hand. Here are some key factors to consider:

Material Compatibility:

– Cobalt drill bits: Ideal for drilling through tough metals like stainless steel, titanium, and cast iron. They can also handle other materials like wood and hard plastics.

– Carbide drill bits: Best suited for drilling through hard materials like concrete, brick, and tiles.

Heat Resistance:

– Cobalt drill bits: Maintain their hardness and sharpness even at high temperatures, making them suitable for high-speed drilling.

– Carbide drill bits: Can withstand high temperatures but may lose some sharpness over time.

Durability:

– Cobalt drill bits: Durable and long-lasting, capable of handling demanding drilling tasks.

– Carbide drill bits: Exceptionally durable, maintaining their cutting edge even after extended use.

Precision:

– Cobalt drill bits: Versatile and suitable for various applications but may not provide the same level of precision as carbide drill bits.

– Carbide drill bits: Offer superior precision and accuracy, making them ideal for tasks that require clean, precise holes.

Price:

– Cobalt drill bits: Generally less expensive than carbide drill bits.

– Carbide drill bits: Typically more expensive due to their superior hardness and durability.

Overall, both cobalt and carbide drill bits have their strengths and are designed for specific applications. Cobalt drill bits are versatile and great for drilling through tough metals, while carbide drill bits excel in precision and durability. Consider the materials you will be drilling and the level of precision required to choose the best option for your needs.

Choosing the Right Drill Bit for Your Needs

Now that we have explored the characteristics and best uses of cobalt and carbide drill bits, you can make an informed decision based on your specific drilling needs. Remember to consider the material compatibility, heat resistance, durability, precision, and price when choosing between cobalt and carbide drill bits. By selecting the appropriate drill bit for the task at hand, you can ensure smoother, more efficient drilling and achieve the desired results.

Key Takeaways: Which is Better, Cobalt or Carbide Drill Bits?

- Cobalt drill bits are better for general purpose drilling, while carbide drill bits are better for harder materials like concrete and masonry.

- Cobalt drill bits have better heat resistance and can withstand higher temperatures compared to carbide drill bits.

- Carbide drill bits are more brittle but are more effective at drilling through tough materials due to their higher hardness.

- Cobalt drill bits are typically more affordable and easier to find than carbide drill bits, making them a popular choice for most drilling needs.

- Choosing the right drill bit depends on the specific drilling task and the material being drilled, so it’s important to consider the hardness and heat resistance required for optimal performance.

Frequently Asked Questions

Looking to find out which drill bit is better between cobalt and carbide? We’ve got you covered! Check out these commonly asked questions to help you make an informed decision.

1. What are the main differences between cobalt and carbide drill bits?

Cobalt drill bits are made from high-speed steel with added cobalt, which increases their heat resistance and makes them ideal for drilling into hard materials such as stainless steel. On the other hand, carbide drill bits are made from tungsten carbide, an incredibly hard and durable material. They are excellent for drilling through hard materials like concrete, masonry, and tile.

The main difference lies in the materials they are best suited for. Cobalt drill bits are great for metalworking applications, while carbide drill bits excel in tasks that involve hard materials like stone or ceramics.

2. Which drill bit is better for drilling through metal?

If you are primarily drilling through metal, cobalt drill bits are the way to go. The addition of cobalt to the high-speed steel composition increases the drill bits’ strength and heat resistance, allowing them to withstand the high temperatures generated during metal drilling. Cobalt drill bits offer excellent performance and durability when drilling through various metals, including stainless steel and cast iron.

Carbide drill bits, although tough, are not specifically designed for metal drilling. They are better suited for drilling into hard materials like concrete, masonry, or ceramics.

3. Are carbide drill bits more expensive than cobalt drill bits?

Yes, carbide drill bits tend to be more expensive than cobalt drill bits. The manufacturing process of carbide drill bits, which involves sintering tungsten carbide particles together, adds to their cost. Additionally, the hardness and durability of carbide make it a premium material for drill bits, further contributing to the higher price point. However, it’s important to consider the specific application needs when determining the value of the drill bits.

If you frequently work with hard materials like concrete or masonry, the durability and longevity of carbide drill bits may outweigh the higher initial cost.

4. Can cobalt and carbide drill bits be used interchangeably?

Cobalt and carbide drill bits are designed for different materials and applications, so they are not interchangeable. Cobalt drill bits are best used for metal drilling, while carbide drill bits are specifically designed for tough materials like concrete, masonry, and tile. Trying to use a cobalt drill bit on a hard material or a carbide drill bit on metal may result in poor drilling performance and quickly dull or damage the bit.

It’s essential to select the right drill bit for the specific material you are working with to achieve optimal results.

5. How do I choose between cobalt and carbide drill bits?

Choosing between cobalt and carbide drill bits depends on the materials you commonly work with. If you primarily drill into various types of metal, cobalt drill bits are the better choice due to their heat resistance and durability. On the other hand, if your projects involve drilling into hard materials like concrete, masonry, or tile, carbide drill bits are the more suitable option.

Consider the specific needs of your projects and the longevity of the drill bits when making your decision. It’s important to invest in high-quality drill bits that align with your intended applications to ensure efficient and precise drilling.

Which COBALT Drill Bit Is Best? Find Out! (Milwaukee, Drill America, Bosch or Dewalt)

Summary

So, what’s the final verdict on cobalt vs. carbide drill bits? Well, both have their advantages and disadvantages. Cobalt drill bits are great for drilling through tough materials like stainless steel, but they may not last as long. On the other hand, carbide drill bits are more durable and can handle high heat, but they may not be as effective in drilling hard materials. Ultimately, it depends on the specific task at hand and your personal preferences. Always remember to choose the right drill bit for the job to get the best results!