When it comes to drill bits, an important question arises: which is better, M35 or M42? It’s a common dilemma for those seeking the best tool for their drilling needs. So, let’s dive in and discover the differences between these two drill bit types.

M35 and M42 are both high-speed steel (HSS) drill bits, but what sets them apart? Well, the answer lies in their composition. M35 drill bits contain 5% cobalt, while M42 drill bits take it up a notch with 8% cobalt. This higher cobalt content gives M42 bits an edge in terms of durability and heat resistance.

But hey, don’t worry if all these technical terms seem overwhelming at first. In this article, we’re going to break it down for you, making it easy to understand which drill bit is the better choice for your projects. So, let’s get started and uncover the advantages and disadvantages of M35 and M42 drill bits!

When comparing M35 and M42 drill bits, there are several features to consider.

| M35 Drill Bits | M42 Drill Bits |

| 1. Suitable for general-purpose drilling | 1. Ideal for drilling hard materials like stainless steel |

| 2. Made from high-speed steel with 5% cobalt content | 2. Contains 8% cobalt for enhanced performance and durability |

| 3. Offers good heat resistance and hardness | 3. Provides excellent heat resistance, making it suitable for high-speed applications |

| 4. Cost-effective option for standard drilling tasks | 4. Higher cost but delivers superior performance in tough materials |

| 5. Ideal for drilling through softer materials like wood and plastic | 5. Best choice for drilling through hard metals and alloys |

Ultimately, the choice between M35 and M42 drill bits depends on your specific drilling needs. Consider the materials you’ll be working with and the level of durability and performance required for your projects.

Which is Better: M35 or M42 Drill Bits?

When it comes to choosing the right drill bits for your projects, the options can be overwhelming. Two popular choices are M35 and M42 drill bits. But which one is better? In this article, we will explore the differences between M35 and M42 drill bits, their strengths and weaknesses, and ultimately help you make an informed decision based on your specific needs.

The Composition of M35 Drill Bits

M35 drill bits are made from high-speed steel, a type of tool steel known for its durability and resistance to heat and wear. The “M” in M35 stands for molybdenum, a key alloying element that enhances the strength and heat resistance of the steel. M35 drill bits typically have a cobalt content of 5%, which further increases their hardness and heat resistance.

One of the key advantages of M35 drill bits is their ability to withstand high temperatures without losing their hardness. This makes them ideal for drilling through tough materials like stainless steel, cast iron, and hardened steel. The high cobalt content also improves the chip formation and evacuation, reducing the risk of clogging and overheating.

However, M35 drill bits can be more brittle compared to other options. This means they may be more prone to breaking or chipping if subjected to excessive force or used improperly. It’s important to use the right drilling techniques and take proper precautions to avoid damaging the drill bits.

The Composition of M42 Drill Bits

M42 drill bits are also made from high-speed steel but with a higher cobalt content of 8%. The additional cobalt adds even more hardness and heat resistance to the steel, making M42 drill bits suitable for drilling through even harder materials like super alloys and hardened stainless steel.

The higher cobalt content also means that M42 drill bits can maintain their hardness at even higher temperatures compared to M35 drill bits. This makes them more suitable for heavy-duty drilling applications that generate a lot of heat, such as industrial drilling and metalworking.

One potential drawback of M42 drill bits is their increased price compared to M35 drill bits. The higher cobalt content and improved performance come at a higher cost. However, if you frequently drill through tough materials or require the highest performance, the investment may be worth it in the long run.

Choosing the Right Drill Bits for Your Needs

Now that we’ve explored the differences between M35 and M42 drill bits, how do you choose the right one for your needs? Here are a few factors to consider:

- Material: Consider the type of material you will be drilling through. If you mainly work with stainless steel, cast iron, or hardened steel, both M35 and M42 drill bits can be suitable. However, if you work with super alloys or require the highest performance, M42 drill bits may be the better choice.

- Heat Resistance: If your drilling projects generate a lot of heat, such as high-speed or continuous drilling, M42 drill bits are more suitable due to their higher heat resistance.

- Cost: Consider your budget and the frequency of use. If you rarely drill through tough materials, M35 drill bits can provide adequate performance at a more affordable price point.

Additional Considerations When Choosing Drill Bits

Availability

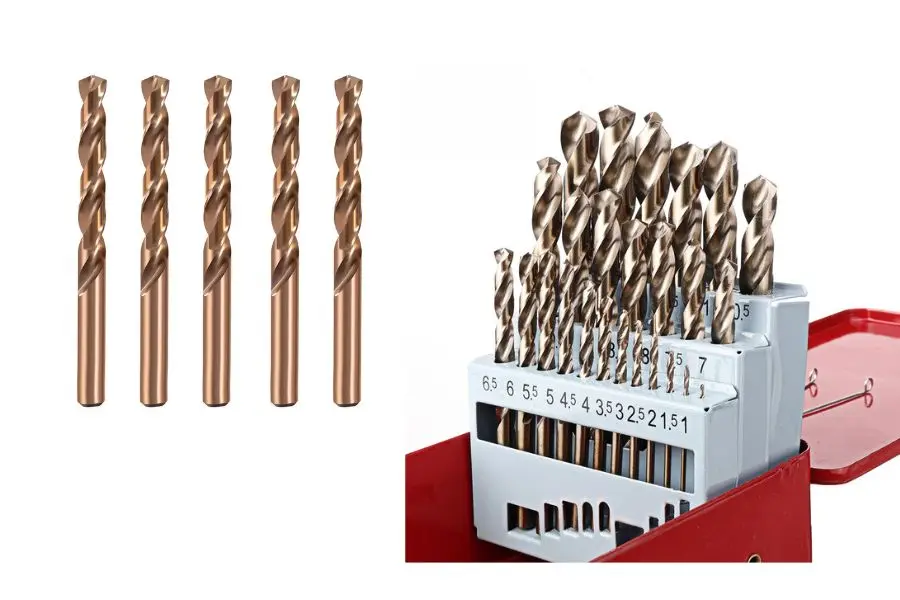

Availability is another aspect to consider when choosing between M35 and M42 drill bits. While both options are widely available, the specific sizes and variations may vary. It’s important to check the availability of the drill bits you need for your projects, especially if you require less common sizes or specialized variations.

Application-Specific Drill Bits

In addition to M35 and M42 drill bits, there are also application-specific drill bits available for various purposes. For example, cobalt-coated drill bits are designed for drilling through stainless steel, while titanium-coated drill bits offer improved wear resistance. Consider these options if your projects have specific requirements or if you want to optimize your drilling performance for certain materials or applications.

The Importance of Proper Technique

No matter which type of drill bits you choose, it’s crucial to use the proper drilling techniques and take good care of your tools. This includes using the correct drilling speed, applying appropriate pressure, and using cutting fluid or lubricants when necessary. Proper technique can prolong the life of your drill bits and ensure optimal drilling performance.

Regular Maintenance and Sharpening

Over time, drill bits can become dull or damaged. It’s important to regularly inspect your drill bits for signs of wear and to sharpen or replace them as needed. Proper maintenance can help extend the lifespan of your drill bits and ensure consistent drilling performance.

In conclusion, both M35 and M42 drill bits have their strengths and weaknesses. M35 drill bits are more affordable and suitable for general-purpose drilling, while M42 drill bits offer higher heat resistance and better performance in demanding applications. Consider your specific needs, budget, and the materials you will be drilling to choose the right drill bits for your projects. Additionally, keep in mind the importance of proper technique, regular maintenance, and the availability of the drill bits you require. By making an informed decision and taking good care of your drill bits, you can achieve optimal drilling results and productivity.

Key Takeaways: Which is Better M35 or M42 Drill Bits?

- M35 drill bits are made from HSS (high-speed steel) with 5% cobalt content, while M42 drill bits have a higher cobalt content of 8%.

- M42 drill bits offer increased hardness and wear resistance compared to M35 drill bits.

- M35 drill bits are more affordable and suitable for general drilling applications.

- M42 drill bits are ideal for drilling through tough materials like stainless steel and hard alloys.

- For everyday household drilling needs, M35 drill bits provide a good balance of performance and cost-effectiveness.

Frequently Asked Questions

Are you unsure about which type of drill bit to choose between M35 and M42? Don’t worry, we’ve got you covered! Below are some frequently asked questions that will help you make an informed decision.

What is the difference between M35 and M42 drill bits?

M35 and M42 are both high-speed steel drill bits known for their exceptional durability and heat resistance. However, they do have some differences. The main distinction lies in their composition. M35 drill bits contain 5% cobalt, making them ideal for general purpose drilling, while M42 drill bits contain 8% cobalt, making them more suitable for drilling hard materials like stainless steel and cast iron. Therefore, if you primarily work with tough materials, M42 drill bits would be the better choice.

Another difference is the cutting speed. Due to the increased cobalt content, M42 drill bits can withstand higher cutting speeds, allowing for faster and more efficient drilling. This makes them a great option for those who require quicker drilling times. On the other hand, M35 drill bits are better suited for applications that don’t require high cutting speeds but still need reliable performance.

Which drill bit is better for general purpose use, M35 or M42?

For general purpose drilling tasks, the M35 drill bit is a reliable choice. Its 5% cobalt composition provides good heat resistance and durability, making it suitable for a wide range of materials, including wood, plastic, and mild steel. M35 drill bits are also more cost-effective compared to their M42 counterparts, making them a preferred option for those looking for a budget-friendly solution without compromising quality.

However, if you anticipate drilling particularly hard materials or need higher cutting speeds, it might be worth considering the M42 drill bit. With its 8% cobalt content, it can handle tough materials such as stainless steel and cast iron more effectively. So, while M35 is great for general tasks, M42 may offer superior performance when working with challenging materials.

Which drill bit is better for drilling hard materials, M35 or M42?

If you often find yourself working with hard materials like stainless steel, cast iron, or hardened steels, then the M42 drill bit is the better choice. Its higher cobalt content (8% compared to 5% in M35) provides increased heat resistance and durability, allowing for excellent performance in tough conditions.

M42 drill bits have the capability to maintain their hardness at high temperatures, which is crucial when drilling hard materials that generate a significant amount of heat. With their enhanced cutting speed capabilities, M42 drill bits ensure efficient drilling through hard materials, saving you both time and effort. So, if you frequently work with challenging materials, investing in M42 drill bits will yield better results.

What factors should I consider when choosing between M35 and M42 drill bits?

When choosing between M35 and M42 drill bits, several factors should be taken into account. The type of materials you work with and the hardness of those materials are crucial considerations. If you primarily drill soft materials or need a versatile option for general tasks, M35 drill bits are a cost-effective choice. On the other hand, if you often drill hard materials and require higher cutting speeds, M42 drill bits will deliver superior performance.

Additionally, your budget and the frequency of usage should also be considered. M35 drill bits are more affordable, making them a great option for occasional use or those on a tighter budget. However, if you frequently work with tough materials and need longer-lasting drill bits, investing in M42 might be a better long-term solution. Ultimately, it’s important to assess your specific needs and choose the drill bit that aligns best with your requirements.

Can I use M35 and M42 drill bits interchangeably?

While M35 and M42 drill bits can both be used for various drilling applications, they do have their specific characteristics and strengths. Ideally, it is recommended to use M35 drill bits for general purpose drilling tasks and M42 drill bits for harder materials or situations that require higher cutting speeds.

Interchanging the drill bits might lead to suboptimal performance, reduced lifespan, or difficulties in drilling certain materials. To ensure you achieve the best results and maximize the lifespan of your drill bits, it’s recommended to use each type for its intended purpose. By using M35 and M42 drill bits correctly, you’ll experience improved drilling efficiency and longevity.

Summary

So, which is better, the M35 or M42 drill bits? Well, it depends on your needs.

M35 drill bits are great for drilling through softer materials like wood or plastic, while M42 drill bits are better for tougher materials like metal or stainless steel.

M35 bits are cheaper and more easily available, but if you’re working on heavy-duty projects, the extra durability of M42 bits might be worth the investment.

In the end, both types of drill bits have their advantages and it’s important to choose the one that suits your specific task. Remember to consider the material, the project, and your budget when making your decision.

Now you’re equipped with the knowledge to make an informed choice between M35 and M42 drill bits!