Curious about what you can’t do on a conventional lathe? Well, you’ve come to the right place! Today, we’re going to explore the operations that just don’t make the cut when it comes to this type of lathe. So, sit back, buckle up, and let’s dive into the world of machining!

When it comes to the world of lathes, there are plenty of operations that can be performed. From threading to facing, these machines are versatile tools. But there’s one operation that a conventional lathe simply can’t handle. Want to take a guess? Don’t worry, we’ll spill all the details in just a moment. Ready for the big reveal?

Drumroll, please… The operation that cannot be done on a conventional lathe is… milling! Yes, you heard it right. Milling, which involves removing material using rotating cutters, is not a task that these lathes are designed for. So, if you’re looking to mill your workpiece, you’ll need to explore other machining options. But don’t worry, there are plenty of tools out there to help you with your milling needs.

Now that you know the answer to the burning question, let’s delve deeper into why milling is a no-go with conventional lathes. Stay tuned as we explore the limitations and alternatives to this crucial machining operation. Get ready for an enlightening journey through the world of lathe operations!

Exciting stuff, right? Now that we’ve set the stage, let’s dive into the details and discover why conventional lathes just can’t handle the milling operation. So, grab your curiosity and let’s unravel the mysteries together!

Conventional lathes are versatile machines, but there is one operation they cannot perform: thread milling. Thread milling involves creating threads on a workpiece using a milling cutter. While conventional lathes excel at turning operations like external and internal threading, thread milling requires the use of a dedicated thread mill or a CNC machine. Therefore, if you need to perform thread milling operations, a conventional lathe will not be suitable.

Which Operations Cannot Be Done on a Conventional Lathe?

When it comes to machining operations, the conventional lathe is a versatile tool. However, there are certain operations that cannot be performed on this type of lathe. In this article, we will explore the limitations of the conventional lathe and discuss the operations that cannot be accomplished using this machine. Whether you are a machining enthusiast or a professional, understanding these limitations will help you make informed decisions about your machining processes.

The Limitations of a Conventional Lathe

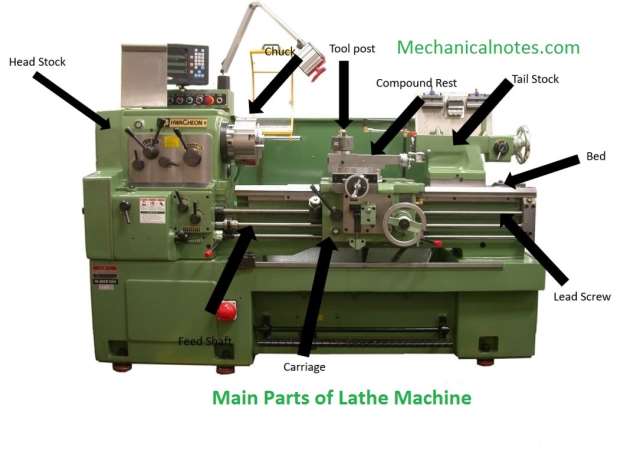

A conventional lathe is a machine tool used for shaping and machining various materials, such as metal, wood, and plastic. It consists of a rotating workpiece and a cutting tool that is moved along the workpiece to remove material and create the desired shape. While the conventional lathe is capable of performing a wide range of operations, it has its limitations.

1. Complex Contours

One of the main limitations of a conventional lathe is its inability to create complex contours. The turning process on a lathe involves rotating the workpiece and using a single-point cutting tool to remove material. This restricts the lathe to performing operations that produce cylindrical or tapered shapes, such as turning, facing, and taper turning. Creating intricate shapes with multiple curves and angles requires the use of specialized machines like milling machines or CNC machining centers.

Moreover, the conventional lathe is limited in its ability to produce shapes with high precision and tight tolerances. The accuracy of the cuts is dependent on the manual skills of the operator and the stability of the machine itself. For more precise and complex operations, computer-controlled machines like CNC lathes are preferred.

2. Thread Cutting

While the conventional lathe is capable of producing threads, it has limitations when it comes to cutting certain types of threads. It can easily cut straight threads using a threading tool, but when it comes to cutting tapered threads or threads with special profiles, the lathe falls short. Creating threads with non-standard pitches or complex thread profiles requires the use of specialized thread cutting tools or CNC lathes.

Additionally, the conventional lathe may not be suitable for cutting threads in harder materials or materials with high tensile strength. The cutting tools used on a conventional lathe may wear out quickly or may not be able to effectively cut through these materials. In such cases, alternative methods like thread milling or thread grinding are often employed.

Alternatives to Conventional Lathe Operations

While the conventional lathe has its limitations, there are alternative machines and methods that can be used to perform operations that cannot be done on a lathe. These alternatives offer increased versatility, precision, and efficiency, allowing for the machining of complex shapes and the cutting of specialized threads.

1. CNC Machining Centers

CNC machining centers, also known as milling machines, are highly versatile tools that can machine complex contours and produce intricate shapes with high precision. These computer-controlled machines use a variety of cutting tools, such as end mills, drills, and reamers, to remove material from the workpiece. CNC machining centers can perform a wide range of operations, including milling, drilling, tapping, and contouring, making them suitable for applications that require complex shapes and tight tolerances.

Unlike a conventional lathe, which requires manual input and control from the operator, CNC machining centers can be programmed to perform a series of operations automatically. This eliminates the need for manual adjustments and minimizes the risk of errors, resulting in improved efficiency and productivity.

2. Thread Milling and Grinding

For cutting non-standard threads or threads with complex profiles, thread milling and grinding are commonly used methods. Thread milling uses a milling cutter to create threads by moving it along the workpiece in a helical motion. This method allows for the creation of threads with various pitches and profiles. Thread grinding, on the other hand, involves using a grinding wheel to shape and finish the threads to the desired specifications. Both methods offer greater flexibility and precision compared to conventional lathe thread cutting.

In conclusion, while the conventional lathe is a versatile machine tool, it has its limitations when it comes to performing complex operations and creating intricate contours. Understanding these limitations and exploring alternative methods can help you make informed decisions about your machining processes and ensure that you achieve the desired results. Whether you are working with metals, wood, or plastics, it is important to choose the right machine and method for the job to achieve the best possible outcome.

Key Takeaways: What Operations Cannot Be Done on a Conventional Lathe?

- Turning a square shape

- Drilling a hole perpendicular to the axis

- Making internal threads

- Creating complex shapes with multiple angles

- Cutting precise threads with high thread counts

Frequently Asked Questions

In the world of conventional lathes, there are some limitations to what can be achieved. Let’s explore some common questions related to the operations that cannot be done on a conventional lathe.

1. Can a conventional lathe perform complex milling operations?

No, a conventional lathe is primarily designed for turning operations, such as cylindrical shapes or threads. It lacks the necessary features and control to carry out complex milling operations. Unlike a milling machine, a lathe does not have a milling head or a table that can move in multiple axes. While you can perform simple milling operations on a lathe, intricate or precise milling tasks are not suitable for this machine.

For milling operations, it’s recommended to use a milling machine or a CNC lathe that is specifically designed to handle the complexities involved in milling.

2. Is it possible to perform drilling operations on a conventional lathe?

Yes, it is possible to perform drilling operations on a conventional lathe, but with certain limitations. Basic drilling tasks, such as making holes in a workpiece, can be accomplished using a lathe. However, a lathe lacks the precision and speed control that a dedicated drilling machine offers. Additionally, a lathe may not be suitable for drilling deep holes due to its limited spindle travel.

For complex or precise drilling operations, it is advisable to use a drilling machine or a drill press that provides better control, accuracy, and flexibility for achieving desired results.

3. Can a conventional lathe handle grinding operations?

No, a conventional lathe is not designed for grinding operations. Grinding requires specialized machinery with grinding wheels, grinding heads, and control systems that can precisely remove material to achieve the desired surface finish or shape. While a lathe can perform some surface smoothing, it cannot provide the precision and grinding capabilities required for intricate grinding tasks.

If grinding operations are needed, it is recommended to use a grinding machine or a surface grinder that is specifically designed for this purpose.

4. Is it possible to perform sawing or cutting operations on a conventional lathe?

A conventional lathe is not suitable for sawing or cutting operations. Its design does not incorporate a cutting blade or a sawing mechanism. Lathes are primarily used for shaping or turning operations involving rotational movement of the workpiece. For cutting or sawing tasks, it is better to use a bandsaw, circular saw, or other cutting machines that are specifically designed for these operations.

5. Can a conventional lathe be used for 3D printing or additive manufacturing?

No, a conventional lathe is not capable of 3D printing or additive manufacturing. These processes involve the addition of material layer by layer to create a 3D object, which is fundamentally different from the subtractive nature of lathe operations. 3D printing requires specialized equipment, such as a 3D printer, which is designed for precise control of material deposition in various directions to build complex geometries.

If you are interested in 3D printing or additive manufacturing, it is recommended to explore dedicated 3D printers or additive manufacturing machines that are specifically designed for these operations.

Summary

So, to sum it all up, there is one operation that cannot be done on a conventional lathe. That operation is drilling a hole perpendicular to the axis of the lathe. The reason for this is that the lathe’s spindle and chuck are aligned with the axis of rotation, making it difficult to drill a hole at a perfect 90-degree angle. To perform this operation, a drill press or dedicated drilling machine is required.