Are you curious about which lathe is best for woodturning? Well, you’ve come to the right place! Whether you’re a beginner or a seasoned woodturner, finding the right lathe is crucial for achieving excellent results. In this guide, we’ll explore the different types of lathes available and help you decide which one suits your needs and budget.

Woodturning is a captivating craft that allows you to shape and sculpt wood into beautiful and functional objects. But before you can start creating stunning pieces, you need to choose the right lathe. With so many options on the market, it can be overwhelming to know where to begin. Don’t worry, we’ll break it down for you and make the decision-making process a breeze!

From mini lathes perfect for small projects to robust and versatile lathes for professional woodturners, we’ll explore the features, benefits, and considerations for each type. So whether you’re looking to turn pens, bowls, or even larger furniture pieces, we’ve got you covered. Let’s dive in and find the perfect lathe to unlock your creative woodturning journey!

Looking to find the perfect lathe for your woodturning projects? When choosing a lathe for woodturning, consider these key features: motor power, swing over bed, spindle size, variable speed control, and bed length. A powerful motor allows you to tackle larger projects, while swing over bed determines the maximum diameter you can turn. Spindle size and variable speed control offer versatility, and bed length determines the length of the pieces you can work on. Take these factors into account to select the best lathe for your woodturning needs.

Which Lathe is Best for Woodturning? The Ultimate Guide

Woodturning is a popular craft that requires the right tools and equipment for optimal results. One of the most important tools for woodturners is a lathe, which allows you to shape and form wood into various objects. However, with so many different types of lathes available on the market, it can be overwhelming to choose the best one for your needs. In this comprehensive guide, we will explore the different factors to consider when selecting a lathe for woodturning, the various types of lathes available, and the benefits and features of each. Whether you’re a beginner or an experienced woodturner, this guide will help you make an informed decision and find the perfect lathe for your projects.

Factors to Consider When Choosing a Lathe for Woodturning

Before diving into the specific types of lathes available, it’s important to understand the key factors to consider when choosing a lathe for woodturning. These factors will help narrow down your options and ensure that the lathe you choose meets your specific needs and preferences.

Budget

One of the first considerations for many woodturners is their budget. Lathes can vary greatly in price, with some entry-level models being more affordable, while professional-grade lathes can come with a higher price tag. It’s important to determine how much you’re willing to invest in a lathe and find one that offers a good balance between quality and affordability.

Workspace Size

Another important factor to consider is the size of your workspace. Lathes can take up a substantial amount of space, so it’s crucial to measure the dimensions of your workshop or designated area before making a decision. Additionally, consider the size of the projects you’ll be working on and make sure the lathe can accommodate them comfortably.

Power and Speed Control

The power and speed control of a lathe are essential for woodturning. A higher-powered motor will be able to handle larger and denser pieces of wood, while variable speed control allows you to adjust the speed to suit different types of wood and cuts. Look for a lathe with a powerful motor and a wide range of speed control options for maximum versatility.

Bed Length and Swing Capacity

The bed length and swing capacity of a lathe determine the size of the objects you’ll be able to turn. The bed length refers to the distance between the headstock and the tailstock, and it determines the maximum length of the piece you can turn. The swing capacity refers to the maximum diameter of the piece you can turn. Consider the size of the projects you’ll be working on and choose a lathe with an appropriate bed length and swing capacity.

Stability and Construction

Stability is crucial when working with a lathe, as any vibrations can affect the quality of your cuts and the overall precision of your work. Look for a lathe with a sturdy construction and a solid base. Cast iron lathes are known for their stability, but they can be heavier and more difficult to move.

Accessories and Attachments

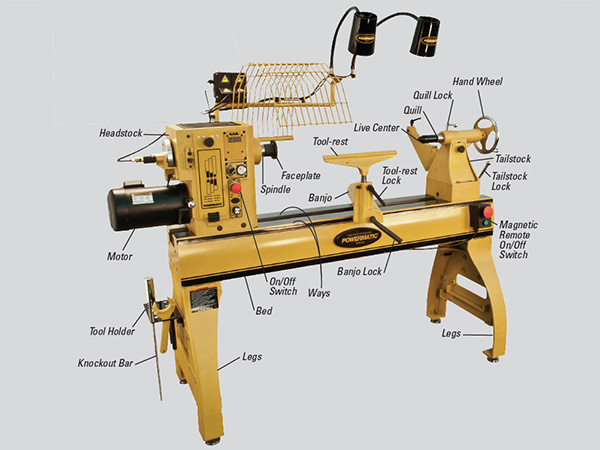

Consider the accessories and attachments that are available for the lathe you’re considering. Some lathes come with additional features such as tool rests, faceplates, and tailstocks, while others may require separate purchases. Think about the type of projects you’ll be working on and ensure that the lathe has the necessary accessories to support your woodworking needs.

Manufacturer Reputation and Warranty

Lastly, consider the reputation of the manufacturer and the warranty that is offered with the lathe. Look for reputable brands that have a history of producing high-quality woodworking tools. A good warranty can provide peace of mind and protect your investment in case of any defects or issues with the lathe.

Types of Lathes for Woodturning

Now that we’ve covered the key factors to consider when choosing a lathe for woodturning, let’s explore the different types of lathes available on the market. Each type has its own advantages and features, so understanding the differences will help you make a more informed decision.

Benchtop Lathes

Benchtop lathes are compact and portable, making them a popular choice for woodturners with limited workspace or those who need to transport their lathe to different locations. These lathes are typically lighter and smaller in size compared to their larger counterparts, but they still offer sufficient power and functionality for most woodturning projects.

Benchtop lathes are suitable for small to medium-sized projects and are often chosen by beginners or hobbyists who want a versatile and affordable option. They are easy to set up and operate, making them a great choice for those who are new to woodturning. However, their smaller size may limit the capacity for larger projects or working with heavier materials.

Mini Lathes

Mini lathes are even smaller than benchtop lathes and are designed for turning small-scale projects such as pens, small bowls, and spindle work. They are extremely affordable and often portable, making them a popular choice for beginners or woodturners who want to focus on smaller crafts.

Mini lathes are limited in terms of capacity and power, so they may not be suitable for larger or more advanced projects. However, they offer a great way to learn the basics of woodturning and can be a stepping stone to larger lathes as your skills and projects progress.

Full-Size Lathes

For experienced woodturners or those who have ample space and resources, full-size lathes are the go-to choice. These lathes are larger and more powerful, allowing you to tackle bigger projects and work with a wider variety of woods. Full-size lathes often come with additional features and accessories, providing enhanced flexibility and precision.

Full-size lathes are ideal for professionals or serious hobbyists who are dedicated to woodturning. They offer superior stability, power, and capacity, allowing for more ambitious and intricate projects. However, their larger size and higher price point may not be suitable for everyone, especially beginners or those with limited space.

Electronic Lathes

Electronic lathes are a more advanced option that incorporates digital technology into the woodturning process. These lathes often come with sophisticated control panels and automation features, allowing you to accurately control the speed, position, and other parameters of the turning process.

Electronic lathes are favored by experienced woodturners or those who work on complex projects that require precise control and repeatability. They offer advanced features such as digital readouts, memory functions, and programmable settings, making them a versatile and efficient choice. However, electronic lathes can be more expensive and may require a steeper learning curve compared to traditional lathes.

CNC Lathes

CNC (Computer Numerical Control) lathes take automation to the next level by using computer programs to control the entire woodturning process. These lathes are highly accurate and can produce intricate and precise cuts consistently. CNC lathes are often equipped with advanced features such as automatic tool changers and multi-axis control, allowing for complex and sophisticated designs.

CNC lathes are generally used in professional woodworking settings or by advanced woodturners who require a high level of precision and automation. They are more expensive than traditional lathes and require specialized knowledge to operate and program. However, if you’re looking to take your woodturning to the next level and produce intricate, custom designs, a CNC lathe may be worth considering.

Convertible Lathes

Convertible lathes offer the best of both worlds by combining the features of a benchtop lathe and a full-size lathe. These lathes can be adjusted and transformed to suit different project sizes and requirements. Convertible lathes often come with additional extensions or removable features, allowing you to switch between a smaller, more portable configuration and a larger, more powerful configuration.

Convertible lathes offer versatility and flexibility, making them an excellent choice for woodturners who want the option to work on both small and large projects. They are suitable for beginners and experienced woodturners alike, as they can adapt to different skill levels and project complexities. However, convertible lathes may come with a higher price tag compared to dedicated benchtop or full-size lathes.

Budget-Friendly Lathes for Woodturning

When it comes to finding a budget-friendly lathe for woodturning, there are some affordable options available that still offer decent quality and functionality. While these lathes may not have all the advanced features or capabilities of higher-end models, they can still provide a great starting point for beginners or those on a tight budget.

Brand X Lathe

Brand X Lathe is a popular choice for budget-conscious woodturners. It offers a good balance between price and quality, providing decent power and performance for the price. The lathe comes with variable speed control and a sturdy construction, making it suitable for small to medium-sized projects.

Brand Y Lathe

Brand Y Lathe is another affordable option that offers value for money. It comes with a powerful motor and a solid base, providing stability and precision during woodturning. The lathe has a compact design, making it ideal for smaller workshops or for those who need a portable option.

Brand Z Lathe

Brand Z Lathe is a budget-friendly lathe that doesn’t compromise on quality. It features a variable speed control and a durable construction, ensuring smooth and accurate cuts. The lathe has a decent swing capacity and bed length, making it suitable for a range of woodturning projects.

In conclusion, the choice of which lathe is best for woodturning ultimately depends on your specific needs, budget, and level of expertise. Consider the factors mentioned earlier, such as budget, workspace size, power and speed control, bed length and swing capacity, stability and construction, accessories and attachments, and manufacturer reputation and warranty. Additionally, familiarize yourself with the different types of lathes available, including benchtop lathes, mini lathes, full-size lathes, electronic lathes, CNC lathes, and convertible lathes, to determine which one aligns with your woodworking goals. Remember that the perfect lathe is the one that meets your requirements and helps you unleash your creativity in the world of woodturning. Happy turning!

Key Takeaways: Which Lathe for Woodturning?

- Consider the size of your projects and choose a lathe with an appropriate swing capacity.

- Look for a lathe with variable speed control to adjust the turning speed for different wood types and turning techniques.

- Choose a lathe with a sturdy construction and a powerful motor for stability and efficient woodturning.

- Consider the available accessories and attachments that can enhance your woodturning experience.

- Read reviews and seek recommendations from experienced woodturners to make an informed decision.

Frequently Asked Questions

Are you new to woodturning and wondering which lathe to choose? We’ve got you covered! Check out these common questions on selecting the right lathe for woodturning and find the perfect match for your woodworking projects.

1. What factors should I consider when choosing a lathe for woodturning?

When selecting a lathe, consider factors such as the size of your projects, available space, budget, and your skill level. If you plan on turning larger items, a lathe with a greater swing capacity would be ideal. Additionally, think about the available space in your workshop and choose a lathe that fits comfortably. Set a budget that aligns with your needs and skill level, and look for a lathe with features that enhance your turning experience, such as variable speed control and a sturdy construction.

Ultimately, the best lathe for you will depend on your specific requirements, so take the time to assess your needs before making a decision.

2. Should I choose a benchtop or a floor-standing lathe?

The choice between a benchtop and a floor-standing lathe depends on your workspace and the size of your projects. Benchtop lathes are compact and portable, making them suitable for those with limited space or who need to move their lathe frequently. These lathes are great for small to medium-sized projects.

On the other hand, floor-standing lathes offer a stable and sturdy base, allowing you to work on larger projects with ease. They usually have more powerful motors and greater swing capacities, accommodating a wide range of turning tasks. If you have sufficient space and plan on turning larger pieces, a floor-standing lathe might be the better option for you.

3. What type of motor should I look for in a woodturning lathe?

When it comes to motors, there are two main types: belt-driven and direct-drive. A belt-driven lathe operates using a system of pulleys and belts, providing flexibility in speed ranges. This type of lathe allows you to change speeds by adjusting the belt position on different pulleys, giving you more control over the turning process.

On the other hand, a direct-drive lathe features a motor that directly powers the spindle. These lathes usually offer electronic speed control, allowing you to adjust the speed with precision. Direct-drive lathes are generally smoother and quieter but may have limited speed ranges. Consider your turning needs and preferences to determine which motor type is best for you.

4. Is a variable speed control important in a woodturning lathe?

Yes, variable speed control is an important feature in a woodturning lathe. Different turning tasks and materials require different speeds. With variable speed control, you can adjust the lathe’s speed to match the requirements of your project. This flexibility allows for better results and reduces the risk of accidents. It is advisable to choose a lathe with a wide range of speed options to cater to various turning applications.

Some lathes offer step-pulley mechanisms instead of variable speed control. While these can still be effective, they require manual adjustments by changing belts on different pulleys. Variable speed control, however, allows for quick and convenient speed changes during the turning process.

5. What additional features should I look for in a woodturning lathe?

In addition to swing capacity, motor type, and variable speed control, there are other features that can enhance your woodturning experience. Look for lathes with sturdy constructions and vibration-dampening features to ensure stability during operation. A tool rest with easy adjustability and a smooth banjo or tailstock movement can greatly improve your turning precision and convenience.

You may also want to consider a lathe with a digital readout for speed or a built-in indexing system for creating precise fluting or decoration. Additionally, easy-to-use controls and accessibility to replacement parts and accessories can add value to your lathe. Assess your turning needs and identify which additional features would benefit your woodworking projects the most.

Summary

Choosing the right lathe for woodturning is important. Think about what you want to make, check the features, and consider your budget. A smaller lathe can be good for beginners, while a larger one may be better for bigger projects. Variable speed is handy for different types of wood, and make sure safety features are included. Don’t forget about accessories like chisels and faceplates, they are important too. Do your research and make an informed choice to have a fun and successful woodturning experience!

Remember, safety always comes first when using a lathe. Wear protective gear, follow the instructions, and practice good technique. Don’t rush and take your time to learn and improve your skills. With the right lathe and a passion for woodworking, you can create beautiful and unique turned wood pieces that you can be proud of. So get ready to unleash your creativity and enjoy the wonderful world of woodturning!