Picture this: you’re in a workshop, ready to operate a lathe. But before you get started, you need to know the actions that are considered dangerous. In this article, we’ll explore which of the following actions can put you at risk when operating a lathe. So, grab your safety goggles and let’s dive in!

When it comes to operating a lathe, safety should always be a top priority. Knowing what not to do is just as important as knowing what to do. In this guide, we’ll walk you through the actions that could potentially lead to accidents. So, if you’re curious about how to stay safe while working with a lathe, keep reading.

Are you wondering which actions should be avoided when using a lathe? Look no further! In this article, we’ll discuss the risky maneuvers that you should steer clear of. By understanding what not to do, you’ll be better equipped to operate a lathe safely and confidently. So, let’s get started on this journey to a hazard-free workshop!

When operating a lathe, it’s important to be aware of certain actions that can be dangerous. Safety should always be a top priority. Some actions to avoid include: not wearing appropriate safety gear, operating the lathe without proper training, standing in the line of fire of the rotating workpiece, wearing loose clothing or jewelry near the machine, and removing chips or debris while the lathe is still running. By following proper safety protocols and being cautious, you can help prevent accidents when operating a lathe.

The Danger Zone: Actions to Avoid When Operating a Lathe

Welcome to our comprehensive guide on the dangerous actions to avoid when operating a lathe. A lathe is a powerful and versatile machine used in woodworking and metalworking applications. While lathe operations can be highly rewarding, it’s crucial to prioritize safety to prevent accidents and injuries. In this article, we will explore the actions that are considered dangerous when operating a lathe, providing you with the knowledge you need to stay safe and make the most of this incredible tool.

Safe Practices for Lathe Operation

Before delving into the dangerous actions to avoid, let’s first establish some safe practices that should be followed when operating a lathe. These guidelines are essential for preventing accidents and promoting a safe working environment:

Maintaining a Proper Workspace

One of the first steps toward safe lathe operation is ensuring a well-maintained workspace. This includes keeping the area clean, organized, and free from any clutter or obstacles. Clearing the workspace of unnecessary objects reduces the risk of accidents, allows for smooth movement around the lathe, and minimizes distractions that could lead to mistakes.

In addition, it’s crucial to provide adequate lighting in the workspace. Sufficient illumination allows the operator to observe the workpiece and tools clearly, reducing the likelihood of errors or mishaps.

Another important aspect of maintaining a proper workspace is installing appropriate ventilation systems. especially when working with materials that generate dust or fumes. Good air quality helps prevent health issues and ensures a comfortable environment for the lathe operator.

Understanding and Following Safety Procedures

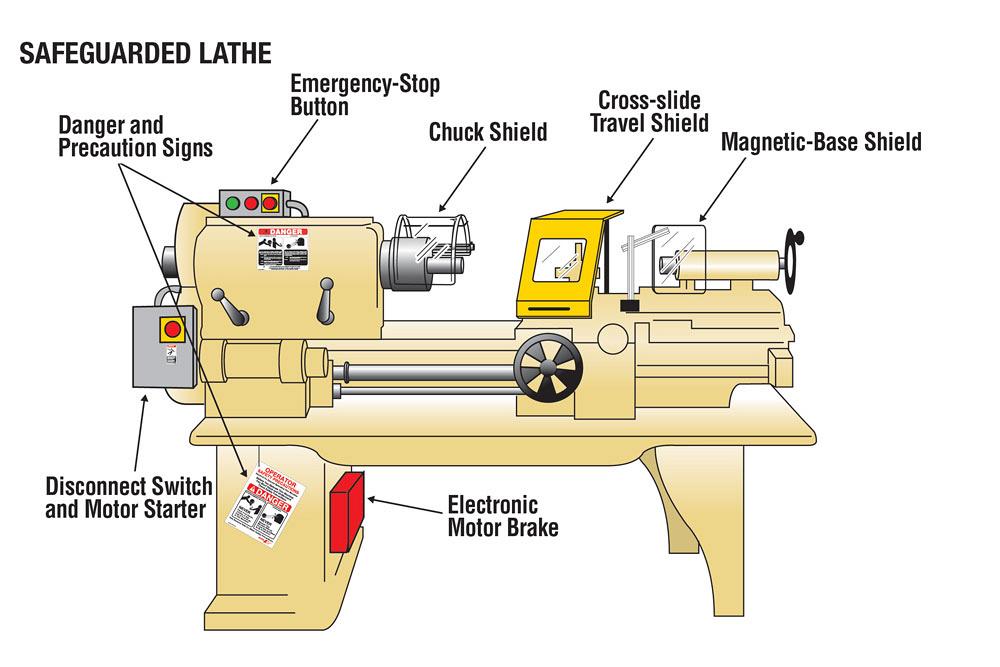

Before operating a lathe, it’s essential to familiarize yourself with the machine’s specific safety features and procedures. This includes understanding emergency stop mechanisms, safety guards, and the proper use of personal protective equipment (PPE) such as goggles, gloves, and ear protection.

Furthermore, make sure to follow the manufacturer’s instructions and recommendations at all times. They often provide critical information on equipment maintenance, tool usage, and safe operating practices specific to the lathe model.

Lastly, be mindful of the environment surrounding the lathe. Ensure there are no distractions, unauthorized personnel, or potential hazards nearby. By creating a dedicated and hazard-free workspace, you can significantly minimize the risk of accidents.

1. Loose-Fitting Clothing and Jewelry

The first dangerous action to avoid when operating a lathe is wearing loose-fitting clothing or jewelry. Loose clothing, such as baggy shirts or long sleeves, can easily get caught in the rotating parts of the lathe, leading to severe injuries or even amputations.

Jewelry, including rings, bracelets, and necklaces, pose a similar risk. These items can snag on the lathe’s components and forcefully pull the operator’s hand into the machinery. To prevent such accidents, it’s crucial to remove any loose-fitting clothing and ensure there are no jewelry pieces that could become entangled while operating the lathe.

The key is to wear fitted clothing that closely follows the body’s contours, reducing the chances of getting entangled and ensuring a safe working environment. It’s also advisable to tie back long hair to prevent it from getting caught.

2. Failing to Wear Safety Glasses

When operating a lathe, eye protection is paramount. The high-speed rotation of the workpiece, cutting tools, and debris generated during the machining process can all pose significant hazards to the operator’s eyes. Without proper protection, particles can fly into the eyes, causing serious injuries and impairing vision.

For this reason, always wear safety glasses or goggles specifically designed for machining operations. These safety eyewear options provide adequate protection against impact, flying debris, and even chemical splashes, if necessary. By wearing safety glasses, you can significantly reduce the risk of eye injuries and maintain clear vision during lathe operations.

3. Neglecting to Secure the Workpiece

One crucial safety requirement when operating a lathe is properly securing the workpiece before starting any machining operations. Failing to secure the workpiece can result in dangerous situations, where the material may fly off the lathe, causing injuries or property damage.

Depending on the lathe and the workpiece, there are various methods for securing the material. Common techniques include using lathe chucks, faceplates, collets, or clamps. Choosing the appropriate method for securing the workpiece ensures stability and prevents unwanted movement during the machining process, reducing the risk of accidents.

Prior to starting the lathe, always double-check that the workpiece is securely fastened according to the manufacturer’s guidelines and recommendations. Take extra precautions when working with irregularly shaped or heavy materials, as they may require additional support or specialized fixtures to ensure safe operation.

4. Inadequate Speed and Feed Adjustments

Adjusting the speed and feed rate of the lathe according to the specific material and operation is essential for safe and efficient machining. Inadequate adjustments can result in various hazards, including tool breakage, poor surface finish, and excessive heat generation.

When operating a lathe, it’s vital to refer to the machining charts, manuals, or experienced professionals to determine the appropriate speed and feed settings for the given material and operation. Using incorrect speed or feed rates can cause tools to break, leading to flying fragments that can cause severe injuries.

Always take the time to set the lathe to the correct speed and feed rate, ensuring a smooth and controlled operation. Monitor the machining process closely, making adjustments as necessary to maintain optimal cutting conditions and prevent any potential hazards from arising.

5. Improper Use of Cutting Tools

Selecting and using the right cutting tools for a lathe operation is crucial for safety and achieving desired results. Improper use of cutting tools can lead to accidents, poor workpiece quality, and damage to the lathe itself.

When choosing cutting tools, ensure they are specifically designed for lathe operations and compatible with the material being machined. Blunt or improperly sharpened tools can cause excessive friction and heat buildup, potentially leading to tool failure or workpiece damage.

Additionally, it’s crucial to use cutting tools with the correct geometry, such as rake angle and relief angle, to ensure smooth chip evacuation and minimize cutting forces. Proper tool selection and usage not only promote safety but also enhance productivity and produce high-quality results.

6. Lack of Proper Training and Experience

Operating a lathe requires skill, knowledge, and experience. Lack of proper training significantly increases the risk of accidents and injuries. It’s crucial for operators to undergo comprehensive training to understand the machine’s capabilities, safe operating practices, and troubleshooting techniques.

Training programs often cover topics such as lathe operation basics, tool selection and usage, workpiece setup, and maintenance procedures. By equipping themselves with the necessary knowledge and experience, operators can confidently and safely use the lathe, minimizing the risk of accidents.

Moreover, continuous learning and staying updated with industry advancements are essential for both safety and enhancing lathe operation skills. Regularly attending workshops, seminars, and training sessions can help operators sharpen their skills and stay up to date with the latest safety standards and best practices.

Additional Safety Measures for Lathe Operation

In addition to the aforementioned dangerous actions to avoid, there are several other safety measures to consider when operating a lathe. These additional precautions further ensure the wellbeing of the operator and those in the vicinity:

Use a Lathe Safety Checklist:

Before starting any lathe operation, it’s wise to use a comprehensive safety checklist. This checklist should include items such as verifying that all safety guards are in place, checking the lathe’s condition and cleanliness, and inspecting all tools and accessories for any signs of damage or wear.

Keep Hands and Tools Clear:

Always keep hands, fingers, and loose clothing at a safe distance from the rotating parts of the lathe. It’s important to maintain proper hand positioning and use appropriate tools or fixtures to feed the workpiece into the lathe. This minimizes the risk of getting fingers caught in the machinery and provides a safer working environment.

Regularly Inspect the Lathe:

Performing routine inspections on the lathe is crucial for identifying potential issues or hazards before they escalate. Check for any loose or damaged components, excessive vibration, or abnormalities in the performance of the machine. Addressing these concerns promptly helps maintain the lathe’s integrity and ensures safe operation.

Always Follow Lockout/Tagout Procedures:

When performing maintenance or making adjustments to the lathe, it’s essential to follow lockout/tagout procedures. Lockout/tagout procedures involve disconnecting the lathe from its power source, locking out the controls, and tagging the machine to indicate that maintenance is in progress. These procedures prevent accidental startup and protect individuals working on or near the lathe.

By adhering to these additional safety measures, operators can further minimize the risk of accidents and create a safe working environment when operating a lathe.

Conclusion

In conclusion, operating a lathe can be a rewarding experience, but it’s vital to prioritize safety at all times. By avoiding dangerous actions such as wearing loose-fitting clothing or jewelry, neglecting eye protection, failing to secure the workpiece properly, making inadequate speed and feed adjustments, misusing cutting tools, and lacking proper training, operators can greatly reduce the risk of accidents and injuries.

Additionally, remembering to follow safe practices, inspecting the lathe regularly, and implementing additional safety measures further contribute to a safe working environment. By prioritizing safety and adhering to best practices, operators can enjoy the benefits of using a lathe without compromising their well-being or the quality of their work. Remember, safety should always be the top priority when operating any machinery, including a lathe.

Key Takeaways: Which Actions are Considered Dangerous When Operating a Lathe?

- Always avoid wearing loose clothing or jewelry that can get caught in the lathe’s moving parts.

- Do not operate the lathe without proper eye protection, such as safety goggles or a face shield.

- Never reach into the lathe’s cutting area while it is still rotating.

- Ensure that all tools and workpieces are securely tightened and properly aligned before starting the lathe.

- Avoid using excessive speed settings that can cause the lathe to vibrate or the workpiece to spin out of control.

Frequently Asked Questions

When operating a lathe, it’s essential to be aware of the potential dangers and take the necessary precautions to ensure safety. Here are some common questions about actions that are considered dangerous when operating a lathe, along with their answers:

1. Can I wear loose clothing or jewelry while operating a lathe?

No, it is highly recommended to avoid wearing loose clothing or jewelry while operating a lathe. Loose clothing or jewelry can get caught in the rotating parts of the lathe, causing severe injuries or accidents. It’s crucial to wear fitted clothing without any hanging accessories to reduce the risk of entanglement.

Additionally, avoid wearing gloves while operating a lathe, as they can also get caught in the moving parts and compromise your ability to control the machine effectively. Always prioritize wearing appropriate safety gear, such as goggles, a face shield, and a fitted apron.

2. Is it safe to remove or adjust the workpiece while the lathe is still running?

No, it is never safe to remove or adjust the workpiece while the lathe is still running. Always ensure that the lathe is turned off and the spindle has come to a complete stop before attempting to remove or adjust the workpiece. Removing or adjusting the workpiece while the lathe is still running can lead to accidents, such as hands getting caught in the rotating parts or the workpiece being thrown off with force.

Remember to exercise caution and never rush when working with a lathe. Take the time to familiarize yourself with the machine’s safety features and follow the manufacturer’s instructions for proper operation and maintenance.

3. Is it safe to use excessive force or pressure on the lathe tools?

No, using excessive force or pressure on the lathe tools is not safe and can lead to accidents or damage to the machine. The cutting tools used on a lathe are designed to operate with a specific level of force and pressure. Applying excessive force can cause the tool to break or dislodge, posing a risk of flying debris or injury.

It’s important to let the cutting tool do the work while operating a lathe. Use smooth and controlled movements to guide the tool, allowing it to shave off the material gradually. Applying excessive force not only jeopardizes your safety but can also result in poor-quality work and unnecessary wear on the machine.

4. Can I operate a lathe without proper training or experience?

No, it is not safe to operate a lathe without proper training or experience. Lathe machines are powerful tools that require knowledge and skill to operate safely and effectively. Without proper training, you may not be aware of the potential hazards or how to handle unexpected situations that may arise during operation.

Before operating a lathe, make sure to receive comprehensive training from a qualified instructor. Familiarize yourself with the machine’s controls, safety features, and proper operating procedures. It’s also essential to practice on scrap material before working on actual projects to hone your skills and gain confidence.

5. Is it safe to leave a lathe unattended while it is still running?

No, it is never safe to leave a lathe unattended while it is still running. Always turn off the lathe and ensure that the spindle has come to a complete stop before leaving the machine unattended. Leaving a lathe running unattended can lead to accidents, such as the workpiece becoming dislodged and causing damage or injury.

Stay present and alert while operating a lathe, and never leave the machine running without supervision. If you need to step away momentarily, shut off the lathe and wait for it to come to a stop before attending to any other tasks.

Facing on the Lathe

Summary

When operating a lathe, there are certain actions that can be really dangerous. First, never wear loose clothing or jewelry that can get caught in the machine. Secondly, avoid removing chips or adjusting the workpiece while the lathe is still spinning. Additionally, it’s crucial to never leave the lathe unattended while it’s running. Lastly, be careful not to use the lathe if you are feeling tired or impaired in any way.

Remember, operating a lathe can be risky, so always prioritize safety by following these guidelines.