When it comes to standard table saws, it’s important to know their features inside and out. But do you know which of the following is not a feature of a standard table saw? Well, let’s dive in and find out!

Meet the ultimate woodworking tool that every DIY enthusiast dreams of – the standard table saw. But what sets it apart from the rest? Let’s explore the features that make this powerhouse a must-have for any woodworker worth their sawdust.

Now, imagine a table saw that doesn’t come with a particular feature. That’s right, we’re on a mission to uncover the one missing feature that’s not found in a standard table saw. Join us on this tabletop adventure as we unravel the mystery of what’s not in store for our trusty piece of woodworking machinery.

When it comes to standard table saws, there are various features to consider. However, one feature that is not typically found in a standard table saw is a laser guide. Laser guides are a popular feature in more advanced and specialized table saw models, but they are not commonly included in standard models. Other features of a standard table saw often include a powerful motor, adjustable fence, dust collection system, safety features, and a sturdy table surface.

Which of the Following is Not a Feature of a Standard Table Saw?

A table saw is an essential tool for any woodworking enthusiast or professional. It is designed to make accurate and precise cuts in various materials, including wood, plastic, and even metal. A standard table saw typically comes with a range of features and functionalities that enhance its usability and performance. However, not all table saws are created equal, and some may lack certain features that are commonly found in standard models. In this article, we will explore some of the key features of a standard table saw and identify which of the following is not typically included.

1. Blade Guard and Splitter

A blade guard and splitter are vital safety features found on most standard table saws. The blade guard is a transparent cover that sits over the top of the saw blade, protecting the user from accidental contact with the spinning blade. It also helps to contain any flying debris. The splitter, on the other hand, is a vertical piece of metal or plastic that sits behind the blade, preventing the material from pinching the blade and causing kickback.

Without a blade guard and splitter, the risk of accidents and injuries significantly increases. A standard table saw should always come equipped with these safety features to ensure the user’s protection while operating the machine. If a table saw does not have a blade guard and splitter, it should not be considered a standard model and may pose serious safety hazards.

2. Riving Knife

A riving knife is another safety feature commonly found in standard table saws. It is a specialized splitter that moves up and down with the blade, maintaining a slight distance behind the blade’s teeth. The purpose of the riving knife is to prevent kickback by keeping the material aligned with the blade, reducing the likelihood of the material being pinched and thrown back at the operator.

In addition to its safety benefits, a riving knife also aids in achieving cleaner and more accurate cuts. It helps to minimize tear-out and prevents the material from getting trapped between the blade and the fence, leading to better overall performance. Therefore, a standard table saw should always be equipped with a riving knife to ensure both safety and improved cutting results.

3. Adjustable Blade Height and Bevel

One of the primary functionalities of a table saw is its ability to make various types of cuts. A standard table saw should have an adjustable blade height and bevel feature that allows the user to customize the depth and angle of the cuts. By adjusting the blade height, you can control the thickness of the material being cut. On the other hand, the bevel feature enables you to tilt the blade to make angled cuts, such as bevels or miters.

Without the ability to adjust the blade height and bevel, a table saw loses much of its versatility and becomes limited in its cutting capabilities. A standard table saw should have easily accessible controls or mechanisms that allow for precise adjustments, ensuring the user’s ability to achieve desired cuts efficiently and accurately.

4. Dust Collection System

Woodworking can generate a significant amount of sawdust and debris. To keep the work area clean and maintain good visibility, a table saw should have an effective dust collection system. This system typically includes a dust port or chute connected to a vacuum or dust extractor, which pulls in the airborne particles and collects them in a bag or container.

However, it is important to note that not all table saws come with a built-in dust collection system. Some models may require a separate dust collector to be attached, while others may not have any provisions for dust collection at all. Regardless, having a reliable dust collection system significantly improves the overall experience of using a table saw, minimizing the mess and promoting a healthier working environment.

5. Precision Fence System

A table saw’s fence system is crucial for making accurate and straight cuts. It acts as a guide, keeping the material aligned and providing stability throughout the cutting process. A precision fence system allows for easy adjustment, ensuring that the fence is parallel to the blade and maintains consistent contact with the material.

Although a standard table saw should come with a precision fence system, the quality and features of the fence can vary between different models. Some may offer enhanced features like micro-adjustments or T-tracks for additional support and versatility. However, regardless of the specific features, a quality and reliable fence system is essential to the functioning of a standard table saw.

6. Electric Brake

When it comes to safety features, an electric brake is an invaluable addition to a standard table saw. This feature helps to bring the blade to a complete stop within seconds of releasing the power switch. It significantly reduces the risk of injuries by minimizing the time the blade is spinning after the user has finished cutting.

Without an electric brake, the blade may continue to spin for a considerable amount of time, posing a hazard to the user and anyone in close proximity. Additionally, the electric brake also allows for faster blade changes, as it stops the blade from spinning, making it easier and safer to switch out blades when necessary.

7. Miter Gauge

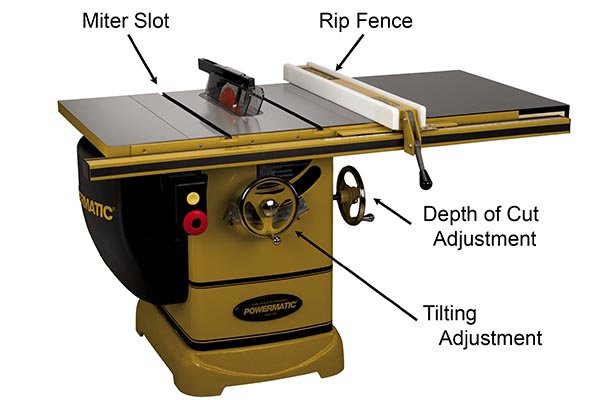

A miter gauge is a specialized tool that helps make accurate crosscuts and angled cuts on a table saw. It consists of a long guide or fence, which can be adjusted to the desired angle, and a small platform that holds the workpiece securely in place. The miter gauge is typically placed in the miter slot on the table saw’s surface.

A standard table saw should come with a miter gauge as a standard accessory. It provides added versatility and allows for precise cuts at various angles. Some miter gauges may also have a built-in stop or extension wings for additional support and stability. However, the absence of a miter gauge does not necessarily make a table saw non-standard, as this accessory can be purchased separately.

Additional Features of a Standard Table Saw

In addition to the features discussed above, a standard table saw may also include the following:

1. Blade Tilt and Elevation Mechanism

A standard table saw allows the user to tilt the blade for making beveled cuts. It should have a reliable and easy-to-use mechanism for adjusting the blade tilt and elevation, ensuring precise and accurate cuts.

2. Large Worktable

A standard table saw should have a large and sturdy worktable that provides ample space for maneuvering the material being cut. This enhances safety and allows for better control and accuracy during operation.

3. Push Stick or Block

For added safety, a table saw may come with a push stick or block, which is used to guide the material through the blade while keeping the user’s hands at a safe distance from the blade.

4. On/Off Switch and Emergency Stop

A standard table saw should have a conveniently located on/off switch and an emergency stop button, allowing for easy and immediate shut-off in case of an emergency or accident.

5. Dado Capability

Some table saws have the ability to accommodate dado sets, which are specialized blades that allow for making wide, flat-bottomed grooves in the material. This feature significantly expands the table saw’s capabilities and versatility.

6. Extension Wings

Extension wings are additional sections that can be attached to the sides of the table saw, increasing the overall surface area and providing support for larger workpieces.

7. Blade Storage

A standard table saw may come with built-in storage for spare blades, ensuring easy access and protection for different types of blades that may be required for specific cuts or materials.

8. Mobile Base or Wheels

Some table saws are equipped with a mobile base or wheels, allowing for easy transportation and mobility within the workshop or job site.

9. Quick-Release Fence

A quick-release fence system enables easy and rapid adjustments of the fence position, saving time and increasing productivity during woodworking projects.

10. Anti-Kickback Pawls

Anti-kickback pawls are additional safety devices that help prevent kickback by gripping the material and preventing it from being pulled back towards the user.

These additional features are not necessarily found on every standard table saw, but they can certainly enhance the overall performance and usability of the machine. When considering purchasing a table saw, it is important to evaluate the specific features that are essential for your woodworking needs and choose a model that best meets those requirements.

The Importance of Choosing a Standard Table Saw

Now that we have discussed the various features of a standard table saw, it is important to reiterate the significance of choosing a table saw with these standard features. A table saw is a powerful and potentially dangerous tool, and having the appropriate safety features in place is crucial for the user’s protection.

A standard table saw not only ensures safety but also offers enhanced functionality and versatility. It allows for more precise and accurate cuts, provides support for various types of projects, and promotes efficiency in woodworking tasks. By investing in a standard table saw, woodworkers can enjoy improved results, increased productivity, and a better overall experience in their craft.

Conclusion

Choosing the right table saw can make a significant difference in the quality and efficiency of woodworking projects. When evaluating the features of a table saw, it is crucial to identify which features are considered standard and which may be optional or add-ons. This article has outlined the key features of a standard table saw and identified which of the following is not a feature of a standard table saw.

Some of the essential features of a standard table saw include a blade guard and splitter, a riving knife, adjustable blade height and bevel options, a dust collection system, a precision fence system, an electric brake, and a miter gauge. These features contribute to the overall safety, usability, and performance of a table saw.

Choosing a standard table saw with these features ensures the user’s protection and enhances the woodworking experience. Additional features like blade tilt mechanism, large worktable, push stick, on/off switch, dado capability, extension wings, blade storage, mobile base, quick-release fence, and anti-kickback pawls provide added benefits and convenience.

Ultimately, selecting the right table saw depends on individual needs and preferences. By understanding the standard features and considering additional options, woodworkers can make informed decisions and invest in a table saw that suits their specific requirements. So, whether you are a DIY enthusiast or a professional woodworker, take the time to research and choose a standard table saw that will offer the safety, performance, and versatility you need to bring your woodworking projects to life.

Key Takeaways: Which of the Following is Not a Feature of a Standard Table Saw?

- A standard table saw typically does not have a built-in laser guide for precise cutting.

- Most table saws do not come equipped with an automatic blade brake for increased safety.

- Many standard table saws do not include a dust collection system to keep your workspace clean.

- Some table saw models do not offer the option for mobile bases or wheels for easy portability.

- A standard table saw may not have an adjustable riving knife to prevent kickbacks during operation.

Frequently Asked Questions

Welcome to our FAQ section where we answer common questions about the features of a standard table saw.

What are some important safety features to look for in a standard table saw?

When it comes to safety features, a standard table saw should include a riving knife or splitter, anti-kickback pawls, and a blade guard. The riving knife or splitter helps prevent kickback by keeping the material from pinching the blade. Anti-kickback pawls grip the material and prevent it from being thrown back towards the operator. The blade guard is essential for protecting your hands from coming into contact with the spinning blade.

Additionally, a table saw should have a flesh-sensing technology if available. This feature can detect contact with skin and automatically stop the blade, reducing the risk of serious injury. Always prioritize safety when selecting a standard table saw.

What type of blade should I use with a standard table saw?

A standard table saw typically requires a carbide-tipped blade, as they provide better durability and performance for cutting various materials. When selecting a blade, consider the desired application – ripping, crosscutting, or both – and the material you will be cutting. A combination blade is a versatile option that can handle both types of cuts.

It’s important to choose the right blade for the job to ensure clean and accurate cuts. Keep in mind that the size and number of teeth on the blade also play a role in determining the quality of the cut. Choose a blade with the appropriate tooth configuration based on your specific cutting needs.

Can a standard table saw be used for making bevel cuts?

Yes, a standard table saw can be used to make bevel cuts. Many table saws have a tilting arbor that allows the blade to be angled, enabling bevel cuts. However, it’s important to note that not all table saws have this feature, so be sure to check before purchasing. If you frequently need to make bevel cuts, look for a table saw with a wide range of bevel angles and a reliable mechanism for adjusting the angle.

Remember to always follow the manufacturer’s instructions and take appropriate safety precautions when making bevel cuts with a table saw. Keep your hands well clear of the blade and use a miter gauge or fence to guide the workpiece accurately.

What is the maximum cutting depth of a standard table saw?

The maximum cutting depth of a standard table saw can vary depending on the specific model. However, a typical table saw will have a maximum cutting depth of around 3 inches when the blade is set at a 90-degree angle. It’s important to check the specifications of the table saw you are considering to ensure it meets your cutting needs.

If you require a larger cutting depth, you may need to consider other types of saws, such as a sliding compound miter saw or a track saw, which provide greater cutting capacity.

Is a standard table saw suitable for cutting all types of materials?

A standard table saw is designed to cut a wide range of materials, including wood, plywood, and even some types of plastic. However, there are limitations to what a standard table saw can handle. It may not be the best choice for cutting metal or other extremely hard materials.

If you anticipate working with challenging materials, consider using specialized blades or a different type of saw specifically designed for those materials. Always consult the manufacturer’s recommendations and use the appropriate safety measures when cutting different materials with a table saw.

Summary

Table saws are a common tool for woodworking, but it’s important to know their features. Safety should always be the top priority, so knowing what a standard table saw does not have can help prevent accidents. One important feature that a standard table saw does not have is a flesh-sensing technology. This means that it cannot detect human contact and stop the blade before causing injury. Another feature it lacks is a riving knife, which helps prevent kickback and keeps the workpiece from getting stuck. Additionally, a standard table saw does not have a blade guard, which helps protect fingers and hands from coming too close to the saw blade. It’s important to take precautions and use the right safety equipment when working with a table saw to avoid accidents and injuries.