When it comes to working with a lathe, it’s important to prioritize safety above all else. Are you curious about which practices could potentially be dangerous when operating this powerful machine? Well, you’ve come to the right place! In this article, we’ll explore which of the following actions and behaviors are unsafe around the lathe. So, let’s dive in and learn how to stay safe while using this tool!

As you embark on your lathe journey, it’s essential to be aware of the potential hazards that exist. Whether you’re a beginner or a seasoned professional, understanding what to avoid is crucial. So, which of the following activities should you steer clear of when working with a lathe? Let’s find out!

Knowing what not to do is just as important as knowing what to do. By identifying and avoiding unsafe practices around the lathe, you’ll be able to protect yourself and those around you. So, let’s explore the potential hazards and learn how to prioritize safety in the lathe workshop. Get ready to unlock the knowledge that will keep you safe!

- Loose clothing or jewelry

- Long hair

- Unprotected eyes

- Excessive clutter or debris

- Untrained or inexperienced operators

When working with a lathe, safety should always be a top priority. Avoid the following unsafe practices to prevent accidents and injuries. First, make sure to remove any loose clothing or jewelry that could get caught in the lathe. Keep long hair tied back and wear protective eyewear to shield your eyes. Additionally, keep your work area clear of clutter or debris that could interfere with the machine. Finally, ensure that only trained and experienced operators are allowed to use the lathe. Stay safe!

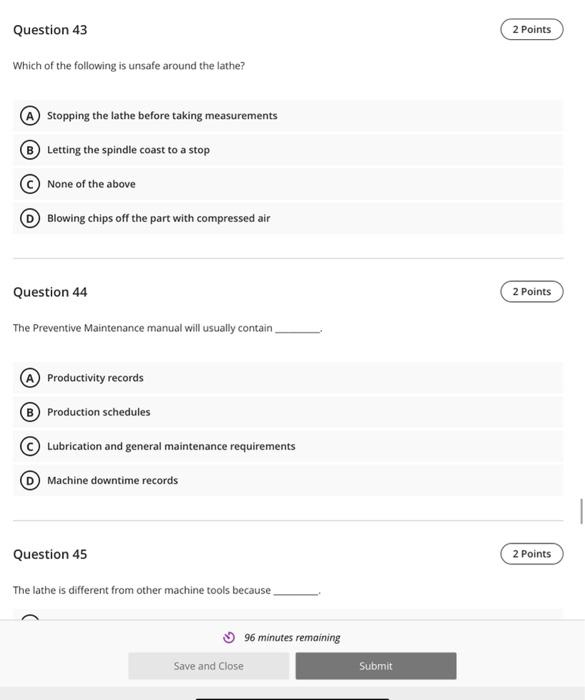

Unsafe Practices to Avoid Around the Lathe

Welcome to this guide on the safety precautions you should take when working with a lathe. The lathe is a powerful and versatile tool used for shaping materials such as wood, metal, and plastics. While it can be an invaluable tool, it is essential to understand the potential dangers associated with its operation. In this article, we will explore the unsafe practices that should be avoided when working with a lathe to ensure the safety of yourself and others.

Common Mistakes that can Lead to Accidents

1. Inadequate Personal Protective Equipment (PPE)

One of the most common mistakes made when operating a lathe is the failure to wear adequate personal protective equipment (PPE). When working with a lathe, it is crucial to protect yourself from flying debris, dust, and other hazards. Always wear safety glasses or a face shield to protect your eyes, and use ear protection to prevent hearing damage. Additionally, wearing gloves and an apron can provide added protection against cuts and scrapes.

2. Poor Workpiece Securing

Another dangerous mistake is failing to properly secure the workpiece on the lathe. A loose or improperly secured workpiece can result in it flying off the lathe and causing serious injury. Always ensure that the workpiece is firmly clamped or mounted on the lathe before starting any operations. Use appropriate chucks, faceplates, or other holding devices to secure the workpiece securely in place.

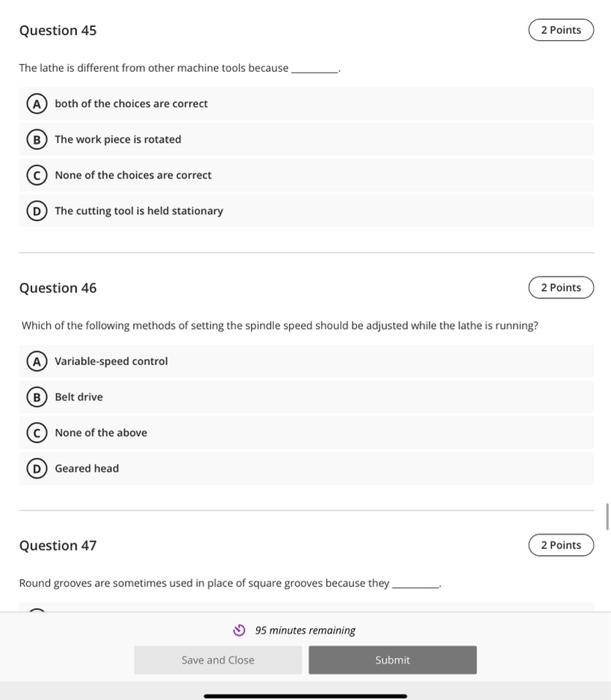

3. Using Dull or Improper Tools

Using dull or improper tools is not only inefficient but can also lead to accidents. Dull tools require more force to cut, increasing the chances of slips and other mishaps. Additionally, using the wrong type of tool for a specific task can result in damage to the workpiece and potential harm to the operator. Make sure to keep your lathe tools sharp and use the appropriate tool for each cutting operation.

Preventing Accidents with Proper Safety Protocols

1. Familiarize Yourself with the Lathe

Before operating a lathe, take the time to familiarize yourself with its components and safety features. Read the manufacturer’s instructions and understand how to safely operate the lathe. Identify emergency controls, such as the stop button or emergency foot pedal, and know how to use them in case of an accident. Understanding the lathe’s capabilities and limitations will help you work more safely.

2. Keep the Work Area Clean and Organized

A cluttered work area increases the risk of accidents. Keep your work area clean and organized, ensuring that there are no loose objects or debris that could interfere with the operation of the lathe. Store tools and accessories properly when not in use, and maintain good housekeeping practices to create a safe working environment.

3. Practice Safe Turning Techniques

Safe turning techniques are essential for preventing accidents while working on a lathe. Keep your hands and fingers away from the cutting area, using tools such as chisels or gouges to shape the workpiece. Always approach the spinning workpiece from the side, never from the top or front. Maintain a firm grip on the tools and be mindful of their sharp edges to avoid slips or unexpected movements.

Proper Maintenance and Inspection

1. Regularly Inspect the Lathe

Regular inspections of the lathe are crucial to identify any potential hazards or maintenance requirements. Check for loose fastenings, damaged or worn-out parts, and any signs of excessive vibration during operation. If any issues are identified, address them promptly, and do not operate the lathe until it is in proper working condition.

2. Keep the Lathe Well-Maintained

Proper maintenance of the lathe ensures its optimal performance and reduces the risk of accidents. Lubricate moving parts as recommended by the manufacturer to prevent excessive wear and tear. Keep the lathe clean and free from dust and debris that can impair its operation. Additionally, follow the manufacturer’s guidelines for regular servicing and inspections to ensure that the lathe remains safe to use.

3. Stay Educated and Up to Date with Safety Practices

Lastly, it is essential to stay educated and up to date with safety practices related to working with lathes. Attend safety training sessions or workshops to enhance your knowledge and skills. Keep yourself informed about any new safety guidelines or recommendations specific to lathe operations. Regularly refreshing your knowledge will help you maintain a safe working environment and prevent accidents.

Key Takeaways: Which of the Following is Unsafe Around the Lathe?

- Loose clothing and jewelry can get caught in the lathe, causing serious injuries.

- Not wearing safety goggles can lead to eye injuries from flying debris.

- Using dull tools can cause them to slip and result in accidents.

- Standing too close to the lathe can put you at risk of being hit by rotating parts.

- Ignoring safety guards and devices increases the likelihood of accidents and injuries.

Frequently Asked Questions

Welcome to our Frequently Asked Questions section where we answer common questions about safety around the lathe. Read on to find out more!

1. Why is wearing loose clothing dangerous near a lathe?

Wearing loose clothing around a lathe can be extremely dangerous due to the risk of entanglement. When loose clothing, such as baggy shirts or long sleeves, comes into contact with the spinning parts of the lathe, it can quickly get caught and pull you towards the machine. This can result in serious injuries, including limb amputation or even death.

Therefore, it is crucial to always wear fitted clothing and avoid anything with loose or dangling parts when working with a lathe. Additionally, make sure to tuck in any loose ends like belts or scarves to eliminate the risk of them getting caught in the machine.

2. What makes using gloves unsafe around a lathe?

Using gloves around a lathe can be unsafe because they can get caught in the rotating parts of the machine, creating a serious hazard. Gloves can reduce your tactile sensitivity, making it harder to feel the materials you are working with, which may result in mistakes or accidents.

Instead of gloves, it is recommended to use proper hand protection, such as fingerless gloves or grip-enhancing gloves, which allow for a better grip while providing the necessary level of dexterity. It is important to prioritize safety while working around a lathe and avoid any potential hazards that gloves might introduce.

3. What are the risks associated with not wearing safety glasses near a lathe?

Not wearing safety glasses near a lathe can pose significant risks to your eyesight. When operating a lathe, there is a possibility of chips, sparks, or fragments flying off the workpiece, which can cause severe eye injuries if they come into contact with your eyes. Safety glasses act as a protective barrier, shielding your eyes from these potential hazards.

Always ensure you wear safety glasses that meet the required safety standards when working with a lathe. Clear lenses are typically recommended, as they provide good visibility while still offering the necessary eye protection.

4. Why is it important to secure workpieces properly on the lathe?

Securing workpieces properly on the lathe is crucial for maintaining a safe working environment. When workpieces are not securely fastened, they can become loose or fly off the lathe during rotation, becoming potential projectiles. This poses a significant risk to the operator and anyone nearby.

To ensure safety, always make sure to use appropriate clamps or fixtures to securely attach the workpiece to the lathe. Check that the workpiece is stable before starting the lathe and periodically inspect its stability during operation. This will minimize the chances of accidents caused by unsecured workpieces.

5. Why should the lathe be turned off before making adjustments or measurements?

Turning off the lathe before making adjustments or measurements is crucial to prevent accidental activation and potential harm. The spinning parts of the lathe, such as the spindle or chuck, are hazardous and can cause severe injuries if they are accidentally engaged while you are working on the machine.

To ensure safety, always power off the lathe and wait for all moving parts to come to a complete stop before making any adjustments or measurements. This simple precautionary step can help prevent accidents and protect both you and those around you.

Determining Safe Lathe Speeds (Woodturning How-to)

Summary

It’s important to be safe around lathes. Here’s what you need to remember:

1. Don’t wear loose clothing or jewelry that can get caught in the lathe.

2. Keep a safe distance from the rotating parts to avoid getting injured.

3. Always use proper eye protection to protect your eyes from flying debris.

4. Never leave the lathe running unattended and always turn it off after use.

5. Avoid touching the lathe while it’s still running to prevent accidents.

By following these safety guidelines, you can enjoy using the lathe while staying safe!