Have you ever wondered about the limitations of a capstan lathe? Well, wonder no more! In this article, we will explore the question, “Which of the following operations cannot be done on a capstan lathe?” So, if you’re curious about the capabilities and constraints of this type of lathe, keep reading!

Capstan lathes are versatile machines used for various machining operations, but they do have their limitations. Understanding what a capstan lathe can and cannot do is essential for any engineer or hobbyist working with this type of lathe. So, let’s dive in and explore the operations that cannot be performed using a capstan lathe.

Whether you’re just starting your engineering journey or looking to expand your knowledge, understanding the limitations of a capstan lathe is crucial. So, let’s get started and unravel the secrets behind this fascinating piece of machinery!

Discover the limitations of a capstan lathe! While this versatile machine is capable of performing various operations, there are a few it cannot handle. One such operation is rotary drilling due to the nature of its design. However, a capstan lathe excels in other tasks like turning, facing, threading, and parting. Understanding the capabilities and limitations of this machine can help optimize your machining operations.

The Limitations of a Capstan Lathe: Which Operations Cannot Be Done?

Capstan lathes are versatile machines used for a wide range of machining operations. However, there are certain limitations to consider when using a capstan lathe. In this article, we will explore the operations that cannot be performed on a capstan lathe, providing detailed information and insights into each limitation. Whether you are a machinist, a student, or simply curious about the capabilities of this machine, this article will shed light on what a capstan lathe cannot do.

Limitation #1: Boring Operations

One operation that cannot be performed on a capstan lathe is boring. Boring is the process of enlarging an existing hole or creating a new hole with precise dimensions. While a capstan lathe excels in facing, turning, and threading operations, it is not equipped to handle boring operations efficiently. Boring requires specialized tools such as boring bars and reamers, which are not compatible with the design and tooling setup of a capstan lathe.

The main reason behind this limitation is the absence of a rigid tailstock on a capstan lathe. The tailstock provides the needed support and stability for boring operations, allowing for accurate and concentric hole creation. Without a tailstock, the capstan lathe lacks the necessary rigidity and precision required for efficient and accurate boring. Machinists typically opt for other machines like a turret lathe or a vertical machining center to accomplish boring operations.

Limitation #2: Taper Turning

Taper turning, as the name suggests, is the process of creating tapered surfaces on a workpiece. This operation requires the lathe to move both the cross-slide and the top slide simultaneously at different rates to achieve the desired taper. Unfortunately, a capstan lathe is not designed to handle taper turning operations effectively.

The main limitation lies in the movability of the top slide on a capstan lathe. In contrast to engine lathes or toolroom lathes, where the top slide can be easily adjusted to create tapers, the limited movement of the top slide on a capstan lathe restricts its ability to produce accurate and consistent tapered surfaces. Taper turning requires precise control over the tool’s movement, which is not feasible on a capstan lathe. Therefore, machinists often resort to using other lathe types or specialized taper-turning attachments for this particular operation.

Limitation #3: Grooving and Parting Operations

Grooving and parting are essential operations in machining, involving the creation of narrow grooves or the separation of a workpiece into two distinct parts. However, these operations pose a challenge on a capstan lathe due to its limited range of motion and tooling setup.

Capstan lathes typically feature a limited travel range for the upper slide, restricting the depth and width of the grooves that can be cut. Additionally, parting operations require sturdy and reliable support, which is compromised by the absence of a rigid tailstock on a capstan lathe. The lack of support can result in vibration, poor surface finish, and tool breakage, making it impractical to perform grooving and parting operations on a capstan lathe. Machinists often opt for machines like a CNC lathe or a vertical machining center with better stability and cutting capabilities for such operations.

Limitation #4: Internal Threading and Thread Cutting

While a capstan lathe is well-suited for external threading operations, its limitations become evident when attempting to perform internal threading or thread cutting. Internal threading involves creating threads inside a hole or a cylindrical workpiece, whereas thread cutting refers to the process of cutting external threads on a workpiece.

Capstan lathes lack the necessary mechanism to perform internal threading effectively. The absence of a rigid tailstock, coupled with limited tooling options, limits the precision and repeatability required for accurate internal threading. Additionally, the design of capstan lathe spindle limiting the size and pitch of the threads that can be cut effectively.

For internal threading and thread cutting, machinists often rely on dedicated thread cutting machines, CNC lathes with live tooling, or thread milling operations to ensure the highest level of accuracy and efficiency.

Limitation #5: Complex Contouring and 3D Machining

Capstan lathes excel in simple turning operations but are not well-suited for complex contouring and 3D machining. These operations involve machining intricate shapes, curves, and irregular surfaces, which is beyond the capabilities of a capstan lathe.

The design and mechanics of a capstan lathe prioritize simplicity and speed in performing repetitive tasks. This machine is ideal for high-volume production of relatively simple components. However, the limited tooling options, restricted range of motion, and lack of axis control make it challenging to perform complex contouring and 3D machining operations on a capstan lathe.

Machinists typically turn to CNC milling machines, multi-axis lathes, or specialized machining centers to accomplish these advanced machining tasks with precision and ease.

Limitation #6: High-Precision Machining

Capstan lathes are known for their speed, efficiency, and adaptability in mass production environments. However, they are not the best choice when it comes to high-precision machining. Achieving ultra-high precision and tight tolerances requires a level of control and stability that capstan lathes do not possess.

The limited rigidity, lack of fine-tuning options, and restricted tooling set on a capstan lathe make it difficult to achieve the extreme precision needed in industries such as aerospace, defense, and medical. Machinists working on projects with tight tolerances typically opt for advanced CNC machines or specialized machining centers that offer greater control, accuracy, and repeatability.

Limitation #7: Long Workpieces and Large Diameters

Capstan lathes are well-suited for machining small to medium-sized components with relatively short lengths and diameters. However, they are not the ideal choice for machining long workpieces or large-diameter parts.

This limitation is primarily due to the machine’s compact size and limited travel range. Capstan lathes are designed to optimize space and increase productivity in mass production environments. As a result, workpieces that exceed the machine’s length or diameter capacity may not fit or be effectively machined on a capstan lathe.

For machining long workpieces or large-diameter parts, machinists typically rely on larger lathes, turning centers, or CNC machines with extended bed lengths and larger chuck capacities.

The Importance of Understanding the Limitations

Knowing the limitations of a capstan lathe is crucial for machinists and manufacturers to make informed decisions about their machining processes. By understanding what a capstan lathe cannot do, they can optimize their operations by choosing the appropriate machines for specific tasks.

While capstan lathes offer numerous benefits such as high-speed production, ease of use, and versatility, it is essential to recognize their limitations to ensure the best possible outcomes. By evaluating the intricacies and demands of a given project, machinists can determine which operations are best suited for a capstan lathe and when it is necessary to explore alternative machines or methods.

Ultimately, the key to efficient machining lies in leveraging the strengths of each machine and understanding their limitations to achieve the desired results – whether it’s using a capstan lathe for high-speed turning operations or exploring other machines for complex machining tasks.

The Future of Capstan Lathes

As technology continues to advance, new innovations and enhancements are introduced to traditional machine tools such as capstan lathes. While the current limitations still stand, manufacturers and machine builders are constantly striving to overcome these limitations through improved designs, enhanced features, and better integration of modern technology.

Future iterations of capstan lathes may incorporate advanced control systems, increased tooling options, and improved rigidity to expand their capabilities. These advancements could potentially bridge the gap between the limitations of today’s capstan lathes and the demands of complex machining operations.

Until then, machinists must remain aware of the limitations and choose their machines wisely to achieve optimal results in every machining endeavor.

Key Takeaways: Which of the Following Operations Cannot Be Done on a Capstan Lathe?

- A capstan lathe is a type of lathe machine used for high-speed production work.

- You can perform operations like turning, drilling, boring, and facing on a capstan lathe.

- However, grinding is an operation that cannot be done on a capstan lathe.

- Capstan lathes are popularly used in industries for mass production of small and intricate parts.

- It’s important to understand the capabilities and limitations of different machines for efficient manufacturing processes.

Frequently Asked Questions

Welcome to our frequently asked questions section on capstan lathes. Here, we’ll address common inquiries about what operations can and cannot be done on a capstan lathe. Read on to discover more!

1. What are the different operations that can be performed on a capstan lathe?

A capstan lathe is a versatile machine that can perform various operations. Some of the key operations include turning, facing, threading, drilling, and parting. These operations make capstan lathes ideal for precise machining and manufacturing of small to medium-sized parts.

With the help of specialized tools and attachments, such as turret heads, cross slides, and cut-off slides, capstan lathes are capable of executing complex operations with high precision and efficiency.

2. Can a capstan lathe be used for milling or grinding operations?

No, a capstan lathe is not designed for milling or grinding operations. Capstan lathes are primarily used for turning, which involves removing material from a workpiece to give it the desired shape or dimensions. Milling and grinding involve different cutting techniques and require specific machines designed explicitly for these operations.

If milling or grinding operations are required, it is best to use dedicated machines such as milling machines or surface grinders. These machines are specifically designed for these processes and offer better precision and efficiency.

3. Is it possible to perform heavy-duty operations on a capstan lathe?

Capstan lathes are generally not suitable for heavy-duty operations. These machines are more commonly used for light to medium-duty machining tasks. The lightweight construction and smaller size of capstan lathes make them ideal for handling precision work on smaller components.

If heavy-duty operations are required, it is advisable to use larger and sturdier machines such as engine lathes or CNC lathes. These machines are designed to handle heavy workpieces and provide the necessary power and rigidity for demanding machining tasks.

4. Can a capstan lathe perform threading operations?

Yes, capstan lathes are well-suited for threading operations. Threading is the process of cutting external or internal threads on a workpiece. Capstan lathes are equipped with special threading tools and attachments, such as thread chasing dials and leadscrew mechanism, which allow for the precise cutting of threads.

The presence of turret heads on capstan lathes further enhances their threading capabilities by enabling the use of multiple tools for different thread profiles. This makes capstan lathes highly efficient for producing threaded components with accuracy and consistency.

5. Can a capstan lathe perform boring operations?

While capstan lathes can perform various machining operations, they are not specifically designed for boring. Boring involves enlarging an existing hole or creating a precise cylindrical hole in a workpiece. Capstan lathes are primarily used for turning operations, which focus on external machining.

If boring operations are required, it is recommended to use machines specifically designed for boring, such as boring mills or vertical boring machines. These machines incorporate features like boring heads and adjustable boring bars, allowing for accurate and efficient boring of workpieces.

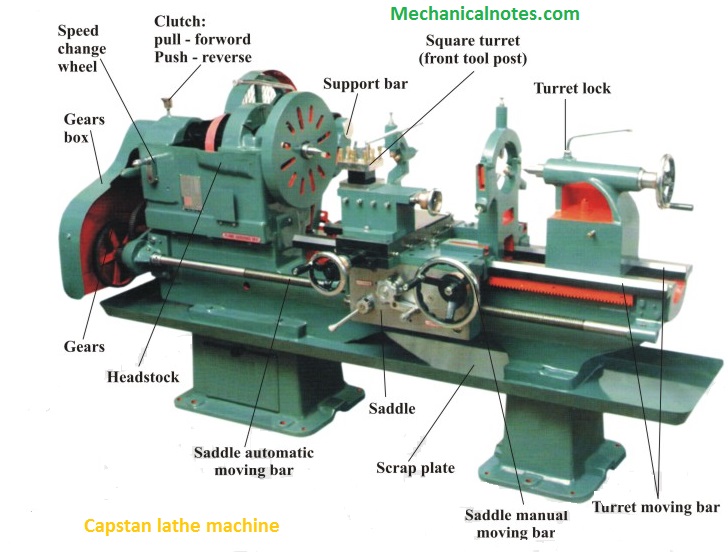

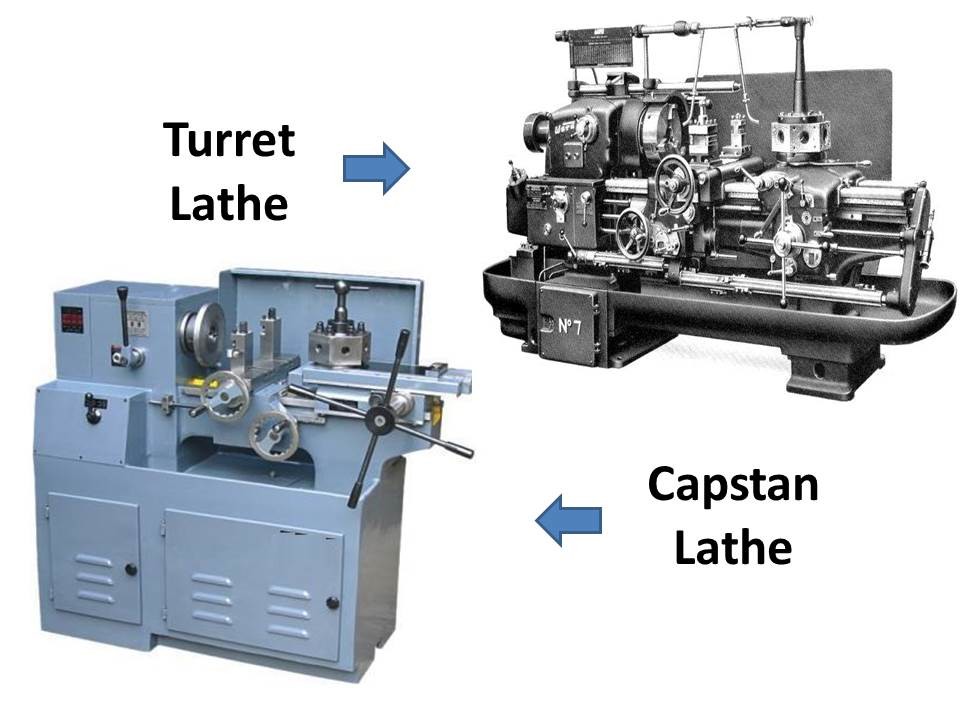

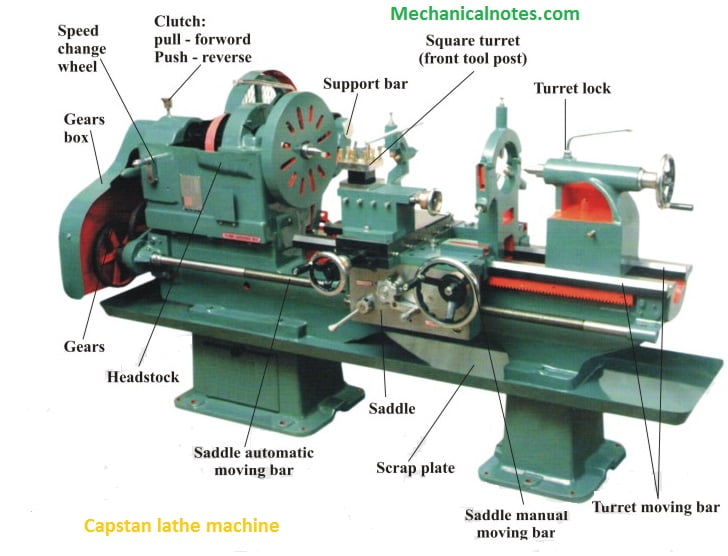

Various operations on Capstan and Turret lathe

Summary

A capstan lathe is a special type of machine used for cutting and shaping materials. In this article, we learned about different operations that can and cannot be done on a capstan lathe.

Firstly, we discovered that a capstan lathe can perform operations such as facing, turning, grooving, and threading. These operations involve cutting and shaping the material to create desired shapes and threads.

However, there are certain operations that a capstan lathe cannot do. These include operations like drilling and boring, which require a different type of machine called a turret lathe.

In conclusion, a capstan lathe is a versatile machine that can perform many useful operations, but it has limitations. Understanding these limitations helps us choose the right machine for different manufacturing needs.